How to Choose the Best Laser Cutting Machine

Choosing how to choose a laser cutting machine can feel overwhelming, but focusing on a few critical factors can simplify the process. You need to consider the materials you plan to cut, the size of your projects, and the power requirements. The right machine boosts efficiency, saves costs, and ensures safety. For instance, high-power machines handle metals better, while CO2 lasers excel with non-metals. Automation and robotics in laser cutting enhance precision and speed, making them invaluable in manufacturing. When buying a laser cutter or a laser engraving machine, prioritize these aspects to make an informed decision.

Understanding Different Types of Laser Cutters

When you're figuring out how to choose a laser cutting machine, understanding the different types of laser cutters is crucial. Each type has its unique strengths and applications, making it essential to match the machine to your specific needs.

CO2 Laser Cutters

CO2 laser cutters are incredibly popular for their versatility and cost-effectiveness. They use a gas mixture to produce a laser beam, which is perfect for cutting non-metal materials like wood, acrylic, and paper. These machines excel in industries such as crafting, signage, and packaging, where precision and efficiency are key. If you're looking for a reliable laser engraving machine for non-metal projects, a CO2 laser cutter might be your best bet.

Fiber Laser Cutters

Fiber laser cutters are the go-to choice for metal cutting. They use a fiber optic cable to amplify the laser beam, making them ideal for cutting reflective and conductor-grade metals. These machines operate at twice the speed of CO2-based laser cutters, offering significant advantages in terms of speed and efficiency. If your projects involve metal, a fiber laser cutter will provide the power and precision you need.

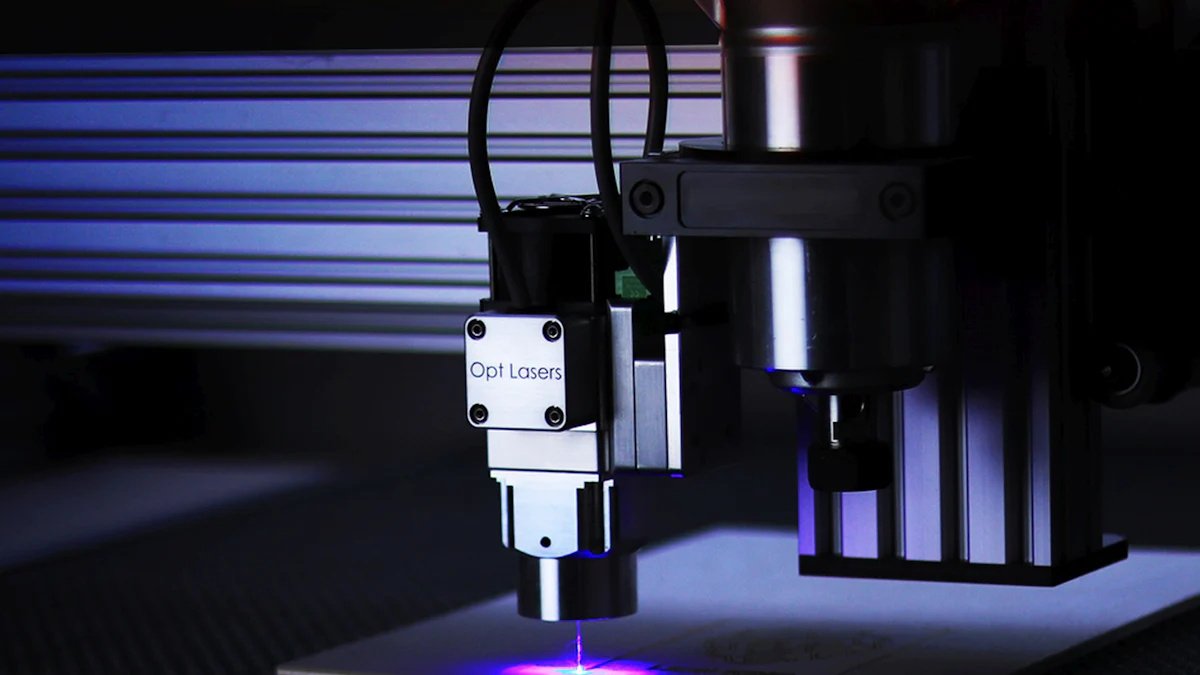

Diode Laser Cutters

Diode laser cutters are perfect for small-scale projects. They use light from a diode to create precise cuts in materials like cardboard, fabric, wood, and acrylic. These machines offer a balance of precision and flexibility, making them a popular choice among hobbyists and small businesses. While they are cost-effective, it's important to note their limitations in terms of power and material compatibility. If you're starting with a laser engraver for smaller projects, a diode laser cutter could be a practical option.

Assessing Power and Space Requirements

When choosing a laser cutting machine, you need to think about the power of the laser and the space it will occupy. These factors can significantly impact your machine's performance and your workspace's efficiency.

Power Requirements

Understanding wattage and its impact on cutting capabilities

The power of the laser plays a crucial role in determining what materials you can cut and how quickly you can do it. Higher wattage means more power, allowing you to cut through thicker materials with ease. For instance, if you plan to cut metals, you'll need a laser with higher wattage. On the other hand, for engraving or cutting thinner materials, a lower wattage might suffice. Understanding the power of the laser helps you match the machine to your specific needs.

Electrical setup considerations

Before setting up your laser cutter, check your electrical setup. Ensure that your workspace can handle the power requirements of the machine. Some high-power lasers may need special electrical configurations or dedicated circuits. It's essential to consult with an electrician to avoid any electrical issues. Proper setup ensures that your machine runs smoothly and safely.

Space Needs

Size of the machine and workspace layout

The size of the bed and the overall dimensions of the machine will dictate how much space you need. Make sure your workspace can accommodate the machine comfortably. Consider the layout of your workspace to ensure easy access and movement around the machine. A well-organized space enhances productivity and safety.

Ventilation and safety zones

Proper ventilation is vital when operating a laser cutter. The cutting process can produce fumes and particles that need to be safely extracted. Ensure your workspace has adequate ventilation systems in place. Additionally, establish safety zones around the machine to protect yourself and others from potential hazards. Clear safety protocols and designated zones contribute to a safer working environment.

Evaluating Costs and Maintenance

When you're figuring out how to choose a laser cutting machine, understanding the costs involved is crucial. The initial purchase price and ongoing maintenance expenses can significantly impact your budget. Let's break down these costs to help you make an informed decision.

Initial Purchase Costs

Factors influencing price

The price of a laser engraving machine varies widely. Factors like the type of laser, power, and technology used play a big role. For instance, diode lasers might start around $1,000, while CO2 lasers range from $2,000 to $5,000. If you're considering industrial-grade machines, prices can soar over $1 million. Higher-powered lasers and fiber laser cutters typically cost more due to their advanced capabilities. When buying a laser cutter, remember that a higher price often means better quality, precision, and efficiency.

Budgeting for your needs

Creating a budget is essential when buying a laser engraving machine. Consider not just the initial cost but also the true cost of ownership. This includes operational expenses like electricity, materials, and potential upgrades. Think about your specific needs and how much you're willing to invest in a long-term investment. A well-planned budget ensures you get the best value without overspending.

Maintenance and Operating Costs

Regular maintenance tasks

Owning a laser cutter involves regular maintenance to keep it running smoothly. Tasks include cleaning lenses, checking alignment, and replacing worn parts. These activities prevent breakdowns and extend the machine's lifespan. Regular upkeep is a small price to pay for maintaining efficiency and avoiding costly repairs.

Cost of consumables and parts

Consumables like lenses, mirrors, and filters need periodic replacement. The cost of these parts can add up over time. Additionally, consider the electricity usage of your machine. High-power lasers consume more energy, impacting your utility bills. Understanding these costs helps you plan for the future and manage your expenses effectively.

By evaluating both the initial purchase and ongoing maintenance costs, you can make a smart choice when buying a laser engraving machine. This approach ensures you select a machine that fits your budget and meets your needs.

Considering Safety Features

When you're buying a laser engraving machine, safety should be at the top of your list. Laser cutters can be dangerous if not handled properly, so it's crucial to know what safety features to look for and how to use them effectively.

Essential Safety Features

Enclosures and Shields

Enclosures and shields play a vital role in protecting you from the laser beam. They act as barriers, preventing accidental exposure to the laser's harmful rays. When choosing a machine, ensure it comes with robust enclosures that fully cover the laser path. Shields should be made of materials that can withstand the laser's intensity, providing an extra layer of protection. These features not only safeguard you but also keep the workspace safe for others.

Emergency Stop Functions

An emergency stop function is a must-have on any laser cutter. This feature allows you to quickly halt the machine's operation in case of an emergency. Look for machines with easily accessible emergency stop buttons. They should be prominently placed so you can reach them without delay. This function can prevent accidents and minimize damage, making it an essential component of any laser cutting setup.

User Training and Safety Protocols

Importance of Proper Training

Proper training is key to safely operating a laser engraving machine. Manufacturers often provide training sessions that cover the general hazards of laser cutting and the specific procedures for your machine. It's important to understand the risks involved and how to mitigate them. Training ensures you know how to handle the machine and its components safely. Specialists recommend consulting with experts if you're new to laser cutting. They can offer valuable insights and help you avoid potential hazards.

"Proper training is key when using a laser cutter. Laser cutters include dangerous components, and it is important to know and understand the risks." - Manufacturer

Developing Safety Protocols

Developing safety protocols is essential for maintaining a safe working environment. Establish clear guidelines for operating the laser cutter, including steps for setup, operation, and shutdown. Regularly review and update these protocols to address any new safety concerns. Encourage all users to follow these guidelines strictly. Implementing safety protocols not only protects you but also ensures the longevity of your equipment.

By focusing on these safety features and protocols, you can create a secure environment for using your laser engraving machine. This approach helps you enjoy the benefits of laser cutting while minimizing risks.

Importance of Support and Warranties

When you're investing in a laser engraving machine, the support and warranties offered by the manufacturer play a crucial role in your decision-making process. These factors ensure that your long-term investment remains protected and that you have the necessary assistance when needed.

Manufacturer Support

Availability of Customer Service

Reliable customer service is essential when purchasing a laser engraving machine. You want to ensure that the company you choose offers prompt and helpful support. For instance, Boss Laser provides free lifetime tech support via phone and email to the original purchaser. This kind of support can be invaluable when you encounter issues or have questions about your machine. Always check if the manufacturer has a dedicated customer service team ready to assist you.

Access to Technical Support

Technical support is another critical aspect to consider. Machines can be complex, and having access to knowledgeable technicians can save you time and frustration. OMTech Laser emphasizes the importance of contacting their technical support center for assistance during the warranty period. This ensures that you receive expert guidance and replacement parts if necessary. Look for manufacturers that offer comprehensive technical support to help you maintain and troubleshoot your machine effectively.

Warranties and Guarantees

Types of Warranties Offered

Understanding the types of warranties available can give you peace of mind. Some companies, like Thunder Laser USA, offer a generous 2-year warranty covering all parts and components. This kind of warranty assures you that any issues will be addressed swiftly. When evaluating warranties, consider the duration and what specific parts or services are covered. A robust warranty can protect your investment and reduce unexpected costs.

What to Look for in a Warranty

When reviewing warranties, pay attention to the details. Check if the warranty covers both parts and labor, and whether it includes shipping costs for replacements. Boss Laser, for example, requires clients to cover shipping charges for replacement parts after two years. Understanding these terms helps you avoid surprises later on. Additionally, consider the ease of claiming warranty services. A straightforward process with minimal hassle is always preferable.

By prioritizing support and warranties, you ensure that your laser engraving machine remains a valuable asset for years to come. This approach not only safeguards your investment but also provides you with the confidence to focus on your projects without worrying about potential issues.

Choosing the best laser cutting machine involves several key factors. You need to consider the type of materials you plan to cut, the power and space requirements, and the costs involved. Safety features and manufacturer support also play a crucial role. By understanding these elements, you can make an informed decision that aligns with your specific needs. Remember, investing in the right machine is a long-term investment that enhances efficiency and productivity. Take your time to research and evaluate your options carefully. This approach ensures you select a machine that meets your goals and budget.

FAQ

What materials can I cut with a laser cutting machine?

You can cut a wide variety of materials with a laser cutting machine. CO2 lasers work well with non-metal materials like wood, acrylic, and paper. Fiber lasers excel at cutting metals, including steel and aluminum. Diode lasers handle small-scale projects involving materials like cardboard and fabric.

How do I determine the right laser power for my projects?

Consider the thickness and type of material you plan to cut. Higher wattage lasers cut thicker materials more efficiently. For engraving or cutting thin materials, lower wattage suffices. Match the laser power to your specific needs for optimal results.

Is a laser cutting machine safe to use?

Yes, laser cutting machines are safe when used correctly. Look for machines with essential safety features like enclosures, shields, and emergency stop functions. Proper training and adherence to safety protocols further enhance safety.

How much space do I need for a laser cutting machine?

The space required depends on the machine's size and your workspace layout. Ensure your workspace accommodates the machine comfortably, with room for ventilation and safety zones. A well-organized space boosts productivity and safety.

What are the ongoing costs of owning a laser cutting machine?

Ongoing costs include maintenance tasks like cleaning lenses and replacing worn parts. Consumables such as lenses and filters need periodic replacement. Consider electricity usage, especially for high-power lasers, as it impacts utility bills.

How important is manufacturer support when buying a laser cutter?

Manufacturer support is crucial. Reliable customer service and technical support ensure you receive assistance when needed. Check if the manufacturer offers prompt support and access to knowledgeable technicians.

What should I look for in a warranty?

Look for warranties that cover both parts and labor. Check if the warranty includes shipping costs for replacements. A robust warranty protects your investment and reduces unexpected costs.

Can I use a laser cutting machine for engraving?

Yes, laser cutting machines can engrave various materials. CO2 lasers work well for engraving non-metals, while fiber lasers handle metal engraving. Choose the right laser type and power for your engraving needs.

How do I maintain my laser cutting machine?

Regular maintenance involves cleaning lenses, checking alignment, and replacing worn parts. These tasks prevent breakdowns and extend the machine's lifespan. Follow the manufacturer's maintenance guidelines for optimal performance.

Are there any limitations to using a laser cutting machine?

Laser cutting machines have limitations based on the type and power of the laser. Diode lasers may not handle thick materials or metals. Consider your project's requirements and choose a machine that aligns with your needs.

See Also

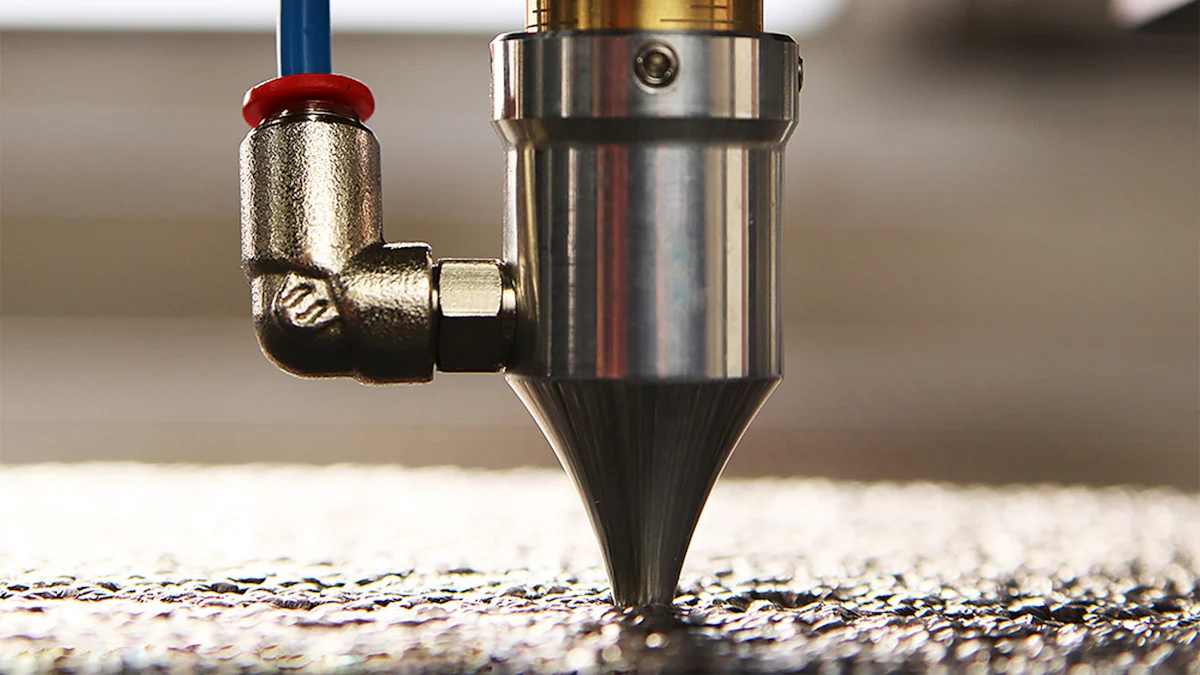

Essential Advice for Selecting Top Water Jet Cutters

Maximizing Efficiency with Your Laser Cutting Machine

Guidelines for Selecting the Ideal Wood Cutting Machine