How to Buy a Laser Cutting Machine for Beginners

Choosing the right laser cutter can feel overwhelming, especially if you're just starting out. You want a machine that fits your budget and meets your needs. Many beginners find YAG and CO2 laser cutters to be ideal choices. These machines offer affordability and versatility, making them perfect for home use or small studios. Laser cutting opens up a world of creativity and precision. Imagine crafting intricate designs with ease. Whether you're working with wood, acrylic, or fabric, a laser cutter can transform your ideas into reality. Ready to explore how to buy a laser cutting machine? Let's dive in!

Understanding Types of Laser Cutters

When you're diving into the world of laser cutting, understanding the different types of laser cutters is crucial. Each type has its unique features and applications, making it essential to choose the right one for your needs.

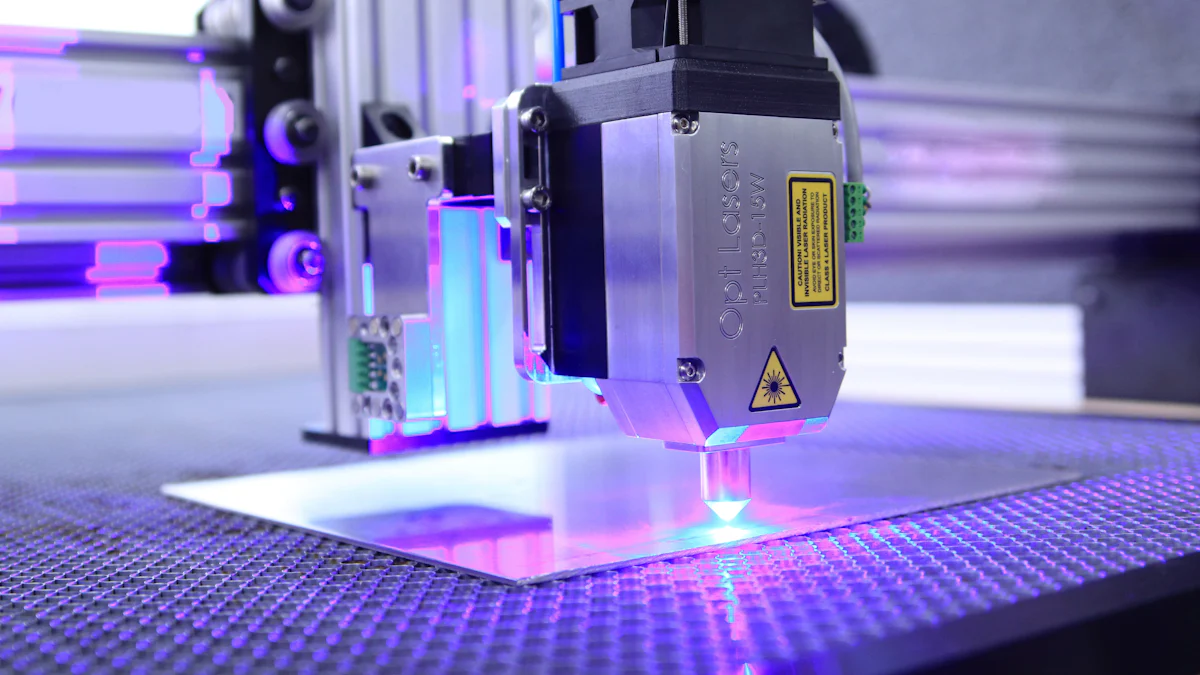

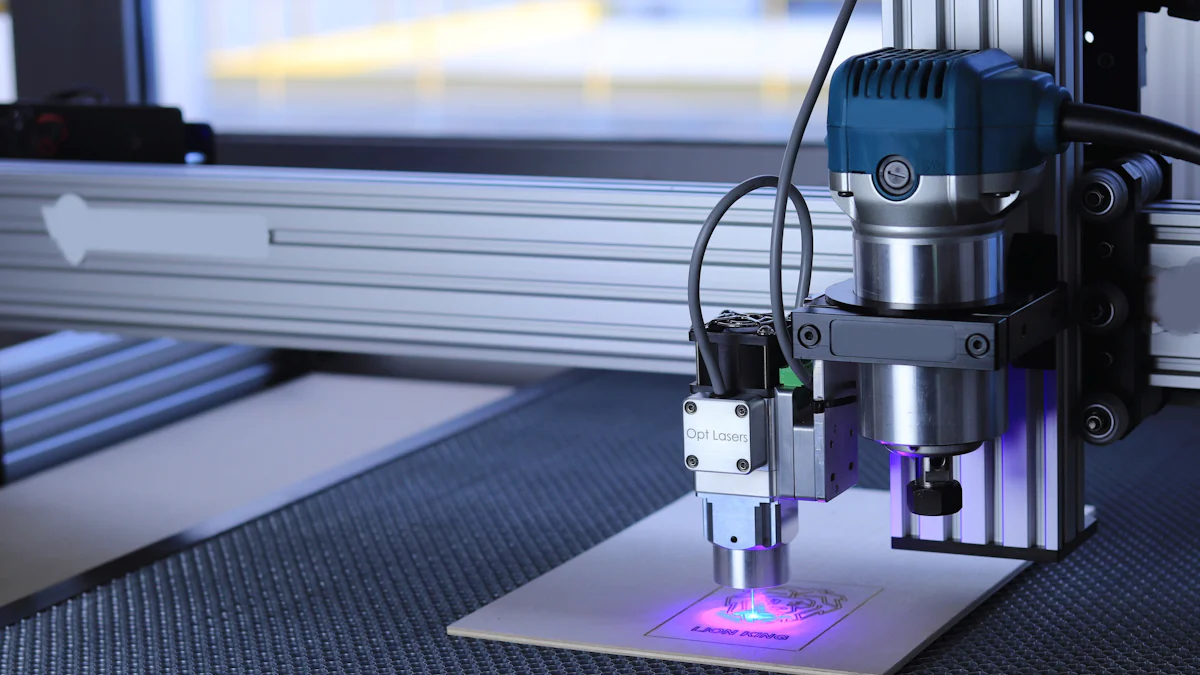

Diode Laser Cutters

Overview and suitability for beginners

Diode laser engraving machines are a fantastic starting point for beginners. They offer excellent energy efficiency, converting electrical energy into laser light with minimal loss. This efficiency makes them cost-effective and environmentally friendly. Diode lasers are simpler in construction, which means they require less maintenance and have a longer operational lifespan. Their compact size and robustness make them ideal for mobile applications, allowing you to experiment with laser cutting without needing a large workspace.

Common applications and materials

Diode laser cutters excel in cutting and engraving a variety of materials. They're particularly effective for high-speed cutting of thin metal sheets, plastics, and composites. You can use them in industries like automotive and electronics, but they're also perfect for hobbyists working with non-metallic materials. Whether you're crafting intricate designs on wood or engraving coated metals, diode lasers provide versatility and precision.

CO2 Laser Cutters

Overview and suitability for beginners

CO2 laser engravers are another excellent choice for beginners. These machines are powerful and versatile, capable of handling a wide range of non-metallic materials. They're perfect for creating detailed designs on wood, paper, acrylic, textiles, and leather. CO2 lasers are commonly used in hobbies, small businesses, and even industrial applications. If you're looking to explore various creative projects, a CO2 laser cutter might be the right fit for you.

Common applications and materials

CO2 laser cutters shine in cutting and engraving non-metallic materials. You can use them to craft beautiful designs on wood, create intricate patterns on textiles, or engrave personalized items on leather. Their ability to handle diverse laser engraving materials makes them a favorite among artists and small business owners. Whether you're making custom gifts or designing unique home decor, CO2 lasers offer endless possibilities.

Fiber Laser Cutters

Overview and suitability for beginners

Fiber laser cutters are known for their high precision and speed. They're ideal for professionals who need portability and accuracy. These machines are compact and lightweight, making them suitable for on-the-go use. If you're looking for a laser cutter that offers both power and flexibility, fiber lasers are worth considering. They provide excellent results, especially when working with metals.

Common applications and materials

Fiber laser cutters excel in cutting and engraving a variety of materials, including metals. They're perfect for projects that require high precision, such as jewelry making or detailed metalwork. Fiber lasers are also great for professionals who need to transport their equipment easily. Whether you're engraving intricate designs on metal or creating precise cuts, fiber lasers deliver exceptional performance.

Key Factors to Consider When Purchasing

When you're figuring out how to buy a laser cutting machine, several key factors come into play. These considerations ensure you make an informed decision that aligns with your needs and budget.

Safety Features

Importance of safety in laser cutting

Safety should be your top priority when working with laser cutters. These machines can pose risks if not handled properly. Understanding the importance of safety precautions is crucial. An enclosed laser cutter, for instance, minimizes exposure to harmful laser beams and fumes. This feature protects both you and your workspace.

Essential safety features to look for

When choosing the best laser engraver, look for essential safety features. These include:

- Emergency stop button: Allows you to halt operations immediately in case of an emergency.

- Interlock system: Prevents the laser from operating if the enclosure is open.

- Ventilation system: Ensures proper exhaust of fumes and smoke.

- Laser shielding: Protects against accidental exposure to laser beams.

These features not only enhance safety but also improve your overall experience with laser engraving machines.

Power and Performance

Understanding power ratings

Power ratings in laser cutters determine their capability to cut through various materials. Higher power means the laser cutter can handle thicker materials with ease. However, more power also means higher energy consumption. It's essential to understand these ratings to match them with your intended use.

Matching power to intended use

Consider what materials you'll work with and the level of precision and speed you need. For instance, if you're focusing on intricate designs, a laser cutter with high beam quality is ideal. On the other hand, if you're cutting thicker materials, prioritize power. Balancing these aspects ensures you get the most out of your machine.

Budget Considerations

Setting a realistic budget

Setting a realistic budget is vital when exploring how to buy a laser cutting machine. Prices vary widely based on features, power, and brand. Affordable laser cutters are available, but they might lack some advanced features. Determine what you're willing to spend and what features are non-negotiable for your projects.

Balancing cost with features

While it's tempting to go for the cheapest option, consider the long-term benefits of investing in a quality machine. A higher upfront cost might mean better performance and durability. Additionally, check for warranties that can protect your investment. Balancing cost with features ensures you get a machine that meets your needs without breaking the bank.

Size and Workspace Requirements

When you're setting up your laser cutting machine, the size of the machine and the space you have available are crucial considerations. Let's break it down to make sure you get the right fit for your workspace.

Assessing Available Space

First things first, take a good look at your workspace. Measure the area where you plan to place your laser cutter. You want to ensure there's enough room not just for the machine itself but also for you to move around comfortably. Remember, an enclosed laser cutter often requires additional space for ventilation and safety features. Think about the layout of your room. Is there enough clearance for the machine's doors or lids to open fully? Also, consider the proximity to power outlets and any necessary ventilation systems. A well-planned space can make your laser cutting experience much smoother and safer.

Choosing the Right Machine Size

Once you've assessed your space, it's time to choose a machine size that fits. Laser cutters come in various sizes, from compact models perfect for small home studios to larger machines suited for industrial use. If you're working in a limited space, a smaller enclosed laser cutter might be ideal. These models are designed to fit snugly into tight areas while still offering powerful performance. On the other hand, if you have ample space and plan to work on larger projects, consider a bigger machine. Larger enclosed laser cutters can handle bigger materials and offer more versatility in terms of project size. However, they require more room and may need additional setup for ventilation and safety.

Recommended Beginner-Friendly Models

Choosing the right laser cutter can be a game-changer for your creative projects. As a beginner, you want a machine that's easy to use and reliable. Here are some top picks for beginner-friendly laser engraving machines that can help you get started on the right foot.

Best Laser Engraver for Beginners

Glowforge Aura

The Glowforge Aura stands out as one of the best laser engravers for beginners. Its user-friendly interface makes it easy to start crafting right away. You don't need a large workspace, as this enclosed laser cutter fits comfortably in most home studios. The Glowforge Aura excels in precision and versatility, allowing you to work with materials like wood, leather, and acrylic. Its compact design doesn't compromise on power, making it a favorite among hobbyists and small business owners.

xTool S1

Another excellent choice for those new to laser cutting is the xTool S1. This model is perfect if you need to cut thicker materials without investing in a CO2 laser. The xTool S1 offers a balance of power and affordability, making it one of the best laser engravers for beginners. Its enclosed design ensures safety while providing a clear view of your work. Whether you're engraving intricate designs or cutting through wood, the xTool S1 delivers impressive results.

Best Home Laser Cutter

OMTech Polar

For those looking for the best home laser cutter, the OMTech Polar is a top contender. This machine is designed specifically for home use, offering ease of operation and a compact form factor. The OMTech Polar handles a variety of materials, making it ideal for crafting, DIY projects, and small business applications. Its enclosed laser cutter design ensures safety and efficiency, allowing you to focus on your creativity without worrying about safety hazards.

WAINLUX K6 Pro

The WAINLUX K6 Pro is another great option for home use. It's a budget-friendly choice that doesn't skimp on features. This enclosed laser cutter is perfect for beginners who want to explore laser engraving without breaking the bank. The WAINLUX K6 Pro is easy to set up and operate, making it a popular choice for those new to laser cutting. Its compact size means it fits well in smaller spaces, yet it still offers powerful performance for a variety of projects.

Entry-Level Laser Engraver

Creality Falcon2

If you're searching for an entry-level laser engraver, the Creality Falcon2 is worth considering. This model offers good performance at an accessible price point. The Creality Falcon2 is designed for those who want to dive into laser engraving without a steep learning curve. Its enclosed design ensures safety, while its straightforward controls make it easy to use. Whether you're working on small crafts or larger projects, the Creality Falcon2 provides reliable results.

xTool P2

The xTool P2 is another excellent entry-level laser engraver. Known for its performance, power, and accuracy, the xTool P2 is a great choice for beginners who want to explore the full potential of laser cutting. This enclosed laser cutter is versatile, handling a wide range of materials with ease. Its user-friendly interface and robust design make it a favorite among newcomers to laser engraving.

These models offer a range of features and capabilities, ensuring you find the best fit for your needs. Whether you're looking for the best laser engraver for beginners or the best home laser cutter, these options provide a solid starting point for your creative journey.

Practical Tips for Setup and Use

Getting started with your new laser cutter can be exciting, but it also requires careful setup and maintenance. Here are some practical tips to help you get the most out of your machine.

Initial Setup and Calibration

Step-by-step setup guide

-

Unpack Your Laser Cutter: Begin by carefully unpacking your enclosed laser cutter. Check that all components are included and undamaged. Refer to the user manual for a list of parts.

-

Choose the Right Location: Place your laser cutter in a well-ventilated area. Ensure there's enough space around the machine for airflow and safety. Avoid placing it near flammable materials.

-

Connect to Power: Plug your laser cutter into a grounded electrical outlet. Make sure the power supply matches the specifications in the manual.

-

Install Software: Install any necessary software on your computer. Most laser cutters come with a CD or a link to download the software. Follow the installation instructions carefully.

-

Calibrate the Machine: Calibration is crucial for precision. Use the provided tools to align the laser beam. Adjust the focus according to the material thickness. Many modern machines offer user-friendly interfaces to guide you through this process.

-

Test Run: Perform a test run using a simple design. This helps ensure everything is working correctly. Adjust settings as needed for optimal performance.

Basic Maintenance and Troubleshooting

Routine maintenance tips

Regular maintenance keeps your laser cutter running smoothly. Here are some essential tips:

-

Clean the Lens and Mirrors: Dust and debris can affect laser performance. Use a soft cloth and lens cleaner to wipe the lens and mirrors regularly.

-

Check the Cooling System: Ensure the cooling system is functioning properly. Replace the water or coolant as recommended by the manufacturer.

-

Inspect Belts and Rails: Look for wear and tear on belts and rails. Lubricate them periodically to prevent friction and ensure smooth movement.

-

Update Software: Keep your software up to date. Manufacturers often release updates to improve functionality and fix bugs.

Common issues and solutions

Even with proper maintenance, you might encounter some issues. Here are common problems and their solutions:

-

Laser Not Cutting Through Material: Check the focus and power settings. Ensure the lens is clean and the material is suitable for your laser cutter.

-

Uneven Cuts: This could be due to misalignment. Recalibrate the machine and check the stability of the work surface.

-

Software Errors: Restart the software and check for updates. If the problem persists, consult the user manual or contact customer support.

-

Overheating: Ensure the cooling system is working. Check for blockages in the ventilation system and clean them if necessary.

By following these setup and maintenance tips, you'll ensure your enclosed laser cutter operates efficiently and safely. Whether you're working on laser engraving projects for beginners or more advanced tasks, these guidelines will help you achieve the best results.

You've now got a solid grasp on how to buy a laser cutting machine. From understanding the types of laser cutters to considering key factors like safety and budget, you're well-equipped to make an informed decision. Remember, an enclosed laser cutter offers safety and efficiency, making it a great choice for beginners. Regular maintenance, like cleaning lenses and checking for wear, ensures your laser cutter remains a reliable tool. Dive into the world of laser cutting with confidence, and let your creativity shine through every project you undertake.

FAQ

What is a laser cutter, and how does it work?

A laser cutter is a machine that uses a focused laser beam to cut or engrave materials. It works by directing the laser through optics to precisely cut or etch designs onto various surfaces. The laser's intensity and speed can be adjusted to suit different materials, making it a versatile tool for creative projects.

Why should beginners consider using laser cutters?

Laser cutters offer an excellent opportunity for beginners to explore their creativity. They allow you to craft intricate designs with precision and ease. Whether you're interested in prototyping, manufacturing, or personal projects, laser cutting provides a versatile and efficient method for working with various materials.

What materials can I use with a laser cutter?

You can use a laser cutter on a wide range of materials, including wood, acrylic, fabric, leather, and some metals. Each material requires specific settings for optimal results. Always check your machine's specifications to ensure compatibility with the materials you plan to use.

How do I choose the right laser cutter for my needs?

Consider factors like the types of materials you want to work with, your budget, and the space available in your workspace. Look for features such as power, safety, and ease of use. Reading reviews and user experiences can also provide valuable insights into the reliability and performance of different models.

Are enclosed laser cutters safer than open ones?

Yes, enclosed laser cutters are generally safer because they minimize exposure to harmful laser beams and fumes. They often come with additional safety features like interlock systems and ventilation, making them a great choice for beginners who prioritize safety.

How much maintenance does a laser cutter require?

Regular maintenance is essential to keep your laser cutter running smoothly. This includes cleaning the lens and mirrors, checking the cooling system, and inspecting belts and rails for wear. Following the manufacturer's maintenance guidelines will help ensure your machine's longevity and performance.

Can I use a laser cutter for business purposes?

Absolutely! Many small businesses use laser cutters for creating custom products, signage, and prototypes. The precision and versatility of laser cutting make it an ideal tool for entrepreneurs looking to offer unique and personalized items.

What are some common issues with laser cutters, and how can I solve them?

Common issues include the laser not cutting through materials, uneven cuts, and software errors. Solutions involve checking the focus and power settings, recalibrating the machine, and ensuring the software is up to date. Regular maintenance can prevent many of these problems.

Is laser cutting environmentally friendly?

Laser cutting can be environmentally friendly, especially when using diode lasers known for their energy efficiency. By choosing sustainable materials and recycling waste, you can further reduce the environmental impact of your laser cutting projects.

How can I learn more about using a laser cutter effectively?

Many resources are available online, including tutorials, forums, and user groups. Joining a community of laser cutting enthusiasts can provide support and inspiration. Additionally, experimenting with different projects will help you gain hands-on experience and improve your skills.

See Also

Comparative Guide To Laser Cutting Machine Prices

Maximizing Efficiency With Your Laser Cutting Machine

Beginner's Guide To Operating A Die Cutting Machine