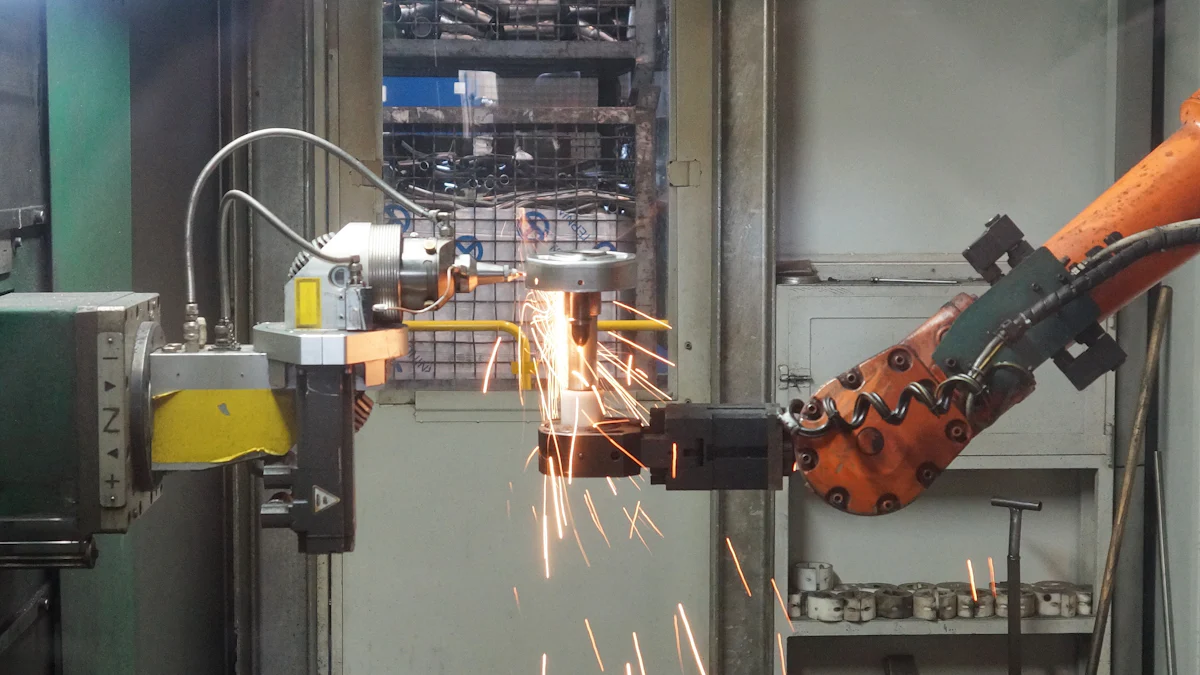

How Much Laser Cutting Machine Cost New vs Used

When considering how much laser cutting machine cost, it's important to note that prices vary widely based on the machine's type, size, and features. New laser cutting machines tend to be more expensive due to their advanced technology, warranties, and dependable support. For example, entry-level CO2 laser cutters typically start at around $2,000, while premium fiber laser machines can surpass $100,000. Alternatively, used machines offer a more budget-friendly option, often at significantly lower prices, though they might require additional maintenance or repairs. Understanding these cost factors is crucial in deciding whether to invest in a new machine or opt for a used one that suits your requirements.

Key Takeaways

- New laser cutting machines offer advanced technology and warranties, making them ideal for businesses seeking reliability and long-term performance.

- Used laser cutting machines provide a budget-friendly alternative, often costing significantly less, but require careful evaluation of their condition and maintenance history.

- Consider the upfront costs versus long-term value; while new machines have higher initial expenses, they may save money on maintenance and repairs over time.

- Evaluate your operational needs and production volume to determine whether a new or used machine aligns better with your business goals.

- Research financing options for both new and used machines to make your investment more manageable and to explore potential maintenance packages.

- Be aware of the depreciation rates for new machines, which can lose 20% to 30% of their value within the first year, while used machines often retain a higher resale value.

- Always check the availability of spare parts and manufacturer support when considering used machines to avoid potential future challenges.

Cost Comparison

Typical Price Ranges for New Laser Cutting Machines

Entry-Level Machines

Entry-level laser cutting machines provide an affordable starting point for small businesses or hobbyists. These machines, such as CO2 laser cutters, typically range from $2,000 to $20,000. For example, entry-level fiber metal laser cutting machines start at around $15,000. While these machines may lack advanced features, they are ideal for basic cutting tasks and light-duty operations.

Mid-Range Machines

Mid-range laser cutting machines cater to businesses requiring higher precision and efficiency. These machines often cost between $50,000 and $100,000. For instance, mid-range tube laser cutting machines fall within this price bracket. They offer enhanced capabilities, such as faster cutting speeds and the ability to handle thicker materials, making them suitable for medium-scale production.

High-End Industrial Machines

High-end industrial laser cutting machines represent the pinnacle of performance and technology. These machines can cost anywhere from $100,000 to over $500,000. For example, fiber laser cutters optimized for metals often reach this price range. These machines deliver exceptional precision, speed, and durability, making them indispensable for large-scale manufacturing and heavy-duty applications.

Typical Price Ranges for Used Laser Cutting Machines

Budget-Friendly Options

Used laser cutting machines provide a cost-effective alternative for buyers on a tight budget. Budget-friendly options often start at $5,000 and can go up to $20,000, depending on the machine's condition and features. These machines are ideal for those looking to save money while still gaining access to basic laser cutting capabilities.

Mid-Tier Used Machines

Mid-tier used machines strike a balance between affordability and performance. Prices for these machines typically range from $20,000 to $50,000. Buyers in this category can find reliable machines with moderate wear and tear, offering good value for their investment.

Premium Used Machines

Premium used machines are high-quality options that retain much of their original performance. These machines often cost between $50,000 and $100,000. They are ideal for businesses seeking advanced features and capabilities without the expense of purchasing new equipment.

Factors Influencing New Machine Costs

Technology and Features

The technology and features of a laser cutting machine significantly impact its price. Machines with advanced features, such as automated loading systems or multi-material cutting capabilities, command higher prices. For example, fiber laser cutters optimized for metals often include cutting-edge technology, which increases their cost.

Brand Reputation

The brand of a laser cutting machine also plays a crucial role in determining its price. Well-known brands with a reputation for quality and reliability often charge a premium. Investing in a reputable brand can provide you with better performance and long-term support.

Warranty and Support

New laser cutting machines typically come with warranties and manufacturer support. These benefits add to the upfront cost but provide peace of mind and assistance in case of technical issues. A comprehensive warranty can save you money on repairs and maintenance in the long run.

Factors Influencing Used Machine Costs

Machine Condition and Age

The condition and age of a used laser cutting machine play a significant role in determining its price. Machines in excellent condition with minimal wear and tear often command higher prices. For example, a well-maintained fiber laser cutter can still deliver exceptional performance even after years of use. On the other hand, older machines may show signs of wear, such as reduced cutting precision or slower speeds, which can lower their value. Age also impacts the availability of spare parts. Older models may require discontinued components, making repairs more challenging and costly. When evaluating a used machine, you should carefully inspect its physical condition and inquire about its operational history.

Maintenance and Repair History

A machine's maintenance and repair history directly affects its reliability and cost. Regularly serviced machines with detailed maintenance records are more likely to perform efficiently and require fewer repairs. For instance, a metal laser cutting machine with a consistent service history will likely have fewer operational issues compared to one with sporadic or neglected maintenance. Conversely, machines with a history of frequent breakdowns or major repairs may pose risks, even if they come at a lower price. Always request maintenance logs and repair documentation when considering a used machine. These records provide valuable insights into the machine's overall health and potential future costs.

Availability and Market Demand

The availability of specific models and the current market demand also influence the cost of used laser cutting machines. Popular models, such as fiber metal laser cutting machines, often retain their value due to high demand. Limited availability can drive up prices, especially for machines with sought-after features like multi-material cutting capabilities. Conversely, less popular or outdated models may sell for lower prices due to reduced demand. Market trends also play a role. For example, if businesses increasingly adopt newer technologies, older models may become more affordable. Understanding market dynamics helps you identify the best time to purchase a used machine at a competitive price.

Pros and Cons of New vs Used Machines

Benefits of New Machines

Access to Latest Technology

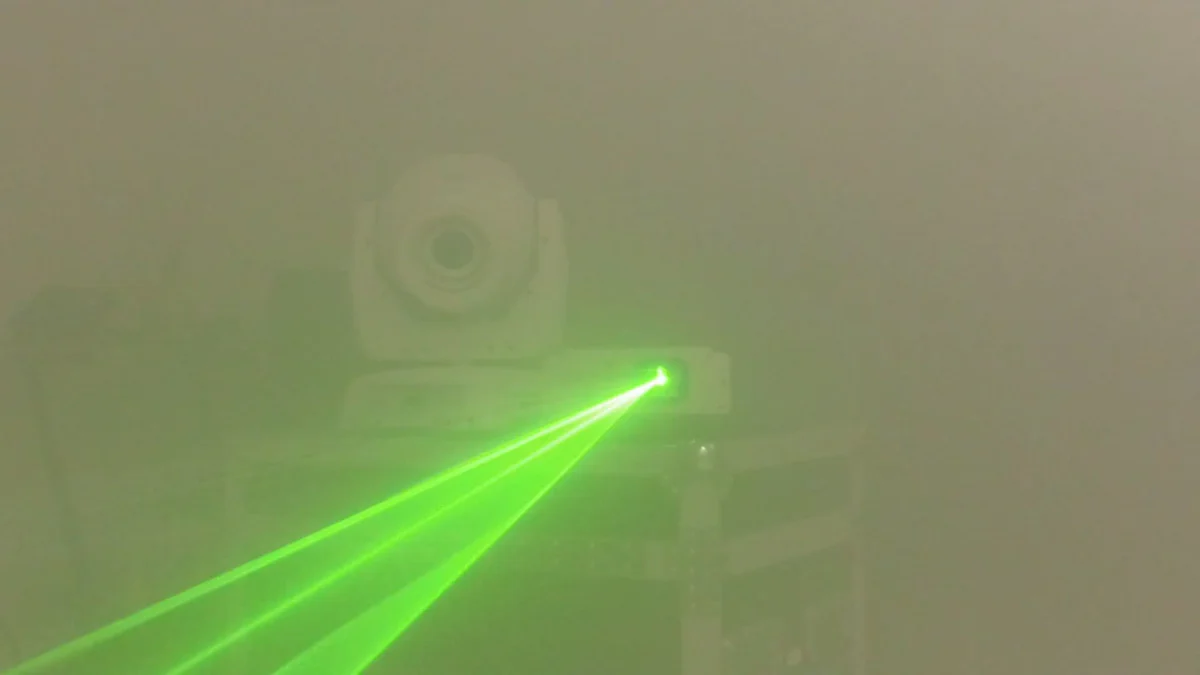

New laser cutting machines provide you with cutting-edge technology. These machines often include advanced features like automated systems, higher precision, and faster cutting speeds. For example, fiber laser cutters designed for metals offer superior performance and energy efficiency. Investing in the latest technology can enhance your productivity and ensure compatibility with modern manufacturing requirements.

Manufacturer Warranty and Support

When you purchase a new machine, you gain access to manufacturer warranties and dedicated support. These warranties cover potential defects and technical issues, saving you from unexpected repair costs. Additionally, manufacturers often provide training and customer service, ensuring you can operate the machine efficiently. This level of support adds value to your investment and reduces downtime.

Longer Lifespan and Reliability

New machines typically offer a longer lifespan due to their unused components and advanced engineering. They are less likely to experience frequent breakdowns, ensuring consistent performance over time. With proper maintenance, a new laser cutting machine can serve your business for many years, making it a reliable choice for long-term operations.

Drawbacks of New Machines

Higher Upfront Costs

The most significant drawback of new machines is their high initial cost. Advanced features and brand reputation contribute to these expenses. For instance, high-end industrial laser cutters can exceed $500,000, which may strain your budget. If you are starting a business or have limited funds, this upfront investment might not be feasible.

Depreciation Over Time

New machines lose value quickly after purchase. Depreciation affects their resale price, making it challenging to recover your investment if you decide to sell. While the machine's performance remains intact, its market value decreases, which could impact your financial planning.

Benefits of Used Machines

Lower Initial Investment

Used laser cutting machines offer a more affordable entry point. These machines often cost significantly less than new ones, allowing you to save money while still acquiring essential capabilities. For example, budget-friendly used machines can start at $5,000, making them an attractive option for small businesses or hobbyists.

Faster Availability

Purchasing a used machine often involves shorter lead times. Unlike new machines that may require weeks or months for manufacturing and delivery, used machines are readily available. This quick access enables you to start operations sooner, which can lead to faster returns on your investment.

Potential for High-Quality Machines at Reduced Costs

You can find high-quality used machines that retain much of their original performance. Premium used options, priced between $50,000 and $100,000, often include advanced features and capabilities. By carefully evaluating the machine's condition and maintenance history, you can secure a reliable machine at a fraction of the cost of a new one.

Drawbacks of Used Machines

Limited Warranty or Support

When you purchase a used laser cutting machine, you often miss out on the benefits of a manufacturer’s warranty. Most used machines no longer qualify for warranty coverage, leaving you responsible for repair costs if issues arise. Additionally, support from the original manufacturer may be limited or unavailable. Without access to technical assistance or training, you might face challenges in operating or maintaining the machine effectively. This lack of support can increase downtime and disrupt your workflow, especially if you encounter complex technical problems.

Potential Hidden Maintenance Costs

Used machines can come with hidden maintenance costs that may not be immediately apparent. Even if the machine appears to be in good condition, internal components might have wear and tear that affects performance. For example, older machines may require frequent part replacements or repairs, which can quickly add up. If the previous owner neglected regular maintenance, you could inherit unresolved issues that impact the machine's reliability. To avoid unexpected expenses, you should thoroughly inspect the machine and review its maintenance history before making a purchase.

Shorter Remaining Lifespan

A used laser cutting machine typically has a shorter remaining lifespan compared to a new one. The machine’s age and usage history directly influence how long it will continue to perform efficiently. Over time, components degrade, leading to reduced precision, slower speeds, and potential breakdowns. While some high-quality used machines can still deliver excellent results, they may not match the longevity of a new machine. If you plan to use the machine for long-term operations, this reduced lifespan could limit its value and require you to invest in another replacement sooner than expected.

Key Considerations When Choosing

Assessing Your Budget and Operational Needs

Upfront Costs vs Long-Term Value

When deciding between a new or used laser cutting machine, you must weigh the upfront costs against the long-term value. New machines often come with higher initial expenses, but they deliver advanced technology, longer lifespans, and greater reliability. Over time, these benefits can offset the initial investment by reducing maintenance costs and downtime. For example, a brand-new machine with energy-efficient features may lower operational expenses, making it a cost-effective choice in the long run.

On the other hand, used machines offer a more affordable entry point. You can save thousands of dollars upfront, which is especially beneficial if you have a limited budget. However, hidden maintenance costs and shorter lifespans may reduce their overall value. A poorly maintained used machine could lead to frequent repairs, which might outweigh the initial savings. Carefully consider how much you are willing to invest now versus the potential costs over time.

Financing Options for New and Used Machines

Financing options can significantly impact your decision. Many manufacturers and dealers offer financing plans for new machines, allowing you to spread the cost over time. This approach makes high-end machines more accessible, even if your budget is tight. Additionally, some financing plans include maintenance packages, which can further reduce long-term expenses.

For used machines, financing options may be limited, but they still exist. Some sellers provide installment plans or leasing options. However, you should evaluate the terms carefully. Ensure that the total cost, including interest, aligns with the machine's value and expected lifespan. Whether you choose new or used, explore all available financing options to find one that fits your financial situation.

Evaluating Machine Performance and Features

Importance of Technology and Precision

Technology plays a crucial role in the performance of a laser cutting machine. New machines often feature cutting-edge advancements, such as automated systems and enhanced precision. These features improve productivity and ensure consistent results. For instance, a fiber laser cutter designed for metals can deliver exceptional accuracy and speed, making it ideal for high-demand operations.

Used machines may lack the latest technology, but they can still meet your needs if precision is not your top priority. For example, businesses in developing regions often opt for used machines because they prioritize affordability over advanced features. Evaluate the level of precision and technology required for your operations before making a decision.

Compatibility with Your Business Requirements

Your business needs should guide your choice. Consider the materials you work with, the volume of production, and the complexity of your projects. A high-end industrial machine may be necessary for large-scale manufacturing, while an entry-level model could suffice for smaller tasks. Ensure that the machine you choose aligns with your operational goals.

Used machines can be a good fit for businesses with straightforward requirements. However, you must verify that the machine's capabilities match your needs. If the machine cannot handle your workload or material specifications, it may hinder your productivity. Always assess compatibility to avoid costly mistakes.

Maintenance and After-Sales Support

Availability of Spare Parts

Spare parts availability is a critical factor when choosing between new and used machines. New machines typically come with readily available parts, ensuring quick repairs and minimal downtime. Manufacturers often stock components for their latest models, making maintenance more convenient.

For used machines, spare parts may be harder to find, especially for older models. Some components might be discontinued, leading to delays and higher repair costs. Before purchasing a used machine, research the availability of parts and consider the potential challenges of sourcing them.

Manufacturer or Dealer Support

Support from the manufacturer or dealer can make a significant difference in your experience. New machines usually include warranties and customer service, providing peace of mind. You can rely on the manufacturer for technical assistance, training, and troubleshooting, which helps maintain smooth operations.

Used machines often lack these benefits. Most warranties expire before resale, leaving you responsible for repairs. Some sellers may offer limited support, but it is not guaranteed. Ask the seller about any available maintenance plans or warranties to ensure you have a safety net. Reliable support can save you time and money, even for a pre-owned machine.

Expected Lifespan and Resale Value

Depreciation Rates for New Machines

New laser cutting machines experience significant depreciation as soon as they are purchased. The value of a brand-new machine can drop by 20% to 30% within the first year. This rapid depreciation occurs because the market often favors newer models with the latest technology. For example, if you invest in a high-end industrial laser cutter for $200,000, its resale value might decrease to $140,000 or less after just one year.

However, the long-term benefits of new machines can offset this initial depreciation. New machines typically offer extended lifespans due to their advanced engineering and unused components. With proper maintenance, these machines can remain operational for 10 to 15 years or more. This longevity ensures consistent performance and reliability, making them a worthwhile investment for businesses focused on long-term operations.

“Brand-new machines carry a lot of benefits and advantages. From how they’re set up alone to what they can do, it’s clear that they are better, more efficient, and can last longer.”

If you plan to use the machine for many years, the depreciation becomes less of a concern. The machine's efficiency and reduced maintenance costs can justify the higher upfront price over time.

Resale Potential for Used Machines

Used laser cutting machines often retain a higher percentage of their original value when resold. If you purchase a used machine at a lower price, you can recover a significant portion of your investment when you decide to sell it. For instance, a used machine bought for $50,000 might still fetch $40,000 after a few years, depending on its condition and market demand.

This strong resale potential makes used machines an attractive option for budget-conscious buyers. You save money upfront and face less financial loss when upgrading or selling the equipment. Additionally, the demand for affordable, pre-owned machines remains high, especially in regions where businesses prioritize cost savings over advanced features.

“If you buy used, not only is the equipment being purchased much more affordable, but when you do decide to resell it, you’ll be able to recoup a larger percentage of the original price you paid for your machine.”

However, the resale value of a used machine depends heavily on its condition and maintenance history. Machines with consistent service records and minimal wear and tear command higher prices. Conversely, poorly maintained machines with frequent breakdowns may lose value quickly. To maximize resale potential, ensure regular maintenance and keep detailed service records.

New laser cutting machines provide advanced technology, warranties, and reliable performance. They ensure long-term efficiency but require a significant upfront investment. On the other hand, used machines offer affordability and faster returns on investment. However, you must carefully evaluate their condition and maintenance history to avoid hidden costs or outdated functionality. To make the best decision, assess your budget, operational needs, and long-term goals. Whether you prioritize cutting-edge features or cost savings, understanding how much laser cutting machine cost will help you choose the right option for your business.

FAQ

How much does a laser cutting machine typically cost?

The cost of a laser cutting machine varies widely based on its type, size, and features.

Is it better to buy a new or used laser cutting machine?

Your choice depends on your budget and operational needs. New machines provide advanced technology, warranties, and longer lifespans, making them ideal for long-term use. Used machines, on the other hand, offer lower upfront costs and faster availability but may require more maintenance. Carefully assess your priorities before deciding.

What factors influence the cost of a new laser cutting machine?

Several factors affect the price of a new machine, including its technology, brand reputation, and included warranties. Machines with advanced features, such as automated systems or multi-material cutting capabilities, tend to cost more. Brands known for quality and reliability also charge a premium.

“Reliable after-sales service and a solid warranty can significantly affect the long-term value of a machine.”

What should I consider when buying a used laser cutting machine?

When purchasing a used machine, focus on its condition, maintenance history, and age. Machines with consistent service records and minimal wear offer better reliability. Also, check the availability of spare parts and ensure the machine meets your operational requirements.

Do laser cutting machines lose value over time?

Yes, new machines experience significant depreciation, often losing 20% to 30% of their value within the first year. However, used machines retain a higher percentage of their value, making them a better option if you plan to resell in the future.

“This serious depreciation in value means that if you purchase equipment brand new, you won’t recoup nearly as much of that original cost as you might expect.”

Are there financing options available for laser cutting machines?

Yes, many manufacturers and dealers offer financing plans for new machines, allowing you to spread the cost over time. Some used machines also come with financing or leasing options, though these may be less common. Always review the terms to ensure they align with your financial goals.

How does energy efficiency impact the cost of a laser cutting machine?

Energy-efficient machines, such as fiber laser cutters, often have higher upfront costs. However, their lower power consumption can reduce operational expenses over time, making them a cost-effective choice for businesses focused on long-term savings.

“Opting for a fiber laser cutting machine might be more expensive upfront, but its energy efficiency can lead to lower long-term power consumption and reduced electric bills.”

Can a used machine perform as well as a new one?

A well-maintained used machine can deliver excellent performance, especially if it has advanced features and minimal wear. However, older machines may lack the latest technology, which could affect precision and efficiency. Evaluate the machine’s condition and capabilities to ensure it meets your needs.

What are the risks of buying a used laser cutting machine?

Used machines may come with hidden maintenance costs or limited warranties. Without proper inspection, you could inherit unresolved issues that impact performance. Always review the machine’s maintenance history and consider having a safety net, such as a repair budget, in case problems arise.

How do I decide which laser cutting machine is right for my business?

Start by assessing your budget, production volume, and material requirements. Determine whether you need advanced features or basic functionality. Consider the long-term value, including operational costs and potential resale value. By aligning your choice with your business goals, you can make an informed decision.

See Also

A Comprehensive Guide To Laser Cutting Machine Costs

Understanding The Costs Of Water Jet Cutting Machines

Exploring The Prices And Types Of Cutting Machines

Cost Analysis Of Coal Cutting Machines Explained

The Functionality Of Laser Cutting Machines: Benefits And Drawbacks