How Much Is a Laser Metal Cutting Machine Guide

Laser metal cutting machines come with a wide price range, starting from $5,000 for basic models and exceeding $1,000,000 for advanced industrial systems. The cost depends heavily on factors like the machine type, power output, and additional features. For instance, high-power lasers, such as those exceeding 6000W, are essential for cutting thicker materials but significantly increase the price. The brand and material compatibility also play a crucial role. Understanding these elements helps you make informed decisions when determining how much is a laser metal cutting machine that fits your needs.

Key Takeaways

- Laser cutting machines range from $5,000 for basic models to over $1,000,000 for advanced systems, with costs influenced by type, power, and features.

- CO2 lasers are versatile and affordable for general cutting, while fiber lasers offer speed and precision for metal cutting, making them ideal for industrial use.

- Consider hidden costs such as maintenance, software, and energy consumption when budgeting for a laser cutting machine to avoid unexpected expenses.

- Assess your specific cutting needs and material types to choose the right machine, ensuring it aligns with your production goals and budget.

- Research reputable brands and compare features to find a reliable machine that meets your requirements, as established manufacturers often provide better support and durability.

- Buying used or refurbished machines can save money, but ensure you evaluate their condition and maintenance history to avoid future costs.

- Energy-efficient models, like fiber lasers, can significantly reduce long-term operational costs, making them a smart investment for businesses.

Types of Laser Metal Cutting Machines and Their Costs

When exploring laser metal cutting machines, understanding the different types and their costs is crucial.

CO2 Laser Cutting Machines

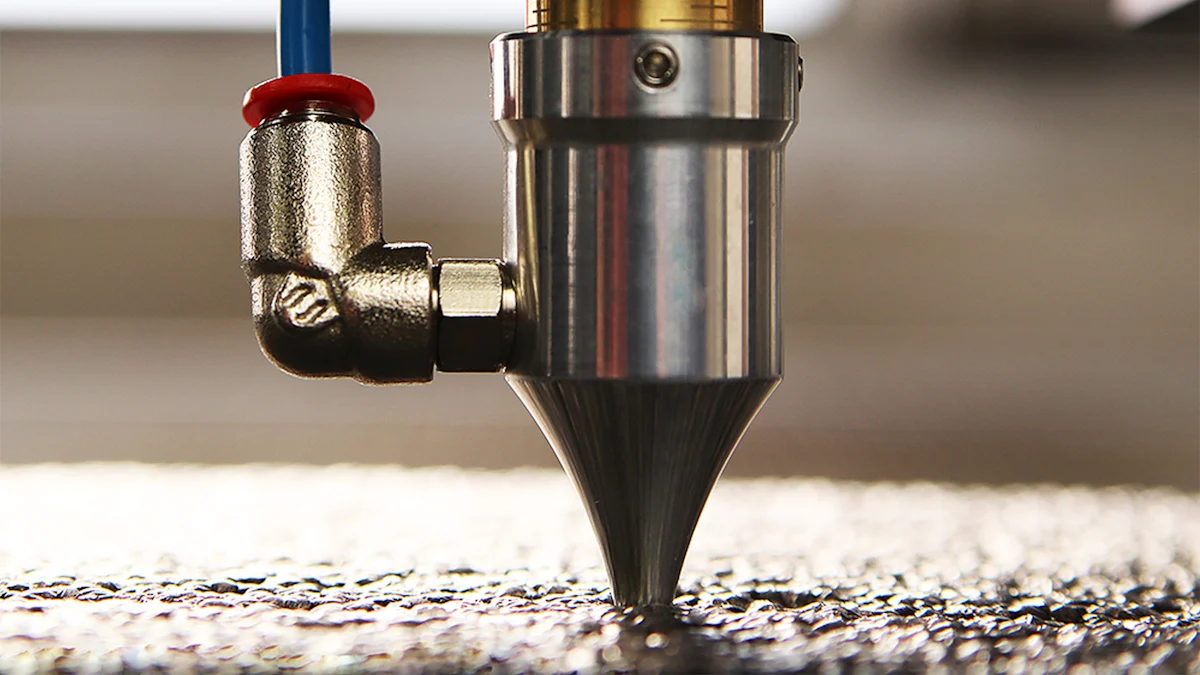

CO2 laser cutting machines are among the most common and versatile options available. These machines use carbon dioxide gas to generate the laser beam. They are ideal for cutting a variety of materials, including wood, plastic, and thin metals.

- Cost: Prices for CO2 laser cutters typically start at around $2,000 for entry-level models. Advanced models with higher power and larger cutting areas can cost significantly more.

- Advantages:

- Suitable for intricate designs and complex shapes.

- Offers precise and accurate cuts with minimal material waste.

- Works well for non-metal materials in addition to metals.

- Limitations:

- Less efficient when cutting thicker metals.

- Higher maintenance requirements compared to other types.

If you’re looking for an affordable option for general-purpose cutting, CO2 lasers might be the right choice.

Fiber Laser Cutting Machines

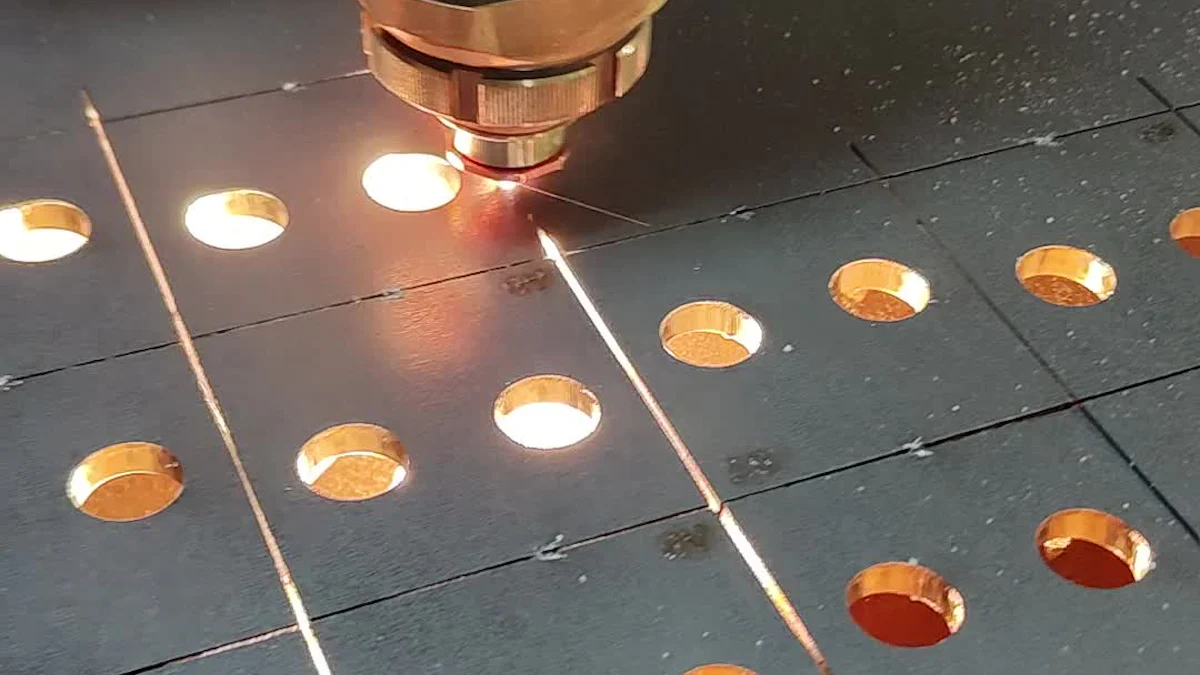

Fiber laser cutting machines are known for their efficiency and precision. These machines use fiber optic cables to produce a concentrated laser beam. They excel at cutting metals like aluminum, brass, and stainless steel, making them a popular choice for industrial applications.

- Cost: Fiber laser cutters range from $30,000 to $600,000, depending on the machine’s power, size, and features.

- Advantages:

- Faster cutting speeds compared to CO2 lasers.

- Capable of cutting thicker materials with high precision.

- Energy-efficient design reduces operational costs.

- Limitations:

- Higher upfront cost than CO2 lasers.

- Limited effectiveness on non-metal materials.

For businesses requiring high-speed and precise metal cutting, fiber lasers provide excellent value despite their higher price tag.

Crystal Laser Cutting Machines

Crystal laser cutting machines, such as YAG (Yttrium Aluminum Garnet) lasers, represent the most advanced and expensive category. These machines use crystals to generate the laser beam, enabling them to cut through the thickest materials with unmatched speed and accuracy.

- Cost: Prices for crystal laser cutters start at $200,000 and can exceed $1,000,000 for industrial-grade models.

- Advantages:

- Exceptional cutting power for thick and dense materials.

- Superior speed and performance for demanding applications.

- Limitations:

- High initial investment.

- Shorter lifespan of the laser source compared to fiber lasers.

Crystal lasers are best suited for industries requiring heavy-duty cutting capabilities, such as aerospace or automotive manufacturing.

Pro Tip: When deciding how much is a laser metal cutting machine that fits your needs, consider not only the upfront cost but also the machine’s long-term efficiency and maintenance requirements.

Key Factors Affecting the Price

When determining the cost of a laser metal cutting machine, several key factors come into play.

Power Output

The power output of a laser cutting machine plays a significant role in its price. Machines with higher wattage can cut through thicker and denser materials with ease. For instance, a 1000W laser cutter is suitable for thin metals, while a 6000W or higher machine is necessary for industrial-grade applications.

Higher power levels also translate to faster cutting speeds, which can boost productivity. However, this comes at a cost. Machines with greater wattage are more expensive upfront and consume more energy during operation. If you plan to cut thick materials like stainless steel or aluminum, investing in a high-power machine ensures better performance and precision.

Did You Know? Laser power directly affects the machine's efficiency. A higher wattage laser not only cuts faster but also reduces material stress, extending the machine's lifespan.

Material Compatibility

The type of materials you intend to cut significantly influences the machine's cost. Some machines, like CO2 lasers, are versatile and can handle non-metal materials such as wood and plastic in addition to metals. Fiber lasers, on the other hand, excel at cutting reflective metals like brass and aluminum but are less effective on non-metal materials.

If your projects involve a variety of materials, you may need a machine with broader compatibility. Machines designed for specific materials, such as crystal lasers for dense metals, often come with a higher price tag. Choosing a machine tailored to your material needs ensures optimal performance and cost-effectiveness.

Pro Tip: Cutting mild steel is generally cheaper than cutting stainless steel or aluminum due to differences in material properties and laser requirements.

Machine Size and Cutting Area

The size of the machine and its cutting area also impact the price. Larger machines with expansive work tables can accommodate bigger materials and are ideal for industrial applications. However, they require more materials and motors during manufacturing, which increases their cost.

Smaller machines are more affordable and suitable for hobbyists or small businesses. When selecting a machine, consider the dimensions of the parts you plan to cut. A machine with a cutting area that matches your needs will save you money while ensuring efficiency.

Quick Tip: A larger cutting area provides flexibility for future projects but may not be necessary if your current needs involve smaller parts.

Brand and Manufacturer

The brand and manufacturer of a laser metal cutting machine significantly influence its price and performance.

Smaller or lesser-known brands may offer lower prices, but they often compromise on quality or after-sales service. This can lead to higher maintenance costs and frequent repairs. Established manufacturers like Trumpf, Bystronic, and Amada are industry leaders known for their cutting-edge designs and robust machines. Their products cater to both small businesses and large-scale industrial operations.

Quick Tip: Always research the manufacturer's reputation. Look for customer reviews, service options, and the availability of replacement parts before making a purchase.

Additional Features

Additional features can enhance the functionality of a laser metal cutting machine but also increase its cost. Features like automatic loading systems, advanced cooling mechanisms, and real-time monitoring software improve efficiency and precision. Machines equipped with these features are ideal for high-volume production environments.

Some models include user-friendly interfaces, which simplify operation and reduce training time. Others offer customization options, such as adjustable cutting speeds or specialized nozzles for unique materials. While these features add convenience, they come at a higher price. Evaluate whether these extras align with your specific needs and budget.

Pro Tip: Focus on features that directly impact your workflow. Avoid paying for unnecessary add-ons that do not contribute to your production goals.

Cost Comparison for Different Use Cases

When choosing a laser metal cutting machine, your intended use plays a significant role in determining the right model and price range. Whether you need a machine for industrial-scale production, small business operations, or personal projects, understanding the cost implications for each use case ensures you make an informed decision.

Industrial Applications

For industrial applications, laser metal cutting machines must handle high-volume production and demanding materials. These machines often feature advanced technology, higher power output, and larger cutting areas to meet rigorous requirements.

- Cost Range: Industrial-grade machines typically start at $200,000 and can exceed $1,000,000. Brands like Mitsubishi and Trumpf dominate this category with their reliable and high-performance models.

- Key Features:

- High wattage (6,000W or more) for cutting thick metals like steel and titanium.

- Large work tables to accommodate oversized materials.

- Automation features, such as robotic arms and automatic loading systems, to boost efficiency.

- Best For: Aerospace, automotive, and heavy machinery industries where precision and speed are critical.

Tip: Investing in a reputable brand ensures durability and access to reliable customer support. While the upfront cost is high, the long-term performance justifies the expense.

Small Business Applications

Small businesses often require versatile and cost-effective machines that balance performance with affordability. These machines cater to moderate production needs and a variety of materials.

- Cost Range: Machines for small businesses usually fall between $30,000 and $200,000. Fiber lasers are a popular choice due to their efficiency and ability to cut metals like aluminum and stainless steel.

- Key Features:

- Mid-range power output (1,000W to 3,000W) for cutting thin to medium-thickness materials.

- Compact designs to save space in smaller workshops.

- User-friendly interfaces to reduce training time.

- Best For: Metal fabrication shops, signage businesses, and custom part manufacturers.

Pro Tip: Look for machines with energy-efficient designs to lower operational costs. Brands like Bystronic and Amada offer excellent options for small businesses.

Hobbyist and DIY Applications

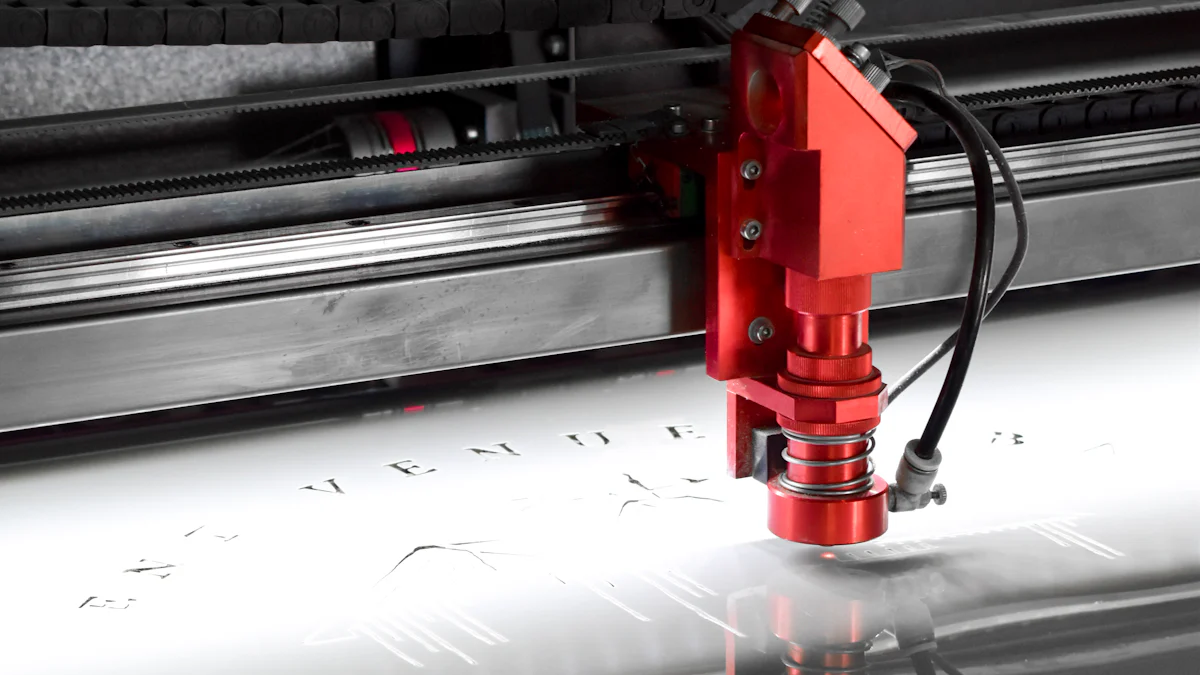

Hobbyists and DIY enthusiasts need affordable and easy-to-use machines for personal projects. These machines are ideal for cutting thin metals and non-metal materials like wood and acrylic.

- Cost Range: Entry-level models start at $5,000 and can go up to $30,000. CO2 lasers are a common choice for this category due to their versatility and lower price point.

- Key Features:

- Low to mid-range power output (up to 1,000W) suitable for light-duty tasks.

- Smaller cutting areas to fit home workshops.

- Basic software for simple design and cutting operations.

- Best For: Crafting, prototyping, and small-scale decorative projects.

Quick Tip: Consider used or refurbished machines to save money. Ensure the machine comes from a trusted manufacturer to avoid quality issues.

By aligning your machine choice with your specific use case, you can maximize value and efficiency. Whether you need a robust industrial system or a budget-friendly option for personal use, understanding these categories helps you make the right investment.

Hidden Costs to Consider

When purchasing a laser metal cutting machine, the upfront cost is only part of the equation. You also need to account for hidden expenses that can impact your budget over time. These costs often catch buyers off guard, but understanding them ensures you make a well-informed decision.

Maintenance and Repairs

Maintenance and repair costs are inevitable with any laser cutting machine. Over time, components like lenses, mirrors, and laser sources wear out and require replacement. Regular maintenance keeps your machine running efficiently and prevents costly breakdowns. However, these services come at a price.

- Routine Maintenance: Tasks like cleaning optics, aligning the laser beam, and replacing filters are essential. These can cost hundreds to thousands of dollars annually, depending on the machine's complexity.

- Repairs: Unexpected repairs, such as fixing a damaged laser source or motor, can be expensive. For industrial-grade machines, repair costs may reach tens of thousands of dollars.

- Service Contracts: Many manufacturers offer service contracts for ongoing maintenance. While these contracts provide convenience, they add to your overall expenses.

Tip: Budget for regular maintenance and keep spare parts on hand to minimize downtime. Machines from reputable brands often have lower repair costs due to their durability.

Software and Licensing

Laser cutting machines rely on specialized software for design and operation. While some machines include basic software, advanced features often require additional purchases or subscriptions. These costs can add up quickly.

- Initial Software Purchase: High-end machines may require proprietary software, which can cost several thousand dollars.

- Licensing Fees: Some software comes with annual licensing fees. These fees ensure you receive updates and technical support but increase your long-term expenses.

- Training Costs: Learning to use the software effectively may require training sessions. Manufacturers or third-party providers often charge for these services.

Quick Tip: Look for machines with user-friendly software that meets your needs without requiring costly upgrades. Open-source options can also reduce software expenses.

Safety Equipment

Operating a laser metal cutting machine involves safety risks, especially with high-power models. To protect yourself and your team, you need proper safety equipment. These items are essential but often overlooked during the initial purchase.

- Protective Gear: Items like laser safety glasses, gloves, and face shields are necessary to prevent injuries. High-quality gear can cost hundreds of dollars.

- Ventilation Systems: Cutting metals produces fumes and particles that require proper ventilation. Installing an exhaust system or air purifier adds to your setup costs.

- Fire Prevention: Laser cutting generates heat, increasing the risk of fire. Fire extinguishers, fire blankets, and heat-resistant mats are crucial safety investments.

Pro Tip: Never compromise on safety. Investing in high-quality safety equipment protects both your health and your machine.

By considering these hidden costs, you can better prepare for the total investment required for a laser metal cutting machine. Factoring in maintenance, software, and safety expenses ensures you avoid surprises and maximize the value of your purchase.

Energy Consumption

Energy consumption plays a crucial role in the overall cost of operating a laser metal cutting machine. The amount of energy your machine uses depends on its power output, efficiency, and the type of laser technology it employs. Understanding these factors helps you estimate long-term operational expenses.

High-power machines, such as those used for industrial applications, consume significantly more energy than smaller models. For instance, a 6,000W industrial-grade laser cutter requires a substantial power supply to maintain its performance. This increased energy demand results in higher electricity bills, which can impact your budget over time. On the other hand, machines designed for small businesses or hobbyists typically have lower power outputs, making them more energy-efficient and cost-effective for light-duty tasks.

Quick Fact: Fiber lasers are generally more energy-efficient than CO2 or crystal lasers. They convert a higher percentage of electrical energy into laser energy, reducing waste and lowering operational costs.

The size of the machine also affects energy consumption. Larger machines with expansive cutting areas require more power to operate their motors and cooling systems. Smaller machines, often used by hobbyists or small businesses, consume less energy due to their compact design and lower power requirements. If your projects involve smaller-scale cutting jobs, opting for a machine with a smaller cutting area can save you money on energy costs.

To minimize energy expenses, consider the following tips:

- Choose an energy-efficient model: Machines with advanced designs, like fiber lasers, offer better energy efficiency without compromising performance.

- Optimize usage: Operate the machine only when necessary and avoid running it at maximum power unless required.

- Maintain the machine regularly: Proper maintenance ensures the machine operates efficiently, reducing unnecessary energy consumption.

By evaluating the energy consumption of different laser cutting machines, you can make an informed decision that aligns with your budget and production needs. Balancing power requirements with energy efficiency ensures you achieve optimal performance while keeping operational costs under control.

Tips for Choosing the Right Machine Within Your Budget

Assess Your Needs

Start by identifying your specific requirements. Consider the materials you plan to cut and the thickness of those materials. For example, if you work with reflective metals like aluminum or brass, a fiber laser cutter may be the best option. On the other hand, if your projects involve non-metal materials such as wood or acrylic, a CO2 laser cutter might suit your needs better.

Think about the scale of your operations. Are you running a large industrial facility, a small business, or working on personal projects? Industrial applications often demand high-power machines with large cutting areas, while hobbyists can opt for compact, entry-level models. Understanding your workload and production goals will help you narrow down your options.

Pro Tip: Write down your most common cutting tasks and match them to the machine's capabilities. This ensures you choose a machine that aligns with your daily operations.

Set a Realistic Budget

Establishing a clear budget is crucial when purchasing a laser metal cutting machine. The price range varies widely, from $5,000 for basic models to over $1,000,000 for advanced industrial systems. Factor in not just the upfront cost but also the long-term expenses, such as maintenance, energy consumption, and software licensing.

Remember to account for hidden costs. Installation and setup fees can add up, especially for heavy-duty machines that require professional handling. Proper calibration during installation ensures optimal performance, which can save you money in the long run. Additionally, consider after-sales support. Machines with extended warranties and accessible technical support may have a higher initial cost but reduce the risk of expensive repairs later.

Quick Tip: Avoid stretching your budget too thin. A slightly higher upfront investment in a reliable machine can save you significant costs over time.

Research and Compare Options

Take the time to research different brands and models. Reputable manufacturers like Trumpf, Bystronic, and Amada are known for their durable and high-performing machines. Compare their features, power output, and cutting capabilities to find the best fit for your needs.

Look for user reviews and testimonials. These provide valuable insights into the machine's performance and reliability. Pay attention to feedback about maintenance requirements and energy efficiency. Machines with lower energy consumption can significantly reduce operational costs over time.

Create a comparison chart to evaluate your options side by side. Include factors like price, power, cutting area, and additional features. This visual representation helps you make an informed decision.

Pro Tip: Visit trade shows or request demonstrations from manufacturers. Seeing the machine in action gives you a better understanding of its capabilities and ease of use.

By assessing your needs, setting a realistic budget, and thoroughly researching your options, you can confidently choose a laser metal cutting machine that fits both your requirements and financial plan.

Consider Used or Refurbished Machines

Purchasing a used or refurbished laser metal cutting machine can be a smart way to save money without sacrificing functionality. These machines often provide excellent value, especially for small businesses or hobbyists with limited budgets. However, you need to carefully evaluate their condition and performance to ensure they meet your requirements.

Benefits of Buying Used or Refurbished Machines

- Lower Initial Cost: Used machines typically cost significantly less than new ones. This allows you to access advanced features or higher power levels at a fraction of the price.

- Faster Availability: Unlike new machines, which may have long lead times, used models are often readily available. This can help you start your projects sooner.

- Proven Performance: Refurbished machines undergo thorough inspections and repairs, ensuring they perform reliably. Many sellers also offer warranties, adding an extra layer of security.

Quick Tip: Look for machines refurbished by the original manufacturer or a trusted third-party service. These machines are more likely to meet quality standards.

Key Considerations When Buying Used

While used machines offer cost savings, they come with potential risks. You must assess these factors to make an informed decision:

- Machine History: Request detailed records of the machine’s usage, maintenance, and repairs. Machines with a history of heavy industrial use may have more wear and tear.

- Condition of Components: Inspect critical parts like the laser source, lenses, and motors. Replacing worn-out components can be expensive and negate the cost savings.

- Software Compatibility: Ensure the machine’s software is up-to-date and compatible with your design tools. Outdated software may limit functionality or require costly upgrades.

- Energy Efficiency: Older machines may consume more energy, leading to higher operational costs. Compare the energy consumption of the used model with newer alternatives.

Pro Tip: Bring a technician or expert to evaluate the machine before purchasing. Their insights can help you avoid hidden issues.

Where to Find Reliable Used Machines

Finding a trustworthy seller is crucial when buying a used or refurbished laser cutter. Here are some reliable sources:

- Manufacturer’s Refurbished Programs: Many manufacturers offer certified refurbished machines with warranties and support.

- Authorized Dealers: Dealers often inspect and repair used machines before reselling them, ensuring better quality.

- Online Marketplaces: Platforms like eBay or specialized industrial equipment websites list used machines. However, exercise caution and verify the seller’s reputation.

Quick Fact: Machines from reputable brands like Trumpf or Bystronic retain their value better and are easier to maintain, even when purchased used.

Balancing Cost and Risk

Used machines can reduce your upfront investment, but they may come with higher maintenance or repair costs. For example, replacing a laser tube or recalibrating the machine can add unexpected expenses. To minimize risks, prioritize machines with a clear maintenance history and accessible spare parts.

By considering used or refurbished options, you can stretch your budget while still acquiring a reliable laser metal cutting machine. With careful research and evaluation, this approach can provide excellent value for your specific needs.

Laser metal cutting machines offer a wide price range, from $5,000 for basic models to over $1,000,000 for industrial-grade systems. The cost depends on factors like machine type, power output, and brand. Hidden expenses, such as maintenance, software, and energy consumption, also play a significant role in the total investment. Energy-efficient models, like fiber lasers, can help reduce long-term operating costs. By evaluating your needs, setting a realistic budget, and researching options, you can confidently determine how much is a laser metal cutting machine that aligns with your goals and resources.

FAQ

What factors determine the cost of a laser metal cutting machine?

Several factors influence the price of a laser metal cutting machine. These include the type of laser (CO2, fiber, or crystal), power output, cutting area size, and additional features like automation or cooling systems. The brand and manufacturer also play a significant role in pricing. Machines from reputable brands often cost more but provide better reliability and support.

Tip: Align the machine's features with your specific needs to avoid overpaying for unnecessary capabilities.

How do I choose the right machine for my needs?

To select the right machine, assess your workload, materials, and production goals. Consider the thickness and type of materials you plan to cut. Evaluate the machine's power output and cutting area to ensure compatibility with your projects. For industrial use, prioritize high-power machines with large cutting areas. For smaller tasks, compact models may suffice.

Pro Tip: Write down your most common cutting tasks and match them to the machine's specifications for better decision-making.

Is it better to buy a new or used laser cutting machine?

Both options have advantages. New machines come with warranties, the latest technology, and reliable performance. Used or refurbished machines cost less and can still meet your needs if inspected thoroughly. However, older machines may have higher maintenance costs or outdated software.

Quick Tip: If buying used, check the machine's maintenance history and ensure spare parts are available.

What is the importance of the machine's cutting area?

The cutting area determines the size of materials you can process. A larger cutting area accommodates bigger projects and provides flexibility for future needs. Smaller cutting areas are more affordable and suitable for compact spaces or light-duty tasks.

Did You Know? Choosing a cutting area that matches your project dimensions can save money and improve efficiency.

How does power output affect the machine's performance?

Power output impacts the machine's ability to cut through different materials and thicknesses. Higher wattage allows for faster cutting and better precision on thicker metals. However, machines with excessive power may lead to unnecessary costs if your projects don't require it.

Tip: Match the machine's power to the materials you plan to cut for optimal performance and cost-effectiveness.

What hidden costs should I consider when buying a laser cutter?

Hidden costs include maintenance, software licensing, safety equipment, and energy consumption. Regular maintenance ensures the machine operates efficiently but adds to long-term expenses. Advanced software or annual subscriptions may also increase costs. Safety gear and ventilation systems are essential for safe operation.

Pro Tip: Budget for these expenses to avoid surprises and ensure smooth operation.

How does automation impact the cost of a laser cutting machine?

Automation features, such as automatic loading systems or real-time monitoring, enhance productivity but increase the machine's price. Assess your production needs to determine if these features justify the additional cost. For high-volume operations, automation can save time and labor expenses.

Quick Fact: Automation is ideal for industrial applications but may not be necessary for small-scale projects.

Can I use one machine for multiple materials?

Some machines, like CO2 lasers, handle a variety of materials, including wood, plastic, and thin metals. Fiber lasers excel at cutting reflective metals like aluminum and brass but are less effective on non-metal materials. Choose a machine based on the materials you work with most frequently.

Tip: Versatile machines may cost more upfront but save money by eliminating the need for multiple devices.

How do I ensure my machine remains energy-efficient?

Energy efficiency depends on the machine's design and power usage. Fiber lasers are generally more energy-efficient than CO2 or crystal lasers. Regular maintenance, such as cleaning optics and aligning the laser beam, also helps reduce energy waste.

Did You Know? Operating the machine at optimal settings minimizes energy consumption and extends its lifespan.

What safety measures should I take when using a laser cutter?

Safety is crucial when operating a laser cutter. Use protective gear like laser safety glasses and gloves. Install proper ventilation to manage fumes and particles. Keep fire extinguishers nearby to address potential fire hazards.

Pro Tip: Never compromise on safety equipment. High-quality gear protects both you and your investment.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Understanding the Costs of Water Jet Cutting Machines

Exploring Prices and Types of Cutting Machines