How Much Is a Laser Cutting Machine?

If you're wondering how much is laser cutting machine, the prices vary widely, starting at just $300 for basic models and reaching over $1,000,000 for advanced industrial systems. The cost largely depends on factors such as the type of laser, power output, and the size of the machine. For example, machines with higher wattage, capable of cutting thicker materials, typically come with a higher price tag. Additional features like automation or customization options can also drive up the cost. Knowing your budget and specific requirements will help you determine how much is laser cutting machine that suits your needs.

Key Takeaways

- Laser cutting machines range in price from $300 for basic models to over $1,000,000 for advanced industrial systems, depending on features and capabilities.

- Key factors influencing the cost include the type of laser technology, power output, machine size, and additional features like automation and cooling systems.

- For hobbyists, entry-level machines are budget-friendly and suitable for light tasks, while small businesses may benefit from mid-range machines that offer more versatility.

- Investing in a reputable brand can provide better reliability and customer support, which may save money on repairs and maintenance in the long run.

- Consider your specific cutting needs and budget before purchasing; a lower-wattage machine can save costs if you don't require heavy-duty capabilities.

- Evaluate whether to buy new or used based on your budget and needs; new machines offer the latest technology and warranties, while used machines can be more affordable but may come with risks.

- Outsourcing laser cutting can be a cost-effective option for occasional needs, but owning a machine provides greater control, faster turnaround, and potential long-term savings.

Factors That Influence the Cost of a Laser Cutting Machine

When you're shopping for a laser cutting machine, understanding what drives the price can help you make a smarter choice. Let’s break down the key factors that influence the cost.

Type of Laser Technology

The type of laser technology plays a big role in determining the price. Different lasers serve different purposes, and their complexity impacts their cost:

- Fiber lasers are among the most expensive. They use advanced technology to deliver high precision and speed, making them ideal for cutting metals. Their complex design and efficiency justify their higher price.

- CO2 lasers are more affordable than fiber lasers. They work well for cutting non-metal materials like wood, acrylic, and leather. These machines strike a balance between performance and cost.

- Diode lasers are the cheapest option. They are compact and have fewer components, which makes them perfect for hobbyists or light-duty tasks.

Choosing the right laser type depends on your cutting needs. If you’re working with metals, a fiber laser might be worth the investment. For non-metals or smaller projects, CO2 or diode lasers could save you money.

Power and Wattage

The power of a laser cutting machine directly affects its price. Machines with higher wattage can cut through thicker materials and handle tougher jobs. However, this added capability comes at a cost.

For example:

- A low-power laser (20-50 watts) is suitable for engraving or cutting thin materials. These machines are more affordable but limited in application.

- A mid-range laser (100-300 watts) offers more versatility. It can cut thicker materials and is ideal for small businesses.

- A high-power laser (over 500 watts) is designed for industrial use. These machines can cut through metals like steel or aluminum with ease, but they come with a hefty price tag.

If you don’t need to cut thick materials, opting for a lower-wattage machine can save you money without sacrificing performance.

Machine Size and Cutting Area

The size of the machine and its cutting area also impact the cost. Larger machines with bigger cutting areas are more expensive because they require more materials and advanced engineering.

- Compact machines are budget-friendly and great for small projects or limited workspace. They’re popular among hobbyists.

- Mid-sized machines offer a balance between size and cost. They’re suitable for small businesses that need to handle moderate workloads.

- Large industrial machines come with a premium price. They’re built for high-volume production and can handle oversized materials.

Before deciding, think about the size of the materials you’ll work with and the space available in your workshop. A smaller machine might be all you need, but if you plan to scale up, investing in a larger model could pay off in the long run.

Additional Features and Accessories

When choosing a laser cutting machine, additional features and accessories can significantly impact the price. These extras often enhance functionality, improve efficiency, or expand the machine's capabilities. However, they also add to the overall cost, so it's essential to evaluate whether they align with your needs.

Here are some common features and accessories to consider:

- Automation Options: Machines with automated loading and unloading systems save time and reduce manual labor. These features are particularly useful for high-volume production but come at a premium.

- Rotary Attachments: If you plan to engrave or cut cylindrical objects like bottles or pipes, a rotary attachment is a must-have. This accessory adds versatility but increases the initial investment.

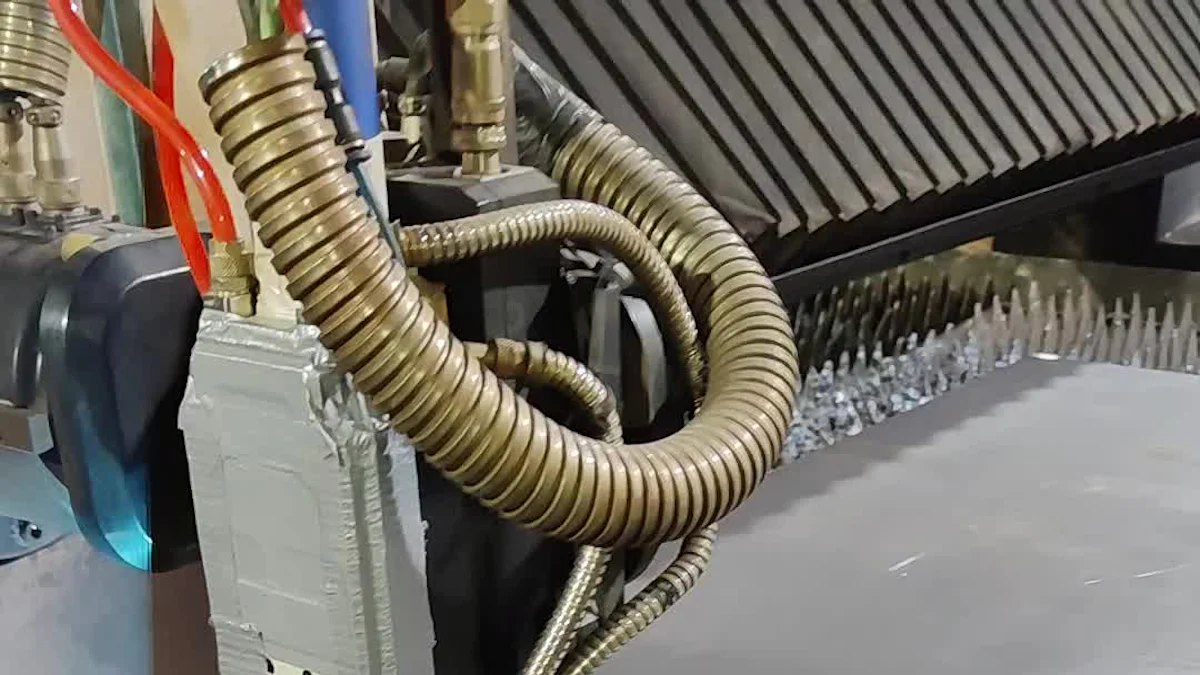

- Cooling Systems: High-powered lasers generate heat, and cooling systems help maintain optimal performance. While necessary for industrial-grade machines, they add to the cost.

- Software Upgrades: Advanced software for design and control can streamline operations. Some machines include basic software, but premium versions with additional tools may require extra payment.

- Safety Features: Features like enclosed designs, emergency stop buttons, and ventilation systems ensure safe operation. These are crucial for industrial environments and often raise the price.

Before committing to these extras, think about your specific projects. For instance, if you're working on simple flat materials, you might not need a rotary attachment. On the other hand, automation could be a game-changer for businesses aiming to scale up production.

Brand and Manufacturer

The brand and manufacturer of a laser cutting machine play a significant role in its cost. Established brands often charge more, but they provide reliability, better customer support, and access to replacement parts. Lesser-known brands may offer lower prices, but they might lack the same level of quality or service.

Here’s what to keep in mind when evaluating brands:

- Reputation: Well-known manufacturers like Epilog, Trotec, and Boss Laser have built their reputations on quality and performance. Their machines tend to last longer and deliver consistent results.

- Warranty and Support: A good warranty and responsive customer service can save you money in the long run. Brands with strong after-sales support ensure you get help when needed.

- Availability of Parts: Machines from reputable manufacturers often have readily available replacement parts. This reduces downtime and maintenance costs.

- Price vs. Value: While premium brands cost more upfront, they often provide better value over time. Cheaper brands might seem appealing, but frequent repairs or limited capabilities could end up costing you more.

When deciding on a brand, balance your budget with your expectations. If you're a hobbyist, a less expensive brand might suffice. For businesses, investing in a trusted manufacturer ensures reliability and long-term savings.

Types of Laser Cutting Machines and Their Price Ranges

When you're exploring laser cutting machines, understanding the different types and their price ranges can help you make an informed decision.

Entry-Level Machines for Hobbyists

Entry-level laser cutting machines are perfect if you're a hobbyist or just starting out. These machines are compact, easy to use, and affordable. They’re designed for light-duty tasks like engraving or cutting thin materials such as paper, wood, or acrylic.

- Price Range: $300 to $1,500

- Best For: DIY projects, crafting, and small-scale personalization

- Features:

- Low power (usually under 50 watts)

- Small cutting areas

- Basic software for simple designs

These machines often use diode or low-powered CO2 lasers, which keep costs down. While they lack advanced features, they’re a great way to experiment with laser cutting without a significant investment. If you’re wondering how much is laser cutting machine for beginners, this category offers the most budget-friendly options.

Mid-Range Machines for Small Businesses

If you run a small business, mid-range laser cutting machines provide a balance between affordability and functionality.

- Price Range: $1,500 to $10,000

- Best For: Small businesses, custom product makers, and moderate workloads

- Features:

- Medium power (50 to 300 watts)

- Larger cutting areas for bigger projects

- Enhanced software with more design options

Mid-range machines often use CO2 lasers, which are ideal for cutting non-metal materials like wood, leather, and acrylic. Some models even include additional features like rotary attachments for engraving cylindrical objects. These machines are a solid investment if you need reliable performance without breaking the bank.

Industrial-Grade Machines

Industrial-grade laser cutting machines are built for heavy-duty applications. These machines deliver high precision, speed, and power, making them suitable for large-scale production and cutting thick materials like metals.

- Price Range: $20,000 to over $250,000

- Best For: Manufacturing, metal fabrication, and high-volume production

- Features:

- High power (over 500 watts)

- Large cutting areas for oversized materials

- Advanced automation and cooling systems

- Fiber laser technology for cutting metals with precision

These machines often come with productivity-enhancing features like automated material handling and advanced software. While the upfront cost is significant, the efficiency and capabilities of industrial-grade machines can lead to long-term savings. If your business requires cutting-edge performance, this category is worth considering.

Expert Insight: "Advanced automation and additional features integrated into laser cutting machines can contribute to their overall cost. Evaluate the necessity of these features based on your production requirements and budget constraints to make an informed decision."

Understanding these categories helps you align your budget with your needs. Whether you're a hobbyist, a small business owner, or part of a large manufacturing operation, there's a laser cutting machine that fits your requirements.

Specialized Machines for Specific Applications

Specialized laser cutting machines cater to unique industries and tasks. These machines are designed with specific applications in mind, offering features and capabilities that standard models may not provide. If your work involves niche requirements, investing in a specialized machine could be the right move.

Examples of Specialized Machines

- Metal Fabrication Machines These machines excel at cutting metals like steel, aluminum, and brass. They often use fiber laser technology, which delivers precision and speed. Metal fabrication machines are ideal for industries like automotive, aerospace, and construction.

- Price Range: $40,000 to $108,000

- Key Features: High power output, advanced cooling systems, and automation options for handling heavy materials.

- Laser Engraving Machines Designed for detailed engraving, these machines are perfect for creating intricate designs on wood, glass, leather, or even metal. They are widely used in jewelry making, personalized gifts, and artistic projects.

- Price Range: $1,000 to $15,000

- Key Features: High precision, smaller cutting areas, and software tailored for engraving tasks.

- Textile Cutting Machines These machines specialize in cutting fabrics and textiles with precision. They are commonly used in the fashion and upholstery industries. Textile cutting machines often include features like conveyor belts for continuous cutting.

- Price Range: $10,000 to $50,000

- Key Features: Large cutting areas, fabric-specific settings, and high-speed operation.

- Medical Device Cutting Machines In the medical field, laser cutting machines are used to create intricate components for devices like stents or surgical tools. These machines require extreme precision and cleanliness.

- Price Range: $50,000 to $200,000

- Key Features: Micron-level accuracy, cleanroom compatibility, and specialized software.

Why Choose a Specialized Machine?

Specialized machines offer tailored solutions for specific needs. For example, if you work in metal fabrication, a general-purpose CO2 laser might not deliver the precision or power you need. A fiber laser designed for metal cutting ensures better results and efficiency.

Expert Insight: "Advanced automation and additional features integrated into laser cutting machines can contribute to their overall cost. Evaluate the necessity of these features based on your production requirements and budget constraints to make an informed decision."

Considerations Before Buying

Before investing in a specialized machine, ask yourself these questions:

- What materials will you primarily work with?

- Do you need high precision or speed for your projects?

- Is your budget aligned with the cost of a specialized machine?

By answering these, you can determine if a specialized machine is worth the investment. While these machines often come with a higher price tag, their efficiency and tailored features can save you time and money in the long run.

New vs. Used Laser Cutting Machines: Which Is Better?

When deciding between a new or used laser cutting machine, you need to weigh the pros and cons carefully. Each option has its own set of advantages and potential drawbacks. Let’s explore what you should consider.

Advantages of Buying New

Purchasing a new laser cutting machine offers several benefits that can make it a worthwhile investment.

- Latest Technology: New machines come equipped with the most advanced features and cutting-edge technology. This ensures better performance, higher precision, and improved efficiency.

- Warranty and Support: Manufacturers typically provide warranties and robust customer support for new machines. If something goes wrong, you’ll have peace of mind knowing help is readily available.

- Longer Lifespan: A new machine hasn’t been subjected to wear and tear. This means it will likely last longer and require fewer repairs in the early years.

- Customization Options: Many manufacturers allow you to customize new machines to suit your specific needs. Whether it’s adding automation features or upgrading software, you can tailor the machine to your requirements.

If you’re looking for reliability and the latest features, a new machine might be the better choice. However, it’s essential to consider your budget since new machines often come with a higher price tag.

Advantages of Buying Used

Opting for a used laser cutting machine can be a smart move, especially if you’re working with a limited budget. Here’s why:

- Lower Initial Cost: Used machines are significantly cheaper than new ones. For example, while a new industrial-grade machine can cost over $250,000, a used one might be available for a fraction of that price.

- Faster ROI: The lower upfront cost means you can recover your investment more quickly, especially if the machine meets your production needs.

- Immediate Availability: Used machines are often ready for immediate purchase and delivery. You won’t have to wait for manufacturing or customization, which can save time.

- Proven Performance: A well-maintained used machine has already demonstrated its capabilities. You can assess its performance based on its history and reviews from previous owners.

Buying used can be a cost-effective way to get started, particularly for small businesses or hobbyists. However, it’s crucial to evaluate the machine’s condition and history before making a purchase.

Risks of Buying Used

While used machines can save you money, they also come with certain risks that you should be aware of.

- Limited Warranty: Most used machines don’t come with a warranty. If the machine breaks down, you’ll have to cover the repair costs yourself.

- Hidden Issues: A used machine may have underlying problems that aren’t immediately apparent. These issues could lead to unexpected downtime and additional expenses.

- Outdated Technology: Older machines might lack the advanced features and efficiency of newer models. This could limit your capabilities and affect the quality of your work.

- Higher Maintenance Costs: Used machines often require more frequent maintenance and repairs. Over time, these costs can add up and offset the initial savings.

Before buying a used machine, inspect it thoroughly or hire an expert to evaluate its condition. Ask for maintenance records and test the machine to ensure it meets your needs.

Pro Tip: If you’re considering a used machine, look for reputable sellers who offer refurbished models. Refurbished machines are often inspected, repaired, and tested to ensure they’re in good working condition.

Choosing between new and used depends on your budget, production goals, and risk tolerance. If you’re wondering how much is laser cutting machine that fits your needs, both options have their merits. Carefully assess your priorities to make the best decision.

Outsourcing vs. Owning a Laser Cutting Machine

When it comes to laser cutting, you face a critical decision: should you outsource the work or invest in your own machine? Both options have their advantages, and the right choice depends on your needs, budget, and long-term goals. Let’s explore the benefits of each approach and when one might be better than the other.

Benefits of Outsourcing

Outsourcing laser cutting services can be a practical solution, especially if your needs are occasional or project-specific. Here’s why outsourcing might work for you:

- Lower Initial Investment: You don’t need to spend thousands—or even hundreds of thousands—on purchasing a machine. This makes outsourcing ideal for businesses or individuals with limited budgets.

- Access to Advanced Technology: Professional laser cutting services often use high-end machines with advanced features. You can benefit from top-notch precision and quality without owning the equipment.

- No Maintenance Hassles: Laser cutting machines require regular upkeep, which can be costly and time-consuming. By outsourcing, you avoid maintenance responsibilities entirely.

- Flexibility: If your projects vary in size or material, outsourcing allows you to work with different providers who specialize in specific tasks. This flexibility ensures you get the best results for each project.

- Scalability: For businesses, outsourcing lets you handle large orders without worrying about production capacity. You can scale up or down based on demand without investing in additional equipment.

Pro Tip: Outsourcing works well for startups, hobbyists, or businesses testing the waters before committing to a laser cutting machine.

Benefits of Owning

Owning a laser cutting machine offers control and convenience that outsourcing simply can’t match. Here’s why investing in your own machine might be the better choice:

- Long-Term Cost Savings: While the upfront cost is significant, owning a machine can save money over time. You eliminate recurring outsourcing fees, which adds up if you have frequent projects.

- Faster Turnaround: With your own machine, you can complete projects on your schedule. There’s no waiting for third-party providers, which speeds up production.

- Customization and Experimentation: Owning a machine gives you the freedom to experiment with designs, materials, and techniques. This is especially valuable for creative professionals or businesses offering custom products.

- Increased Profit Margins: For businesses, cutting out the middleman means higher profits. You control the entire process, from design to production.

- Skill Development: Operating your own machine helps you or your team develop valuable skills. Over time, this expertise can lead to better results and innovative applications.

Did You Know? Laser cutting machines, like CO2 lasers or fiber lasers, offer versatility for cutting various materials, from wood to metals. Owning one can open up endless possibilities for your projects.

When to Choose Outsourcing

Outsourcing makes sense in specific scenarios. Consider this option if:

- You Have Limited Usage: If you only need laser cutting occasionally, outsourcing is more cost-effective than owning a machine that sits idle most of the time.

- Your Budget Is Tight: The initial cost of a laser cutting machine can be prohibitive. Outsourcing allows you to access professional services without a hefty investment.

- You Need Specialized Work: Some projects require advanced machines or expertise that you may not have. Outsourcing ensures high-quality results for complex tasks.

- You’re Testing the Market: If you’re unsure about the demand for your products, outsourcing lets you gauge interest before committing to a machine.

Quick Tip: Start with outsourcing to understand your needs. If demand grows or projects become frequent, consider transitioning to owning a machine.

Both outsourcing and owning have their merits. Your choice depends on your workload, budget, and long-term goals. By weighing these factors, you can decide which path aligns best with your needs.

When to Choose Owning

Owning a laser cutting machine can be a game-changer if you’re looking for control and efficiency in your projects. It’s not just about having the equipment at your fingertips; it’s about unlocking opportunities that outsourcing simply can’t provide. Here’s when owning a laser cutting machine makes the most sense.

1. You Have Frequent or High-Volume Projects

If you find yourself regularly needing laser cutting services, owning a machine can save you time and money. Instead of paying per project or waiting for third-party providers, you can handle everything in-house. This is especially beneficial for businesses with high production demands or individuals working on multiple projects. The ability to cut, engrave, or etch on-demand ensures faster turnaround times and greater flexibility.

Quick Tip: Calculate how much you currently spend on outsourcing. If the costs are adding up, investing in your own machine might be more economical in the long run.

2. You Want Full Creative Control

Owning a laser cutting machine gives you the freedom to experiment and innovate. Whether you’re designing intricate patterns, testing new materials, or creating custom products, having your own machine allows you to push boundaries without restrictions. This is particularly valuable for artists, designers, and small businesses offering personalized items.

For example, with a CO2 laser, you can work on materials like wood, acrylic, and leather, while a fiber laser lets you cut metals with precision. The versatility of these machines opens up endless possibilities for creativity.

3. You’re Focused on Long-Term Savings

While the upfront cost of a laser cutting machine can seem steep, it often pays off over time. By eliminating outsourcing fees, you can reduce production costs and increase profit margins. This is especially true for businesses that rely heavily on laser cutting for their operations. Plus, owning a machine means you’re not limited by the pricing or availability of external services.

Did You Know? A mid-range laser cutting machine, priced between $1,500 and $10,000, can handle a variety of tasks and materials, making it a cost-effective choice for small businesses.

4. You Need Precision and Consistency

Laser cutting machines are known for their accuracy and clean cuts. If your projects demand high precision, owning a machine ensures consistent results every time. This is crucial for industries like manufacturing, where even minor errors can lead to wasted materials or defective products. With your own machine, you can maintain quality control and meet exact specifications.

5. You’re Ready to Scale Your Business

For businesses looking to grow, owning a laser cutting machine can be a strategic move. It allows you to take on larger orders, expand your product offerings, and improve production efficiency. Features like automation and advanced software can further streamline your workflow, helping you meet increased demand without compromising on quality.

Pro Insight: Investing in a machine with additional features, such as rotary attachments or cooling systems, can enhance your capabilities and support business growth.

Final Thoughts

Owning a laser cutting machine isn’t just an expense—it’s an investment in your potential. If you have frequent projects, value creative freedom, or aim to scale your operations, owning a machine can provide the tools you need to succeed. Take the time to assess your needs, budget, and goals to determine if this is the right step for you.

Tips for Choosing the Right Laser Cutting Machine

Choosing the right laser cutting machine can feel overwhelming, especially with so many options available. To make the process easier, focus on a few key factors that align with your needs and goals. Here’s how you can narrow down your choices.

Assess Your Budget

Your budget is the foundation of your decision. Start by determining how much you’re willing to invest. Laser cutting machines range from affordable entry-level models to high-end industrial systems. Knowing your financial limits helps you avoid overspending while still getting a machine that meets your requirements.

- Entry-Level Machines: If you’re a hobbyist or just starting out, machines priced between $300 and $1,500 are a great choice. These are perfect for light-duty tasks like engraving or cutting thin materials.

- Mid-Range Machines: For small businesses, consider machines in the $1,500 to $10,000 range. These offer more power and versatility, making them suitable for moderate workloads.

- Industrial-Grade Machines: If you need heavy-duty performance, be prepared to spend $20,000 or more. These machines handle large-scale production and thicker materials with ease.

Pro Tip: Don’t just focus on the upfront cost. Factor in long-term expenses like maintenance, replacement parts, and energy consumption. A slightly higher initial investment might save you money over time.

Identify Your Cutting Needs

Understanding your specific cutting needs is crucial. The type of materials you’ll work with and the complexity of your projects will influence your choice. Ask yourself these questions:

-

What Materials Will You Cut? If you’re working with non-metals like wood, acrylic, or leather, a CO2 laser is a cost-effective option. For metals, a fiber laser offers the precision and power you need.

-

How Thick Are the Materials? Thicker materials require higher wattage. For example, a low-power laser (20-50 watts) works for thin materials, while a high-power laser (over 500 watts) is ideal for metals and industrial applications.

-

What’s the Scale of Your Projects? Small-scale projects can be handled by compact machines with smaller cutting areas. For larger or high-volume tasks, invest in a machine with a bigger cutting area and advanced features.

Example: A small business making custom wooden signs might only need a mid-range CO2 laser. On the other hand, a metal fabrication shop would benefit from a high-powered fiber laser.

Research Brands and Models

Not all laser cutting machines are created equal. Researching brands and models ensures you get a reliable machine that fits your needs. Here’s what to look for:

- Reputation: Established brands like Epilog, Trotec, and Boss Laser are known for quality and durability. Their machines often come with better warranties and customer support.

- Customer Reviews: Read reviews from other users to learn about real-world performance. Look for feedback on reliability, ease of use, and maintenance.

- Service Centers: Choose a brand with service centers near your location. Quick access to repairs and technical support minimizes downtime and keeps your business running smoothly.

- Features vs. Price: Compare models within your budget. Some machines might offer extra features like rotary attachments or advanced software. Decide if these add-ons are worth the additional cost.

Quick Insight: A used machine might seem like a bargain, but hidden issues like outdated technology or limited service life can lead to higher costs in the long run. Investing in a new machine often provides better value and peace of mind.

By assessing your budget, identifying your needs, and researching thoroughly, you can confidently choose a laser cutting machine that aligns with your goals. Whether you’re a hobbyist, a small business owner, or part of a large manufacturing operation, the right machine can elevate your projects and maximize your investment.

Consider Long-Term Costs

When choosing a laser cutting machine, it’s easy to focus on the upfront price. However, long-term costs can significantly impact your budget and overall satisfaction. Taking these into account ensures you make a smart investment.

Maintenance and Repairs

Every laser cutting machine requires regular maintenance to perform at its best. Over time, parts may wear out and need replacement. For instance, high-powered lasers often need cooling systems, which can add to maintenance expenses. If you opt for a used machine, these costs might increase due to its shorter service life or outdated components.

A used machine may save you money initially, but frequent repairs and downtime can quickly eat into those savings.

To avoid unexpected expenses, look for machines with readily available replacement parts and strong manufacturer support. Brands with local service centers can also minimize downtime, ensuring your business keeps running smoothly.

Energy Consumption

Laser cutting machines vary in energy efficiency. High-powered industrial models consume more electricity, which can lead to higher utility bills. While these machines offer superior performance, you should weigh the cost of operation against your production needs. For smaller projects, a mid-range or entry-level machine might be more cost-effective in the long run.

Depreciation and Resale Value

Consider how well the machine will hold its value over time. Machines from reputable brands often retain their resale value better than cheaper, lesser-known models. If you plan to upgrade in the future, investing in a high-quality machine now could make it easier to recoup some of your initial costs.

Software and Upgrades

Some machines require periodic software updates or additional purchases to unlock advanced features. While these upgrades can enhance functionality, they also add to the total cost of ownership. Before buying, check if the machine includes lifetime software access or if you’ll need to pay for updates later.

Pro Tip: Calculate the total cost of ownership, including maintenance, energy, and potential upgrades. This gives you a clearer picture of what you’ll spend over the machine’s lifespan.

By considering these factors, you can avoid surprises and choose a machine that fits your budget both now and in the future.

Seek Expert Advice

Navigating the world of laser cutting machines can feel overwhelming, especially with so many options available. Seeking expert advice can save you time, money, and frustration.

Consult Industry Professionals

Reach out to professionals who have experience with laser cutting machines. They can provide insights into the best brands, models, and features for your specific needs. For example, a small business owner might recommend a mid-range CO2 laser for cutting non-metals, while a metal fabricator could suggest a fiber laser for precision work.

Visit Trade Shows and Demonstrations

Attending trade shows or product demonstrations allows you to see machines in action. You can ask questions, compare models, and even test the equipment yourself. This hands-on experience helps you understand what to expect and ensures you’re making an informed decision.

Talk to Manufacturers and Dealers

Reputable manufacturers and dealers often have knowledgeable staff who can guide you through the buying process. They can explain the technical details, recommend suitable models, and even offer financing options. Look for companies with strong customer support and local service centers to ensure you’ll get help when needed.

New laser manufacturers with nearby service centers can reduce downtime and keep your business running smoothly.

Join Online Communities

Online forums and social media groups dedicated to laser cutting are excellent resources. Members often share reviews, tips, and troubleshooting advice. Engaging with these communities can help you learn from others’ experiences and avoid common pitfalls.

Quick Tip: Don’t hesitate to ask questions. Whether you’re a beginner or an experienced user, seeking advice ensures you make the best choice for your needs.

By consulting experts and doing your research, you can confidently invest in a laser cutting machine that aligns with your goals and budget.

The cost depends on factors like the type of laser, power, size, and additional features.

FAQ

How much does a laser cutting machine cost?

Laser cutting machines range from $300 to over $1,000,000. Entry-level models for hobbyists typically cost between $300 and $1,500. Mid-range machines for small businesses fall between $1,500 and $10,000. Industrial-grade machines, designed for heavy-duty tasks, can cost anywhere from $20,000 to $250,000 or more. Specialized machines for unique applications, like metal fabrication, may exceed $100,000.

Quick Tip: Consider your budget and the type of projects you’ll work on before deciding which price range suits you best.

What factors influence the price of a laser cutting machine?

Several factors affect the cost of a laser cutting machine:

- Type of Laser: Fiber lasers are more expensive than CO2 or diode lasers due to their advanced technology.

- Power and Wattage: Higher wattage machines, capable of cutting thicker materials, cost more.

- Size and Cutting Area: Larger machines with bigger cutting areas require more materials and engineering, increasing the price.

- Additional Features: Automation, rotary attachments, and cooling systems add to the cost.

- Brand Reputation: Established brands often charge more but provide better reliability and support.

As one business owner shared, “The wattage and design of the laser significantly impact the price. Higher wattage lasers are worth the investment for tougher jobs.”

Should I buy a new or used laser cutting machine?

This depends on your budget and needs. New machines offer the latest technology, warranties, and longer lifespans. They’re ideal if you want reliability and customization options. Used machines cost less upfront and provide faster ROI, but they may come with hidden issues or outdated features.

Pro Tip: If you’re considering a used machine, look for refurbished models from reputable sellers. These often undergo thorough inspections and repairs.

What materials can a laser cutting machine handle?

Laser cutting machines can cut a wide range of materials, depending on the type of laser:

- CO2 Lasers: Best for non-metals like wood, acrylic, leather, and glass.

- Fiber Lasers: Ideal for metals such as steel, aluminum, and brass.

- Diode Lasers: Suitable for light-duty tasks on thin materials like paper or fabric.

Did You Know? Some specialized machines are designed for unique materials, like textiles or medical-grade components.

How do I choose the right laser cutting machine for my needs?

To choose the right machine, consider these steps:

- Define Your Budget: Decide how much you’re willing to spend, including long-term costs like maintenance.

- Identify Your Materials: Determine what materials you’ll cut most often.

- Evaluate Power Needs: Choose a wattage that matches the thickness of your materials.

- Research Brands: Look for reputable manufacturers with good customer support.

- Think About Features: Decide if you need extras like automation or rotary attachments.

One expert noted, “Laser cutters can be configured to fit specific production styles. Understanding your workflow helps you pick the right machine.”

Can I use a laser cutting machine for business purposes?

Absolutely! Many small to medium-sized businesses use laser cutting machines to create custom products, signage, or prototypes. These machines offer precision, speed, and versatility, making them valuable tools for production and fabrication industries.

Example: A small business owner might use a mid-range CO2 laser to craft personalized wooden signs or leather goods.

What are the maintenance requirements for a laser cutting machine?

Regular maintenance ensures optimal performance. Key tasks include:

- Cleaning the lenses and mirrors to maintain cutting accuracy.

- Checking and replacing worn parts, like belts or filters.

- Ensuring proper alignment of the laser beam.

- Monitoring the cooling system for high-powered machines.

Pro Tip: Follow the manufacturer’s maintenance schedule to avoid costly repairs and downtime.

Is outsourcing laser cutting better than owning a machine?

Outsourcing works well if you have occasional or project-specific needs. It eliminates the upfront cost of buying a machine and avoids maintenance responsibilities. However, owning a machine offers long-term savings, faster turnaround times, and creative control.

Quick Insight: Start with outsourcing to test demand. If your workload grows, investing in a machine might make more sense.

What safety precautions should I take when using a laser cutting machine?

Safety is crucial when operating a laser cutter. Follow these precautions:

- Wear protective eyewear to shield your eyes from laser beams.

- Ensure proper ventilation to remove fumes and smoke.

- Keep a fire extinguisher nearby in case of emergencies.

- Use machines with safety features like enclosed designs and emergency stop buttons.

Reminder: Always read the user manual and follow the manufacturer’s safety guidelines.

Can I upgrade my laser cutting machine later?

Yes, many laser cutting machines allow upgrades. You can add features like rotary attachments, advanced software, or higher wattage lasers. Upgrading helps you expand your machine’s capabilities without buying a new one.

Pro Tip: Check with the manufacturer to see what upgrades are compatible with your model.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Understanding the Costs of Water Jet Cutting Machines

Exploring Prices and Types of Cutting Machines