How Much Is a Laser Cutting Machine Comparison Guide

When considering a laser cutting machine, one of the first questions you might ask is, "How much is a laser cutting machine?" Prices can vary widely, ranging from $3,000 for entry-level models to over $1 million for high-end industrial machines. This significant price range depends on factors like machine type, power output, and features. Understanding these costs and comparing models is essential. It helps you make a smart investment that aligns with your budget and cutting needs. By evaluating these factors, you can ensure the machine you choose delivers value and meets your expectations.

Key Takeaways

- Laser cutting machines vary significantly in price, ranging from $2,600 for entry-level models to over $1 million for high-end industrial machines.

- Understanding the type of materials you will cut is crucial; CO2 lasers are best for non-metals, while fiber lasers excel at cutting metals.

- Consider operational costs such as electricity, consumables, and maintenance when budgeting for a laser cutting machine to ensure a comprehensive understanding of total ownership costs.

- Evaluate your specific cutting needs, including material type, thickness, and production volume, to select the most suitable machine for your projects.

- Investing in a machine with advanced features may have a higher upfront cost but can lead to long-term savings through increased efficiency and reduced operational costs.

- Research and compare different models to find the best fit for your budget and requirements, and consider testing machines before purchase to ensure they meet your expectations.

- Don't overlook additional costs like software, training, and installation, as these can significantly impact your overall investment.

Understanding Laser Cutting Technology and Its Types

What Is Laser Cutting and How Does It Work?

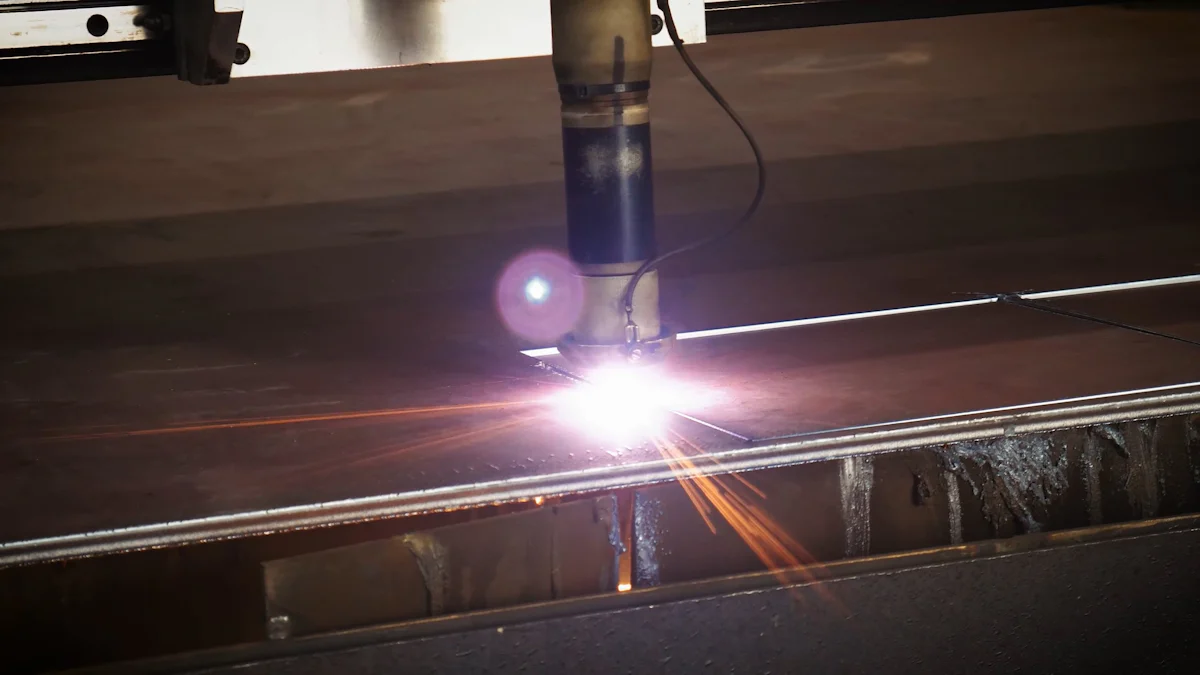

Laser cutting is a precise and efficient method for cutting materials using a focused laser beam. The process involves directing a high-powered laser onto the material, which melts, burns, or vaporizes it to create clean and accurate cuts. You can achieve intricate designs and patterns with minimal waste, making laser cutting a popular choice in industries like manufacturing, automotive, and art.

The technology relies on three main components: the laser source, the cutting head, and the control system. The laser source generates the beam, while the cutting head focuses it onto the material. The control system ensures precision by guiding the laser along the desired path. This combination allows you to cut a wide range of materials, from metals to non-metals, with exceptional accuracy.

Types of Laser Cutting Machines

Laser cutting machines come in various types, each designed for specific applications. Understanding these types helps you choose the right machine for your needs.

CO2 Laser Cutting Machines

CO2 laser cutting machines are ideal for non-metal materials. They excel in cutting materials like fabric, wood, and acrylic. If you work with thick board materials, these machines deliver excellent performance. Their advanced technology ensures precision, even when handling intricate details. For industries like signage, woodworking, and textile, CO2 lasers provide reliable and efficient solutions.

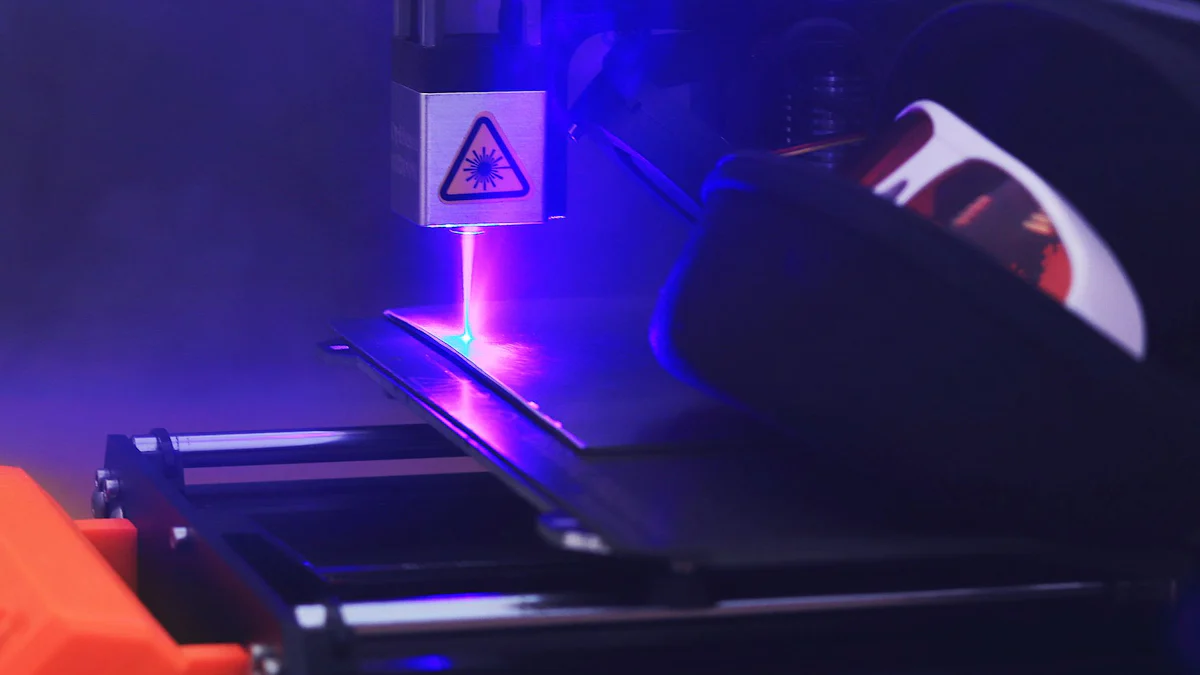

Fiber Laser Cutting Machines

Fiber laser cutting machines are perfect for metal cutting. They specialize in high-speed and accurate cutting of thin metal sheets. These machines perform exceptionally well with materials such as stainless steel, carbon steel, and aluminum alloys. If you need a machine for industrial applications requiring speed and precision, fiber lasers are a top choice. Their ability to handle metals makes them indispensable in industries like aerospace, automotive, and electronics.

YAG Laser Cutting Machines

YAG laser cutting machines (Yttrium Aluminum Garnet) are versatile tools that can cut both metals and some non-metals. They are often used for applications requiring high energy density, such as engraving and welding. While not as common as CO2 or fiber lasers, YAG machines offer unique advantages in specialized tasks. If your projects involve detailed engraving or welding, this type of laser cutter could meet your requirements.

By understanding the strengths of each type, you can select a laser cutting machine that aligns with your materials and project goals.

How Much Is a Laser Cutting Machine? Key Factors Influencing Costs

When determining how much is a laser cutting machine, several factors influence the price. Understanding these factors helps you make an informed decision and ensures you choose a machine that fits your needs and budget.

Machine Type and Technology

The type of laser cutting machine you select plays a significant role in its cost. Machines like CO2 lasers are generally more affordable and suitable for non-metal materials. On the other hand, fiber lasers are more expensive due to their advanced technology and ability to cut metals with high precision. If you need a machine for specialized tasks like engraving or welding, YAG lasers might be the right choice, though they often come with a higher price tag.

The technology embedded in the machine also impacts its cost. Machines with higher technical content, such as those equipped with advanced automation or multi-axis capabilities, tend to cost more. These features enhance performance, precision, and efficiency, making them ideal for industrial applications. However, they may not be necessary for smaller-scale projects, so evaluating your specific requirements is essential.

Cutting Speed and Precision

Cutting speed and precision are critical factors that affect both the machine's performance and its price. Machines capable of faster cutting speeds allow you to complete projects more quickly, which can save time and increase productivity. However, this speed often comes at a higher cost. Similarly, machines offering greater precision, such as those with advanced control systems or additional axes, are typically more expensive.

For larger designs or intricate patterns, slower cutting speeds may be required, which can increase operational costs due to extended material usage. If your projects demand high-quality cuts with minimal errors, investing in a machine with superior precision and speed might be worth the added expense.

Power Output and Material Compatibility

The power output of a laser cutting machine directly influences its cutting capability and price. Machines with higher power levels can cut through thicker materials, making them suitable for heavy-duty applications. For example, a high-power fiber laser can handle metals like stainless steel and aluminum alloys with ease. However, these machines are more expensive than lower-power models designed for lighter materials.

Material compatibility also affects the cost. Machines capable of cutting a wide range of materials, from metals to non-metals, often feature advanced components and software, which increase their price. If your projects involve diverse materials, investing in a versatile machine can provide long-term value.

When considering how much is a laser cutting machine, remember that operational costs, such as electricity and consumables, also vary based on power output. High-power machines may have higher energy consumption, so factoring in these ongoing expenses is crucial.

Operational Costs (Electricity, Consumables, etc.)

Operational costs play a significant role in determining how much is a laser cutting machine over its lifetime. These costs include electricity consumption, consumables like gases and lenses, and other recurring expenses. Understanding these factors helps you estimate the total cost of ownership and plan your budget effectively.

-

Electricity Consumption

Laser cutting machines, especially high-power models, consume substantial amounts of electricity. Machines with higher power output require more energy to operate, which increases your monthly utility bills. For instance, a fiber laser with advanced technology may offer better cutting capabilities but will likely have higher energy demands compared to a CO2 laser. To minimize electricity costs, consider machines with energy-efficient designs or features that optimize power usage during operation. -

Consumables

Consumables such as lenses, nozzles, and assist gases (like oxygen, nitrogen, or compressed air) also contribute to operational expenses. The type of material you cut and the machine's power level influence the amount and type of consumables required. For example:- CO2 lasers often need more frequent lens replacements due to their design.

- Fiber lasers typically have lower consumable costs because they do not rely on mirrors or gases as extensively.

Regular maintenance of these components ensures consistent performance but adds to the overall cost. Planning for these recurring expenses is essential to avoid unexpected financial strain.

-

Software and Control Systems

Advanced software and control systems can improve cutting precision and efficiency but may require periodic updates or subscriptions. Machines with sophisticated automation features often come with higher operational costs due to the need for specialized software support. However, these systems can save time and reduce material waste, offering long-term cost benefits.

By evaluating these operational costs, you can choose a machine that balances performance with affordability. This approach ensures that your investment remains cost-effective over time.

Maintenance and Longevity

Maintenance and longevity are critical factors that influence the overall cost of owning a laser cutting machine. Proper care and regular servicing not only extend the machine's lifespan but also ensure optimal performance.

-

Routine Maintenance

Laser cutting machines require regular maintenance to function efficiently. Tasks like cleaning lenses, replacing worn-out parts, and calibrating the laser beam are essential. Neglecting these tasks can lead to reduced cutting quality and higher repair costs. For example:- CO2 lasers need more frequent maintenance due to their reliance on mirrors and gas tubes.

- Fiber lasers, with fewer moving parts, generally have lower maintenance requirements.

Investing in a machine with robust components can reduce the frequency and cost of maintenance.

-

Durability and Build Quality

The machine's build quality significantly impacts its longevity. Machines made with high-quality materials and advanced engineering tend to last longer and require fewer repairs. While these machines may have a higher upfront cost, their durability often results in lower long-term expenses. For instance, fiber lasers are known for their reliability and can operate for years with minimal issues. -

Manufacturer Support and Warranty

Choosing a machine from a reputable manufacturer with a comprehensive warranty can save you money on repairs and replacements. Some manufacturers offer extended warranties or service packages, which cover maintenance and part replacements for a fixed period. This support ensures that your machine remains in top condition without incurring unexpected costs.

By prioritizing maintenance and selecting a durable machine, you can maximize your investment and reduce the total cost of ownership. A well-maintained machine not only performs better but also retains its value over time.

Pros and Cons of Different Laser Cutting Machine Types

CO2 Laser Cutting Machines

Advantages

-

Versatility in Material Cutting

CO2 laser cutting machines excel at cutting non-metal materials. You can use them for wood, acrylic, fabric, and even leather. Their ability to handle a wide range of materials makes them ideal for industries like signage, textiles, and woodworking. -

Cost-Effective Option

These machines are generally more affordable compared to fiber or YAG lasers. If your projects involve non-metals, CO2 lasers provide a budget-friendly solution without compromising on quality. -

High Precision for Intricate Designs

CO2 lasers deliver excellent precision, especially for detailed patterns and designs. This makes them a great choice for applications requiring fine craftsmanship, such as engraving or decorative work. -

Lower Maintenance Costs

Maintenance tasks, such as cleaning and debris removal, are relatively simple and inexpensive. The overall maintenance cost is less than 1% of the total operational cost, making these machines economical in the long run.

Disadvantages

-

Limited Metal Cutting Capability

CO2 lasers struggle with cutting metals efficiently. If your projects involve metals like stainless steel or aluminum, you may find their performance lacking compared to fiber lasers. -

Higher Consumable Costs

These machines rely heavily on consumables like lenses and assist gases. Frequent lens replacements and gas usage can increase operational costs over time. -

Slower Cutting Speeds

CO2 lasers operate at slower speeds when compared to fiber lasers. This can impact productivity, especially for large-scale projects requiring quick turnaround times.

Fiber Laser Cutting Machines

Advantages

-

Exceptional Metal Cutting Performance

Fiber lasers are designed for cutting metals with high precision and speed. You can use them for materials like stainless steel, carbon steel, and aluminum alloys. Their efficiency makes them indispensable in industries like aerospace and automotive. -

Energy Efficiency

These machines consume less electricity compared to CO2 lasers. Their energy-efficient design helps reduce operational costs, making them a cost-effective choice for long-term use. -

Low Maintenance Requirements

Fiber lasers have fewer moving parts, which reduces the need for frequent maintenance. This results in lower maintenance costs and less downtime, ensuring consistent performance. -

Durability and Longevity

Built with advanced engineering, fiber lasers offer exceptional durability. They can operate for years with minimal issues, providing a reliable solution for industrial applications.

Disadvantages

-

Higher Initial Cost

Fiber lasers are more expensive upfront due to their advanced technology. If you are on a tight budget, this could be a significant drawback. -

Limited Non-Metal Cutting Capability

These machines are not ideal for cutting non-metal materials like wood or acrylic. If your projects involve diverse materials, you may need an additional machine. -

Specialized Software Requirements

Fiber lasers often require advanced software for optimal performance. Periodic updates or subscriptions can add to the overall operational cost.

YAG Laser Cutting Machines

Advantages

-

Versatility in Applications

YAG lasers can cut both metals and some non-metals. You can use them for specialized tasks like engraving, welding, and drilling. Their high energy density makes them suitable for intricate and detailed work. -

High Energy Efficiency

These machines are designed to maximize energy usage, reducing electricity consumption. This makes them a practical choice for projects requiring prolonged operation. -

Precision in Specialized Tasks

YAG lasers excel in applications that demand extreme precision, such as engraving fine details or welding delicate components. Their accuracy ensures high-quality results.

Disadvantages

-

Higher Operational Costs

The cost of consumables, such as auxiliary gases and spare parts, can be significant. These recurring expenses add to the overall cost of ownership. -

Limited Popularity and Availability

YAG lasers are less common compared to CO2 and fiber lasers. Finding replacement parts or technical support can be challenging, especially in remote areas. -

Higher Maintenance Needs

These machines require regular maintenance to ensure optimal performance. Tasks like cleaning and calibrating the laser beam can be time-consuming and costly.

By weighing the pros and cons of each type, you can determine which laser cutting machine aligns best with your specific needs and budget. Each machine offers unique advantages, so understanding their strengths and limitations will help you make an informed decision.

Cost Comparison of Laser Cutting Machine Models

When exploring how much is a laser cutting machine, understanding the cost differences between various models is essential. Machines fall into three main categories based on their price range and capabilities. Each category caters to specific needs, from hobbyists to large-scale industrial operations.

Entry-Level Models (e.g., $2,600–$40,000)

Entry-level laser cutting machines are ideal for beginners or small businesses. These machines typically include CO2 laser cutters, which are well-suited for non-metal materials like wood, acrylic, and fabric. Their affordability makes them accessible to users with limited budgets.

-

Key Features:

- Suitable for light-duty applications.

- Limited cutting power, often unable to handle metals effectively.

- Compact designs that fit smaller workspaces.

-

Advantages:

- Affordable starting price, often as low as $2,600.

- Easy to operate, making them perfect for first-time users.

- Lower maintenance costs compared to more advanced models.

-

Limitations:

- Slower cutting speeds and reduced precision.

- Limited material compatibility, especially for metals.

- Shorter lifespan due to basic build quality.

Example: A small business creating custom signage might find an entry-level CO2 laser cutter sufficient for their needs. However, if you plan to expand into metal cutting, upgrading to a mid-range or high-end model may be necessary.

Mid-Range Models (e.g., $30,000–$100,000)

Mid-range laser cutting machines offer a balance between performance and cost. These machines often include fiber lasers, which excel at cutting metals like stainless steel and aluminum. They cater to businesses requiring higher precision and faster cutting speeds.

-

Key Features:

- Enhanced cutting power for metals and some non-metals.

- Improved speed and accuracy compared to entry-level models.

- Energy-efficient designs that reduce operational costs.

-

Advantages:

- Versatility in handling a wider range of materials.

- Lower consumable costs, especially for fiber lasers.

- Durable construction ensures longer operational life.

-

Limitations:

- Higher upfront cost, starting around $30,000.

- Specialized software requirements may increase operational expenses.

- Limited capability for intricate non-metal designs compared to CO2 lasers.

Example: A mid-sized manufacturing company producing metal components can benefit from a mid-range fiber laser cutter. Its efficiency and precision make it a valuable investment for industrial applications.

High-End Models (e.g., $100,000–$1 million)

High-end laser cutting machines are designed for large-scale industrial use. These machines include advanced fiber lasers and YAG lasers, offering unparalleled cutting speed, precision, and durability. They are suitable for businesses with demanding production requirements.

-

Key Features:

- High power output for cutting thick metals and complex shapes.

- Advanced automation and multi-axis capabilities.

- Robust build quality for continuous operation.

-

Advantages:

- Exceptional cutting performance for both metals and non-metals.

- Reduced downtime due to minimal maintenance needs.

- Long-term cost savings through energy efficiency and durability.

-

Limitations:

- Significant initial investment, often exceeding $100,000.

- Higher operational costs, including electricity and consumables.

- Requires skilled operators and advanced training.

Example: Aerospace and automotive industries rely on high-end fiber lasers for their precision and ability to handle complex designs. While the upfront cost is steep, the long-term benefits justify the investment.

By comparing these categories, you can determine which model aligns with your budget and project requirements. Entry-level machines suit hobbyists and small businesses, mid-range models cater to growing enterprises, and high-end machines meet the demands of industrial-scale operations.

Additional Costs to Consider (Software, Training, etc.)

When purchasing a laser cutting machine, you should account for additional costs beyond the machine's price. These expenses can significantly impact your overall investment and long-term budget. Understanding these costs ensures you make a well-informed decision.

Software Expenses

Laser cutting machines often require specialized software for design and operation. This software allows you to create precise patterns and control the cutting process. While some machines include basic software, advanced features may require premium versions or subscriptions.

- Initial Purchase or Licensing Fees: Many machines come with proprietary software that requires a one-time purchase or an annual license. For example, fiber laser machines often use advanced software for metal cutting, which can cost several hundred dollars annually.

- Upgrades and Updates: Regular updates ensure compatibility with new materials and improve performance. However, these updates may come at an additional cost.

- Third-Party Software: If the included software lacks certain features, you might need to invest in third-party programs. These tools can enhance functionality but add to your expenses.

Tip: Evaluate the software's capabilities before purchasing the machine. Ensure it meets your design and operational needs to avoid unexpected costs.

Training Costs

Operating a laser cutting machine requires skill and knowledge. While entry-level machines are user-friendly, mid-range and high-end models often demand specialized training.

- Initial Training: Manufacturers or suppliers may offer training sessions for new users. These sessions can range from free tutorials to paid workshops, depending on the machine's complexity.

- Advanced Training: For machines like fiber lasers, which involve intricate settings and software, advanced training might be necessary. This training ensures you maximize the machine's potential and avoid costly errors.

- Ongoing Learning: As technology evolves, staying updated on new techniques and features is crucial. Attending workshops or online courses can help you stay ahead but may incur additional costs.

Example: A small business upgrading to a fiber laser cutter might need to invest in training for employees to handle the machine's advanced features effectively.

Installation and Setup

Setting up a laser cutting machine involves more than just plugging it in. You may need to prepare your workspace and hire professionals for installation.

- Workspace Preparation: Machines like CO2 lasers require proper ventilation systems to handle fumes and gases. Fiber lasers may need a stable power supply and specific environmental conditions.

- Professional Installation: Some manufacturers recommend professional installation to ensure optimal performance. This service often comes at an extra cost but prevents potential issues during operation.

Maintenance Contracts and Extended Warranties

While regular maintenance is essential, you might also consider purchasing maintenance contracts or extended warranties.

- Maintenance Contracts: These agreements cover routine servicing and repairs, reducing downtime and unexpected expenses. For instance, fiber lasers, known for their durability, still benefit from periodic checks to maintain efficiency.

- Extended Warranties: Manufacturers often offer extended warranties for an additional fee. These warranties provide peace of mind by covering major repairs or replacements beyond the standard warranty period.

Consumables and Accessories

Consumables like lenses, nozzles, and assist gases contribute to ongoing costs. Additionally, you might need accessories to enhance the machine's functionality.

- Consumables: CO2 lasers typically require more frequent lens replacements, while fiber lasers have lower consumable costs. YAG lasers, though cheaper initially, consume more power and auxiliary gases.

- Accessories: Items like rotary attachments for cylindrical objects or upgraded cutting heads can expand your machine's capabilities but increase your expenses.

By considering these additional costs, you can better plan your budget and avoid surprises. Investing in the right software, training, and maintenance ensures your laser cutting machine operates efficiently and delivers long-term value.

Choosing the Right Laser Cutting Machine for Your Needs

Selecting the right laser cutting machine requires careful consideration of your budget, project requirements, and the machine's features. By evaluating these factors, you can make a decision that aligns with your goals and ensures long-term value.

Assessing Your Budget and Long-Term ROI

Your budget is a critical factor when choosing a laser cutting machine. Prices vary widely, ranging from entry-level models costing $2,600 to $10,000 to high-end industrial machines priced between $100,000 and $1 million. Understanding how much you can invest upfront helps narrow down your options.

To maximize your investment, consider the long-term return on investment (ROI). Machines with higher initial costs often provide better durability, efficiency, and performance. For example, a mid-range fiber laser cutter priced between $30,000 and $100,000 may offer faster cutting speeds and lower operational costs compared to cheaper models. Over time, these benefits can offset the higher purchase price.

Tip: Calculate the potential savings from reduced maintenance, energy efficiency, and increased productivity. This approach helps you determine whether a higher-priced machine will deliver better value in the long run.

Identifying Your Cutting Requirements

Understanding your specific cutting needs is essential. Different machines excel at different tasks, so identifying your requirements ensures you choose the right tool for the job.

-

Material Type

Determine the materials you plan to cut. CO2 lasers are ideal for non-metals like wood, acrylic, and fabric, while fiber lasers specialize in metals such as stainless steel and aluminum. If your projects involve both metals and non-metals, consider a versatile machine like a YAG laser. -

Cutting Thickness

The thickness of the material affects the required power output. For instance, a high-power fiber laser can cut through thick metals but may be unnecessary for thin materials. Entry-level machines with lower power are sufficient for light-duty applications. -

Production Volume

Assess the scale of your operations. For small-scale or hobbyist projects, an entry-level machine priced between $3,000 and $10,000 may suffice. For industrial-scale production, invest in a high-end model with advanced features to handle large volumes efficiently. -

Precision and Speed

If your projects demand intricate designs or fast turnaround times, prioritize machines with high precision and speed. Mid-range and high-end models often include advanced control systems that enhance accuracy and productivity.

Example: A small business creating custom signage might benefit from a CO2 laser cutter, while a manufacturing company producing metal components would require a fiber laser for its precision and speed.

Evaluating Features and Material Compatibility

The features and compatibility of a laser cutting machine play a significant role in its performance. Evaluating these aspects ensures the machine meets your needs and delivers optimal results.

-

Power Output

Higher power levels enable cutting through thicker materials. For example, a 6kW fiber laser can handle heavy-duty tasks but comes at a higher cost. Choose a machine with power output that matches your material and project requirements. -

Work Area Size

The size of the work area determines the maximum dimensions of the materials you can cut. Entry-level machines often have smaller workspaces, while industrial models offer larger areas for handling bigger projects. -

Software and Automation

Advanced software enhances precision and efficiency. Machines with automation features, such as multi-axis capabilities, reduce manual effort and improve consistency. However, these features may increase the machine's price and operational complexity. -

Durability and Build Quality

A well-built machine lasts longer and requires less maintenance. Fiber lasers, known for their robust construction, offer excellent durability. Investing in a high-quality machine reduces downtime and repair costs over time. -

Material Compatibility

Ensure the machine can handle the materials you plan to cut. For instance, CO2 lasers excel at non-metals, while fiber lasers are better suited for metals. If your projects involve diverse materials, opt for a machine with versatile capabilities.

By thoroughly assessing these factors, you can select a laser cutting machine that aligns with your budget, cutting requirements, and desired features. This approach ensures your investment delivers value and supports your long-term goals.

Tips for Making an Informed Purchase

When buying a laser cutting machine, making an informed decision ensures you get the best value for your investment. By following these tips, you can confidently choose a machine that meets your needs and budget.

1. Research and Compare Models

Start by researching different laser cutting machine models. Compare their features, capabilities, and price ranges to find the one that suits your requirements. For example:

- Entry-level machines: These cost between $2,600 and $10,000 and are ideal for hobbyists or small businesses working with non-metal materials.

- Mid-range machines: Prices range from $10,000 to $50,000. These machines offer better precision and speed, making them suitable for businesses handling metals and higher production volumes.

- High-end machines: These can cost anywhere from $100,000 to $1 million. They are designed for industrial use, offering advanced features and exceptional durability.

Tip: Create a comparison chart to evaluate the pros and cons of each model side by side.

2. Define Your Budget and Stick to It

Set a clear budget before exploring options. Laser cutting machines vary widely in price, from $3,000 for basic models to over $1 million for industrial-grade machines. Knowing your financial limits helps you avoid overspending.

- If you’re a beginner, consider starting with an affordable CO2 laser cutter priced between $2,600 and $20,000.

- For businesses requiring metal cutting, mid-range fiber lasers costing $30,000 to $100,000 may be a better fit.

- Industrial operations may need high-power fiber lasers, which can exceed $500,000.

Pro Tip: Factor in long-term costs like maintenance, consumables, and operational expenses when setting your budget.

3. Assess Your Cutting Needs

Identify the materials and projects you plan to work on. This ensures you select a machine with the right capabilities.

- Material type: CO2 lasers excel at cutting non-metals like wood and acrylic, while fiber lasers are better for metals such as stainless steel and aluminum.

- Cutting thickness: Choose a machine with sufficient power output for your material thickness. For instance, a 6kW fiber laser can handle thick metals but may not be necessary for lighter tasks.

- Production volume: For large-scale operations, invest in a high-speed machine to maximize efficiency.

Example: A small business creating custom signs might benefit from an entry-level CO2 laser, while a manufacturer producing metal parts would require a mid-range fiber laser.

4. Evaluate Additional Costs

Beyond the machine’s price, consider other expenses that impact your total investment:

- Software: Some machines require advanced design software, which may involve licensing fees or subscriptions.

- Training: Mid-range and high-end machines often demand specialized training for operators.

- Installation: Professional setup may be necessary, especially for larger machines.

- Consumables: Items like lenses, nozzles, and assist gases add to operational costs.

Tip: Ask manufacturers about bundled packages that include software, training, and maintenance to save money.

5. Check Manufacturer Reputation and Support

Choose a reputable manufacturer with a proven track record. Reliable brands often provide better customer support, warranties, and replacement parts.

- Look for companies offering extended warranties or maintenance contracts.

- Read customer reviews to gauge satisfaction with the machine and after-sales service.

Pro Tip: Opt for a manufacturer that provides comprehensive training and technical support to ensure smooth operation.

6. Test the Machine Before Purchase

Whenever possible, request a demonstration or trial of the machine. Testing allows you to evaluate its performance, ease of use, and compatibility with your materials.

- Observe the cutting speed and precision.

- Check the quality of the finished cuts.

- Ensure the machine meets your specific project requirements.

Example: If you plan to cut intricate designs, test the machine’s ability to handle fine details without compromising accuracy.

By following these tips, you can confidently select a laser cutting machine that aligns with your goals and delivers long-term value. A well-informed purchase not only saves money but also ensures your machine meets your expectations.

Understanding the cost of a laser cutting machine involves evaluating multiple factors, including machine type, power, and operational expenses. Each machine type—CO2, fiber, and YAG—offers unique advantages and limitations. CO2 lasers excel at non-metals, fiber lasers dominate metal cutting, and YAG lasers provide versatility for specialized tasks. To make the right choice, assess your budget, cutting needs, and long-term ROI. Consider additional costs like maintenance, training, and consumables. By balancing price with practicality, you can invest in a machine that aligns with your goals and delivers exceptional value.

FAQ

How much does a laser cutting machine cost?

The cost of a laser cutting machine varies widely. Entry-level models start at around $2,600, while high-end industrial machines can exceed $1 million. The price depends on factors like machine type, power output, and features. For example, CO2 lasers are more affordable and suitable for non-metals, while fiber lasers, designed for metal cutting, are more expensive due to their advanced technology.

Tip: Consider not just the upfront cost but also operational expenses like electricity, consumables, and maintenance when estimating the total investment.

What factors influence the price of a laser cutting machine?

Several factors affect the price of a laser cutting machine:

- Machine Type: CO2, fiber, and YAG lasers vary in cost based on their capabilities.

- Power Output: Higher power levels allow for cutting thicker materials but increase the price.

- Cutting Speed and Precision: Machines with faster speeds and higher precision often cost more.

- Material Compatibility: Machines that handle a wider range of materials tend to be pricier.

- Additional Features: Automation, software, and multi-axis capabilities add to the cost.

Understanding these factors helps you choose a machine that fits your budget and meets your needs.

Which laser cutting machine is best for beginners?

For beginners, entry-level CO2 laser cutting machines are the best choice. These machines are affordable, easy to operate, and ideal for cutting non-metal materials like wood, acrylic, and fabric. They typically cost between $2,600 and $10,000, making them accessible for hobbyists or small businesses.

Example: If you’re starting a custom signage business, a CO2 laser cutter can handle intricate designs without requiring advanced technical skills.

Are fiber lasers worth the higher cost?

Fiber lasers are worth the investment if your projects involve metal cutting or require high precision and speed. These machines excel at cutting metals like stainless steel and aluminum. They also consume less energy and have lower maintenance needs compared to CO2 lasers. While their initial cost is higher, ranging from $30,000 to $100,000 for mid-range models, their efficiency and durability provide long-term value.

Pro Tip: Evaluate your production volume and material requirements to determine if a fiber laser aligns with your goals.

What are the ongoing costs of owning a laser cutting machine?

Owning a laser cutting machine involves several ongoing costs:

- Electricity: High-power machines consume more energy, increasing utility bills.

- Consumables: Items like lenses, nozzles, and assist gases (oxygen, nitrogen) need regular replacement.

- Maintenance: Routine servicing ensures optimal performance but adds to the overall cost.

- Software Updates: Advanced machines may require periodic software upgrades or subscriptions.

Planning for these expenses ensures you can maintain the machine without unexpected financial strain.

How do I choose the right laser cutting machine for my needs?

To choose the right machine, consider these steps:

- Define Your Budget: Determine how much you can invest upfront and account for long-term costs.

- Identify Your Materials: CO2 lasers work well for non-metals, while fiber lasers are ideal for metals.

- Assess Cutting Requirements: Consider the thickness, precision, and speed needed for your projects.

- Evaluate Features: Look for power output, work area size, and automation capabilities.

- Research Manufacturers: Choose a reputable brand with good customer support and warranties.

Tip: Testing the machine before purchase can help you ensure it meets your specific needs.

Can I use one machine for both metals and non-metals?

Yes, but it depends on the machine type. YAG lasers offer versatility, handling both metals and some non-metals. However, they are less common and may have higher operational costs. Fiber lasers excel at metals but struggle with non-metals, while CO2 lasers are better suited for non-metals. If your projects involve diverse materials, consider a machine designed for multi-material compatibility.

How can I calculate the return on investment (ROI) for a laser cutting machine?

To calculate ROI, consider these factors:

- Initial Cost: Include the machine price, installation, and training expenses.

- Operational Savings: Factor in reduced labor, faster production, and lower material waste.

- Revenue Increase: Estimate how the machine will boost your production capacity and sales.

- Lifespan: Divide the total benefits by the machine’s expected lifespan to determine annual ROI.

Example: A mid-range fiber laser might cost $50,000 but save $10,000 annually in operational costs, providing a full ROI in five years.

Do laser cutting machines require special training?

Yes, especially for mid-range and high-end models. While entry-level machines are user-friendly, advanced machines like fiber lasers demand specialized training to operate efficiently. Manufacturers often provide training sessions, and online courses are available for ongoing learning. Investing in proper training ensures you maximize the machine’s potential and avoid costly mistakes.

What additional costs should I consider when buying a laser cutting machine?

In addition to the machine’s price, consider these costs:

- Software: Some machines require premium design software with licensing fees.

- Installation: Professional setup may be necessary for larger machines.

- Ventilation Systems: CO2 lasers need proper ventilation to handle fumes.

- Accessories: Items like rotary attachments or upgraded cutting heads expand functionality but increase costs.

Tip: Ask manufacturers about bundled packages that include software, training, and accessories to save money.

See Also

Understanding Laser Cutting Machines And Their Various Types

Cost Analysis of Coal Cutting Machines Explained

Guidelines for Selecting the Ideal Water Jet Cutter

The Functionality of Laser Cutting Machines in Manufacturing