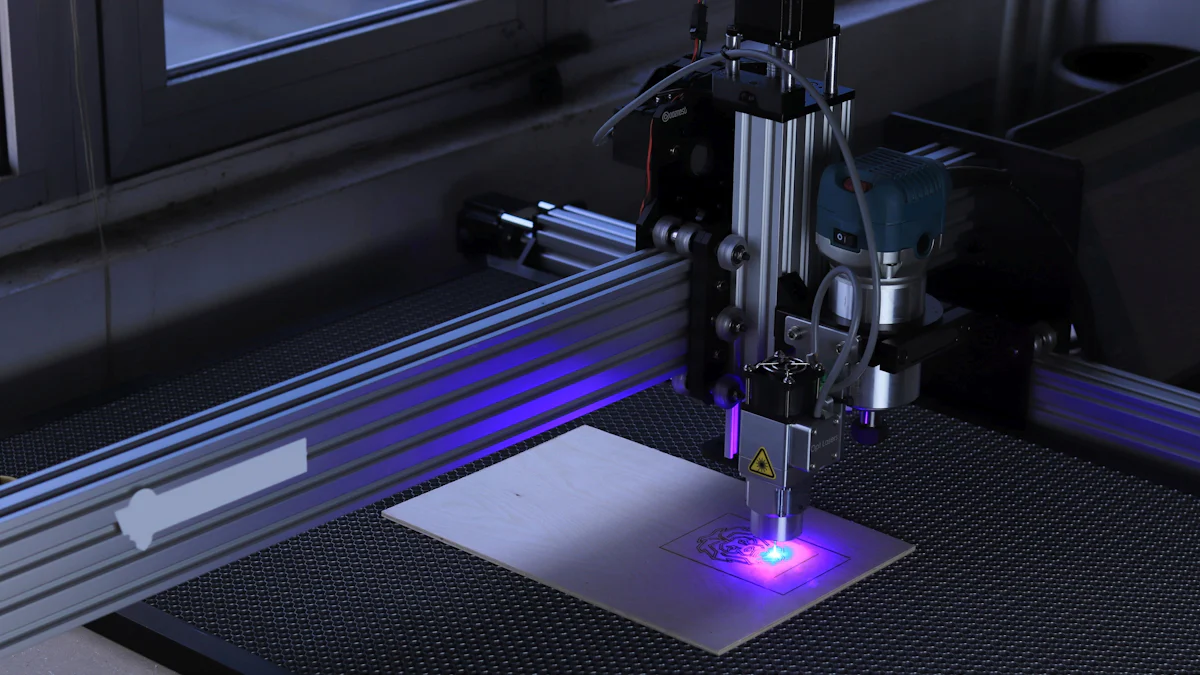

How Much is a Laser Cut Machine Worth Investing?

Investing in a laser cutting machine can transform your business operations. You might wonder how much is a laser cut machine worth investing in. The answer depends on several factors, including the type of machine and its applications. The market for laser cutting machines is booming, with a projected growth rate of 7.6% from 2024 to 2032. This growth indicates a rising demand across industries like automotive and aerospace. As technology advances, these machines become more affordable and versatile, making them a valuable asset for businesses seeking precision and efficiency.

Initial Costs of Laser Cutting Machines

When you consider investing in a laser cutting machine, understanding the initial costs is crucial. These costs can vary widely based on several factors, which we will explore in this section.

Purchase Price

The purchase price of a laser cutting machine depends on various elements. Let's break down these components to give you a clearer picture.

Price Ranges for Different Models

Laser cutting machines come in a wide range of prices. You can find hobbyist models starting at around $500, while high-end industrial machines can exceed $600,000. The price often reflects the machine's capabilities, such as power output and material compatibility. For instance, machines designed to handle thicker materials or those with advanced features like automation tend to be more expensive.

Factors Influencing Cost

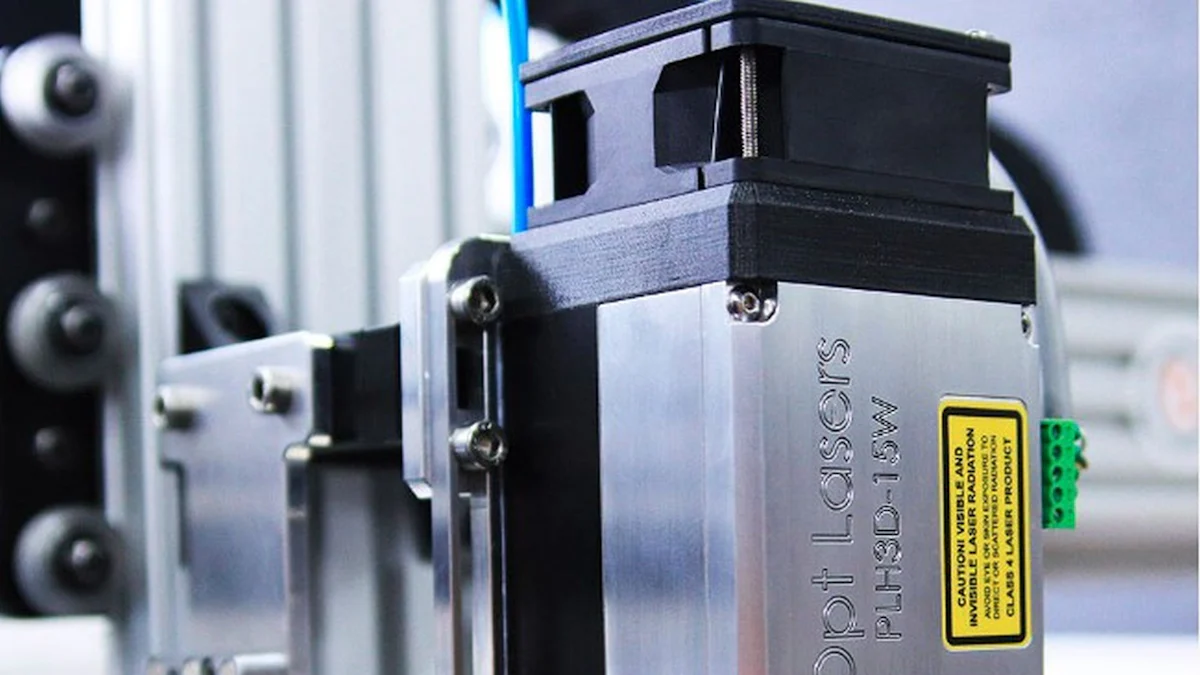

Several factors influence the cost of a laser cutting machine:

- Type of Laser Used: CO2 lasers are generally less expensive than fiber lasers, but each type has its own advantages.

- Power Output: Higher wattage machines can cut through thicker materials, which can justify their higher cost.

- Materials Compatibility: Machines that can cut a wider variety of materials often come at a premium.

- Working Area Size: Larger working areas allow for bigger projects, impacting the price.

- Speed and Safety Features: Enhanced speed and safety features can increase the machine's cost but may improve efficiency and safety.

Setup Expenses

Beyond the purchase price, you should also consider setup expenses. These costs ensure your machine operates smoothly and efficiently.

Installation Costs

Installation costs can vary depending on the complexity of the machine and your workspace. Professional installation ensures that the machine is set up correctly, minimizing potential issues down the line. This step is crucial for maintaining the machine's longevity and performance.

Training and Software

Training is essential for operating a laser cutting machine effectively. Investing in training programs can help you and your team maximize the machine's potential. Additionally, software costs should not be overlooked. The right software can enhance the precision and efficiency of your laser cut parts, making it a worthwhile investment.

By understanding these initial costs, you can make an informed decision about whether to invest in a laser cutting machine or consider outsourcing laser cut parts. Weighing these factors against your business needs will help you determine the best path forward.

Operational Costs of Laser Cutting

Understanding the operational costs of laser cutting is essential for making informed investment decisions. These costs can impact your business's profitability and efficiency.

Maintenance

Regular maintenance ensures that your laser cutting machine operates smoothly and delivers high quality laser cut parts. Neglecting maintenance can lead to costly repairs and downtime.

Regular Servicing

You should schedule regular servicing to keep your machine in top condition. This involves routine checks and adjustments to prevent wear and tear. Regular servicing not only extends the machine's lifespan but also maintains the quality of laser cut parts.

Replacement Parts

Over time, some parts of the laser cutting machine may need replacement. The cost of these parts varies depending on the machine's make and model. Investing in high-quality parts can reduce the frequency of replacements and ensure consistent performance.

Energy Consumption

Energy consumption is a significant factor in the operational costs of laser cutting. Efficient machines can help you save on energy bills.

Power Requirements

Laser cutting machines require a substantial amount of power. Understanding the power requirements of your machine helps you estimate energy costs accurately. Machines with energy-efficient features can reduce these costs over time.

Cost-Saving Tips

To minimize energy consumption, consider using machines with efficient cooling systems. These systems help maintain optimal performance while reducing power usage. Additionally, operating the machine during off-peak hours can further lower energy expenses.

Materials for Laser Cut Parts

The cost of materials is another crucial aspect of laser cutting operations. Different materials have varying costs, which can affect your overall expenses.

Types of Materials Used

Laser cutting machines can work with a variety of materials, including metals, plastics, and wood. Each material has unique properties and costs. Selecting the right material for your project ensures high quality cuts and cost-effectiveness.

Cost Variations

The cost of materials can fluctuate based on market demand and availability. Staying informed about these variations helps you plan your budget effectively. By choosing materials wisely, you can produce high quality laser cut parts without overspending.

By understanding these operational costs, you can optimize your laser cutting processes and enhance your business's profitability. Regular maintenance, energy efficiency, and smart material choices are key to achieving cost-effective operations.

Revenue Potential from Laser Cutting

Exploring the revenue potential of laser cutting can open new avenues for your business. Laser cutting machines offer diverse applications across various industries, enhancing your ability to generate income.

Applications in Various Industries

Laser cutting technology finds applications in multiple sectors, each offering unique opportunities for revenue generation.

Manufacturing

In the manufacturing industry, laser cutting machines play a pivotal role. They provide precision and efficiency, essential for producing high-quality components. The industrial sector, which includes manufacturing, held the largest market share of 39.7% in 2023. This dominance highlights the significant demand for laser cutting in manufacturing processes. By investing in a laser cutting machine, you can tap into this growing market and offer services that cater to the needs of manufacturers.

Art and Design

Laser cutting also thrives in the art and design industry. Artists and designers use these machines to create intricate patterns and designs that would be challenging to achieve manually. You can offer custom design services, catering to clients seeking unique and personalized products. This niche market allows you to charge premium prices for bespoke creations, enhancing your revenue potential.

Customization and Prototyping

Customization and prototyping are key areas where laser cutting machines excel. These capabilities enable you to offer unique product offerings that meet specific customer demands.

Unique Product Offerings

With a laser cutting machine, you can produce customized products tailored to individual preferences. This ability to personalize items sets your business apart from competitors. Customers value unique products, and they are often willing to pay more for them. By leveraging this demand, you can increase your profit margins and attract a loyal customer base.

Market Demand

The demand for customized and prototype products continues to rise. As consumers seek personalized experiences, businesses that offer customization gain a competitive edge. By providing prototyping services, you can assist companies in developing new products, further expanding your revenue streams. The adoption of industry 4.0 technologies, such as automation and data analytics, drives this demand, creating a lucrative market for laser cutting services.

ROI Calculation for Laser Cutting Machines

Calculating the return on investment (ROI) for a laser cutter investment is crucial for understanding its financial viability. This section will guide you through the process of determining ROI and highlight factors that can influence your returns.

Simple ROI Formula

To evaluate the efficiency of your laser cutter investment, you need to calculate the ROI. This metric helps you compare the net return of the investment to its cost.

Explanation of the Formula

The basic formula for ROI is:

ROI (%) = [(Net Profit from Investment - Initial Investment) / Initial Investment] x 100

This formula provides a percentage that represents the profitability of your investment. A higher percentage indicates a more profitable investment.

Example Calculation

Imagine you invest $50,000 in a laser cutting machine. Over a year, the machine generates $70,000 in revenue. The net profit would be $70,000 minus the initial investment of $50,000, which equals $20,000. Using the ROI formula:

ROI (%) = [($20,000) / $50,000] x 100 = 40%

This calculation shows a 40% return on investment, indicating a successful investment.

Factors Affecting Return on Investment

Several factors can impact the ROI of your laser cutting machine. Understanding these elements will help you make informed decisions and optimize your returns.

Market Trends

Market trends play a significant role in determining your laser return on investment. As the demand for laser cutting services grows, your potential revenue increases. Staying informed about industry trends and technological advancements can help you capitalize on new opportunities and enhance your ROI.

Business Scale

The scale of your business also affects the return on investment. Larger operations may benefit from economies of scale, reducing costs and increasing profitability. However, smaller businesses can still achieve a favorable ROI by focusing on niche markets and offering specialized services. Tailoring your approach to your business size and capabilities will help you maximize returns.

By understanding and applying these concepts, you can effectively assess the ROI of your laser cutter investment. This knowledge empowers you to make strategic decisions that align with your business goals and market conditions.

Case Studies on Laser Cutting Investments

Exploring real-world examples of laser cutting investments can provide you with valuable insights. These case studies highlight the potential benefits and challenges businesses face when integrating laser cutting technology.

Successful Business Examples

Small Business Success Story

Imagine a small business that specializes in custom signage. Initially, they outsourced their laser cutting needs, which led to long lead times and higher costs. By investing in a laser cutting machine, they brought these tasks in-house. This decision reduced lead times, cut costs, and provided creative flexibility. The business could now offer quicker turnaround times and more customized options to their clients. This strategic move not only increased their customer base but also boosted their revenue.

Large Scale Industry Impact

Consider a large manufacturing company that adopted laser cutting technology to enhance its production capabilities. The company invested in high-end laser cutters to improve precision and efficiency. This investment allowed them to produce complex components with greater accuracy, meeting the stringent demands of the aerospace industry. As a result, the company secured more contracts and expanded its market share. The laser cutting machines transformed their operations, leading to significant growth and profitability.

Lessons Learned

Key Takeaways

- In-House Production: Bringing laser cutting in-house can reduce costs and improve lead times.

- Customization: Offering customized products can attract more customers and increase revenue.

- Precision and Efficiency: Investing in high-quality machines enhances production capabilities and opens new market opportunities.

Common Pitfalls

- Underestimating Costs: Some businesses fail to account for all operational costs, such as maintenance and energy consumption.

- Lack of Training: Insufficient training can lead to inefficient use of the machine, affecting productivity and quality.

- Ignoring Market Trends: Not staying updated with industry trends can result in missed opportunities and reduced competitiveness.

By learning from these examples, you can make informed decisions about investing in laser cutting technology. Understanding both the successes and challenges will help you navigate the complexities of this investment and maximize its potential benefits for your business.

Investing in a laser cutting machine can significantly enhance your business operations. You gain improved production capabilities and precision, which opens up new opportunities. The initial investment may seem substantial, but it pays off as your business grows and thrives with these added capabilities. Consider your specific business needs and market opportunities when deciding. A laser cutting machine can transform your business by ramping up production and improving quality control. This transformation can help you procure additional clients and expand your market reach.

FAQ

What is a laser cutting machine used for?

A laser cutting machine is a versatile tool used for cutting and engraving various materials with precision. You can use it for applications in industries like manufacturing, art, and design. The machine excels at cutting through tough materials quickly and accurately, making it ideal for creating intricate designs and components.

How much does it cost to start a laser cutting business?

Starting a laser cutting business requires an initial investment that typically ranges from $8,000 to $50,000. This cost includes purchasing the laser cutter and setting up your workspace. It's crucial to research and select the right machine for your needs to ensure a successful venture.

Are laser cutting machines expensive to operate?

Operating a laser cutting machine involves costs, usually ranging from $0.50 to $1.00 per minute. While these costs are higher than traditional cutting methods, the machine's ability to cut with precision and speed often justifies the expense. Efficient operation and maintenance can help manage these costs effectively.

What materials can a laser cutting machine work with?

Laser cutting machines can handle a wide variety of materials, including metals, plastics, wood, and more. Each material has unique properties, so selecting the right one for your project ensures high-quality results. The machine's versatility allows you to explore different applications and expand your offerings.

How do I calculate the ROI for a laser cutting machine?

To calculate the return on investment (ROI) for a laser cutting machine, use the formula:

ROI (%) = [(Net Profit from Investment - Initial Investment) / Initial Investment] x 100

This calculation helps you assess the profitability of your investment. A higher percentage indicates a more favorable return, guiding your decision-making process.

Can I offer customization services with a laser cutting machine?

Yes, a laser cutting machine enables you to offer customization services. You can create unique, personalized products tailored to individual preferences. This capability sets your business apart and attracts customers seeking bespoke items, allowing you to charge premium prices.

What industries benefit from laser cutting technology?

Industries such as manufacturing, automotive, aerospace, art, and design benefit significantly from laser cutting technology. The machine's precision and efficiency make it a valuable asset for producing high-quality components and intricate designs, meeting the demands of these sectors.

Is training necessary to operate a laser cutting machine?

Training is essential for operating a laser cutting machine effectively. Proper training ensures you and your team can maximize the machine's potential, leading to improved productivity and quality. Investing in training programs is a worthwhile step to enhance your business operations.

How can I reduce the operational costs of a laser cutting machine?

To reduce operational costs, focus on regular maintenance, energy efficiency, and smart material choices. Schedule routine servicing to keep the machine in top condition. Use energy-efficient features and operate during off-peak hours to save on energy bills. Selecting cost-effective materials also helps manage expenses.

What are the common pitfalls when investing in laser cutting technology?

Common pitfalls include underestimating costs, neglecting training, and ignoring market trends. Failing to account for all operational expenses can impact profitability. Insufficient training may lead to inefficient machine use. Staying updated with industry trends helps you capitalize on opportunities and maintain competitiveness.

See Also

A Comprehensive Guide To Laser Cutting Machine Costs

Understanding The Costs Of Water Jet Cutting Machines

The Value Of Investing In Cricut Cutting Machines