How Much is a CNC Laser Cutting Machine?

When you explore the world of CNC laser cutting machines, you will find a wide range of prices. These machines can cost anywhere from $2,000 to over $1 million. The price depends on factors like type, power, and additional features. Understanding these elements is crucial. You need to know how much is a CNC laser cutting machine to make an informed decision. Different types of laser cutters serve various purposes, and their costs reflect their capabilities. By grasping these factors, you can choose a machine that fits your needs and budget.

Types of Laser Cutters

When you consider purchasing a CNC laser cutting machine, understanding the different types of laser cutters is essential. Each type has unique features and applications, which influence its cost and suitability for various tasks.

CO2 Laser Cutting Machines

CO2 laser cutters are among the most popular types of lasers for cutting non-metal materials. These machines typically range in price from $8,000 to $50,000. They offer power outputs between 100W and 500W, making them ideal for cutting and engraving materials like wood, acrylic, rubber, and textiles. You will find that CO2 lasers are versatile and widely used in industries such as signage, arts and crafts, and packaging. Their ability to handle a variety of materials makes them a valuable tool for many applications.

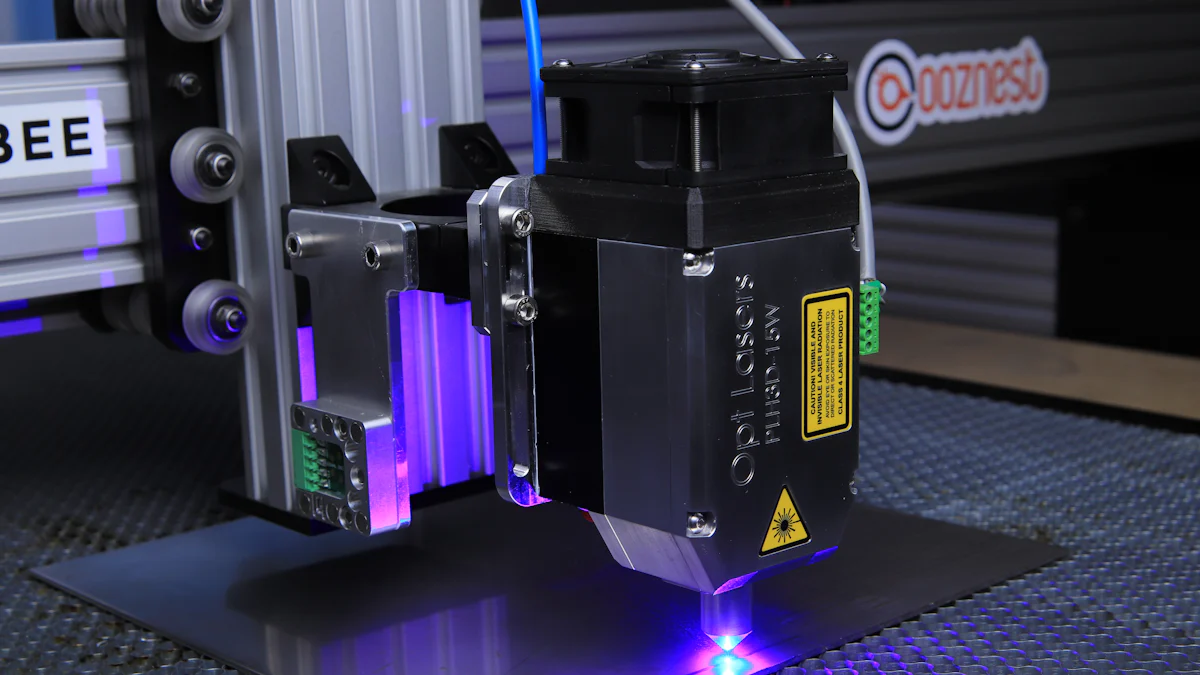

Fiber Laser Cutting Machines

Fiber laser cutters are known for their efficiency and precision, especially when working with metals. These machines use fiber lasers, which provide a high power density, allowing for faster cutting speeds and reduced energy consumption. Fiber laser cutters excel in cutting metals like steel, aluminum, and copper. They are often more expensive than CO2 lasers, but their benefits include lower maintenance costs and longer lifespan. If you need a machine for industrial applications, fiber lasers offer excellent performance and reliability.

Nd:YAG Laser Cutting Machines

Nd:YAG laser cutters are specialized machines used for specific applications. They are particularly effective for engraving and cutting hard materials, such as ceramics and some metals. The pricing for Nd:YAG lasers varies based on their power and capabilities, but they tend to be more costly due to their specialized nature. You might choose an Nd:YAG laser if your work involves intricate designs or requires high precision in challenging materials.

Understanding these types of laser cutters helps you make an informed decision. Each type offers distinct advantages and is suited for different applications and supported materials. By matching the machine to your specific needs, you can ensure optimal performance and value.

Factors Influencing Cost

When you decide to invest in a CNC laser cutting machine, understanding the factors that influence its cost is crucial. These factors determine not only the initial purchase price but also the long-term value and efficiency of the machine.

Power and Size

The power and size of a laser cutting machine significantly impact its price. Higher power machines offer greater cutting capabilities and efficiency. They can cut through thicker materials with ease, providing you with more versatility in your applications. For instance, a machine with a power output of 1000W will cost more than one with 500W due to its enhanced precision and ability to handle a wider range of materials. Larger machines also tend to be more expensive because they accommodate bigger workpieces, which is essential for large-scale production.

How Power Affects Pricing

Power directly correlates with the machine's price. More powerful lasers deliver faster cutting speeds and higher precision, which translates to increased efficiency in your operations. This efficiency is particularly beneficial in industrial applications where time and quality are paramount. However, you must balance power with your specific needs to avoid overspending on unnecessary capabilities.

Brand and Manufacturer

The brand and manufacturer of a laser cutting machine play a pivotal role in its cost. Reputable brands often charge a premium due to their established reputation for quality and reliability. These brands typically offer better service support, which can be invaluable in maintaining the machine's efficiency over time. When comparing brands, consider the long-term benefits of investing in a well-known manufacturer versus a lesser-known one.

Price Variations Among Brands

Price variations among brands arise from differences in quality, service support, and additional features. Some brands offer advanced control systems, intuitive user interfaces, and enhanced safety features, which can justify a higher price. You should evaluate these aspects to determine if the added cost aligns with your requirements and enhances the machine's overall value.

Additional Features

Additional features in a laser cutting machine can significantly increase its price. Features such as design software, servo motors, and cooling systems enhance the machine's precision and efficiency. These features allow for more complex applications and improve the quality of the final product. While these enhancements come at a cost, they can provide substantial benefits in terms of productivity and application versatility.

How Features Increase Price

Features like advanced design software and intuitive interfaces streamline the cutting process, reducing the time and effort required for setup and operation. Safety features ensure a secure working environment, which is crucial in high-precision applications. By investing in these features, you can achieve higher quality outputs and greater efficiency, making them worthwhile considerations despite the added expense.

Understanding these factors helps you make informed decisions when purchasing a laser cutting machine. By considering power, brand, and additional features, you can select a machine that meets your needs and offers the best value for your investment.

Choosing the Right Machine

Selecting the right laser cutting machine requires careful consideration of your budget and application needs. By understanding these aspects, you can make a wise investment that aligns with your specific requirements.

Budget Considerations

Setting a realistic budget is crucial when purchasing a laser cutting machine. Here are some tips to help you establish a budget that meets your needs:

-

Assess Your Financial Capacity: Determine how much you can afford to spend without compromising other financial obligations. This will help you narrow down your options and focus on machines within your price range.

-

Consider Long-term Costs: Factor in not only the initial purchase price but also the long-term costs such as maintenance, repairs, and potential upgrades. A machine with a higher upfront cost might offer better efficiency and lower maintenance expenses over time.

-

Evaluate Cost vs. Features: Balance the cost of the machine with the features it offers. While additional features can enhance precision and quality, ensure they align with your specific needs to avoid unnecessary expenses.

-

Research Financing Options: Explore financing options if the upfront cost is a concern. Many manufacturers offer payment plans or leasing options that can make acquiring a high-quality machine more manageable.

By setting a realistic budget, you can focus on finding a machine that provides the best value for your investment.

Application Needs

Matching the machine type to your specific application needs ensures optimal performance and precision in cutting. Consider the following factors:

-

Material Compatibility: Identify the materials you plan to work with. Different laser cutting machines excel in cutting various materials. For instance, CO2 lasers are ideal for non-metals, while fiber lasers are better suited for metals.

-

Desired Precision and Edge Quality: Determine the level of precision and edge quality required for your projects. High-precision applications may necessitate a machine with advanced features and higher power output.

-

Production Volume: Consider your production needs. If you require high-volume production, opt for a machine with a larger bed size and faster cutting speeds to enhance efficiency.

-

Future Needs: Anticipate potential future requirements. Investing in a machine that can accommodate future growth or new applications can save you from needing another purchase later.

By aligning your machine choice with your application needs, you ensure that the laser cutting machine delivers the desired precision and quality, maximizing its utility and lifespan.

In your journey to find the right laser cutting machine, understanding the cost and types of lasers is crucial. You have explored CO2, fiber, and Nd:YAG laser cutters, each with unique applications and price points. Remember, balancing your budget with specific needs ensures you make a wise investment. Consider factors like power, features, and brand reputation. These elements influence not only the initial purchase price but also the long-term value. By aligning your choice with your application needs, you maximize efficiency and cost-effectiveness in laser cutting.

FAQ

What is a CNC laser cutting machine?

A CNC laser cutting machine uses a laser to cut materials with precision. You control it using a computer, which allows for detailed and accurate designs. These machines are popular in industries like manufacturing and crafting due to their efficiency and versatility.

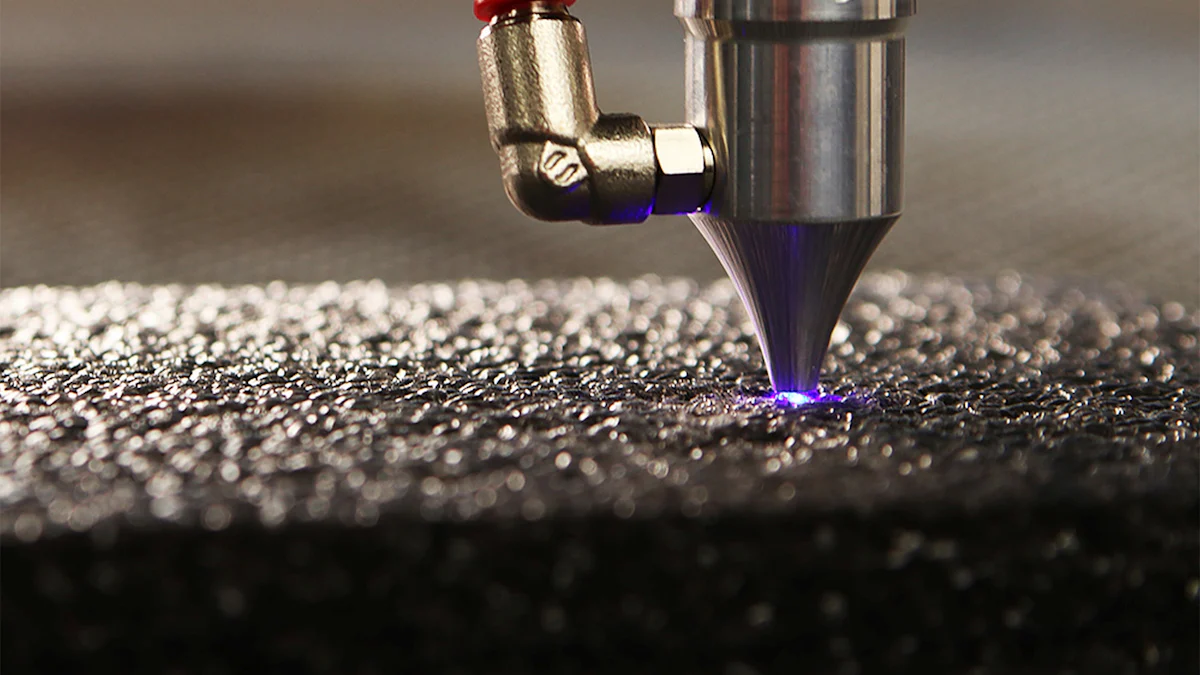

How does laser cutting work?

Laser cutting involves focusing a high-powered laser beam onto a material. The laser melts, burns, or vaporizes the material, creating a clean cut. You can adjust the laser's intensity and speed to suit different materials and thicknesses.

What materials can you cut with a laser cutter?

You can cut a wide range of materials with a laser cutter. Common materials include metals, plastics, wood, and textiles. Each material requires specific settings to achieve the best results, so understanding your machine's capabilities is crucial.

How do you choose the right laser cutting machine?

Choosing the right laser cutting machine depends on your needs. Consider factors like the materials you plan to cut, the precision required, and your budget. Research different types of machines and consult with manufacturers to find the best fit for your applications.

What are the benefits of using laser cutting?

Laser cutting offers several benefits. It provides high precision and accuracy, allowing for intricate designs. The process is fast and efficient, reducing production time. Additionally, laser cutting minimizes waste and produces clean edges, enhancing the quality of the final product.

Is laser cutting safe?

Laser cutting is generally safe when you follow proper safety protocols. Always wear protective eyewear and ensure the machine is in a well-ventilated area. Regular maintenance and inspections help prevent accidents and ensure the machine operates safely.

How do you maintain a laser cutting machine?

Regular maintenance is essential for optimal performance. Clean the machine's lenses and mirrors frequently to ensure clear laser paths. Check for any wear and tear on components and replace them as needed. Follow the manufacturer's guidelines for routine maintenance tasks.

Can you use laser cutting for engraving?

Yes, you can use laser cutting machines for engraving. By adjusting the laser's power and speed, you can etch designs onto various materials. Engraving is ideal for adding logos, text, or intricate patterns to your projects.

What is the cost of operating a laser cutting machine?

Operating costs vary based on factors like power consumption, maintenance, and material costs. While initial investment might be high, laser cutting machines often offer long-term savings through efficiency and reduced waste.

How do you improve laser cutting quality?

To improve laser cutting quality, ensure your machine is well-maintained and calibrated. Use the correct settings for each material, and experiment with different speeds and power levels. Regularly update software and firmware to access the latest features and improvements.

See Also

Comparative Guide to Laser Cutting Machine Prices

Cost Analysis of Water Jet Cutting Machines

Understanding the Functionality of CNC Laser Cutters