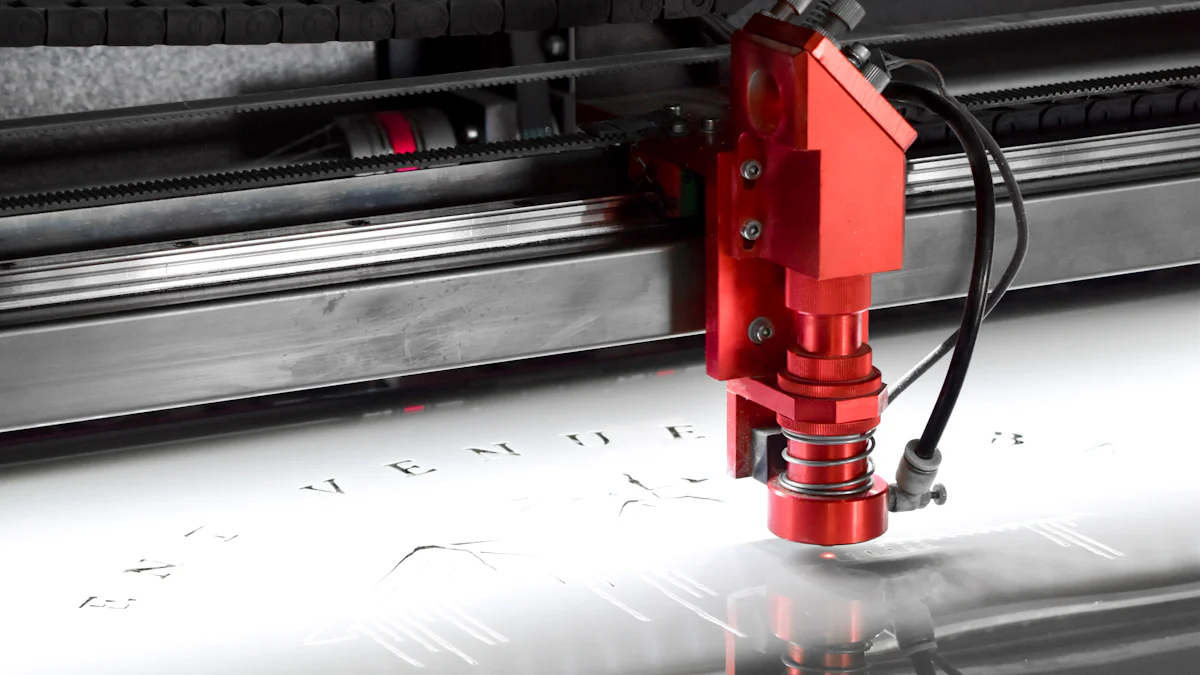

How Much Do Laser Cutting Machines Cost Today?

Understanding how much do laser cutting machines cost today is crucial for anyone considering an investment in this technology. Prices can vary significantly, ranging from as low as $500 for basic models to over $1 million for advanced industrial machines. Several factors influence these costs, including the type of laser cutting machine, its power, and additional features. You must grasp these elements to make an informed decision. Whether you're looking at entry-level options or high-end industrial machines, knowing what affects pricing helps you choose the right machine for your needs.

Types of Laser Cutting Machines

When exploring the world of laser cutting, you will encounter various types of machines, each with unique features and costs. Understanding these differences helps you make an informed decision.

CO2 Laser Cutting Machines

CO2 laser cutting machines are popular for their versatility and efficiency. They excel in cutting non-metal materials like wood, acrylic, and fabric.

Typical Costs

The cost of a CO2 laser cutting machine typically ranges from $8,000 to $50,000. This price range depends on the power output, which usually varies between 100W and 500W. These machines offer advanced cutting technology, allowing you to handle intricate details with precision.

Factors Affecting Pricing

Several factors influence the pricing of CO2 laser cutters. The power output significantly impacts the cost. Higher power machines cut faster and handle thicker materials. Additionally, the brand and manufacturer can affect the price. Reputable brands often charge more due to their reliability and customer support. Accessories and parts also contribute to the overall cost.

Fiber Laser Cutting Machines

Fiber laser cutting machines are known for their high power density and speed. They are ideal for cutting metals and other tough materials.

Cost Range

The cost of a fiber laser cutting machine can vary widely. Entry-level models start around $20,000, while high-end industrial machines can exceed $1 million. The price depends on the machine's power and capabilities.

Influencing Factors

Several factors influence the cost of fiber laser cutters. The power and speed of the machine play a crucial role. Higher power machines cut faster and more efficiently. The brand and manufacturer also impact the price. Well-known brands often charge more due to their reputation and quality. Additional features, such as automation and customization options, can increase the cost.

Nd:YAG Laser Cutting Machines

Nd:YAG laser cutting machines, also known as crystal laser cutters, are used for high-precision applications. They are suitable for cutting metals and other hard materials.

Cost Details

The cost of an Nd:YAG laser cutting machine varies based on its specifications. These machines are generally more expensive than CO2 and fiber lasers due to their precision and specialized applications.

Considerations

When considering an Nd:YAG laser cutter, you should evaluate the machine's power and precision. These factors significantly impact the cost. The brand and manufacturer also play a role in pricing. Reputable brands often charge more for their reliability and support. Additional features, such as advanced software and automation, can increase the overall cost.

Understanding the different types of CNC laser cutting machines and their costs is essential for making an informed decision. Whether you choose a CNC CO2 laser cutter, CNC fiber laser cutter, or CNC crystal laser cutter, knowing the factors that influence pricing helps you select the right machine for your needs.

Factors Influencing Costs

Understanding the factors that influence the cost of laser cutting machines is essential for making informed purchasing decisions. These factors can significantly impact the overall price and functionality of the machine.

Power and Speed

Impact on Price

The power and speed of a laser cutting machine play a crucial role in determining its cost. Machines with higher power outputs can cut through thicker materials and perform operations more quickly. This capability often results in higher prices. For instance, a CNC laser cutting machine with a power output of 500W will typically cost more than one with a 100W output. The increased efficiency and speed of high-power machines make them ideal for industrial applications, where time and precision are critical.

Brand and Manufacturer

Effect of Brand Reputation on Cost

The brand and manufacturer of a laser cutting machine can also affect its price. Reputable brands often charge more due to their established reputation for quality and reliability. When you choose a well-known brand, you are likely paying for the assurance of superior customer support and durable products. However, lesser-known brands might offer similar features at a lower cost, but they may lack the same level of support and reliability.

Additional Features

Costs Associated with Advanced Features and Customization

Additional features and customization options can significantly increase the cost of a laser cutting machine. Features such as automation, advanced software, and specialized cutting capabilities add to the machine's price. For example, a CNC laser cutting machine equipped with automated loading and unloading systems will cost more than a basic model. These advanced features enhance the laser cutting process by improving efficiency and precision, making them valuable for specific applications.

When considering the purchase of a laser cutting machine, it's important to evaluate these factors carefully. By understanding how power, brand, and additional features influence costs, you can select a machine that meets your needs and budget. Whether you're investing in a CNC laser cutting machine for industrial use or a smaller model for personal projects, knowing what affects pricing will guide you in making the right choice.

Understanding the costs of laser cutting machines involves considering several key factors. You should evaluate the type of machine, its power, and the reputation of the manufacturer. These elements help you make an informed decision that aligns with your budget and specific needs. It's not just about finding the cheapest option or the most powerful machine. Instead, focus on how well the machine meets your production requirements and long-term goals. By balancing these considerations, you can select a laser cutting machine that enhances your capabilities and ensures a sound investment.

FAQ

What materials can laser cutting machines be used on?

Laser cutting machines can work on a wide variety of materials. You can use them on wood, acrylic, fabric, leather, metal, and even paper or cardboard. This versatility makes laser cutting machines ideal for enhancing products in various businesses. Whether you create or sell items, there's likely a way a laser machine can help improve your offerings.

How does the power of a laser cutting machine affect its performance?

The power of a laser cutting machine directly impacts its performance. Higher power machines can cut through thicker materials and do so more quickly. If you need to handle heavy-duty tasks, consider investing in a machine with higher power output. This choice ensures efficiency and precision in your cutting operations.

Are there any safety concerns when using laser cutting machines?

Yes, safety is crucial when using laser cutting machines. Always wear protective eyewear to shield your eyes from the laser beam. Ensure proper ventilation in the workspace to avoid inhaling fumes. Regularly maintain the machine to prevent malfunctions. Following these precautions helps ensure a safe working environment.

Can laser cutting machines be used for engraving?

Absolutely, laser cutting machines excel at engraving. You can use them to engrave intricate designs on various materials like wood, metal, and acrylic. This capability allows you to add personalized touches to products, making them unique and appealing to customers.

How do additional features affect the cost of a laser cutting machine?

Additional features can significantly increase the cost of a laser cutting machine. Features like automation, advanced software, and specialized cutting capabilities add to the price. While these features enhance efficiency and precision, consider your specific needs before opting for them to ensure they align with your budget.

What maintenance is required for laser cutting machines?

Regular maintenance is essential for optimal performance. Clean the machine's lenses and mirrors to ensure clear laser paths. Check and replace filters to maintain proper ventilation. Regularly inspect the machine for wear and tear. These steps help prolong the machine's lifespan and maintain its efficiency.

How do I choose the right laser cutting machine for my needs?

To choose the right laser cutting machine, consider the materials you will work with and the machine's power requirements. Evaluate the brand's reputation and the additional features you might need. Balancing these factors with your budget ensures you select a machine that meets your specific needs.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Understanding the Costs of Water Jet Cutting Machines

Exploring Cutting Machine Prices and Their Varieties