How Much is a CNC Laser Cutting Machine in 2024

In 2024, if you're wondering how much is CNC laser cutting machine, you can expect to pay an average of $6,000. The cost varies widely based on several factors. These include the machine's manufacturer, type, power, and the complexity of its parts. Additionally, the area where you purchase the machine can influence the price. Whether you're looking for an entry-level laser cutter or a high-end model, understanding these factors will help you make an informed decision.

Understanding the Cost of CNC Laser Cutting Machines

When you explore the world of CNC laser cutting machines, understanding the cost is crucial. These machines come in various price ranges, each offering different features and capabilities. Let's delve into the specifics.

Price Range Overview

Entry-Level Machines

Entry-level CNC laser cutters are perfect for beginners or those on a budget. You can find these machines priced under $3,500. They offer basic features suitable for small projects and hobbyists. The best budget laser cutter in this category might not have all the bells and whistles, but it provides excellent value for simple tasks.

Mid-Range Machines

Mid-range laser cutters, priced between $3,500 and $10,000, offer a balance of performance and cost. These machines are ideal for small businesses or serious hobbyists. They often include enhanced features like better precision and faster cutting speeds. The best overall laser cutter in this range provides a good mix of quality and affordability.

High-End Machines

High-end CNC laser cutting machines, costing over $10,000, are designed for professional use. These machines boast advanced features, high power, and exceptional precision. They are the best choice for industrial applications and large-scale projects. If you're looking for the best laser cutter for metal, this category offers the most powerful options.

Factors Influencing Price

Machine Type

The type of CNC laser cutter significantly affects its price. CO2, fiber, and diode lasers each have unique characteristics. Fiber lasers, for instance, are often considered the best laser for home business due to their efficiency and versatility.

Power and Wattage

Power and wattage play a crucial role in determining a laser cutter's capabilities. Higher wattage machines can cut through thicker materials and work faster. This feature is essential if you're seeking the best premium laser for demanding tasks.

Features and Capabilities

The features and capabilities of a laser cutting machine also impact its price. Machines with advanced software, larger cutting areas, and higher precision come at a premium. The best laser engraver for schools, for example, might include user-friendly software and safety features, making it suitable for educational environments.

Types of CNC Laser Cutting Machines

When choosing a CNC laser cutter, understanding the different types available is essential. Each type offers unique features and benefits, catering to various needs and applications.

CO2 Laser Cutters

Typical Price Range

CO2 laser cutters are versatile machines that can handle a wide range of materials. You can expect to pay around $15,000 for a powerful CO2 laser cutter capable of cutting plastics, wood, and even thin metals. Prices can increase based on size and power.

Features and Benefits

CO2 laser cutters use a gas laser based on a carbon dioxide mix. They excel in cutting and engraving a broad selection of materials, including glass, acrylic, and thicker woods. These machines are powerful, making them suitable for more demanding tasks. However, they require more power to operate and may struggle with reflective materials due to potential beam bounce-back issues.

Fiber Laser Cutters

Typical Price Range

Fiber laser cutters are the go-to choice for metal cutting. They are efficient and versatile, with prices typically starting higher than CO2 lasers due to their advanced capabilities. The cost reflects their ability to cut a wide range of materials, including highly reflective metals.

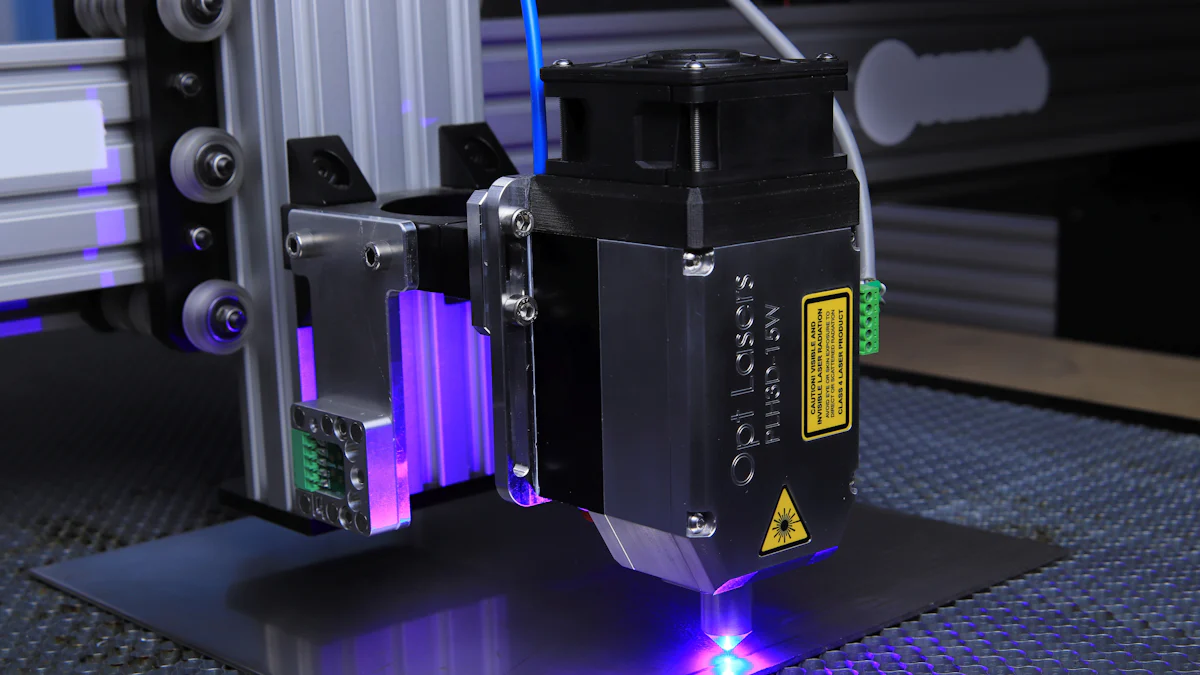

Features and Benefits

Fiber laser cutters are renowned for their precision and efficiency. They are the best laser cutter for metal applications, offering safe and effective cutting of reflective materials. These machines are ideal for industrial use, providing high power and exceptional accuracy.

Diode Laser Cutters

Typical Price Range

Diode laser cutters are more affordable, often used by hobbyists. They are smaller and less expensive, making them accessible for personal projects. Prices vary based on power and features, but they generally remain lower than CO2 and fiber lasers.

Features and Benefits

Diode laser cutters are excellent for engraving on materials like wood, leather, and some plastics. They are not intended for heavy use but offer a cost-effective solution for simple tasks. While they lack the power to cut thicker materials, they provide a user-friendly experience for beginners and hobbyists.

Understanding these types of CNC laser cutting machines helps you choose the best laser cutter for your needs. Whether you require a machine for hobby projects or industrial applications, knowing the features and price ranges will guide your decision.

Additional Costs to Consider

When purchasing a CNC laser cutter, you should consider additional costs beyond the initial price. These costs can significantly impact your budget and the overall cost of ownership. Let's explore these expenses in detail.

Maintenance and Repairs

Regular maintenance is crucial for keeping your CNC laser cutting machine in optimal condition. You should budget for annual maintenance costs, which can vary depending on the machine's complexity and usage. Routine checks help prevent unexpected breakdowns and extend the machine's lifespan. Some manufacturers offer warranty and repair services, which can reduce repair costs. However, it's essential to understand the terms of these services to avoid unexpected expenses. A study on the lifetime costs of laser cutting machines emphasizes the importance of predictive maintenance. By automating monitoring and training personnel, you can reduce expenditures related to parts and service.

Software and Upgrades

Software plays a vital role in the functionality of laser cutters. You may need to purchase additional software or upgrades to enhance your machine's capabilities. These upgrades can include new features, improved performance, or compatibility with different materials. It's important to factor in these costs when planning your budget. Staying updated with the latest software ensures your CNC laser cutter operates efficiently and meets your needs.

Accessories and Consumables

Accessories and consumables are essential for the operation of a laser cutting machine. You might need items like lenses, mirrors, and cutting beds, which can wear out over time. Consumables such as gases and cooling fluids also contribute to ongoing costs. It's wise to keep a stock of these items to avoid interruptions in your work. Planning for these expenses ensures your CNC laser cutting projects run smoothly and efficiently.

Understanding these additional costs helps you make informed decisions when purchasing a CNC laser cutter. By considering maintenance, software, and consumables, you can better manage your budget and ensure the longevity of your investment.

Choosing the best laser cutter involves understanding your specific needs and budget. You have explored various types of CNC laser cutters, from the best small-scale CO2 laser cutter to the best laser cutter for metal. Each offers unique features and benefits. Consider factors like power, precision, and additional costs. For beginners, the best home crafting laser cutter or the best portable laser etcher might be ideal. If you need a best in-office laser cutter, focus on quality and efficiency. This guide empowers you to select the best CNC laser cutter that enhances your projects and provides great value.

FAQ

What Materials Can a CNC Laser Cut?

A CNC laser cutter can handle a variety of materials. You can create personalized signs using acrylic, plywood, and leather. These materials are popular for businesses, shops, and advertisements. Many people seek personalized signs for their businesses and special occasions.

How Do I Choose the Right Laser Cutter for My Needs?

Selecting the right laser cutter depends on your specific needs. Consider the materials you plan to cut and the precision required. Entry-level laser cutters suit hobbyists, while high-end models cater to industrial applications. Evaluate the machine's power, features, and price range to make an informed decision.

Are Laser Cutters Safe to Use?

Yes, laser cutters are safe when used correctly. Always follow the manufacturer's safety guidelines. Wear protective eyewear and ensure proper ventilation in your workspace. Regular maintenance also helps prevent accidents and ensures the machine operates safely.

How Often Should I Maintain My Laser Cutter?

Regular maintenance is crucial for optimal performance. Check your laser cutter's components, such as lenses and mirrors, periodically. Clean and replace parts as needed. Routine maintenance prevents unexpected breakdowns and extends the machine's lifespan.

Can a Laser Cutter Engrave as Well?

Yes, many laser cutters can engrave materials in addition to cutting them. This feature allows you to add intricate designs and text to various surfaces. Engraving enhances the versatility of your laser cutter, making it suitable for a wide range of projects.

What Are the Additional Costs Associated with Laser Cutters?

Beyond the initial purchase, consider costs like maintenance, software upgrades, and consumables. Accessories such as lenses and mirrors may need replacement over time. Budgeting for these expenses ensures smooth operation and longevity of your laser cutter.

How Does Power and Wattage Affect a Laser Cutter's Performance?

Power and wattage determine a laser cutter's capabilities. Higher wattage machines cut through thicker materials and work faster. If you require a laser cutter for demanding tasks, consider investing in a machine with higher power.

Can I Use a Laser Cutter for Metal?

Yes, certain laser cutters, like fiber lasers, excel at cutting metal. They offer precision and efficiency, making them ideal for industrial applications. Ensure your chosen laser cutter is suitable for the specific type of metal you plan to work with.

What Is the Lifespan of a Laser Cutter?

The lifespan of a laser cutter varies based on usage and maintenance. With proper care, a laser cutter can last several years. Regular maintenance and timely repairs help extend its operational life.

Are There Portable Laser Cutters Available?

Yes, portable laser cutters are available for those who need mobility. These compact machines are perfect for small projects and home use. They offer convenience without sacrificing functionality.

See Also

Comparative Guide to Laser Cutting Machine Prices

Cost Analysis of Water Jet Cutting Machines

Exploring Prices and Types of Cutting Machines