How Much Are Laser Metal Cutting Machines for 8x4?

When you explore the market for 8x4 laser metal cutting machines, you'll find a wide price range. These machines can cost anywhere from $2,000 to over $55,000. The variation in price depends on several factors, including the machine's features and specifications. For instance, some models offer basic functionality, while others come equipped with advanced technology and capabilities. This diversity allows you to choose a machine that fits your budget and meets your specific needs. Understanding how much are laser metal cutting machines for 8x4 can help you make an informed purchasing decision.

Pricing Breakdown

Factors Influencing Price

When you consider purchasing an 8x4 laser metal cutting machine, several factors will influence the price.

Brand and Manufacturer

The brand and manufacturer play a significant role in determining the cost. Well-known brands often charge more due to their reputation for quality and reliability. You might find lesser-known brands offering similar features at a lower price, but they may lack the same level of customer support or warranty.

Power and Wattage

Power and wattage directly impact the machine's performance and price. Higher wattage machines cut through thicker metals more efficiently, which makes them more expensive. If your projects involve thinner materials, you can opt for a lower wattage machine to save money.

Additional Features and Accessories

Additional features and accessories can also affect the price. Some machines come with advanced features like automatic loading systems or enhanced safety mechanisms. These features can increase the cost but may improve efficiency and safety in your operations.

Price Range Overview

Understanding the price range helps you make an informed decision based on your budget and needs.

Entry-Level Models

Entry-level models typically range from $2,000 to $10,000. These machines offer basic functionality and are suitable for small-scale operations or hobbyists. They may lack some advanced features but provide a cost-effective solution for simple tasks.

Mid-Range Options

Mid-range options fall between $10,000 and $30,000. These machines offer a balance between cost and features. They often include better power and precision, making them ideal for small to medium-sized businesses.

High-End Machines

High-end machines can cost over $30,000, reaching up to $55,000 or more. These machines come equipped with the latest technology and features, providing superior performance and efficiency. They are best suited for large-scale industrial applications where precision and speed are crucial.

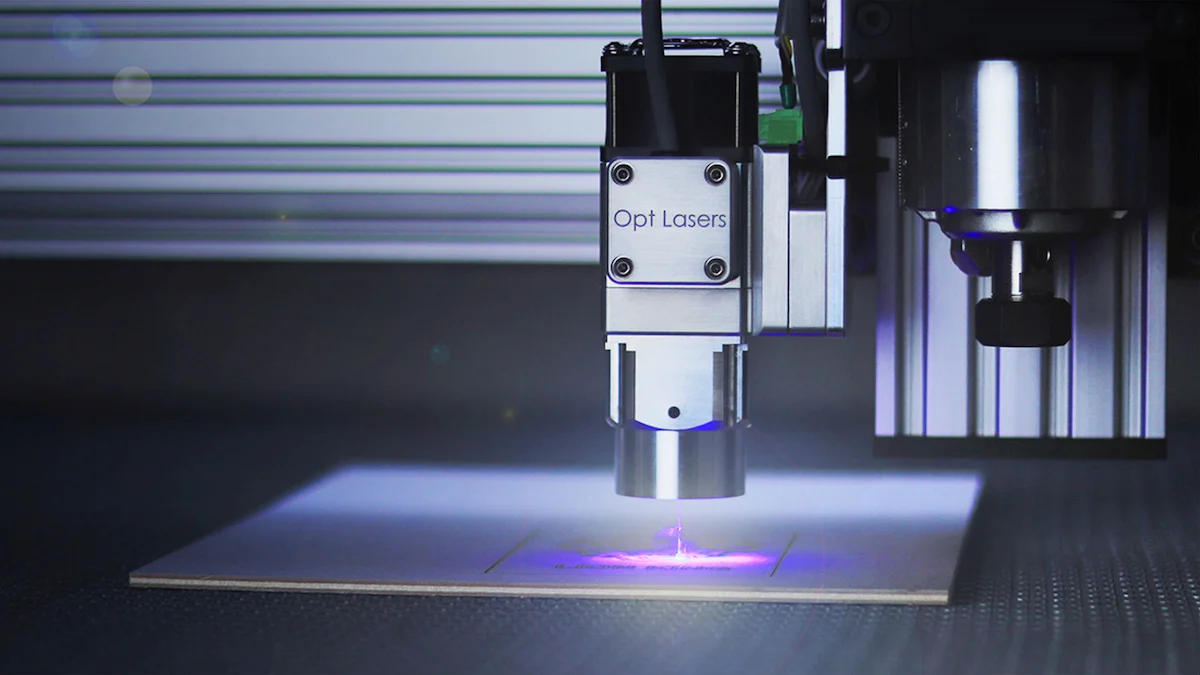

Key Features of 8x4 Laser Metal Cutting Machines

Cutting Speed and Efficiency

When you evaluate laser metal cutting machines, speed and efficiency stand out as crucial factors. Different models offer varying speeds, which can significantly impact your production process.

Speed Variations Across Models

Laser cutting machines exhibit diverse speed capabilities. Some models prioritize rapid cutting, ideal for high-volume tasks. Others focus on precision, sacrificing speed for accuracy. For instance, higher power machines often deliver faster cutting speeds, especially when dealing with thicker materials. This variation allows you to select a machine that aligns with your specific operational needs.

Impact on Production Time

The speed of a laser cutter directly influences production time. Faster machines reduce the time needed to complete projects, enhancing overall productivity. If your operations demand quick turnaround times, investing in a high-speed model can prove beneficial. However, balancing speed with precision ensures that quality is not compromised in the pursuit of efficiency.

Precision and Accuracy

Precision remains a hallmark of laser cutting technology. The ability to achieve fine details and clean cuts sets these machines apart from traditional methods.

Importance for Different Applications

Precision plays a pivotal role across various applications. Whether you're crafting intricate designs or cutting complex patterns, high accuracy ensures the final product meets exact specifications. This level of detail is particularly important in industries where precision is non-negotiable, such as aerospace or medical device manufacturing.

Technological Enhancements

Modern laser cutters incorporate technological advancements to enhance precision. Features like automatic calibration and advanced software controls contribute to achieving consistent results. These enhancements not only improve accuracy but also simplify the operation, making it easier for you to achieve desired outcomes.

Material Compatibility

Understanding material compatibility is essential when selecting a laser cutter. Different machines support various metals and thicknesses, influencing their versatility.

Types of Metals Supported

Most 8x4 laser metal cutting machines can handle a range of metals, including steel, aluminum, and copper. This versatility allows you to work with multiple materials without needing separate equipment. However, verifying the specific metals supported by a machine ensures it meets your project requirements.

Thickness Capabilities

The thickness a machine can cut depends on its power and design. Higher wattage machines typically handle thicker materials more effectively. Knowing the thickness capabilities helps you choose a machine that aligns with your project's demands, ensuring efficient and effective cutting.

Cost vs. Features Analysis

When choosing an 8x4 laser metal cutting machine, you must weigh the cost against the features offered. This analysis helps you determine the best value for your investment.

Comparing Different Models

Value for Money

To ensure you get the most out of your purchase, consider the machine's capabilities and reliability. A higher price doesn't always guarantee better performance. Evaluate what each model offers in terms of power, precision, and additional features. By establishing your budget upfront, you can narrow down your options and avoid overspending. Prioritizing essential features over optional ones can help you find a machine that meets your needs without breaking the bank.

Feature Set Comparison

Different models come with varying feature sets. Some machines offer advanced technology like automatic calibration or enhanced safety mechanisms. Others focus on basic functionality. Compare these features to see which ones align with your operational requirements. A machine with a robust feature set might cost more initially but could save you time and resources in the long run.

Evaluating Long-Term Investment

Maintenance and Operating Costs

Beyond the initial purchase price, consider ongoing maintenance and operating costs. Machines with higher power and advanced features might require more frequent servicing. Factor in material waste and processing time as well. Efficient machines reduce waste and speed up production, leading to cost savings over time. Understanding these costs helps you plan your budget more effectively.

Return on Investment Considerations

Think about the long-term benefits of your investment. A machine that offers high quality and efficiency can enhance your production capabilities. This improvement can lead to increased revenue and a quicker return on investment. Analyze how the machine's features contribute to your business goals. A well-chosen machine not only meets your current needs but also supports future growth.

In your journey to find the right 8x4 laser metal cutting machine, balancing cost with features is crucial. Consider the machine's capabilities and reliability to ensure you get good value for your money. Establishing a specific budget upfront helps narrow down options and avoid overspending. Consult with manufacturers or suppliers to verify specifications and receive tailored recommendations. By focusing on your specific needs and requirements, you can select a machine that aligns with your production goals without compromising on quality or efficiency.

FAQ

Is the laser cutting machine dangerous to operate?

Laser cutting machines can pose risks if not used properly. However, manufacturers design these machines with safety features to protect you. Always follow the user manual and wear appropriate safety gear. Ensure that the work area is well-ventilated to avoid inhaling fumes. Regular maintenance checks also help in preventing accidents.

What materials can I cut with an 8x4 laser metal cutting machine?

You can cut a variety of metals, including steel, aluminum, and copper. Each machine has specific material compatibility, so check the manufacturer's guidelines. Some machines also handle non-metal materials, expanding their versatility.

How do I maintain my laser cutting machine?

Regular maintenance ensures optimal performance. Clean the machine after each use to remove debris. Check the alignment of the laser and replace worn-out parts promptly. Follow the manufacturer's maintenance schedule for detailed instructions.

How does power and wattage affect cutting performance?

Higher wattage machines cut thicker materials more efficiently. They offer faster cutting speeds, which can enhance productivity. If you work with thinner materials, a lower wattage machine might suffice, saving you money.

Can I upgrade my laser cutting machine?

Some machines allow upgrades to enhance performance. You might add features like automatic loading systems or software updates. Consult the manufacturer to understand upgrade options and compatibility.

What should I consider when choosing a laser cutting machine?

Consider factors like power, precision, and additional features. Evaluate your budget and the specific needs of your projects. Research different brands and read customer reviews to make an informed decision.

How long does a laser cutting machine last?

The lifespan of a laser cutting machine depends on usage and maintenance. With proper care, these machines can last several years. Regular servicing and part replacements extend their longevity.

Are there any environmental concerns with laser cutting?

Laser cutting can produce fumes and waste materials. Ensure proper ventilation in your workspace. Some machines come with filtration systems to minimize environmental impact. Dispose of waste materials responsibly.

How do I ensure precision in my cuts?

Precision depends on the machine's technology and your settings. Use advanced features like automatic calibration for consistent results. Practice and adjust settings according to the material and design requirements.

What is the return on investment for a laser cutting machine?

A well-chosen machine enhances production capabilities, leading to increased revenue. Consider initial costs, maintenance, and potential business growth. A machine that meets your needs efficiently offers a quicker return on investment.

See Also

Comparative Guide to Laser Cutting Machine Prices

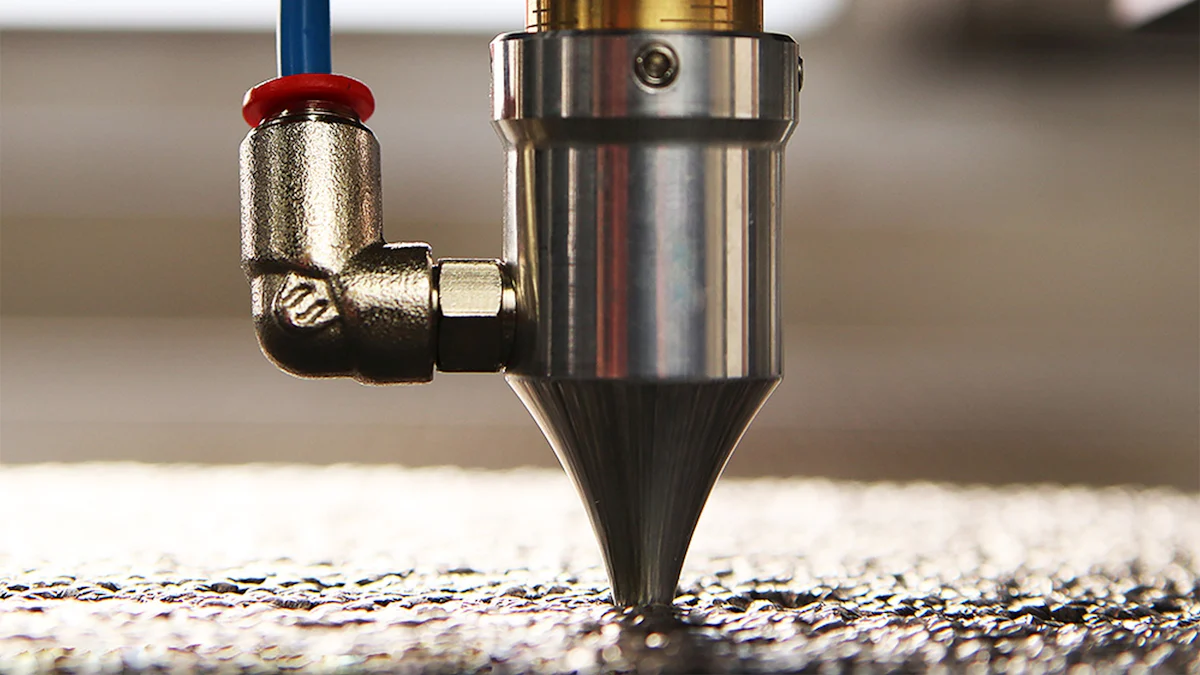

Cost Analysis of Water Jet Cutting Machines

Understanding Prices and Types of Cutting Machines