How Much Are Laser Cutting Machines Stainless Steel?

When you consider purchasing a stainless steel laser cutting machine, you might wonder, "How much are laser cutting machines stainless steel?" The price varies significantly, ranging from $2,000 for basic models to over $200,000 for high-end industrial machines. This wide range reflects the diverse capabilities and features these machines offer. For instance, entry-level models provide essential functions, while advanced machines boast enhanced precision and power. Understanding these price differences helps you make informed decisions based on your specific needs and budget.

Factors Affecting Cost

When you explore the cost of stainless steel laser cutting machines, several factors come into play. Understanding these elements helps you make an informed decision and choose the best laser cutters for your needs.

Machine Power

Impact of wattage on cutting capabilities and cost

The power of a laser cutting machine, measured in wattage, directly influences its cutting capabilities and price. Higher wattage machines can cut through thicker materials with ease. This increased power often results in a higher price tag. For instance, machines with a power range of 1,500W to 6,000W are commonly used for stainless steel cutting. These machines typically cost between $15,000 and $73,000, depending on their specifications.

Efficiency and energy consumption considerations

Efficiency and energy consumption are crucial when evaluating laser cutters. Machines with higher wattage may consume more energy, impacting operational costs. However, they often offer faster cutting speed, which can enhance productivity. Balancing power and efficiency ensures you get the best value for your investment.

Brand and Manufacturer

Reputation and reliability of different brands

The brand of a laser cutting machine significantly affects its cost. Established brands often charge a premium due to their reputation for reliability and durability. These brands invest in cutting-edge technology, ensuring their machines meet industrial standards. When choosing a machine, consider the brand's history and customer reviews to gauge its reliability.

Influence of brand on pricing

Brand influence extends beyond reputation. It also impacts pricing. Premium brands may offer advanced features and superior build quality, justifying their higher prices. However, lesser-known brands might provide competitive options at a lower cost. Evaluating the brand's offerings helps you find the best laser cutters within your budget.

Machine Size and Capacity

How size affects cost and application

The size of a laser cutting machine affects both its cost and application. Larger machines typically cost more due to their enhanced capacity and ability to handle bigger projects. They are ideal for industrial applications where large-scale production is necessary. Smaller machines, while less expensive, may suit smaller operations or hobbyists.

Space and operational requirements

Consider the space and operational requirements of the machine. Larger machines require more space and may need specific environmental conditions to operate efficiently. Ensure your workspace can accommodate the machine's size and that you have the necessary infrastructure to support its operation. This consideration helps you avoid unexpected costs and ensures smooth integration into your workflow.

Additional Features

Automation and software integration

Automation and software integration play a crucial role in modern laser cutting machines. These features enhance the machine's efficiency and precision. Automated systems allow you to streamline operations, reducing manual intervention. This leads to faster production times and consistent quality. Software integration enables you to control the machine with ease. You can input designs directly from CAD software, ensuring accuracy in every cut.

When considering a laser cutting machine, evaluate its automation capabilities. Machines with advanced automation often come at a higher price. However, they offer significant long-term benefits. You save time and reduce labor costs, making them a valuable investment for businesses aiming to increase productivity.

Safety features and their cost implications

Safety features are essential in laser cutting machines. They protect operators and ensure safe operation. Common safety features include emergency stop buttons, protective enclosures, and laser beam shields. These features prevent accidents and minimize risks associated with laser cutting.

Investing in machines with robust safety features is crucial. While they may increase the initial cost, they provide peace of mind and comply with safety regulations. Prioritizing safety ensures a secure working environment, reducing the likelihood of costly accidents and downtime.

Types of Stainless Steel Laser Cutting Machines

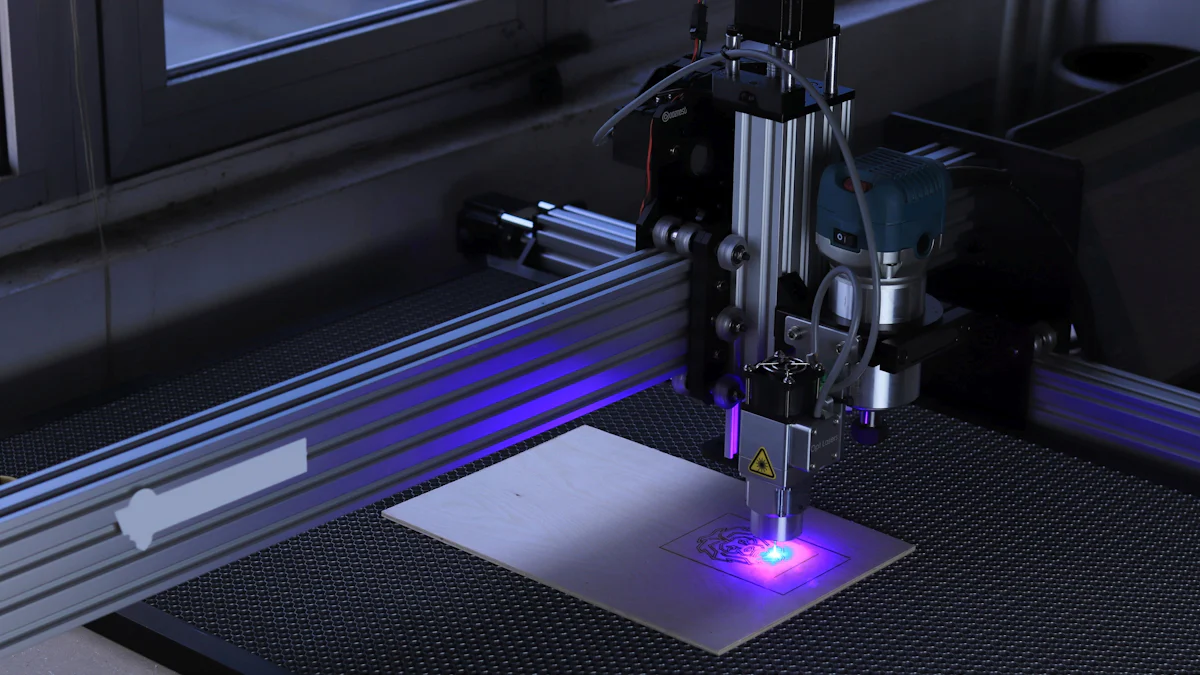

When selecting a stainless steel laser cutting machine, understanding the different types available can help you make an informed decision. Each type offers unique advantages and considerations, impacting your cutting speed and edge quality.

CO2 Laser Cutting Machines

Overview and typical applications

CO2 laser cutting machines utilize a gas mixture to produce a laser beam. These machines excel in cutting non-metal materials like wood, acrylic, and plastics. However, they also handle stainless steel effectively, making them versatile for various applications. You might find CO2 lasers suitable for projects requiring intricate designs and smooth edge quality.

Cost implications and maintenance needs

CO2 lasers generally have lower initial costs compared to fiber lasers. However, they require regular maintenance, including gas refills and mirror alignments. These maintenance tasks can increase operational costs over time. Despite this, CO2 lasers remain popular due to their ability to deliver excellent edge quality at a competitive price.

Fiber Laser Cutting Machines

Advantages over CO2 lasers

Fiber laser cutting machines offer several advantages over CO2 lasers. They provide superior cutting speed and precision, especially for metals like stainless steel. The fiber laser's efficiency reduces energy consumption, making it a cost-effective choice for high-volume production. You benefit from faster production cycles and enhanced edge quality, which can significantly boost your productivity.

Cost and efficiency considerations

While fiber lasers have a higher upfront cost, their efficiency and low maintenance needs often result in long-term savings. The automated features and software integration streamline operations, reducing labor costs and material waste. Investing in a fiber laser can enhance your production process, offering a favorable return on investment.

Other Types of Laser Cutting Machines

Diode Laser Cutting Machines

Diode laser cutting machines represent another option for specific applications. These machines use semiconductor diodes to generate the laser beam. While not as common as CO2 or fiber lasers, diode lasers offer unique benefits for certain tasks.

Cost implications and specific applications

Diode lasers typically have lower power output, making them suitable for thin materials and detailed work. They are often more affordable, appealing to hobbyists or small businesses with limited budgets. However, their cutting speed and edge quality may not match those of CO2 or fiber lasers, limiting their use in industrial settings.

Understanding the types of stainless steel laser cutting machines helps you choose the right one for your needs. Each type offers distinct features that influence cutting speed, edge quality, and overall cost. By evaluating these factors, you can select a machine that aligns with your production goals and budget.

Cost-Benefit Analysis

When investing in a laser cutting machine, it's crucial to weigh the initial costs against the long-term benefits. This analysis helps you determine the value and efficiency of your purchase over time.

Evaluating Initial Investment vs. Long-term Benefits

Return on investment considerations

Purchasing a laser cutting machine involves a significant initial investment. Entry-level models start around $2,000, while industrial-grade machines can exceed $200,000. Despite the high upfront cost, these machines often offer substantial returns on investment. By enhancing your production capabilities, they enable you to take on more complex projects and increase your output. This boost in productivity can lead to higher revenue, offsetting the initial expense over time.

Operational cost savings

Laser cutting machines also provide operational cost savings. Their precision reduces material waste, ensuring you use resources efficiently. Additionally, modern machines often feature energy-efficient designs, lowering electricity costs. By minimizing waste and energy consumption, you can significantly reduce your operational expenses, further enhancing the machine's value.

Assessing Machine Versatility and Future Needs

Scalability and adaptability

A key advantage of laser cutting machines is their versatility. They can handle a wide range of materials and thicknesses, making them suitable for various applications. This adaptability allows you to scale your operations as your business grows. Whether you're expanding your product line or increasing production volume, a versatile machine can meet your evolving needs without requiring additional investments.

Potential for future upgrades

Consider the potential for future upgrades when selecting a laser cutting machine. Many models offer modular designs, allowing you to enhance their capabilities over time. You might add features like advanced software integration or automation systems to improve cutting speed and precision. These upgrades can extend the machine's lifespan and keep it competitive in a rapidly evolving market. By planning for future enhancements, you ensure your investment remains valuable and relevant.

Tips for Buying

When you're ready to purchase a laser cutting machine, consider several key factors to ensure you make the best choice for your business.

Warranty and Support

Importance of after-sales service

After-sales service plays a crucial role in your purchasing decision. Reliable support ensures that any issues with your machine get resolved quickly, minimizing downtime. A company that offers excellent after-sales service provides peace of mind, knowing that help is available when needed. This support often includes technical assistance, troubleshooting, and regular maintenance checks.

Warranty terms and conditions

Understanding the warranty terms and conditions is essential. A comprehensive warranty covers parts and labor for a specified period, protecting you from unexpected repair costs. Check the warranty's duration and what it includes. Some warranties might cover only specific components, while others offer full coverage. Knowing these details helps you avoid surprises and ensures your investment remains protected.

Aligning Purchase with Business Needs

Assessing current and future production needs

Evaluate your current and future production needs before buying a laser cutting machine. Consider the types of materials you work with and the volume of production. A machine that meets your current requirements might not suffice as your business grows. Choose a machine that can handle increased demand and diverse materials, ensuring it remains useful as your business evolves.

Budgeting and financing options

Budgeting is a critical step in the purchasing process. Determine how much you can afford to spend on a laser cutting machine. Explore financing options if necessary. Many suppliers offer leasing or installment plans, making it easier to manage the cost. Weigh the initial investment against potential long-term savings. Investing in a high-quality machine might seem costly upfront, but it can lead to significant savings over time through increased efficiency and reduced operational costs.

"Enterprises need to comprehensively learn the costs and return on investment of laser cutters to maximize profits."

By carefully considering these tips, you can make an informed decision that aligns with your business goals and financial capabilities.

In this blog, you explored the various factors influencing the cost of stainless steel laser cutting machines. You learned about the impact of machine power, brand reputation, and additional features on pricing. Understanding these elements helps you make informed decisions. Align your machine choice with your budget and specific requirements. Consider the type and thickness of materials you plan to cut. Evaluate the machine's power, speed, and precision. Don't forget the importance of a warranty. It ensures quality and provides peace of mind. By considering these aspects, you can select a machine that meets your needs and maximizes your investment.

FAQ

What factors should I consider when choosing a laser cutting machine?

Selecting the right laser cutting machine involves several key considerations:

- Requirements: Identify the materials and thicknesses you plan to cut.

- Budget: Establish your budget upfront to narrow down options.

- Future Needs: Consider potential growth and scalability.

- Performance: Evaluate the machine's power, speed, and precision.

- Operating Costs: Assess long-term costs, including maintenance and energy consumption.

By analyzing these factors, you can choose a machine that aligns with your needs and budget.

How does machine power affect cutting capabilities?

Machine power, measured in wattage, directly impacts cutting capabilities. Higher wattage machines can cut thicker materials more efficiently. For example, machines with 1,500W to 6,000W are ideal for stainless steel. While higher power increases cost, it enhances productivity and cutting precision.

Are fiber laser cutting machines worth the investment?

Fiber laser cutting machines offer significant advantages, such as superior speed and precision. Although they have a higher initial cost, their efficiency and low maintenance needs often lead to long-term savings. Increased productivity and improved product quality make them a worthwhile investment for many businesses.

What are the benefits of automation in laser cutting machines?

Automation streamlines operations by reducing manual intervention. It enhances efficiency and precision, leading to faster production times and consistent quality. While automated machines may cost more initially, they offer significant long-term benefits, including reduced labor costs and increased productivity.

How important is brand reputation when purchasing a laser cutting machine?

Brand reputation plays a crucial role in determining a machine's reliability and durability. Established brands often charge a premium due to their proven track record. However, lesser-known brands might offer competitive options at lower prices. Evaluating brand reputation helps ensure you choose a reliable machine.

What safety features should I look for in a laser cutting machine?

Safety features protect operators and ensure safe operation. Look for emergency stop buttons, protective enclosures, and laser beam shields. Investing in machines with robust safety features is essential. They provide peace of mind and comply with safety regulations, minimizing risks and downtime.

How do CO2 and fiber lasers differ in terms of applications?

CO2 lasers excel in cutting non-metal materials like wood and acrylic but also handle stainless steel. They offer excellent edge quality at a competitive price. Fiber lasers, however, provide superior speed and precision for metals. They are more efficient, making them ideal for high-volume production.

Can I upgrade my laser cutting machine in the future?

Many laser cutting machines offer modular designs, allowing for future upgrades. You can enhance capabilities with advanced software integration or automation systems. Planning for future enhancements ensures your machine remains valuable and competitive in a rapidly evolving market.

What should I know about warranty and support when buying a laser cutting machine?

After-sales service is crucial. Reliable support minimizes downtime by resolving issues quickly. A comprehensive warranty covers parts and labor, protecting you from unexpected repair costs. Understanding warranty terms helps ensure your investment remains protected.

How can I align my laser cutting machine purchase with my business needs?

Evaluate your current and future production needs. Consider the materials you work with and production volume. Choose a machine that can handle increased demand and diverse materials. Budgeting is critical; explore financing options if necessary to manage costs effectively.

See Also

Understanding The Costs Of Laser Cutting Machines

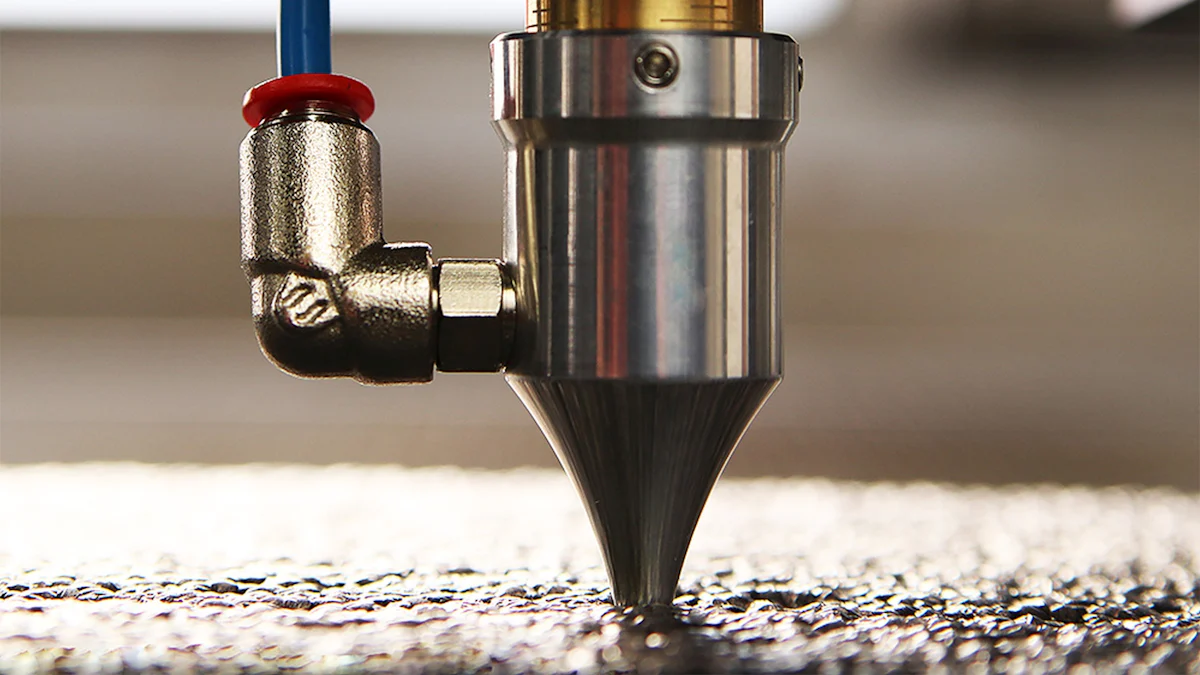

Exploring The Price Of Water Jet Cutting Machines

The Price Range And Types Of Cutting Machines