How Much Are Laser Cutting Machines Reviewed

When considering a purchase, you might wonder, "how much are laser cutting machines?" Prices can vary widely, ranging from as low as $500 to over $600,000. Factors such as brand, type, and features significantly influence these costs. Understanding the price range is crucial before investing in a laser cutter. This knowledge helps you make informed decisions, ensuring you choose a machine that fits your budget and meets your needs. Whether you're a hobbyist or a professional, knowing the cost of a laser cutting machine can guide your purchase effectively.

Price Ranges of Laser Cutting Machines

When exploring the world of laser cutting machines, understanding the price range is essential. This section breaks down the costs into three categories: budget, mid-range, and premium models. Each category offers different features and capabilities, catering to various needs and budgets.

Budget Models

Under $300

If you're just starting out or have a limited budget, you can find laser engravers for under $300. These machines are perfect for beginners and hobbyists. They typically handle simple tasks like engraving on soft materials such as paper and thin wood. While they may not offer the advanced features of more expensive models, they provide a great entry point into the world of laser cutting.

$300 - $500

In the $300 to $500 range, you will find more versatile laser engravers. These machines often come with better build quality and additional features compared to their cheaper counterparts. They can handle a wider variety of materials, making them suitable for small businesses or more serious hobbyists. Although they still have limitations, they offer a good balance between cost and functionality.

Mid-Range Models

$500 - $1000

Mid-range laser cutting machines, priced between $500 and $1000, offer enhanced performance and features. Compact Diode Laser Cutting Machines fall into this category, providing excellent value for those who need to cut thin materials like paper and wood. These machines are ideal for small businesses looking to expand their capabilities without breaking the bank.

$1000 - $2000

For those willing to invest a bit more, the $1000 to $2000 range offers high-performance diode laser engravers. These machines excel in speed and precision, making them the best laser engraver choice for detailed projects. They can cut thicker materials and engrave intricate designs, providing a significant upgrade over budget models.

Premium Models

$2000 and above

Premium laser cutting machines start at $2000 and can go well beyond. CO2 Laser Cutters and Fiber Laser Cutting Machines dominate this category. CO2 lasers, priced from $2,800 to $20,000, handle a wide range of materials, from soft fabrics to hard plastics. They are perfect for complex projects like 3D wood puzzles and fine engravings on glass and ceramics. On the other hand, fiber laser cutting machines, starting at $15,000, are the go-to choice for industrial applications, especially when dealing with metal cutting. These machines offer unparalleled power and precision, making them the best laser engraver for professional use.

Factors Influencing Costs

When choosing a laser cutting machine, understanding the factors that influence costs can help you make an informed decision. These factors include the type of machine, brand reputation, and additional features.

Machine Type

Different types of laser cutters cater to various needs and budgets. Each type offers unique advantages and influences the overall cost.

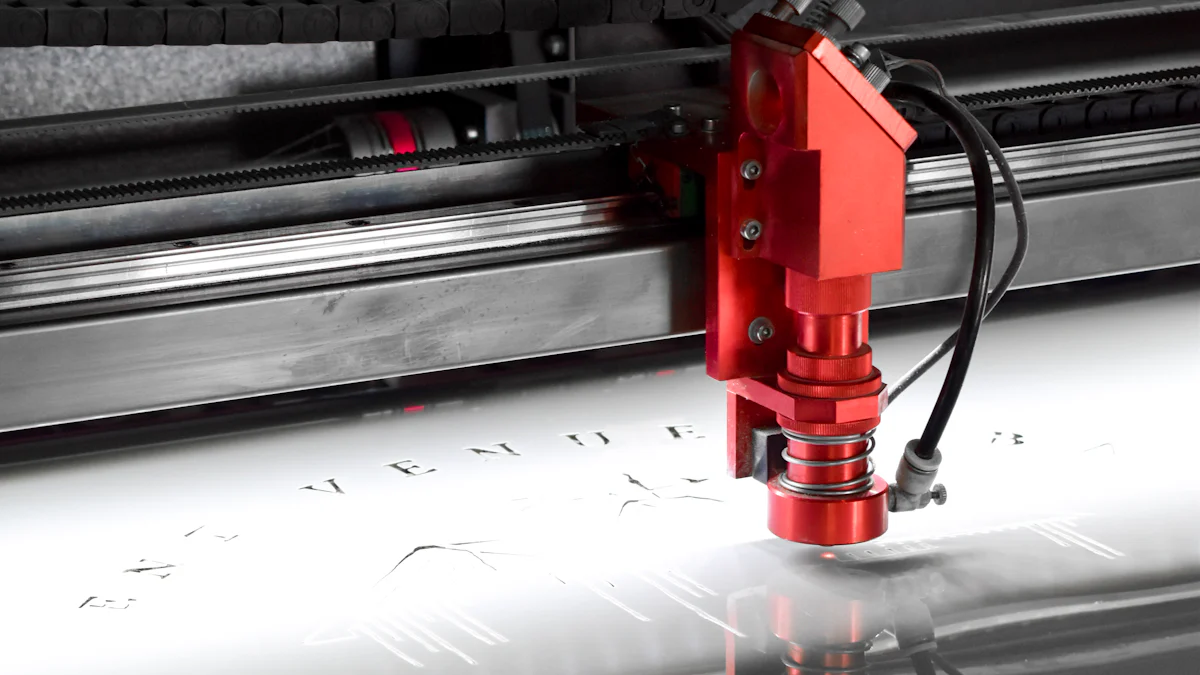

CO2 Laser Cutters

CO2 laser cutters are popular for their versatility. They efficiently handle materials like acrylic, MDF, and fabrics. These machines are ideal for projects requiring clean cuts on non-metal materials. Entry-level CO2 laser cutters start at around $3,500, while high-end models can exceed $20,000. Their ability to work with a wide range of materials makes them a preferred choice for many users.

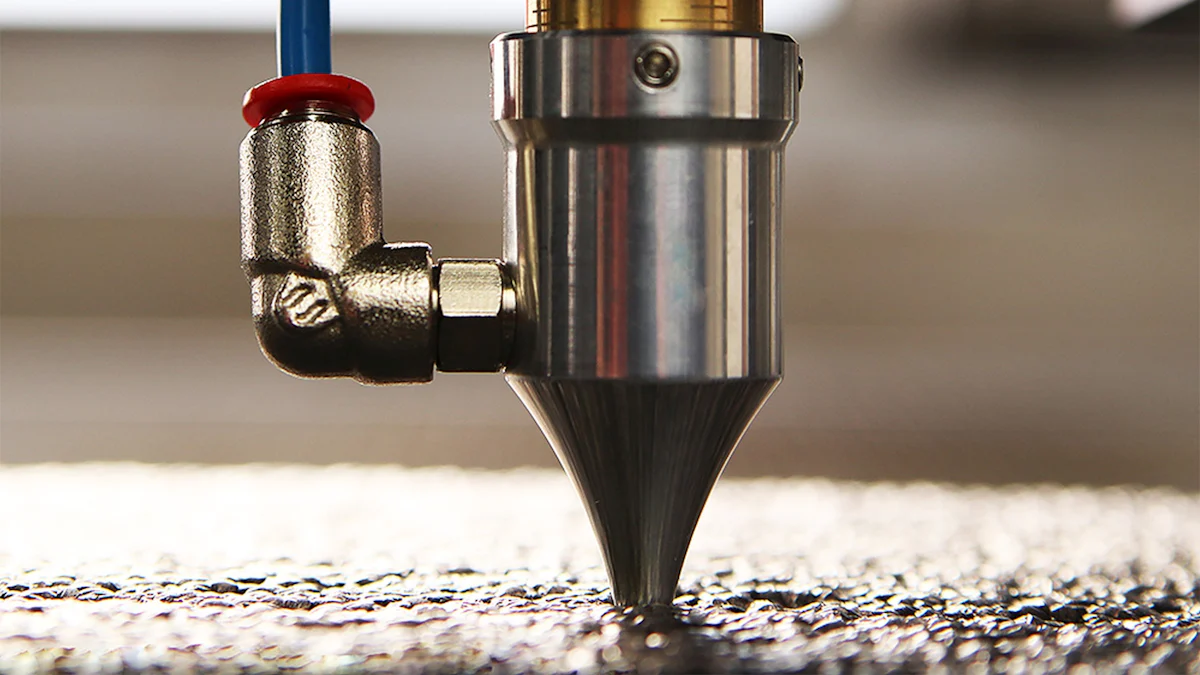

Fiber Laser Cutters

Fiber laser cutters excel in metal cutting, making them the best laser engraver for industrial applications. They are perfect for operations involving metals like stainless steel and carbon steel. Basic models of fiber laser cutters start at approximately $15,000, but industrial-grade machines can cost hundreds of thousands. Their precision and power justify the higher price, especially for professional use.

Diode Laser Cutters

Diode laser cutters are ideal for beginner hobbyists. They offer a cost-effective entry point into laser engraving. These machines are suitable for simple tasks and are often more affordable than CO2 and fiber laser cutters. Diode lasers provide a great balance between functionality and cost for those new to laser cutting.

Brand Reputation

The reputation of a brand can significantly impact the cost of a laser cutting system. Established brands often charge more due to their proven track record and reliability.

Established Brands

Established brands are known for their quality and customer support. They often offer the best laser engraver options with advanced features and durability. While they may come with a higher price tag, the investment can be worthwhile for long-term use.

Emerging Brands

Emerging brands may offer competitive pricing to attract customers. These brands can provide innovative features at a lower cost. However, it's essential to research and ensure they meet your requirements before purchasing.

Additional Features

Additional features can enhance the functionality of a laser engraving machine and influence its cost.

Software Compatibility

Software compatibility is crucial for seamless operation. Machines with advanced software integration may cost more but offer greater flexibility and ease of use. Ensure the laser cutter you choose supports the software you plan to use.

Cutting Speed and Precision

Cutting speed and precision are vital for achieving clean cuts. Machines with higher speed and precision capabilities often come at a premium. Investing in a laser cutting system with these features can improve efficiency and output quality.

Cost-Benefit Analysis

When deciding on a laser cutting machine, weighing the costs against the benefits is crucial. This analysis helps you determine which model best suits your needs and budget.

Investing in Premium Models

Long-term Benefits

Investing in premium laser cutting machines can offer significant long-term benefits. These machines often come with advanced features that enhance operational efficiency. For instance, a fiber laser cutter provides exceptional precision and power, making it ideal for industrial applications. The extended lifespan of these machines justifies the initial investment. Over time, the durability and reliability of premium models can lead to cost savings on maintenance and replacements.

Advanced Features

Premium models often include advanced features that improve performance. Features like a user-friendly control panel, integrated cooling systems, and enhanced software compatibility can significantly enhance your experience. These features not only increase convenience but also boost productivity. According to various laser cutter reviews, premium models often rank as the best laser engraver options due to their superior capabilities. Investing in a high-quality machine ensures you have the tools needed for complex projects.

Choosing Budget Models

Initial Cost Savings

Budget models offer an attractive option for those looking to save on initial costs. These machines provide a cost-effective entry point into the world of laser engraving. While they may lack some advanced features, they still perform basic tasks efficiently. For beginners or hobbyists, a budget laser engraver can be a practical choice. Glowforge review highlights its reputation as a user-friendly laser cutter, making it a popular choice among newcomers.

Limitations and Trade-offs

Choosing a budget model involves certain trade-offs. These machines may have limitations in terms of cutting speed, precision, and material compatibility. While they offer initial cost savings, you might encounter restrictions on the complexity of projects you can undertake. Customer reviews often point out these limitations, emphasizing the importance of understanding what you need from a laser engraving machine. Balancing your budget with your project requirements ensures you select the best option for your needs.

Understanding the costs of laser cutting machines helps you make informed decisions. Consider your needs and budget carefully. For hobbyists, budget models offer a great start. Small businesses might benefit from mid-range options. Professionals should explore premium models for advanced features. Consult experts or suppliers for tailored advice. They can provide demonstrations and share customer experiences. Evaluate brand credibility and customer service. This ensures you choose a reliable laser cutter that meets your requirements and offers long-term benefits.

FAQ

What materials can a laser cutting machine work with?

Laser cutting machines can handle a wide variety of materials. You can use them on wood, acrylic, fabric, leather, metal, paper, and cardboard. This versatility makes them ideal for enhancing products in various businesses. Whether you create custom designs or intricate patterns, a laser cutter can help elevate your offerings.

How does the buying and order process work for laser cutting machines?

The buying and order process for laser cutting machines involves several steps. First, you need to research and select a model that fits your needs and budget. Once you decide, you can place an order through the manufacturer's website or an authorized dealer. After purchasing, the company will arrange for delivery and provide setup instructions. Make sure to check warranty details and customer support options during this process.

What should I know about setting up the Glowforge?

Setting up the Glowforge is straightforward. The manufacturer provides detailed instructions to guide you through the process. You will need to connect the machine to a power source and your computer. The Glowforge software will help you calibrate the machine and test its functions. Ensure you have a well-ventilated area for safe operation. Following these steps will help you get started quickly and efficiently.

Can an acrylic cutting machine handle other materials?

Yes, an acrylic cutting machine can often handle other materials as well. While it excels at cutting and engraving acrylic, it can also work with wood, leather, and certain fabrics. However, always check the machine's specifications to ensure compatibility with the materials you plan to use. This will help you achieve the best results and maintain the machine's longevity.

What are the benefits of using an automatic laser cutter?

An automatic laser cutter offers several benefits. It provides precision and speed, allowing you to complete projects efficiently. The automation reduces manual intervention, minimizing errors and improving consistency. This type of cutter is ideal for high-volume production and complex designs. Investing in an automatic laser cutter can enhance productivity and output quality in your business.

How do I maintain my laser cutting machine?

Regular maintenance is crucial for keeping your laser cutting machine in optimal condition. Clean the lenses and mirrors regularly to ensure clear laser paths. Check for any debris or residue in the cutting area. Lubricate moving parts as recommended by the manufacturer. Periodically inspect the machine for wear and tear, and replace components as needed. Following these steps will help extend the machine's lifespan and maintain its performance.

What safety precautions should I take when using a laser cutter?

Safety is paramount when using a laser cutter. Always wear protective eyewear to shield your eyes from laser exposure. Ensure the workspace is well-ventilated to avoid inhaling fumes. Keep flammable materials away from the cutting area. Follow the manufacturer's guidelines for safe operation. By adhering to these precautions, you can create a safe environment for laser cutting activities.

How do I choose the right laser cutter for my needs?

Choosing the right laser cutter depends on your specific needs and budget. Consider the types of materials you plan to work with and the complexity of your projects. Evaluate the machine's features, such as cutting speed, precision, and software compatibility. Research different brands and read customer reviews to gauge reliability and performance. Consulting with experts or suppliers can also provide valuable insights to help you make an informed decision.

See Also

Understanding The Cost Of Laser Cutting Machines

Exploring The Prices And Varieties Of Cutting Machines

An Overview Of Laser Cutting Machines And Their Types