How Laser Cutting Machines Work Explained

Laser cutting machines revolutionize how you work with materials. They use a non-contact, thermal-based process to cut, melt, or vaporize materials with precision. Imagine a high-powered laser beam focusing intensely on a spot. This beam heats the material until it transforms, allowing you to create intricate designs or functional components. Whether you're crafting jewelry or fabricating parts for the automotive industry, understanding what is a laser cutting machine used for can open up a world of possibilities. Dive into this fascinating technology and see how it can enhance your projects.

Key Takeaways

- Laser cutting machines use focused laser beams to cut, melt, or vaporize materials with high precision, making them ideal for intricate designs.

- Understanding the key components, such as the laser source and cutting head, is essential for maximizing the effectiveness of laser cutting technology.

- Different types of lasers, including CO2 and fiber lasers, are suited for specific materials, so choose the right one based on your project needs.

- Laser cutting offers significant advantages, including speed, efficiency, and reduced material waste, making it a preferred choice in various industries.

- Safety is paramount when using laser cutting machines; always wear protective gear and ensure proper ventilation in your workspace.

- Stay informed about emerging trends like automation and AI integration, which are enhancing the capabilities and efficiency of laser cutting technology.

- Explore the diverse applications of laser cutting, from industrial manufacturing to creative projects, to unlock new possibilities in your work.

Basic Working Principles of Laser Cutting Machines

Understanding how laser cutting machines work can open up a world of possibilities for your projects. Let's dive into the basic principles that make these machines so effective.

How Lasers Cut Materials

The Role of Laser Beams

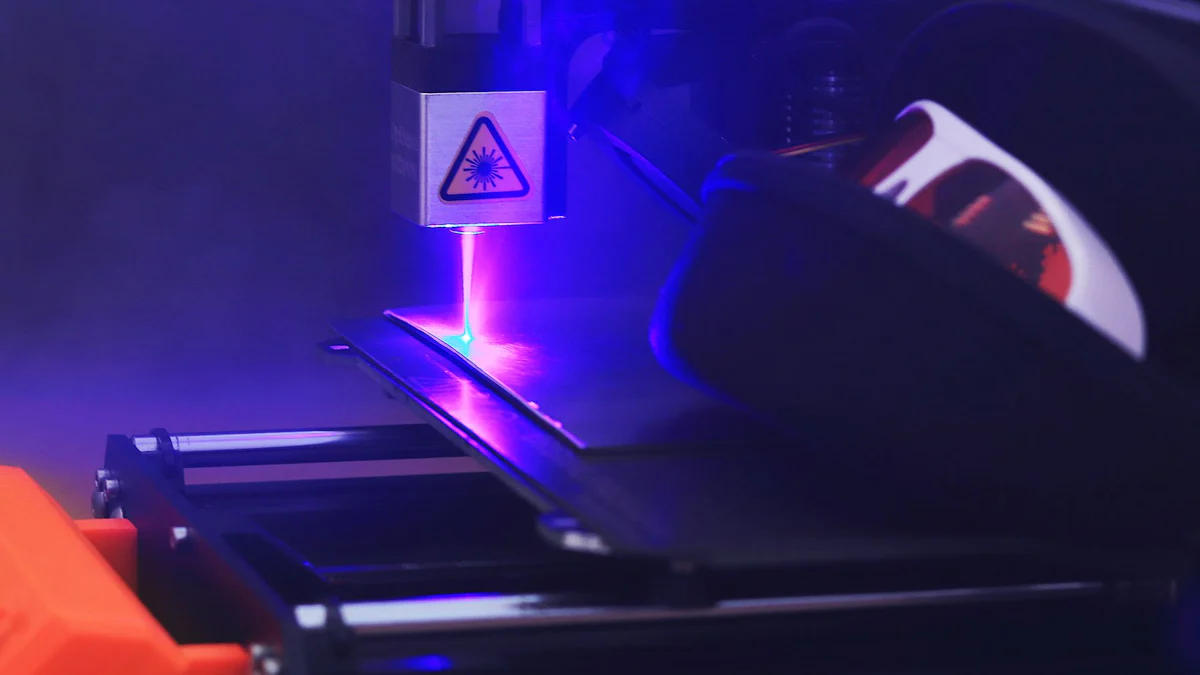

Laser beams play a crucial role in the cutting process. They are generated by the laser source and directed onto the material's surface. This beam is highly focused, allowing it to concentrate energy on a small area. As the beam hits the material, it heats it to the point of melting, vaporization, or burning. This intense energy allows you to cut through various materials with precision.

Interaction with Materials

When the laser beam interacts with the material, it causes a thermal reaction. The material absorbs the energy, which raises its temperature rapidly. Depending on the material's properties and the laser's power, the material either melts, vaporizes, or burns away. This interaction is what enables you to create intricate designs or functional components with ease.

Key Components of a Laser Cutting Machine

To understand what is a laser cutting machine used for, it's essential to know its key components. Each part plays a vital role in the cutting process.

Laser Source

The laser source is the heart of the machine. It generates the laser beam that does the cutting. Different types of lasers, like CO₂ and fiber lasers, are used depending on the material and application. The choice of laser affects the machine's efficiency and the quality of the cut.

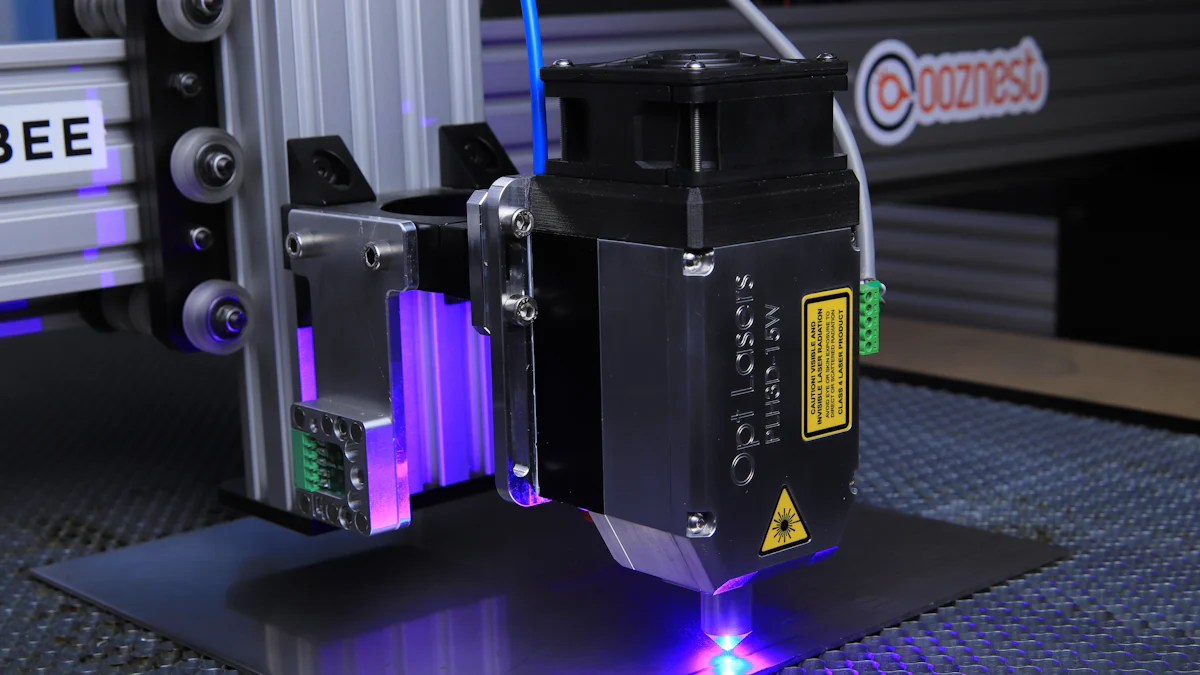

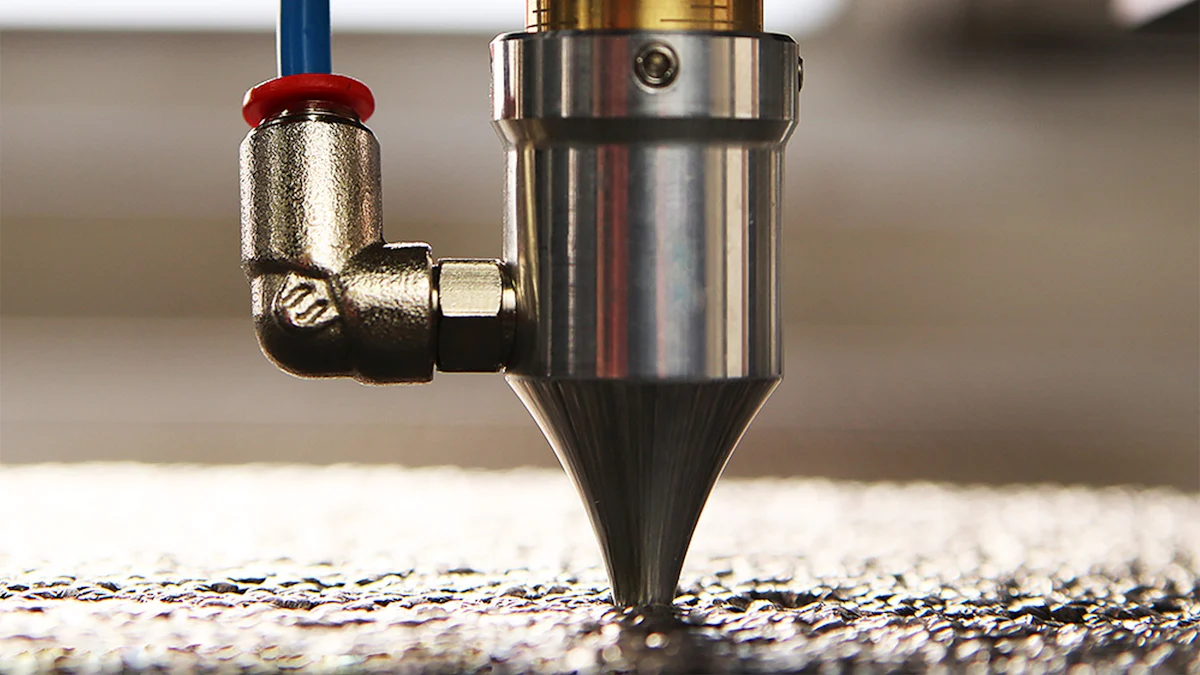

Cutting Head and Nozzle

The cutting head and nozzle guide the laser beam onto the material. The cutting head contains a focusing lens that narrows the beam to a fine point. This precision ensures that the laser cuts accurately along the desired path. The nozzle directs assist gases, like oxygen or nitrogen, to blow away molten material and prevent oxidation, enhancing the quality of the cut.

By understanding these principles and components, you can better appreciate the versatility and precision of laser cutting machines. Whether you're working in industrial settings or creative fields, knowing how these machines operate can significantly enhance your projects.

Types of Lasers Used in Cutting Machines

When it comes to laser cutting machines, the type of laser you use can make a big difference. Each laser type has its own strengths and is suited for specific applications. Let's explore the most common types of lasers used in cutting machines.

CO2 Lasers

CO2 lasers have been around for quite some time. They are one of the most popular choices for laser cutting.

Mechanism and Applications

CO2 lasers work by exciting a gas mixture, primarily carbon dioxide, to produce a laser beam. This beam is then directed onto the material you want to cut. These lasers are great for cutting non-metal materials like wood, acrylic, and plastic. You often find them in industries that require precise and intricate cuts.

Material Compatibility

CO2 lasers excel at cutting non-metallic materials. They can handle wood, paper, leather, and some plastics with ease. However, they struggle with metals unless you use special coatings or additives.

Fiber Lasers

Fiber lasers are relatively newer but have quickly gained popularity due to their efficiency and versatility.

Mechanism and Applications

Fiber lasers generate a laser beam through a series of diodes and fiber optics. This technology allows for a more focused and powerful beam. Fiber lasers are perfect for cutting metals, including stainless steel and aluminum. They are widely used in industries like automotive and aerospace.

Material Compatibility

Fiber lasers shine when it comes to cutting metals. They can cut through a variety of metals with precision and speed. However, they are not as effective on non-metallic materials compared to CO2 lasers.

Other Laser Types

While CO2 and fiber lasers are the most common, other types of lasers also play a role in cutting machines.

Nd:YAG Lasers

Nd:YAG lasers, developed in 1964, use a crystal as the laser medium. They are versatile and can cut both metals and non-metals. You might find them in applications requiring high precision, like medical device manufacturing.

Diode Lasers

Diode lasers are compact and efficient. They are often used for engraving and marking rather than cutting. These lasers are ideal for applications where space and power consumption are concerns.

Understanding the different types of lasers and their applications can help you choose the right tool for your project. Whether you're working with metals or non-metals, there's a laser cutting machine that fits your needs.

Advantages and Limitations of Laser Cutting

Laser cutting machines offer a range of benefits that make them a popular choice for various applications. However, like any technology, they also come with certain limitations. Let's explore both sides to give you a comprehensive understanding.

Advantages

Precision and Accuracy

Laser cutting machines excel in delivering high precision and accuracy. The focused laser beam allows you to achieve intricate designs and detailed cuts that are difficult to replicate with traditional methods. Whether you're working on delicate jewelry or complex automotive parts, laser cutting ensures that each piece meets exact specifications. This precision reduces the need for secondary processes like deburring, saving you time and effort.

Speed and Efficiency

When it comes to speed, laser cutting machines are hard to beat. They can cut through materials quickly, making them ideal for high-volume production. The process is not only fast but also efficient, as it minimizes material waste. You can rely on laser cutting to handle large projects without compromising on quality. Compared to other methods like CNC machining or plasma cutting, laser cutting often proves faster, especially for thin materials and intricate designs.

Limitations

Material Restrictions

Despite their versatility, laser cutting machines do have some material restrictions. They work best with thin materials and may struggle with thicker ones. While they excel at cutting non-metallic materials and metals like stainless steel and aluminum, they might not be suitable for all types of metals or materials that aren't conducive to laser cutting. Understanding these limitations helps you choose the right tool for your project.

Initial Cost and Maintenance

The initial investment for a laser cutting machine can be significant. These machines require a substantial upfront cost, which might be a barrier for small businesses or hobbyists. Additionally, maintenance can add to the overall expense. Regular upkeep is necessary to ensure optimal performance and longevity. However, the long-term benefits, such as reduced labor costs and increased production efficiency, often outweigh these initial expenses.

What is a Laser Cutting Machine Used For

Laser cutting machines have transformed various industries and creative fields. You might wonder what is a laser cutting machine used for. Let's explore some of the key applications.

Industrial Applications

In the industrial world, laser cutting machines play a crucial role. They offer precision and efficiency that traditional methods can't match.

Automotive Industry

In the automotive industry, you use laser cutting machines to create precise parts. These machines cut through metals like steel and aluminum with ease. You can produce components like gears, brackets, and panels quickly. This precision ensures that each part fits perfectly, reducing the need for adjustments. By using laser cutting, you enhance the quality and performance of vehicles.

Aerospace Industry

The aerospace industry demands high precision and reliability. Laser cutting machines meet these demands by producing intricate parts. You can cut lightweight materials like titanium and composites with accuracy. This capability is essential for creating components that must withstand extreme conditions. By using laser cutting, you ensure that each part meets strict safety and performance standards.

Creative and Artistic Uses

Laser cutting machines aren't just for industrial applications. They also open up new possibilities in creative and artistic fields.

Jewelry Making

In jewelry making, you use laser cutting machines to craft intricate designs. These machines allow you to cut precious metals with precision. You can create detailed patterns and shapes that are difficult to achieve by hand. This technology enables you to bring your creative visions to life, producing unique and beautiful pieces.

Custom Signage

Custom signage benefits greatly from laser cutting technology. You can cut various materials like wood, acrylic, and metal to create eye-catching signs. The precision of laser cutting ensures that each letter and design element is sharp and clear. Whether you're making signs for businesses or personal projects, laser cutting helps you achieve professional results.

Understanding what is a laser cutting machine used for can inspire you to explore new possibilities. Whether you're in an industrial setting or a creative field, these machines offer versatility and precision that can enhance your work.

Safety Considerations in Laser Cutting

When working with laser cutting machines, safety should always be your top priority. These machines are powerful tools, and understanding the necessary precautions can help you avoid accidents and ensure a safe working environment.

Protective Measures

Eye Protection

Your eyes are particularly vulnerable when operating laser cutting machines. The intense light emitted by lasers can cause serious eye damage. To protect yourself, always wear appropriate laser safety goggles. These goggles are designed to filter out harmful wavelengths and reduce the risk of injury. Make sure the goggles you choose are suitable for the specific type of laser you're using. This simple step can make a big difference in keeping your eyes safe.

Ventilation Systems

Proper ventilation is crucial when using laser cutting machines. The cutting process can produce fumes and particles that are harmful if inhaled. Installing an effective ventilation system helps remove these contaminants from the air. You should ensure that your workspace has adequate airflow to prevent the buildup of hazardous substances. This not only protects your health but also maintains a clean and safe environment for everyone involved.

Operational Safety

Training and Certification

Before you start using a laser cutting machine, it's essential to undergo proper training. Understanding how the machine operates and knowing the safety protocols can prevent accidents. Many organizations offer certification programs that cover the safe use of laser systems. By completing these programs, you gain valuable knowledge and skills that enhance your ability to work safely. Remember, being well-informed is your best defense against potential hazards.

Regular Maintenance

Keeping your laser cutting machine in good condition is vital for safe operation. Regular maintenance ensures that the machine functions correctly and reduces the risk of malfunctions. You should follow the manufacturer's guidelines for routine checks and servicing. This includes inspecting components like the laser source and cutting head for wear and tear. By staying on top of maintenance, you can extend the lifespan of your machine and maintain a safe working environment.

According to the ANSI Standard Z136.1, safety measures are crucial for laser systems, especially for Class 4 lasers. These standards emphasize the importance of protective measures and operational safety to prevent accidents and injuries.

By prioritizing safety, you can enjoy the benefits of laser cutting technology while minimizing risks. Whether you're a seasoned professional or a newcomer, these precautions help ensure that your experience with laser cutting machines is both productive and safe.

Future Trends and Innovations in Laser Cutting Technology

Laser cutting technology is evolving rapidly, bringing exciting advancements and new applications. As you explore this field, you'll discover how these innovations can enhance your projects and open up new possibilities.

Technological Advancements

Automation and AI Integration

Automation and AI are transforming laser cutting machines. By integrating these technologies, you can achieve higher productivity and precision. Automated systems handle repetitive tasks, reducing human error and operational costs. AI algorithms optimize cutting paths and adjust settings in real-time, ensuring the best results. This combination of automation and AI makes laser cutting more efficient and accessible for various industries.

Enhanced Precision and Speed

The demand for faster and more precise laser cutting continues to grow. New technologies are pushing the boundaries of what these machines can achieve. Enhanced precision allows you to create intricate designs with minimal waste. Faster cutting speeds increase production rates, making it easier to meet tight deadlines. These advancements ensure that laser cutting remains a competitive choice for both industrial and creative applications.

Emerging Applications

Medical Device Manufacturing

Laser cutting technology is making waves in the medical field. You can use it to manufacture precise and intricate components for medical devices. The ability to cut materials with high accuracy ensures that each part meets strict safety and performance standards. This precision is crucial for devices like stents, implants, and surgical instruments. As the healthcare sector continues to grow, the demand for laser-based solutions will only increase.

Sustainable Practices

Sustainability is becoming a key focus in many industries, and laser cutting is no exception. By using laser technology, you can reduce material waste and energy consumption. The precision of laser cutting minimizes scrap, while efficient machines lower power usage. Additionally, laser technology enables eco-friendly processes, such as marking fabrics without harmful solvents. These sustainable practices help you reduce your environmental impact while maintaining high-quality results.

According to AZoOptics, laser technology plays a critical role in Industry 4.0 and optical communications. The surging demand for laser-based solutions in healthcare and the production of micro- and nano-devices drives the growth of the laser technology market.

By staying informed about these future trends and innovations, you can harness the full potential of laser cutting technology. Whether you're in an industrial setting or exploring creative applications, these advancements offer exciting opportunities to enhance your work.

You've now explored the fascinating world of laser cutting machines. These powerful tools use focused laser beams to cut, melt, or vaporize materials with precision. From industrial applications to creative endeavors, they offer versatility and efficiency. Staying informed about future trends and innovations is crucial. As technology advances, new possibilities emerge, enhancing your projects and expanding your capabilities. Keep an eye on developments in automation, AI, and sustainable practices. Embrace these changes to stay ahead and make the most of what laser cutting technology has to offer.

FAQ

What is Laser Cutting?

Laser cutting is a technology that uses a laser to cut or drill materials. You can use it to cut various materials, including metal, wood, plastics, and textiles. This process proves helpful in manufacturing applications where you need a high degree of accuracy. For instance, it allows you to create intricate patterns or shapes in metal parts that would be difficult to produce using traditional methods.

What are the Components of a Laser Cutting Machine?

A laser cutting machine consists of several crucial components, each playing a vital role in the cutting process. These components include:

- Laser Resonator: Generates the laser beam.

- Beam Delivery System: Directs the laser beam to the cutting head.

- Focusing Lens: Concentrates the laser beam onto the material.

- Cutting Head and Nozzle: Guides the beam and directs assist gases.

- Motion Control System: Moves the cutting head or workpiece.

- Workpiece Bed: Supports the material being cut.

- Controller: Manages the machine's operations.

- Assist Gas System: Provides gases like oxygen or nitrogen to enhance cutting quality.

What are the Uses of Laser Cutting Machines?

Laser cutting machines find applications in various industries. You can use them in automotive manufacturing, aerospace engineering, and electronics manufacturing. They also serve hobbyist applications like model making and engraving. These machines can cut a variety of materials, including metals, plastics, glass, and wood.

How Does Laser Cutting Differ from Other Cutting Methods?

Laser cutting offers several advantages over traditional cutting methods. It provides high precision and accuracy, allowing you to achieve intricate designs. The process is non-contact, reducing the risk of material deformation. Additionally, laser cutting minimizes waste and often requires less post-processing compared to other methods.

Is Laser Cutting Safe?

Yes, laser cutting is safe when you follow proper safety measures. Always wear appropriate eye protection to shield your eyes from the laser light. Ensure your workspace has adequate ventilation to remove harmful fumes and particles. Regular maintenance of the machine also helps prevent malfunctions and ensures safe operation.

Can Laser Cutting Machines Cut All Materials?

Laser cutting machines can cut a wide range of materials, but they do have some limitations. They work best with thin materials and may struggle with thicker ones. While they excel at cutting metals like stainless steel and aluminum, they might not be suitable for all types of metals or materials that aren't conducive to laser cutting.

What Factors Affect the Quality of a Laser Cut?

Several factors influence the quality of a laser cut. The type of laser and its power settings play a significant role. The material's properties, such as thickness and composition, also affect the outcome. Proper alignment of the cutting head and the use of assist gases can enhance the cut's quality by preventing oxidation and removing molten material.

How Do I Choose the Right Laser Cutting Machine for My Needs?

Choosing the right laser cutting machine depends on your specific needs. Consider the materials you plan to cut and the precision required. Evaluate the machine's power, speed, and compatibility with different materials. Also, factor in the initial cost, maintenance requirements, and available support services. By assessing these aspects, you can select a machine that best suits your projects.

What Maintenance Does a Laser Cutting Machine Require?

Regular maintenance is crucial for optimal performance. You should follow the manufacturer's guidelines for routine checks and servicing. Inspect components like the laser source and cutting head for wear and tear. Clean the lenses and mirrors to ensure clear beam delivery. By staying on top of maintenance, you can extend the lifespan of your machine and maintain a safe working environment.

Are There Any Emerging Trends in Laser Cutting Technology?

Yes, laser cutting technology continues to evolve with exciting advancements. Automation and AI integration enhance productivity and precision. New technologies push the boundaries of speed and accuracy. Emerging applications include medical device manufacturing and sustainable practices. Staying informed about these trends can help you harness the full potential of laser cutting technology.

See Also

Understanding The Basics Of Laser Cutting Machines

Exploring Different Types Of Laser Cutting Machines

The Functionality Of CNC Laser Cutting Machines