How a Laser Cutting Machine Works: Pros and Cons

Laser cutting machines use a focused laser beam to cut or engrave materials with remarkable precision. The process involves directing intense light energy onto a material’s surface, causing it to melt, burn, or vaporize. This method produces clean edges and intricate designs, making it ideal for industries requiring high accuracy. You can find these machines in applications ranging from automotive manufacturing to creative arts. Understanding how a laser cutting machine works helps you evaluate its benefits and limitations, ensuring you make informed decisions when considering this advanced technology.

Key Takeaways

Laser cutting machines utilize a focused laser beam to achieve high precision and intricate designs, making them ideal for industries like automotive and creative arts.

- The use of assist gases, such as oxygen and nitrogen, enhances cutting speed and quality, ensuring cleaner edges and minimizing oxidation. Laser cutting is versatile, capable of working with various materials including metals, plastics, and textiles, and can be used for cutting, engraving, and marking.

- While laser cutting offers speed and efficiency, it requires a significant initial investment and ongoing maintenance costs, which should be considered before purchase.

- Proper safety measures, including protective gear and ventilation, are essential when operating laser cutting machines to ensure a safe working environment.

- Regular training and maintenance are crucial for optimal performance and safety, helping operators avoid accidents and extend the machine's lifespan.

- Understanding the limitations of laser cutting, such as material restrictions and energy consumption, is vital for making informed decisions about its use in production.

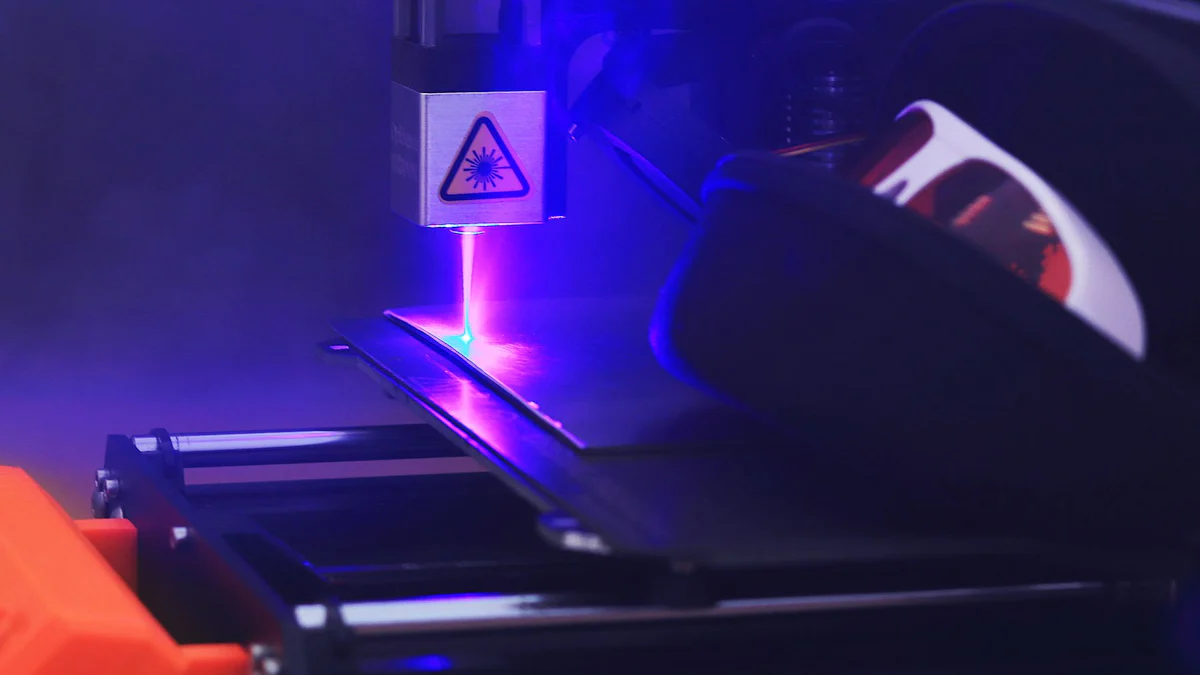

How a Laser Cutting Machine Works

The Basics of Laser Cutting

Laser generation and focusing

Laser cutting begins with the generation of a high-powered laser beam. This beam originates from a laser source, such as a CO2 or fiber laser, and is then focused through a lens or mirror system.

Material heating and melting

When the laser beam hits the material, it generates enough heat to melt, burn, or vaporize the surface. The intense energy ensures that the material heats up rapidly, allowing for clean and accurate cuts. This process minimizes physical contact, reducing wear and tear on the machine while maintaining the integrity of the material.

Use of assist gases (e.g., oxygen, nitrogen)

Assist gases, such as oxygen or nitrogen, play a crucial role in laser cutting. These gases are directed onto the cutting area through a nozzle. Oxygen enhances the cutting speed by reacting with the material, while nitrogen prevents oxidation, ensuring cleaner edges. The choice of gas depends on the material and the desired finish.

Controlled movement of the laser beam

The laser beam moves across the material in a controlled manner, guided by a CNC (Computer Numerical Control) system. This system follows a pre-programmed design, ensuring precise cuts and intricate patterns. The combination of controlled movement and focused energy allows you to achieve detailed results that are difficult to replicate with traditional cutting methods.

Types of Laser Cutting Machines

CO2 lasers

CO2 lasers are among the most common types of laser cutting machines. They use carbon dioxide gas to generate the laser beam. These machines excel at cutting non-metallic materials like wood, acrylic, and textiles. Their versatility makes them a popular choice for industries ranging from manufacturing to creative arts.

Fiber lasers

Fiber lasers use optical fibers to amplify the laser beam. These machines are highly efficient and ideal for cutting metals, including stainless steel and aluminum. Their ability to handle reflective materials sets them apart from other types of lasers. Fiber lasers are often used in industries like automotive and aerospace for their precision and speed.

Crystal lasers

Crystal lasers, such as Nd:YAG and Nd:YVO, produce a highly concentrated beam suitable for cutting thick or hard materials. These machines are less common due to their higher cost and shorter lifespan compared to CO2 and fiber lasers. However, they are invaluable for applications requiring extreme precision, such as medical device manufacturing.

Key Components of a Laser Cutting Machine

Laser source

The laser source is the heart of the machine. It generates the laser beam that performs the cutting or engraving. Different types of lasers, such as CO2, fiber, or crystal, determine the machine's capabilities and the materials it can handle.

Cutting head and lens

The cutting head houses the lens or mirror system that focuses the laser beam onto the material. It also includes a nozzle for directing assist gases. The quality of the lens and the alignment of the cutting head significantly impact the precision and efficiency of the machine.

CNC control system

The CNC control system acts as the brain of the laser cutting machine. It interprets digital designs and controls the movement of the laser beam.

Advantages of Laser Cutting Machines

High Precision and Accuracy

Ability to create intricate designs

Laser cutting machines excel at delivering unmatched precision. You can create intricate designs and complex patterns that are nearly impossible to achieve with traditional cutting methods. The focused laser beam allows you to cut with incredible accuracy, ensuring every detail of your design is captured. This capability makes laser cutting ideal for industries like jewelry making, electronics, and custom engraving, where precision is non-negotiable.

Minimal material distortion

The non-contact nature of laser cutting ensures minimal material distortion. Unlike traditional methods that rely on physical tools, the laser beam applies heat directly to the cutting area without exerting mechanical force.

Speed and Efficiency

Faster cutting compared to traditional methods

Laser cutting machines operate at remarkable speeds. The focused energy of the laser beam allows you to cut through materials much faster than conventional methods. This speed is particularly beneficial for high-volume manufacturing, where time is a critical factor. By using a laser cutting machine, you can significantly reduce production delays and meet tight deadlines with ease.

Reduced production time

This streamlined workflow helps you save valuable time and resources, making your production process more efficient.

Versatility

Works with a wide range of materials

One of the standout features of laser cutting machines is their versatility. You can use them to cut a wide variety of materials, including metals, plastics, wood, textiles, and even ceramics. This flexibility makes laser cutting suitable for diverse industries, from automotive manufacturing to creative arts. Whether you’re crafting intricate designs or producing functional components, a laser cutting machine can handle the task.

Suitable for cutting, engraving, and marking

Laser cutting machines are not limited to cutting alone. You can also use them for engraving and marking, adding value to your projects. For example, you can engrave logos, serial numbers, or decorative patterns onto your materials with ease. This multifunctionality allows you to expand your creative possibilities and cater to a broader range of applications.

Minimal Waste

Optimized material usage

Laser cutting machines excel at maximizing material usage. The precision of the laser beam allows you to cut parts with minimal gaps between them, reducing leftover scraps. This optimized approach ensures that you get the most out of your raw materials, saving costs and minimizing waste. Unlike traditional cutting methods, which often leave behind unusable remnants, laser cutting focuses on efficiency. By using this technology, you can achieve a more sustainable production process while keeping expenses under control.

Clean and smooth edges

One of the standout features of laser cutting is its ability to produce clean and smooth edges. The focused laser beam melts or vaporizes the material with pinpoint accuracy, leaving no jagged or rough surfaces. This eliminates the need for extensive post-processing, such as sanding or polishing, which saves time and effort. Traditional cutting methods often struggle to achieve this level of finish, especially on intricate designs. With laser cutting, you can ensure that your final product meets high-quality standards right from the start.

Automation and Integration

Compatibility with CAD/CAM software

Laser cutting machines integrate seamlessly with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software. This compatibility allows you to design complex patterns and transfer them directly to the machine for cutting. The process eliminates manual errors and ensures that your designs are executed with precision. Whether you’re working on prototypes or large-scale production, this integration streamlines your workflow. By leveraging CAD/CAM software, you can bring your creative ideas to life with unmatched accuracy and efficiency.

Reduced need for manual intervention

Automation is a key advantage of laser cutting machines. Once you program the machine, it operates independently, following the design specifications without requiring constant supervision. This reduces the need for manual intervention, allowing you to focus on other tasks. Traditional cutting methods often demand hands-on involvement, increasing the risk of errors and inconsistencies. With laser cutting, you can achieve consistent results while minimizing labor costs and improving overall productivity.

Limitations of Laser Cutting Machines

High Initial Cost

Expensive equipment and setup

Laser cutting machines require a significant upfront investment. The advanced technology, precision components, and high-quality laser sources contribute to their high price. If you are considering purchasing one, you must account for the cost of the machine itself and the additional expenses for installation and setup. These costs can be a barrier, especially for small businesses or individuals with limited budgets.

Cost of maintenance and repairs

Maintaining a laser cutting machine can also be costly. Regular upkeep is essential to ensure optimal performance and prevent breakdowns. Components like lenses, mirrors, and laser sources may need replacement over time, adding to the overall expense. Repairs can be expensive, particularly if specialized technicians or parts are required. You should factor in these ongoing costs when evaluating whether a laser cutting machine fits your needs.

Material Restrictions

Limited effectiveness on certain materials (e.g., reflective metals)

Laser cutting machines struggle with some materials, particularly highly reflective metals like copper and aluminum. These materials can reflect the laser beam, reducing its efficiency and potentially damaging the machine. While fiber lasers have improved performance with reflective metals, they still face limitations. If your projects involve such materials, you may need to explore alternative cutting methods.

Thickness limitations for some materials

The thickness of the material also affects the performance of laser cutting machines. While they excel at cutting thin to moderately thick materials, they may not be effective for very thick ones. The laser beam loses intensity as it penetrates deeper, leading to slower cutting speeds and less precise results. For industries requiring the processing of thick materials, this limitation can be a significant drawback.

Energy Consumption

High power requirements

Operating a laser cutting machine demands a substantial amount of energy. The laser source, cooling systems, and CNC controls all contribute to high power consumption. This can lead to increased electricity bills, especially if you use the machine frequently. For businesses aiming to reduce operational costs, the energy requirements of laser cutting machines may pose a challenge.

Environmental considerations

The high energy consumption of laser cutting machines also raises environmental concerns. Generating the electricity needed to power these machines often relies on non-renewable energy sources, contributing to carbon emissions. Additionally, the use of assist gases like oxygen and nitrogen can have environmental impacts. If sustainability is a priority for you, it’s important to weigh these factors when deciding whether to use a laser cutting machine.

Heat-Affected Zones (HAZ)

Potential for thermal damage to materials

When you use a laser cutting machine, the intense heat from the laser beam can create a heat-affected zone (HAZ) around the cutting area. This zone refers to the portion of the material that experiences changes in its properties due to the high temperatures. For some materials, this thermal exposure can weaken the structure or alter its appearance. Metals, for instance, may lose their hardness or develop discoloration near the cut edges.

If you work with delicate or heat-sensitive materials, you must carefully monitor the laser's power settings and speed. Adjusting these parameters can help reduce the size of the HAZ and minimize potential damage. However, even with precise control, some materials may still require additional care to maintain their quality.

Need for post-processing in some cases

In certain situations, the heat-affected zone may necessitate post-processing to restore the material's original properties or improve its appearance. For example, you might need to polish or sand the edges to remove discoloration or smooth out any imperfections caused by thermal exposure. Metals may require heat treatment to regain their strength or durability.

While laser cutting minimizes the need for extensive finishing compared to traditional methods, you should still account for the possibility of post-processing. This step ensures that your final product meets the desired standards of quality and functionality.

Comparison with Other Cutting Methods

Laser cutting vs. waterjet cutting

Laser cutting and waterjet cutting are both popular methods for precision cutting, but they differ significantly in their approach. Laser cutting uses a focused beam of light to cut through materials, while waterjet cutting relies on a high-pressure stream of water mixed with abrasive particles.

Laser cutting excels in speed and precision, especially for intricate designs. It produces clean edges with minimal waste, making it ideal for industries that prioritize efficiency. However, waterjet cutting has the advantage of being able to cut through thicker materials and those sensitive to heat, such as stone or glass. If you work with a variety of materials, you may need to weigh the benefits of each method based on your specific needs.

Laser cutting vs. plasma cutting

Plasma cutting is another alternative to laser cutting, particularly for working with metals. This method uses an electrically conductive gas to create a plasma arc that melts through the material. Plasma cutting is often faster for thicker metals and can handle a wider range of material thicknesses compared to laser cutting.

However, laser cutting offers superior precision and cleaner edges. Plasma cutting may leave rough or uneven edges that require additional finishing. If your projects demand high accuracy and minimal post-processing, laser cutting is the better choice. On the other hand, plasma cutting may be more cost-effective for heavy-duty applications.

Laser cutting vs. mechanical cutting

Mechanical cutting involves the use of physical tools, such as saws or drills, to cut through materials. While this method is straightforward and cost-effective, it lacks the precision and versatility of laser cutting. Mechanical tools can cause material distortion due to physical contact, and they often struggle with intricate designs or delicate materials.

Laser cutting eliminates these challenges by using a non-contact process. You can achieve detailed patterns and smooth edges without risking damage to the material. Additionally, laser cutting reduces material waste, as the narrow kerf width allows for optimized usage. If you value efficiency and quality, laser cutting stands out as a more advanced and reliable option.

Practical Applications of Laser Cutting Machines

Industrial Applications

Automotive and aerospace industries

Laser cutting machines play a vital role in the automotive and aerospace sectors.

Electronics and medical device manufacturing

In electronics, laser cutting machines allow you to work with delicate materials like circuit boards and microchips. The precision of the laser ensures clean cuts without damaging sensitive components. Similarly, in medical device manufacturing, laser cutting is essential for creating intricate tools and implants. You can rely on this technology to produce items like surgical instruments, stents, and prosthetics with exceptional accuracy. The non-contact nature of laser cutting also reduces the risk of contamination, which is critical in medical applications.

Creative and Artistic Uses

Custom engraving and design

Laser cutting machines open up endless possibilities for creative projects. You can use them to engrave intricate patterns, logos, or text on various materials, including wood, glass, and metal. Whether you're designing personalized gifts or decorative items, laser engraving adds a professional touch to your creations. The precision of the laser allows you to bring even the most detailed designs to life, making it a favorite tool for artists and designers.

Jewelry and fashion industries

In the jewelry and fashion industries, laser cutting machines enable you to craft unique and intricate pieces. You can cut delicate patterns into metals, fabrics, or leather with ease. For instance, laser cutting allows you to create custom jewelry designs or add detailed embellishments to clothing and accessories. This technology not only enhances creativity but also speeds up production, helping you meet the demands of a fast-paced industry.

Prototyping and Small-Scale Production

Rapid prototyping

Laser cutting machines are invaluable for rapid prototyping. You can quickly transform your digital designs into physical models, allowing you to test and refine your ideas. This process is especially useful for engineers, architects, and product designers who need to create accurate prototypes before moving to full-scale production. The speed and precision of laser cutting ensure that your prototypes are both functional and visually appealing.

Small business and DIY projects

For small businesses and DIY enthusiasts, laser cutting machines offer a cost-effective way to bring ideas to life. You can use them to create custom products, such as signage, home décor, or promotional items. The versatility of laser cutting allows you to work with a wide range of materials, giving you the freedom to experiment and innovate. Whether you're starting a small business or pursuing a hobby, laser cutting machines provide the tools you need to succeed.

Safety Considerations When Using Laser Cutting Machines

Protective Measures

Use of safety goggles and shields

When operating a laser cutting machine, protecting your eyes should be a top priority. The intense laser beam can cause severe eye damage if viewed directly or through reflections. You must wear safety goggles specifically designed to block the wavelength of the laser in use.

Proper ventilation to manage fumes

Laser cutting generates fumes and particulates, especially when working with materials like plastics, wood, or metals. These emissions can pose health risks if inhaled over time. Installing a proper ventilation system is essential to remove harmful fumes from the workspace.

Training and Maintenance

Importance of operator training

Operating a laser cutting machine requires skill and knowledge. Without proper training, you risk damaging the machine or causing accidents. You should invest time in learning how to use the equipment safely and efficiently. Many manufacturers offer training programs that cover essential topics like machine setup, material handling, and safety protocols. These programs help you understand the machine's capabilities and limitations, ensuring you operate it with confidence. Regularly updating your skills also keeps you informed about new features or technologies, enhancing your overall productivity.

Regular maintenance to ensure safe operation

Maintaining your laser cutting machine is crucial for both safety and performance. Over time, components like lenses, mirrors, and filters can wear out or accumulate debris, affecting the machine's efficiency. You should inspect these parts regularly and clean or replace them as needed. Following the manufacturer's maintenance schedule ensures the machine operates smoothly and reduces the risk of malfunctions. Neglecting maintenance can lead to unexpected breakdowns, which may compromise safety. By staying proactive with upkeep, you extend the machine's lifespan and maintain a safe working environment.

Understanding how a laser cutting machine works gives you insight into its key components and capabilities. These machines offer unmatched precision, speed, and versatility, making them indispensable in industries like automotive, aerospace, and creative arts. However, their high initial cost and material limitations require careful consideration. By weighing the pros and cons, you can determine if this technology aligns with your specific needs. Whether you aim for intricate designs or efficient production, laser cutting machines provide a powerful solution for modern manufacturing challenges.

FAQ

What materials can you cut with a laser cutting machine?

You can cut a wide range of materials using a laser cutting machine.

Is laser cutting safe to use?

Yes, laser cutting is safe when you follow proper safety protocols. You must wear safety goggles to protect your eyes from harmful laser radiation. Proper ventilation is essential to manage fumes generated during the cutting process. Training on machine operation and emergency shutdown procedures ensures safe usage. With these precautions, you can minimize risks and operate the machine confidently.

Do I need training to operate a laser cutting machine?

Yes, training is essential before operating a laser cutting machine. You need to understand the controls, emergency shutdown procedures, and the correct use of personal protective equipment (PPE). Proper training helps you avoid accidents and ensures efficient operation. Many manufacturers offer training programs to help you get started.

How precise are laser cutting machines?

Laser cutting machines offer exceptional precision. They can create intricate designs and detailed patterns with minimal distortion. The focused laser beam ensures clean edges and accurate cuts, making them ideal for industries like jewelry making, electronics, and medical device manufacturing. You can rely on these machines for high-quality results.

What are the maintenance requirements for a laser cutting machine?

Regular maintenance is crucial to keep your laser cutting machine in top condition. You should clean lenses and mirrors frequently to prevent debris buildup. Inspect components like the cutting head and filters for wear and replace them as needed. Following the manufacturer's maintenance schedule ensures consistent performance and extends the machine's lifespan.

Can laser cutting machines handle thick materials?

Laser cutting machines perform best with thin to moderately thick materials. While they can cut thicker materials, the process may become slower and less precise. For very thick materials, alternative methods like waterjet or plasma cutting might be more effective. Always consider the material's thickness when choosing a cutting method.

Are laser cutting machines energy-efficient?

Laser cutting machines consume significant energy due to their high-powered laser sources and cooling systems. This can lead to higher electricity bills. However, their efficiency in reducing material waste and eliminating the need for secondary processes often offsets the energy costs. If sustainability is a concern, consider energy-efficient models or renewable energy sources.

What safety gear do I need when using a laser cutting machine?

You must wear safety goggles designed to block the specific wavelength of the laser. These protect your eyes from harmful radiation. Using protective shields around the machine helps contain stray laser beams. Proper ventilation systems are also necessary to manage fumes and particulates, ensuring a safe working environment.

How does laser cutting compare to other cutting methods?

Laser cutting stands out for its precision, speed, and versatility. Unlike mechanical cutting, it uses a non-contact process, reducing material distortion. Compared to plasma cutting, it offers cleaner edges and better accuracy. While waterjet cutting handles thicker materials and heat-sensitive ones better, laser cutting excels in intricate designs and faster production.

Can I use a laser cutting machine for engraving?

Yes, laser cutting machines are excellent for engraving. You can use them to add intricate patterns, logos, or text to materials like wood, glass, and metal. This feature makes them versatile tools for creative projects, allowing you to personalize items or create detailed designs with ease.

See Also

Maximizing Efficiency With Your Laser Cutting Equipment

Advantages and Disadvantages of DE TECH Fabric Cutters

Understanding Laser Cutting Machines and Their Varieties

The Functionality of Laser Cutting Machines in Manufacturing

Benefits and Drawbacks of Cricut Machines for Plastic Cutting