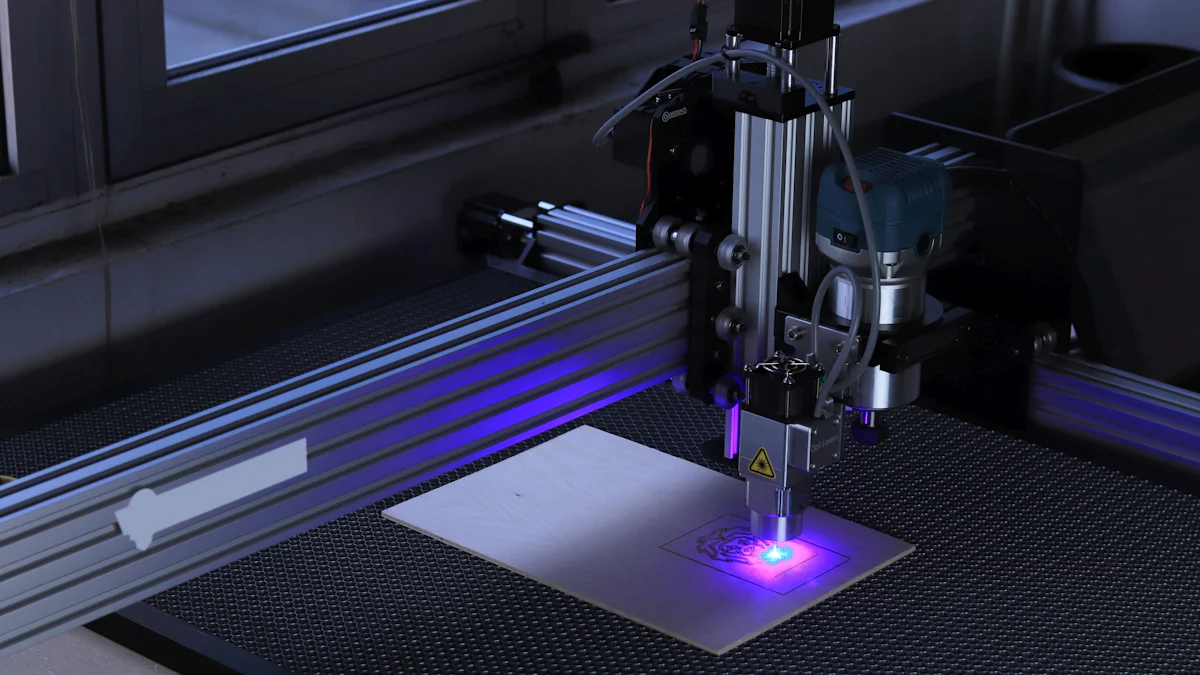

How Does a Fiber Laser Cutting Machine Work

Understanding how does a fiber laser cutting machine work can transform your approach to metal fabrication. These machines utilize a high-efficiency fiber laser source to cut through materials with precision. The core components, such as the laser cutting head and servo motors, play crucial roles in directing the laser beam and ensuring accurate cuts. With their high conversion efficiency, fiber laser cutting machines consume less electricity, making them cost-effective and environmentally friendly. By grasping the workings of these components, you can optimize the machine's performance and achieve superior results.

Core Components of a Fiber Laser Cutting Machine

Understanding the core components of a fiber laser cutting machine is essential for anyone looking to maximize its efficiency and precision. Each part plays a vital role in the overall operation, ensuring that the machine performs optimally.

Fiber Laser Source

The fiber laser source serves as the heart of the machine. It generates the laser beam that cuts through various materials. This component is known for its high efficiency and reliability. You will find that the fiber laser source offers a significant advantage over traditional lasers due to its ability to produce a more focused and powerful beam. This results in cleaner cuts and less material waste. The laser generator within the fiber laser source converts electrical energy into a laser beam, making it a crucial element in the cutting process.

Laser Cutting Head

The laser cutting head is where the magic happens. It directs the laser beam onto the material, ensuring precise cuts. This component includes a cutting nozzle, a focus lens, and a focus tracking system. The cutting head travels along a predetermined path, adjusting its height based on the material's thickness and type. Regular maintenance of the cutting head is necessary to keep the fiber laser cutter functioning smoothly. You should check the cooling system frequently to prevent overheating, as the machine generates substantial heat during operation.

Servo Motors

Servo motors are responsible for the precise movement of the cutting head and the workpiece. They ensure that the laser follows the exact path needed for each cut. These motors provide the necessary control and accuracy, allowing you to achieve intricate designs and patterns. By maintaining the servo motors in good condition, you can enhance the performance of your cnc laser cutting system.

Water Chiller

The water chiller plays a crucial role in maintaining the optimal temperature of your fiber laser cutting machine. It prevents overheating by cooling the laser generator, which is essential for continuous and efficient operation. Without a properly functioning water chiller, the laser generator could overheat, leading to potential damage and reduced performance. Regular maintenance of the water chiller is necessary. You should clean the water tank and replace the circulating water weekly. This practice ensures that the coolant flows unobstructed and prevents any leakage. By keeping the water chiller in top condition, you can extend the lifespan of your machine and maintain its cutting precision.

Air Cutting System

The air cutting system assists in the cutting process by removing debris from the cutting area. It also helps cool the material during cutting, which is vital for achieving clean cuts. The system uses compressed air to blow away particles and prevent them from interfering with the laser beam. This process not only enhances the quality of the cut but also protects the laser generator from potential damage caused by debris. Regular checks of the air cutting system ensure that it functions effectively. You should verify that the air pressure is adequate and that there are no blockages in the system.

Control System

The control system is the brain of your fiber laser cutting machine. It manages the entire cutting process, allowing you to adjust speed, power, and cutting patterns with precision. This system includes both hardware and software components that work together to control the laser generator and other machine parts. A well-maintained control system ensures that your machine operates smoothly and efficiently. Regular software updates and system checks are essential to keep the control system running optimally. By understanding and utilizing the control system effectively, you can maximize the performance of your fiber laser cutting machine.

Stabilizer

The stabilizer in a fiber laser cutting machine plays a pivotal role in maintaining the stability and precision of the cutting process. You will find that this component ensures the cutting head remains steady, even during high-speed operations. A stable cutting head is crucial for achieving consistent and accurate cuts, especially when dealing with intricate designs or patterns.

The stabilizer works by minimizing vibrations and fluctuations that can occur during the cutting process. These disturbances can affect the alignment of the focusing lens and the cutting head, leading to imprecise cuts. By keeping the cutting head stable, the stabilizer helps maintain the correct focus of the laser beam on the material. This stability is essential for the focusing lens to perform its function effectively, ensuring that the laser beam remains concentrated and powerful.

Regular checks and maintenance of the stabilizer are necessary to ensure it functions optimally. You should inspect the stabilizer for any signs of wear or damage and address any issues promptly. Keeping the stabilizer in good condition will enhance the overall performance of your fiber laser cutting machine, allowing you to achieve high-quality results consistently.

Benefits of Using a Fiber Laser Cutting Machine

When you choose a fiber laser cutting machine, you unlock a world of benefits that enhance your cutting operations. These machines stand out for their precision, speed, and versatility, making them an invaluable asset in various industries.

Precision and Accuracy

Fiber laser cutting machines excel in delivering exceptional precision and accuracy. You can achieve intricate designs and patterns with ease, thanks to the focused laser beam that ensures clean cuts. The cutting accuracy of these machines is unmatched, allowing you to produce high-quality cutting results consistently. By maintaining the components like the laser cutting head and servo motors, you ensure that the machine operates at peak performance, providing you with the exactness needed for your projects.

Speed and Efficiency

Speed and efficiency are hallmarks of fiber laser cutting machines. You will notice a significant increase in productivity as these machines cut through materials swiftly without compromising on quality. The fiber laser technology offers increased efficiency by converting electrical energy into light energy with minimal waste. This means you can complete more tasks in less time, optimizing your workflow and reducing operational costs. The water chiller and air cutting system play crucial roles in maintaining the machine's efficiency by preventing overheating and ensuring smooth operation.

Versatility in Material Cutting

The versatility of fiber laser cutting machines is another compelling advantage. You can cut a wide range of materials, from metals to non-metals, with precision and ease. This adaptability makes fiber lasers suitable for various applications, whether you're working in industrial manufacturing, automotive, or custom fabrication. The control system allows you to adjust settings to match the material type and thickness, ensuring optimal results every time. By leveraging the versatility of these cutting machines, you expand your capabilities and meet diverse customer needs.

Drawbacks of Fiber Laser Cutting Machines

While fiber laser cutting machines offer numerous benefits, you should also consider some drawbacks before investing in one. Understanding these limitations will help you make an informed decision and prepare for any challenges you might face.

Initial Cost

The initial cost of a fiber laser cutting machine can be quite high. You may find that the price tag is a significant investment, especially for small businesses or startups. This cost includes not only the machine itself but also the necessary accessories and installation expenses. However, it's important to weigh this initial expense against the long-term benefits, such as reduced operational costs and increased efficiency. By planning your budget carefully, you can manage this financial hurdle and eventually see a return on your investment.

Maintenance Requirements

Regular maintenance is crucial for keeping your fiber laser cutting machine in optimal condition. You need to perform routine checks and servicing to ensure all components function correctly. This includes cleaning the laser cutting head, checking the water chiller, and maintaining the air cutting system. Neglecting maintenance can lead to increased downtime, affecting your productivity and potentially causing costly repairs. By adhering to a strict maintenance schedule, you can minimize downtime and extend the lifespan of your machine.

Limitations in Material Thickness

Fiber laser cutting machines excel at cutting thin to medium-thickness materials. However, you may encounter limitations when working with thicker materials. The laser's power and focus can struggle to penetrate thicker substrates, resulting in less precise cuts. If your projects frequently involve cutting thick materials, you might need to explore alternative cutting methods or invest in a machine with higher power capabilities. Understanding these limitations will help you choose the right equipment for your specific needs.

Practical Applications of Fiber Laser Cutters

Fiber laser cutters have revolutionized various industries with their precision and efficiency. You will find these machines indispensable in several fields due to their ability to deliver high-quality results consistently.

Industrial Manufacturing

In industrial manufacturing, fiber laser cutters play a crucial role. You can use them to cut metals and other materials with unmatched precision. This capability allows you to produce intricate parts and components that meet exact specifications. The speed and accuracy of fiber laser cutters make them ideal for mass production, reducing lead times and increasing productivity. By integrating these machines into your manufacturing process, you enhance the quality and consistency of your products.

Automotive Industry

The automotive industry benefits significantly from fiber laser cutters. You can utilize these machines to cut and shape various parts, from body panels to intricate engine components. The precision of fiber laser cutters ensures that each part fits perfectly, contributing to the overall performance and safety of vehicles. Additionally, the speed of these machines allows you to meet tight production schedules, ensuring timely delivery of vehicles to the market. By adopting fiber laser cutters, you streamline your production process and maintain a competitive edge in the automotive industry.

Aerospace Applications

In aerospace applications, precision is paramount. Fiber laser cutters excel in this field by providing the accuracy needed to produce complex components for aircraft and spacecraft. You can rely on these machines to cut lightweight materials like aluminum and titanium, which are essential for reducing the weight of aerospace structures. The high precision of fiber laser cutters ensures that each component meets stringent safety and performance standards. By incorporating these machines into your aerospace manufacturing process, you enhance the reliability and efficiency of your products.

Custom Fabrication

In the realm of custom fabrication, fiber laser cutting machines stand out as a game-changer. You can harness their capabilities to create bespoke designs and components with unmatched precision and speed. This technology allows you to bring intricate and unique ideas to life, catering to specific client needs or artistic visions.

Key Advantages in Custom Fabrication:

-

Precision and Detail: Fiber lasers excel in delivering high precision, which is crucial for custom projects. You can achieve fine details and complex patterns that other cutting methods might struggle with. This precision ensures that each piece meets exact specifications, enhancing the quality of your custom work.

-

Versatility: These machines can cut a wide range of materials, from metals to plastics. This versatility means you can tackle diverse projects without needing multiple machines. Whether you're crafting metal art pieces or custom automotive parts, fiber lasers provide the flexibility you need.

-

Efficiency: Speed is another significant advantage. Fiber lasers cut faster than many traditional methods, allowing you to complete projects more quickly. This efficiency not only boosts productivity but also reduces lead times, enabling you to meet tight deadlines and satisfy customer demands.

-

Cost-Effectiveness: While the initial investment might seem high, fiber lasers offer low operating costs. They consume less energy and require minimal maintenance compared to other cutting technologies. Over time, this cost-effectiveness can lead to substantial savings, making them a wise choice for custom fabricators.

By integrating fiber laser cutting machines into your custom fabrication process, you unlock new possibilities for creativity and efficiency. You can produce high-quality, tailored products that stand out in the market, giving you a competitive edge in the industry.

Tips for Optimizing Performance and Maintenance

To keep your fiber laser cutting machine running smoothly, you need to focus on performance optimization and regular maintenance. These practices ensure that your machine operates efficiently and lasts longer.

Regular Maintenance Practices

Regular maintenance is crucial for the longevity and efficiency of your fiber laser cutting machine. You should establish a routine to check and clean all components. This includes the laser cutting head, water chiller, and air cutting system. By doing so, you prevent debris buildup and overheating, which can lead to costly repairs.

- Clean the Laser Cutting Head: Dust and debris can accumulate on the cutting head, affecting the quality of cuts. Use a soft cloth to wipe the lens and nozzle regularly.

- Check the Water Chiller: Ensure the water chiller functions properly to prevent the laser source from overheating. Replace the water weekly to maintain optimal cooling.

- Inspect the Air Cutting System: Verify that the air pressure is adequate and there are no blockages. This ensures debris is effectively removed during cutting.

"Fiber lasers have fewer moving parts and consumables compared to other cutting systems. This translates to lower maintenance requirements and costs over the machine's lifetime."

Calibration and Alignment

Calibration and alignment are essential for maintaining the precision of your fiber laser cutting machine. You should regularly calibrate the machine to ensure the laser beam aligns correctly with the cutting path. Misalignment can lead to inaccurate cuts and wasted materials.

- Align the Laser Beam: Use alignment tools to check the laser beam's path. Adjust the mirrors and lenses as needed to ensure the beam is straight and focused.

- Calibrate the Servo Motors: Ensure the motors move the cutting head accurately along the desired path. This prevents errors in cutting patterns and maintains precision.

Software Updates and Upgrades

Keeping your machine's software up-to-date is vital for optimal performance. Software updates often include improvements and bug fixes that enhance the machine's functionality. You should regularly check for updates from the manufacturer and install them promptly.

- Install Software Updates: Check for updates that improve cutting patterns, speed, and power settings. These updates can enhance the machine's efficiency and accuracy.

- Consider Software Upgrades: If available, consider upgrading to newer software versions that offer advanced features. These upgrades can provide better control over the cutting process and expand your machine's capabilities.

By following these tips, you ensure your fiber laser cutting machine remains in top condition. Regular maintenance, precise calibration, and updated software contribute to the machine's efficiency and longevity, ultimately saving you time and money.

Fiber laser cutting machines revolutionize metal fabrication with precision and efficiency. You gain a deeper understanding of their operation by exploring the core components like the laser source and cutting head. Regular maintenance ensures optimal performance, extending the machine's lifespan. Consider the numerous benefits, such as speed and versatility, which make these machines invaluable in industries like automotive and aerospace. By integrating fiber laser technology, you enhance production quality and meet diverse industry demands. Embrace this cutting-edge technology to elevate your manufacturing capabilities and stay competitive.

FAQ

What is a fiber laser cutting machine?

A fiber laser cutting machine uses a high-efficiency laser to cut through materials with precision. It consists of several core components, including the fiber laser source, laser cutting head, and control system. These machines are known for their speed, accuracy, and versatility in cutting various materials.

How does a fiber laser differ from a CO2 laser?

Fiber lasers offer higher efficiency and precision compared to CO2 lasers. They produce a more focused beam, resulting in cleaner cuts and less material waste. Many users, initially skeptical, have transitioned to fiber lasers after witnessing their remarkable capabilities firsthand.

What materials can a fiber laser cutting machine handle?

You can use fiber laser cutting machines to cut a wide range of materials, including metals like steel and aluminum, as well as non-metals such as plastics. This versatility makes them suitable for various applications, from industrial manufacturing to custom fabrication.

Why is regular maintenance important for fiber laser cutting machines?

Regular maintenance ensures your fiber laser cutting machine operates efficiently and lasts longer. By cleaning components like the laser cutting head and checking the water chiller, you prevent issues like debris buildup and overheating, which can lead to costly repairs.

Can fiber laser cutting machines be used in custom fabrication?

Yes, fiber laser cutting machines excel in custom fabrication. They allow you to create bespoke designs and components with high precision and speed. This capability is particularly valuable in industries like furniture and interior design, where customization is key.

What are the benefits of using a fiber laser cutting machine?

Fiber laser cutting machines offer numerous benefits, including exceptional precision, speed, and versatility. They enhance productivity by cutting materials swiftly without compromising quality. Additionally, they consume less energy, making them cost-effective and environmentally friendly.

Are there any drawbacks to using fiber laser cutting machines?

While fiber laser cutting machines provide many advantages, they also have some drawbacks. The initial cost can be high, and regular maintenance is necessary to keep them in optimal condition. Additionally, they may have limitations when cutting thicker materials.

How can I optimize the performance of my fiber laser cutting machine?

To optimize performance, focus on regular maintenance, precise calibration, and software updates. Clean components regularly, align the laser beam accurately, and install software updates to enhance functionality and efficiency.

What industries benefit most from fiber laser cutting machines?

Industries such as automotive, aerospace, and industrial manufacturing benefit significantly from fiber laser cutting machines. These machines provide the precision and speed needed to produce high-quality components, meeting the exact specifications required in these fields.

How do fiber laser cutting machines contribute to environmental sustainability?

Fiber laser cutting machines contribute to environmental sustainability by consuming less electricity compared to traditional cutting methods. Their high conversion efficiency reduces energy waste, making them a more eco-friendly option for metal fabrication.

See Also

Understanding The Functionality Of Fiber Laser Cutters

Exploring The Operation Of CNC Laser Cutters

A Simple Explanation Of Laser Cutting Machines