How Does Laser Cutting Machine Work Easily?

Laser cutting machines revolutionize the way you approach material cutting. They operate by harnessing the power of a focused laser beam, which offers unmatched precision and speed. This technology stands out due to its ability to deliver high-quality cuts at rapid speeds, making it a preferred choice over traditional methods. You benefit from its accuracy, especially when dealing with complex designs. The versatility of laser cutting allows you to work with various materials without contamination, ensuring a clean and efficient process. Understanding how does laser cutting machine work can open up new possibilities in manufacturing and design.

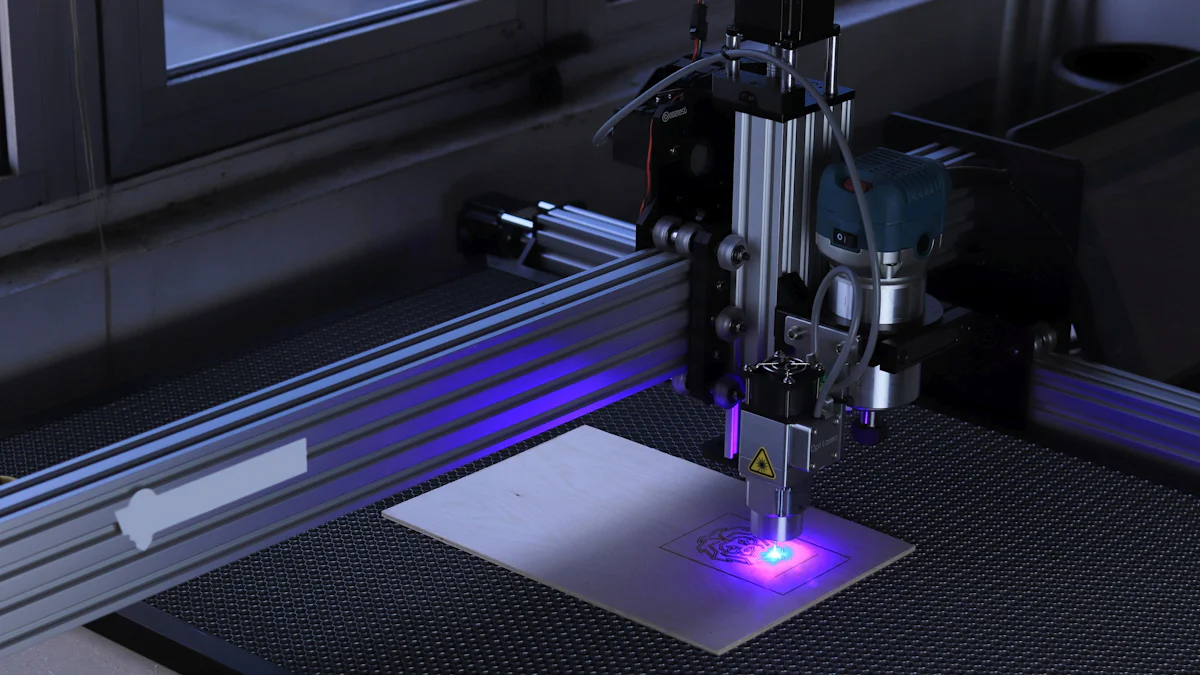

How Does a Laser Cutting Machine Work?

Understanding how does laser cutting machine work involves grasping the fundamental principles that make this technology so effective. At its core, a laser cutting machine uses a high-powered laser beam to cut through materials with precision and speed. This process relies on several key components and technologies working together seamlessly.

The Core Concept of Laser Cutting

The core concept of laser cutting revolves around the use of a focused laser beam. This beam, generated by the laser source, is directed onto the material you wish to cut. The intense heat from the laser causes the material to melt, vaporize, or ignite, allowing for precise cuts. The laser beam's ability to focus on a small area ensures that you achieve high-quality edges without damaging the surrounding material.

Laser cutting machines offer several advantages over traditional cutting methods. They provide unmatched precision, making them ideal for intricate designs and complex shapes. Additionally, they operate at high speeds, increasing efficiency and reducing production time. According to a study published in Nature in 2024, advancements in laser technology have further optimized cutting parameters, enhancing both precision and processing efficiency.

The Role of CNC in Laser Cutting

CNC, or Computer Numerical Control, plays a crucial role in how does laser cutting machine work. It allows you to program the machine using design software, automating the cutting process. This automation minimizes manual intervention, ensuring consistent and accurate results. The CNC system controls the movement of the cutting head, guiding it over the material in the desired pattern.

By using CNC technology, you can easily switch between different designs and materials, making laser cutting machines highly versatile. This flexibility is particularly beneficial in industries where customization and rapid prototyping are essential. A study in Applied Sciences in 2020 highlighted the impact of CNC on cut quality, emphasizing the importance of selecting the right material and process parameters for optimal results.

Components of a Laser Cutting Machine

Understanding the components of a laser cutting machine helps you appreciate its precision and efficiency. Each part plays a crucial role in ensuring that the machine operates smoothly and delivers high-quality cuts.

Laser Source

The laser source serves as the heart of the laser cutting machine. It generates the concentrated beam of light necessary for cutting. This beam possesses high energy, allowing it to melt, vaporize, or ignite the material you are working with. The type of laser source used can vary, with CO2 and fiber lasers being the most common. Each type offers unique advantages, such as different levels of power and efficiency, which can affect the types of materials you can cut.

Mirrors and Lenses

Mirrors and lenses form the beam delivery system. They ensure that the laser beam is accurately directed onto the material. Mirrors reflect the beam along the desired path, while lenses focus it to a fine point. This focused beam allows you to achieve precise cuts with clean edges. The quality of these optical components directly impacts the performance of the laser cutting machine, making them essential for maintaining accuracy and efficiency.

Cutting Head

The cutting head is where the action happens. It houses the lens that focuses the laser beam onto the material. The cutting head moves over the workpiece, guided by the motion control system. This system ensures precise movement, allowing you to cut intricate designs with ease. The cutting head's ability to move accurately over the material is vital for achieving the desired shape and size of the cut.

By understanding these components, you gain insight into how laser cutting machines operate. Each part works together to provide you with a tool that is both powerful and precise, capable of handling a variety of materials and designs.

The Laser Cutting Process

Understanding the laser cutting process helps you appreciate how laser cutting machines achieve such precision and efficiency. This process involves several key steps that work together to deliver high-quality cuts.

Generating the Laser Beam

The first step in the laser cutting process is generating the laser beam. The laser source, often a CO2 or fiber laser, produces a concentrated beam of light. This beam possesses high energy, which is crucial for cutting through materials. The laser source's ability to generate a powerful beam is what makes laser cutting machines so effective. You can think of the laser beam as the tool that does the actual cutting, much like a blade in traditional cutting methods.

Directing and Focusing the Beam

Once the laser beam is generated, the next step involves directing and focusing it onto the material. Mirrors and lenses play a vital role in this part of the process. Mirrors guide the beam along the desired path, while lenses focus it to a fine point. This focused beam allows you to achieve precise cuts with clean edges. The quality of the optical components directly impacts the performance of the laser cutting machine, ensuring that you get the best possible results.

Cutting Through Materials

The final step in the laser cutting process is cutting through the materials. The cutting head, which houses the lens, moves over the workpiece, guided by the CNC system. This system ensures precise movement, allowing you to cut intricate designs with ease. As the focused laser beam interacts with the material, it heats it intensely, causing it to melt, vaporize, or ignite. This thermal separation process results in a high-quality edge finish, making laser cutting ideal for a wide range of applications.

By understanding these steps, you gain insight into how laser cutting machines operate. Each part of the process works together to provide you with a tool that is both powerful and precise, capable of handling a variety of materials and designs.

Types of Laser Cutting Machines

When exploring the world of laser cutting, you encounter various types of laser cutting machines, each with unique features and applications. Understanding these differences helps you choose the right machine for your needs.

CO2 Laser Cutting Machines

The CO2 laser cutter is one of the most popular types of laser cutting machines. It uses a gas mixture, primarily carbon dioxide, to generate the laser beam. This type of laser cutter is known for its high output power and excellent beam quality. You find CO2 laser cutters particularly effective for cutting non-metal materials like wood, acrylic, and plastic. Their ability to produce smooth and precise cuts makes them ideal for intricate designs and detailed work.

Fiber Laser Cutting Machines

The fiber laser cutter represents another significant category in laser cutting technology. Unlike CO2 lasers, fiber lasers use a solid-state laser source. This design offers several advantages, including high power efficiency and ease of beam guidance. Fiber lasers excel in cutting metals, such as stainless steel and aluminum, due to their shorter wavelength, which allows for better absorption by metal surfaces. You benefit from their speed and precision, especially when working with thin materials.

Applications of Different Laser Types

Different types of laser cutting machines serve various industries and applications. You might use a CO2 laser cutter for projects involving organic materials, such as creating signage or crafting intricate patterns on wood. On the other hand, a fiber laser cutter is more suitable for industrial applications, like automotive and aerospace manufacturing, where cutting metals with precision is crucial.

By understanding the strengths of each laser type, you can select the most appropriate machine for your specific tasks. Whether you need to cut metals or non-metals, the right laser cutting machine enhances your productivity and ensures high-quality results.

Benefits of Laser Cutting Technology

Laser cutting technology offers numerous advantages that make it a preferred choice in various industries. By understanding these benefits, you can appreciate why laser cutting stands out as a superior method.

Precision and Accuracy

Laser cutting excels in delivering high precision and accuracy. The focused laser beam allows you to achieve intricate designs with minimal error. This precision is particularly beneficial when working with complex shapes or detailed patterns. Unlike traditional methods, laser cutting ensures that each cut is consistent, reducing the need for post-processing. Engineers often choose laser cutting for its ability to produce precise cuts, making it ideal for applications where accuracy is paramount.

Efficiency and Speed

The efficiency and speed of laser cutting set it apart from other cutting methods. Laser cutting machines operate at high speeds, allowing you to complete projects faster. This speed does not compromise quality; instead, it enhances productivity by reducing production time. The automation provided by laser cutting design software further streamlines the process, enabling you to switch between different designs quickly. This efficiency makes laser cutting a cost-effective solution, especially in industries where time is a critical factor.

Versatility in Material Cutting

One of the standout features of laser cutting is its versatility. You can use laser cutting to work with a wide range of materials, from metals to non-metals. This versatility allows you to tackle diverse projects without needing multiple machines. Whether you are cutting wood, acrylic, or metal, laser cutting provides clean and precise results. The adaptability of laser cutting design software enhances this versatility, giving you the flexibility to customize designs according to specific requirements. This capability makes laser cutting an invaluable tool in fields like manufacturing and design.

By leveraging the benefits of laser cutting technology, you can enhance your productivity and achieve high-quality results across various applications. The combination of precision, speed, and versatility makes laser cutting a powerful tool in modern fabrication.

Laser cutting technology offers you numerous benefits, making it a standout choice in various industries. You gain from its precision and efficiency, which allow for a high level of detail in your projects. This technology revolutionizes manufacturing by providing a precise, efficient, and versatile method for cutting materials. Whether you're working with metals, plastics, or wood, laser cutting ensures clean and accurate results. As the field continues to develop, you can expect even more advantages, such as faster speeds and improved quality, enhancing your productivity and output.

FAQ

What materials can a laser cutting machine cut?

Laser cutting machines can cut a wide range of materials. You can use them to cut metals like steel and aluminum, as well as non-metals such as wood, acrylic, and plastic. The type of laser cutter you choose will determine the materials you can work with effectively.

How precise is laser cutting?

Laser cutting offers high precision. The focused laser beam allows you to achieve intricate designs with minimal error. This precision makes laser cutting ideal for applications requiring detailed patterns and complex shapes.

Is laser cutting faster than traditional cutting methods?

Yes, laser cutting is generally faster than traditional methods. Laser cutting machines operate at high speeds, allowing you to complete projects more quickly. This speed enhances productivity without compromising the quality of the cuts.

Can I use laser cutting for custom designs?

Absolutely! Laser cutting is perfect for custom designs. The CNC system allows you to program the machine with your specific design, ensuring consistent and accurate results. This flexibility makes laser cutting ideal for industries where customization is essential.

What are the safety precautions when using a laser cutting machine?

When using a laser cutting machine, you should follow several safety precautions. Always wear protective eyewear to shield your eyes from the laser beam. Ensure proper ventilation to avoid inhaling fumes. Keep the work area clean and free of flammable materials to prevent accidents.

How does CNC technology enhance laser cutting?

CNC technology automates the laser cutting process. It allows you to program the machine using design software, minimizing manual intervention. This automation ensures consistent and accurate results, making laser cutting more efficient and versatile.

What maintenance does a laser cutting machine require?

Regular maintenance keeps your laser cutting machine in optimal condition. You should clean the mirrors and lenses to ensure the beam remains focused. Check the alignment of the optical components regularly. Follow the manufacturer's guidelines for routine maintenance tasks.

Are there different types of laser cutting machines?

Yes, there are different types of laser cutting machines. The most common are CO2 and fiber laser cutters. CO2 lasers are effective for non-metal materials, while fiber lasers excel in cutting metals. Each type has unique features suited to specific applications.

How does laser cutting benefit manufacturing?

Laser cutting benefits manufacturing by providing precision, speed, and versatility. You can achieve high-quality cuts with minimal error, enhancing the overall efficiency of production processes. This technology allows for rapid prototyping and customization, making it invaluable in modern manufacturing.

Can laser cutting machines handle large-scale projects?

Yes, laser cutting machines can handle large-scale projects. Their high speed and precision make them suitable for extensive production runs. You can rely on laser cutting for both small and large projects, ensuring consistent quality throughout.

See Also

Understanding The Basics Of Laser Cutting Machines

The Functionality Of CNC Laser Cutting Machines

Exploring The Operation Of Fiber Laser Cutters