How Does a Laser Cutting Machine Work?

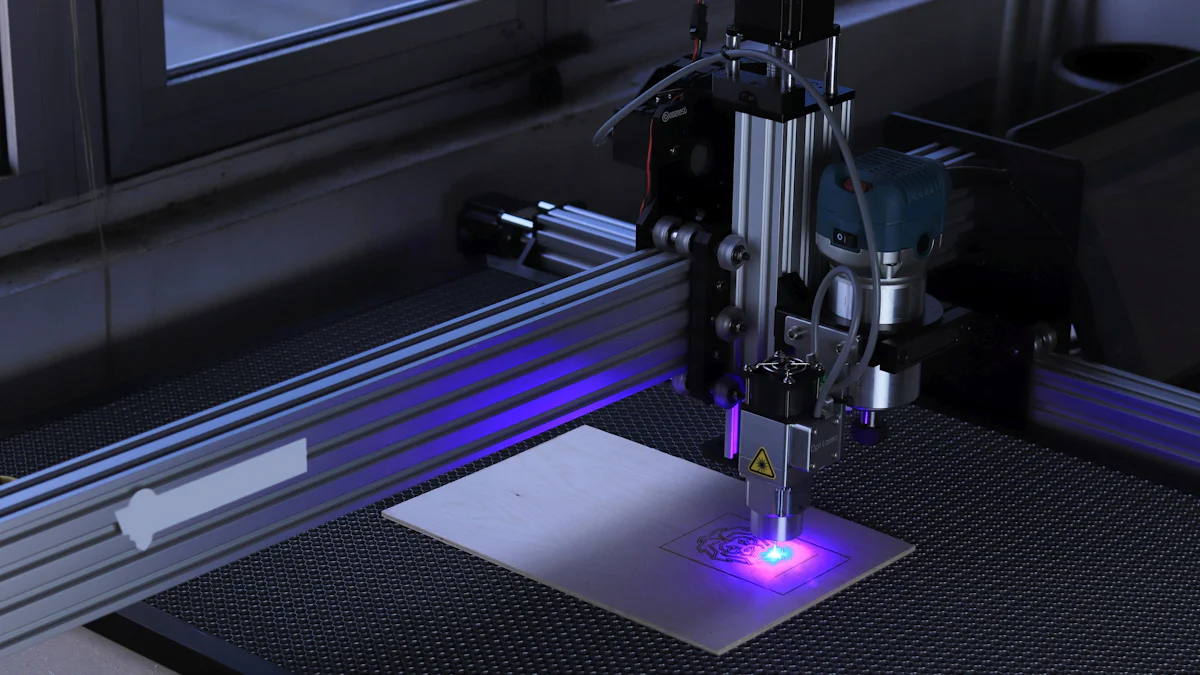

You might wonder, how does a laser cutting machine work? These machines focus a high-powered laser beam to cut or engrave materials with remarkable precision. This laser cutting process is essential in industries like automotive and electronics, where accuracy and efficiency are paramount. By automating the laser cutting process, manufacturers achieve uniform outcomes and reduce downtime. The types of laser cutting machines available today cater to various needs, ensuring that each tool and die component meets exact specifications. This precision is crucial for producing high-quality goods across different sectors.

Types of Laser Cutting Machines

When exploring the world of laser cutting, you will encounter several types of laser cutters, each designed for specific tasks and materials. Understanding these types can help you choose the right machine for your needs.

CO2 Laser Cutting Machines

CO2 lasers are among the most popular laser cutting types. They use a CO2 laser tube to generate a laser beam. This beam travels through a series of mirrors and focuses on the material's surface using a lens. You can use CO2 lasers to cut or engrave with precision.

How CO2 lasers work

CO2 lasers work by exciting carbon dioxide gas with electricity. This process creates a powerful laser beam. The beam is then directed onto the material, where it cuts or engraves based on your design. The non-contact nature of CO2 lasers makes them ideal for delicate materials like glass.

Common uses of CO2 lasers

You will find CO2 laser cutters in industries that require precision and versatility. They excel in cutting non-metal materials such as wood, acrylic, and fabric. Their ability to produce clean cuts makes them a favorite in both architectural and automotive applications.

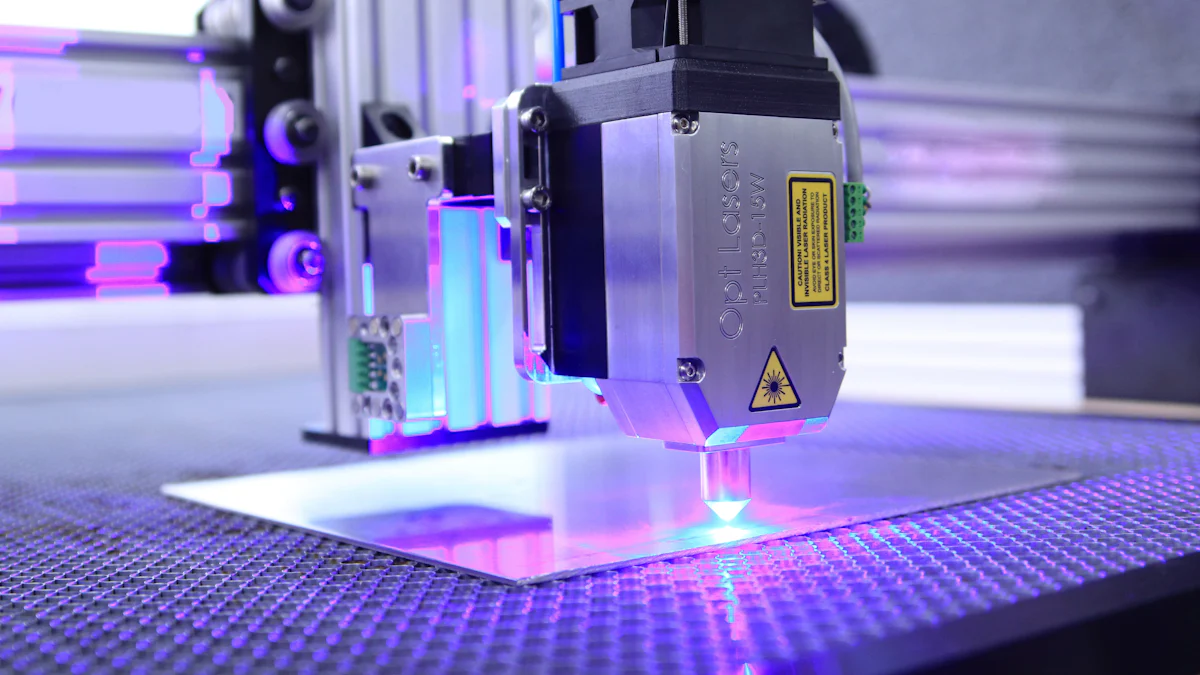

Fiber Laser Cutting Machines

Fiber laser cutters have gained popularity for their efficiency and versatility. They are particularly effective for metal marking and engraving.

Operation of fiber lasers

Fiber lasers operate by using a seed laser, which is amplified through special glass fibers. This process results in a high-intensity laser beam. You can use fiber lasers on a wide range of materials, including metals, alloys, and some plastics.

Advantages of fiber lasers

Fiber lasers offer several advantages. They provide high precision and speed, making them suitable for industrial applications. Their compact size and low maintenance requirements make them an attractive choice for many businesses.

Nd:YAG/Nd:YVO Lasers

Nd:YAG/Nd:YVO lasers are another type of laser used for cutting and engraving.

Functionality of Nd:YAG/Nd:YVO lasers

These lasers use a crystal as the lasing medium. They are known for their ability to produce high-energy pulses, which are ideal for precise cutting and engraving tasks.

Typical applications of these lasers

You will often find Nd:YAG/Nd:YVO lasers in industries that require high precision. They are effective for both cutting and engraving, making them versatile tools in manufacturing and design.

Direct Diode Lasers

How direct diode lasers work

Direct diode lasers operate by emitting laser light directly from semiconductor diodes. These diodes generate a laser beam without the need for additional lasing mediums or complex optical systems. You will find that this simplicity results in a compact and efficient design. The laser beam produced is then focused onto the material's surface, allowing for precise cutting or engraving. This method ensures high energy efficiency and minimal heat generation, making it suitable for delicate materials.

Benefits and applications of direct diode lasers

Direct diode lasers offer several advantages that make them appealing for various applications:

- Compact Size: Their small footprint allows you to integrate them easily into existing systems or use them in space-constrained environments.

- Energy Efficiency: Direct diode lasers consume less power compared to other laser types, reducing operational costs.

- Versatility: You can use them on a wide range of materials, including metals, plastics, and some ceramics.

- Low Maintenance: With fewer components, these lasers require less maintenance, saving you time and resources.

In terms of applications, direct diode lasers excel in industries where precision and efficiency are crucial. You will often see them used in electronics manufacturing for tasks like marking and engraving. Their ability to handle delicate materials also makes them ideal for medical device production. Additionally, their energy efficiency and compact size make them a popular choice for small-scale workshops and creative studios.

Comparison of Laser Types

When choosing a laser cutting machine, understanding the differences between types is crucial. Each type offers unique benefits and limitations, impacting performance, cost, and material suitability.

Performance Differences

Cutting speed and precision

Laser cutting machines vary in speed and precision. Fiber lasers excel in cutting metals quickly and accurately. They use a high-intensity beam that ensures clean cuts, making them ideal for industrial applications. Direct diode lasers also offer fast processing times, especially for thin metal sheets. Their high beam quality and efficiency make them suitable for tasks requiring precision. In contrast, CO2 lasers are slower but provide excellent precision for non-metal materials like wood and acrylic.

Material compatibility

Material compatibility is another key factor. Fiber lasers are versatile, handling metals, alloys, and some plastics with ease. They are particularly effective for cutting metals due to their high power and precision. CO2 lasers work best with non-metals, such as wood and fabric, offering clean cuts without damaging the material. Direct diode lasers can cut a variety of materials, including metals and plastics, thanks to their energy efficiency and compact design.

Cost Considerations

Initial investment

The initial investment for laser cutting machines varies. Fiber lasers often require a higher upfront cost due to their advanced technology and capabilities. However, their efficiency and speed can justify the expense for industrial users. CO2 lasers generally have a lower initial cost, making them accessible for smaller businesses or hobbyists. Direct diode lasers offer a cost-effective option, combining affordability with high performance.

Maintenance costs

Maintenance costs also differ among laser types. Fiber lasers have low maintenance needs, thanks to their robust design and fewer moving parts. This reduces downtime and long-term expenses. CO2 lasers may require more frequent maintenance due to their complex optical systems. Direct diode lasers stand out for their simplicity and reliability, resulting in minimal maintenance requirements and lower operational costs.

Suitability for Various Materials

Metals vs. non-metals

Choosing the right laser cutting machine depends on the materials you work with. Fiber lasers are the go-to choice for cutting metals, offering precision and speed. They handle metals like steel and aluminum efficiently. CO2 lasers excel with non-metals, providing clean cuts for materials like wood and acrylic. Direct diode lasers offer versatility, capable of cutting both metals and non-metals, making them suitable for diverse applications.

Thickness and complexity of materials

Material thickness and complexity also influence your choice. Fiber lasers can cut through thick metals with ease, maintaining precision even with complex designs. CO2 lasers are better suited for thinner materials, where their precision shines. Direct diode lasers handle thin sheets effectively, offering high-speed cutting for intricate designs. Their compact size and efficiency make them ideal for detailed work.

Applications of Laser Cutting Machines

Laser cutting machines have revolutionized various industries by offering precision and efficiency. Understanding the applications of different types of laser cutting machines can help you choose the right tool for your needs.

Industrial Applications

Automotive Industry

In the automotive industry, laser cutting machines play a crucial role. You can use them to cut intricate parts with high precision, ensuring that each component fits perfectly. Fiber lasers are particularly effective here due to their ability to cut metals like steel and aluminum efficiently. This precision reduces waste and enhances the quality of automotive parts.

Aerospace Industry

The aerospace industry demands high precision and reliability. Laser cutting machines meet these requirements by providing accurate cuts on complex materials. You will find that fiber lasers excel in this field, offering the ability to cut through tough metals used in aircraft manufacturing. Their efficiency and speed make them indispensable in producing high-quality aerospace components.

Creative and Artistic Uses

Jewelry Making

For jewelry making, laser cutting machines offer unparalleled precision. You can create intricate designs with ease, allowing for unique and detailed pieces. CO2 lasers are often used in this field due to their ability to cut non-metal materials like acrylic and wood, which are popular in custom jewelry designs.

Custom Signage

Custom signage benefits greatly from laser cutting technology. You can achieve clean and precise cuts on various materials, creating eye-catching signs. CO2 lasers are ideal for this application, as they handle materials like wood and acrylic with ease. This versatility allows for creative freedom in designing custom signs.

Other Notable Applications

Medical Device Manufacturing

In medical device manufacturing, precision is paramount. Laser cutting machines provide the accuracy needed to produce intricate medical devices. Fiber lasers are commonly used due to their ability to cut metals with high precision. This ensures that each medical device meets strict quality standards.

Electronics Industry

The electronics industry relies on laser cutting machines for precision and efficiency. You can use them to cut and engrave delicate components, ensuring that each piece functions correctly. Direct diode lasers are gaining popularity in this field due to their compact size and energy efficiency. They offer high-speed cutting, making them ideal for mass production in electronics manufacturing.

Understanding how laser cutting machines work and their types is essential for selecting the right tool for your needs. These machines, whether CO2, fiber, Nd:YAG, or direct diode, offer unique advantages across various applications. You should consider factors like material compatibility, cutting speed, and cost when choosing a machine. Laser cutting technology continues to shape industries, from automotive to electronics, by providing precision and efficiency. As the industry evolves, advancements in composite laser cutting will further enhance capabilities, ensuring that you can achieve high-quality results in your projects.

FAQ

What factors should I consider when choosing a laser cutting machine?

When selecting a laser cutting machine, you should evaluate several factors to ensure it meets your needs. Consider the materials you plan to process and their compatibility with the laser type. Assess the work area size to accommodate your projects. Look at the laser power for cutting efficiency and precision. Evaluate the machine's speed and throughput for productivity. Consider automation features and software compatibility for ease of use. Maintenance and reliability are crucial for long-term operation. Lastly, check the cooling and extraction systems for safety and performance.

How does laser power affect cutting performance?

Laser power significantly impacts cutting performance. Higher wattage allows you to cut through thicker materials more efficiently. It also enhances cutting speed and precision. If you need to improve performance, consider increasing the laser's power. This adjustment can lead to faster processing times and cleaner cuts, especially in industrial applications.

Can I use one laser cutter for different materials?

Yes, you can use a versatile laser cutter for various materials. However, you must ensure the machine's compatibility with each material type. Fiber lasers excel with metals, while CO2 lasers are ideal for non-metals like wood and acrylic. Direct diode lasers offer versatility, handling both metals and non-metals. Always check the manufacturer's guidelines for material compatibility to avoid damage.

What maintenance does a laser cutting machine require?

Regular maintenance ensures your laser cutting machine operates efficiently. You should clean the lenses and mirrors to maintain beam quality. Check and replace filters in the cooling and extraction systems. Inspect the machine for wear and tear, especially in moving parts. Follow the manufacturer's maintenance schedule to prevent downtime and extend the machine's lifespan.

How does automation improve laser cutting?

Automation enhances laser cutting by increasing efficiency and consistency. Automated systems reduce manual intervention, leading to uniform outcomes. They also minimize errors and waste, improving overall productivity. Implementing automation can streamline your workflow, allowing you to focus on other tasks while the machine operates.

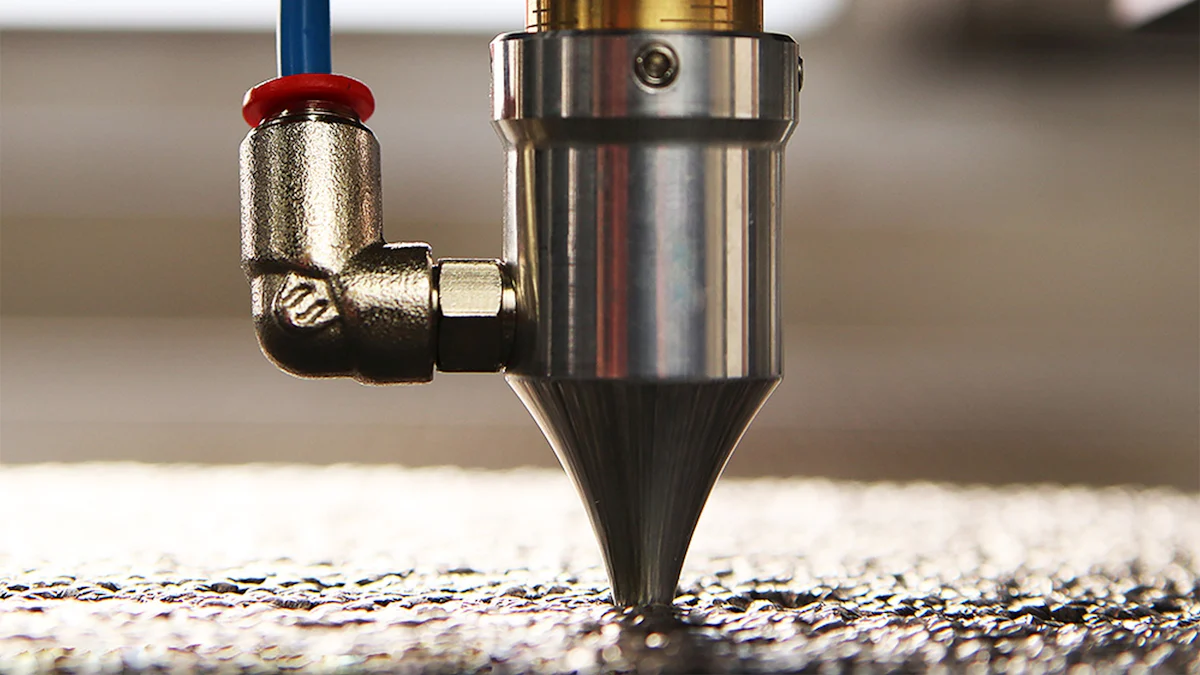

What is the role of gas assist in laser cutting?

Gas assist plays a crucial role in laser cutting by improving cut quality and speed. It helps remove molten material from the cut area, resulting in cleaner edges. Gas assist also cools the material, reducing heat-affected zones. You can use different gases, such as oxygen or nitrogen, depending on the material and desired finish.

How do I ensure safety when using a laser cutting machine?

Safety is paramount when operating a laser cutting machine. Always wear appropriate protective gear, such as safety glasses. Ensure the machine is in a well-ventilated area to prevent fume buildup. Follow the manufacturer's safety guidelines and training procedures. Regularly inspect safety features, like emergency stops and interlocks, to ensure they function correctly.

Can laser cutting machines handle complex designs?

Yes, laser cutting machines excel at handling complex designs. Their precision and accuracy allow you to create intricate patterns and shapes. You can use computer-aided design (CAD) software to program the machine for detailed work. This capability makes laser cutting ideal for industries requiring high precision, such as aerospace and jewelry making.

What are the cost considerations for laser cutting machines?

Cost considerations include the initial investment and ongoing expenses. Fiber lasers often have a higher upfront cost due to their advanced technology. However, their efficiency can justify the expense for industrial users. CO2 lasers generally have a lower initial cost, suitable for smaller businesses. Maintenance costs vary, with fiber lasers requiring less upkeep than CO2 lasers. Evaluate these factors to choose a machine that fits your budget and needs.

How do I improve the efficiency of my laser cutting process?

To enhance efficiency, consider optimizing several aspects of your laser cutting process. Increase the laser's power for faster cutting speeds. Implement automation to reduce manual intervention and errors. Regularly maintain the machine to ensure optimal performance. Use appropriate gas assist to improve cut quality. By addressing these areas, you can achieve higher productivity and better results.

See Also

Understanding The Basics Of Laser Cutting Machines

The Functionality Of Fiber Laser Cutting Machines

Exploring The Operation Of CNC Laser Cutters