How CNC Laser Cutting Machines Operate

CNC laser cutting machines have transformed the process of cutting, inscribing, or engraving materials. But what is a CNC laser cutting machine? It is a device that utilizes a high-power laser beam to deliver exceptional precision. These machines can effortlessly cut through materials such as metal, wood, and plastic. The process starts with generating a laser beam, which is then focused onto the material, and CNC technology is employed for precise control. This synergy allows for the creation of intricate designs and shapes that traditional methods cannot achieve. With tolerances as precise as ±0.01 mm, CNC laser cutting machines guarantee accuracy and consistency in every project.

What is CNC Laser Cutting?

Definition and Overview

When you explore the world of modern manufacturing, you might wonder, "What is CNC laser cutting machine technology?" This advanced process uses a high-powered laser beam to cut, inscribe, or engrave materials with remarkable precision. CNC Laser Cutting Machines are integral to industries like aerospace, automotive, electronics, and construction. They handle a variety of materials, including metals, plastics, wood, and ceramics, with ease.

The operation of a CNC laser cutting machine begins with a digital design file. This file contains detailed instructions for every angle and curve of the desired shape. The machine then uses these instructions to guide the laser beam, ensuring precise cuts and intricate designs. You can achieve complex geometries and small holes that would be challenging with traditional methods.

CNC technology plays a crucial role in this process. It automates the movement and performance of the laser, using G codes and M codes for programming. This automation ensures consistent results, even across large production runs. Each piece becomes an exact replica of the others, maintaining high accuracy and repeatability.

In essence, a CNC laser cutting machine offers you the ability to create detailed and complex designs with minimal effort. Its versatility makes it suitable for various projects, whether you're working with metal, wood, or plastic. By understanding what a CNC laser cutting machine is, you can appreciate its impact on modern manufacturing and its potential to transform your projects.

How CNC Laser Cutting Machines Work

Understanding how CNC laser cutting machines operate can transform your approach to manufacturing. These machines use a high-powered laser beam to cut through materials with precision. The process involves several key steps that ensure accuracy and efficiency.

The Laser Cutting Process

Laser Generation and Beam Delivery

The journey begins with the generation of a laser beam. This high-powered laser beam is created within the machine and then directed towards the material. The beam delivery system ensures that the laser remains focused and intense as it travels. This focus is crucial for achieving clean cuts and intricate designs. The beam's path is meticulously controlled, allowing you to create complex shapes with ease.

Interaction with Material

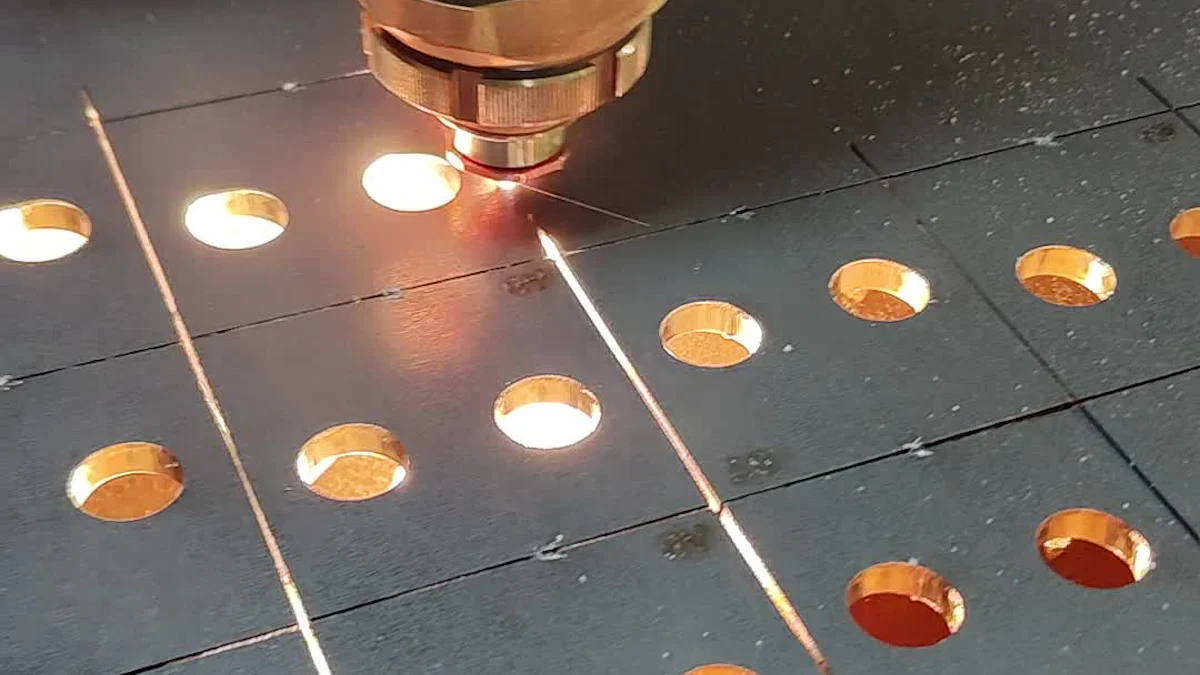

Once the laser beam reaches the material, it interacts by heating it to the point of melting or vaporization. This interaction is the core of the cutting process. The laser's precision allows you to cut through various materials, including metals, plastics, and wood. As the laser cuts, a gas assist may blow away molten material, preventing re-solidification and ensuring a smooth edge. This step is vital for maintaining the quality of the cut.

Role of CNC in Laser Cutting

Programming and Control

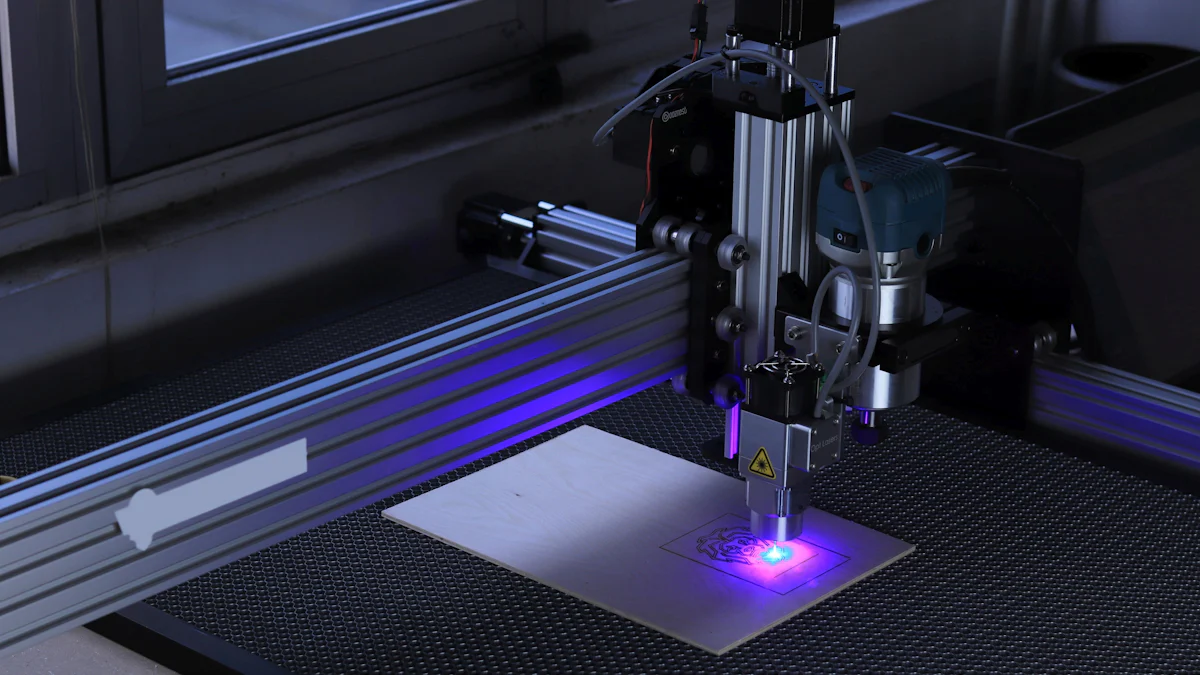

CNC, or computer numerical control, plays a pivotal role in the laser cutting process. It begins with a digital design file created using CAD software. This file is converted into a CNC program using CAM software. The CNC system then guides the laser along the programmed path, ensuring each cut follows the exact specifications. This level of control allows you to achieve consistent results, even in large production runs.

Precision and Automation

Automation is a hallmark of CNC laser cutting. The CNC technology automates the movement of the laser head, reducing the chance of human error. This automation not only saves time but also enhances precision. You can rely on CNC laser cutting machines to produce identical pieces with high accuracy. This precision is essential for industries that demand exacting standards, such as aerospace and electronics.

By understanding the intricacies of the CNC laser cutting process, you can harness its full potential. Whether you're crafting detailed designs or producing large quantities, these machines offer unmatched precision and efficiency.

Types of CNC Laser Cutting Machines

When exploring the world of CNC laser cutting, you will encounter two primary types of laser cutting machines: CO2 laser cutters and fiber laser cutters. Each type has distinct characteristics and applications that cater to different needs in the manufacturing industry.

CO2 Laser Cutting Machines

Characteristics and Applications

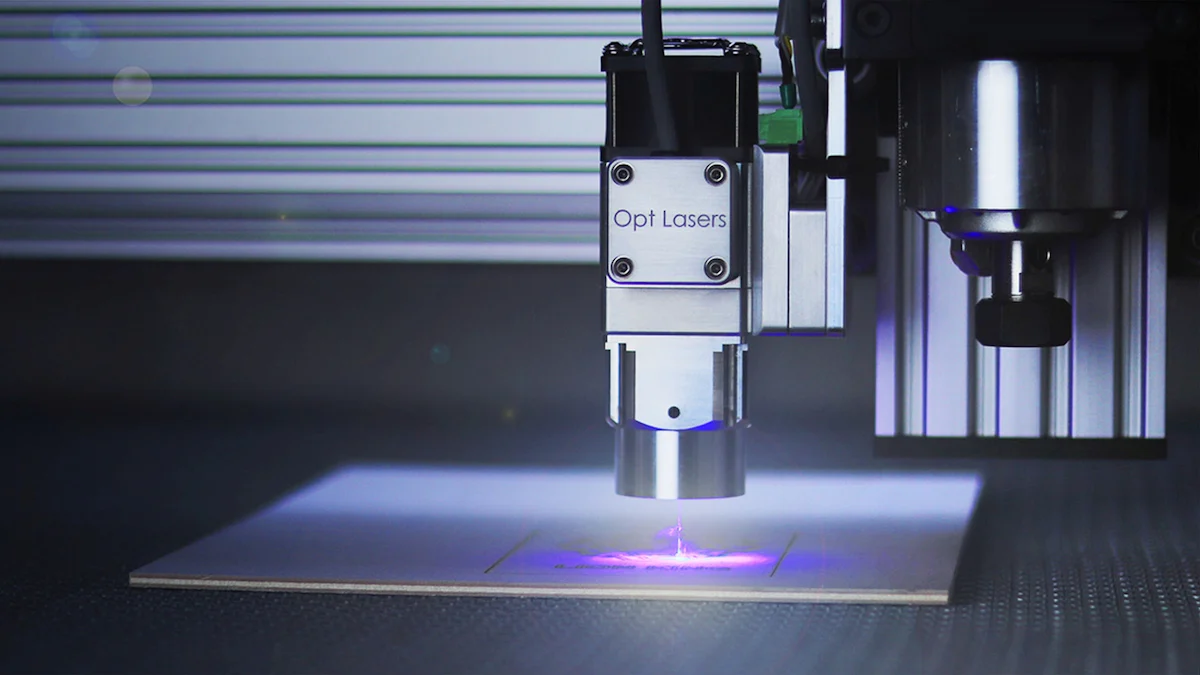

CO2 laser cutters use a gas mixture, primarily carbon dioxide, to generate the laser beam. These machines excel in cutting non-metallic materials such as wood, acrylic, and plastics. You will find them particularly useful in industries like signage, textiles, and packaging. The ability to produce smooth edges on thicker materials makes CO2 laser cutters a popular choice for projects requiring high-quality finishes.

Pros and Cons

Pros:

- CO2 laser cutters are generally more affordable than fiber laser cutters, making them accessible for small businesses and hobbyists.

- They offer excellent edge quality, especially on thicker materials, which is crucial for applications demanding precision and aesthetics.

Cons:

- These machines consume more power compared to fiber laser cutters, which can lead to higher operational costs over time.

- CO2 laser cutters are gradually being replaced by fiber laser technology due to advancements in speed and efficiency.

Fiber Laser Cutting Machines

Characteristics and Applications

Fiber laser cutters utilize a solid-state laser source, which provides a more concentrated and precise beam. These machines are ideal for cutting metallic materials, including steel, aluminum, and copper. You will often see fiber laser cutters in industries such as automotive, aerospace, and electronics, where precision and speed are paramount.

Pros and Cons

Pros:

- Fiber laser cutters offer higher cut precision and faster processing speeds, making them suitable for high-volume production.

- They have a longer working life and require less maintenance, which can reduce downtime and increase productivity.

Cons:

- The initial cost of fiber laser cutters is higher than that of CO2 laser cutters, which might be a barrier for some businesses.

- While they excel in cutting metals, fiber laser cutters may not perform as well on non-metallic materials compared to CO2 laser cutters.

Understanding the differences between these types of laser cutting machines will help you choose the right tool for your specific needs. Whether you prioritize cost, material compatibility, or cutting precision, both CO2 and fiber laser cutters offer unique advantages that can enhance your manufacturing capabilities.

Advantages and Disadvantages of CNC Laser Cutting

CNC laser cutting machines have become a cornerstone in modern manufacturing, offering a range of benefits and some challenges. Understanding these can help you make informed decisions about incorporating this technology into your manufacturing process.

Advantages

Precision and Accuracy

One of the standout features of CNC laser cutting is its unparalleled precision. The computer-controlled laser beam ensures that every cut is exact and uniform, a feat that traditional methods like sawing or milling struggle to achieve. This precision allows you to create intricate designs and complex shapes with ease. The narrow kerf produced by the laser maximizes material usage, reducing waste and enhancing the overall efficiency of the manufacturing process.

Versatility in Material Use

CNC laser cutting machines excel in handling a wide variety of materials. Whether you're working with metals, plastics, wood, or ceramics, these machines offer the flexibility to switch between different materials without compromising on quality. This versatility makes them an invaluable tool in industries ranging from aerospace to electronics, where diverse material requirements are common.

"CNC laser cutting provides a plethora of advantages, making it a popular choice for various industries. Beyond its renowned precision and accuracy, here are some other key benefits: Higher Quality Edges, Narrower Kerfs, Smaller Heat-Affected Zone (HAZ), Less Contamination and Waste, Less Maintenance Required, Less Repair Costs, Greater Operator Safety."

Disadvantages

Initial Cost and Maintenance

While CNC laser cutting machines offer numerous advantages, they come with a significant initial investment. The cost of purchasing and setting up these machines can be a barrier for some businesses, especially smaller ones. Additionally, although they require less maintenance than mechanical cutters, the maintenance costs can still be substantial. Regular upkeep is essential to ensure the machines operate at peak performance, which can add to the overall expense.

Limitations in Material Thickness

Despite their versatility, CNC laser cutting machines have limitations when it comes to cutting very thick materials. The laser's power may not be sufficient to penetrate thicker materials effectively, which can limit the scope of projects you can undertake. For applications requiring cuts through substantial thicknesses, alternative methods might be necessary.

Materials Suitable for CNC Laser Cutting

When you work with CNC laser cutting machines, understanding the materials they can handle is crucial. These machines offer versatility, allowing you to cut a wide range of materials with precision and efficiency.

Metals

CNC laser cutting machines excel in cutting various metals. You can use them to cut steel, stainless steel, and aluminum with ease. The precision of the laser ensures clean cuts and intricate designs, making it ideal for industries like automotive and aerospace. However, some metals, such as copper and aluminum, present challenges due to their high reflectivity. This property can affect the laser's effectiveness, requiring adjustments to the cutting parameters.

Non-metals

Beyond metals, CNC laser cutting machines are adept at cutting non-metallic materials. You can cut plastics, wood, and even ceramics with these machines. The ability to switch between different materials without compromising quality makes them invaluable in industries like signage and packaging. For instance, when cutting acrylic or wood, the laser produces smooth edges, enhancing the aesthetic appeal of the final product.

Considerations for Material Selection

Selecting the right material for CNC laser cutting involves several considerations. First, assess the material's thickness. While laser cutting machines handle a variety of thicknesses, very thick materials may require alternative methods. Next, consider the material's reflectivity. Highly reflective materials might need specific settings to ensure effective cutting. Lastly, evaluate the material's intended use. Different projects may demand varying levels of precision and finish quality, influencing your material choice.

By understanding the materials suitable for CNC laser cutting, you can optimize your projects and achieve the desired results. Whether you're working with metals or non-metals, these machines provide the flexibility and precision needed for diverse applications.

Comparing CNC Laser Cutting Machines

CO2 vs. Fiber Lasers

When you explore CNC laser cutting machines, you'll encounter two main types: CO2 lasers and fiber lasers. Each type offers unique advantages and suits different applications.

-

Material Compatibility:

- CO2 lasers excel in versatility. You can use them on a wide range of materials, including wood, acrylic, and plastics. This makes them ideal for industries like signage and textiles.

- Fiber lasers, on the other hand, specialize in cutting metals. They perform exceptionally well with materials like steel, aluminum, and copper. If your projects involve metalwork, fiber lasers are the go-to choice.

-

Cutting Speed and Precision:

- Fiber lasers outshine CO2 lasers in speed, especially when cutting thin sheets (less than 8 mm). They offer higher precision, making them suitable for intricate designs and detailed work.

- CO2 lasers, while slower, provide excellent edge quality on thicker materials. This makes them valuable for applications requiring smooth finishes.

-

Operational Costs:

- CO2 lasers consume more power, leading to higher operational costs. They require more maintenance, which can add to expenses over time.

- Fiber lasers, in contrast, have lower power consumption and longer working life. This results in reduced operational costs and less downtime.

Understanding how CNC laser cutting machines operate is crucial for modern manufacturing. These machines use a high-power laser beam to cut materials with precision. You can choose between CO2 and fiber laser cutting machines based on your needs. CO2 machines excel in cutting non-metals, while fiber machines are ideal for metals. Selecting the right laser cutting machine depends on your material and project requirements. Using laser cutting design software enhances your ability to create intricate designs. By choosing the appropriate machine and software, you ensure efficiency and quality in your projects.

FAQ

What is CNC laser cutting?

CNC laser cutting is a technology that uses a high-power laser beam guided by computer instructions to cut or engrave materials. This method provides a high degree of accuracy and precision, allowing you to create complex shapes and designs that would be nearly impossible to achieve manually. Industries such as automotive, aerospace, electronics, medical, and construction commonly use this technique.

How does CNC laser cutting work?

A CNC laser cutter operates using computer numerical controls and special computer instructions known as G-code. This machine uses a high-powered laser beam to cut through materials like metal, wood, and plastic. The process involves a non-contact thermal method, where the laser head, equipped with a laser-focusing lens and a nozzle, precisely executes the required operations.

What is a laser cutting machine?

A laser cutting machine is a type of CNC machine. The term CNC stands for Computer Numerical Controlled, which refers to the machine's ability to take commands from digitized drawings. These drawings are transformed into a computer language that describes every angle and curve of the design, allowing for high precision in cutting.

What are the advantages of using CNC laser cutting?

CNC laser cutting machines offer several advantages. They are highly automated and controlled by CNC systems, ensuring consistent results across large production runs. Each piece produced is an exact replica of the others, maintaining high precision and quality. This automation reduces the chance of human error and increases efficiency.

Can CNC laser cutting machines handle different materials?

Yes, CNC laser cutting machines are versatile and can handle a wide range of materials. You can use them to cut metals like steel and aluminum, as well as non-metals such as plastics and wood. This flexibility makes them suitable for various industries with diverse material requirements.

Are there limitations to CNC laser cutting?

While CNC laser cutting machines are versatile, they do have some limitations. They may struggle with cutting very thick materials, as the laser's power might not be sufficient to penetrate effectively. Additionally, highly reflective materials like copper and aluminum can pose challenges, requiring specific settings for effective cutting.

How do I choose between CO2 and fiber laser cutting machines?

Choosing between CO2 and fiber laser cutting machines depends on your specific needs. CO2 lasers excel in cutting non-metallic materials like wood and acrylic, making them ideal for signage and textiles. Fiber lasers, however, specialize in cutting metals such as steel and aluminum, offering higher precision and speed for metalwork projects.

See Also

Understanding The Functionality Of CNC Laser Cutters

A Simple Explanation Of Laser Cutting Machines

The Working Principle Of Fiber Laser Cutters