How a CNC Laser Cutting Machine Works Wonders

CNC laser cutting technology has revolutionized the manufacturing landscape. You can now achieve unparalleled precision and efficiency in your projects. This technology allows you to create intricate designs with ease, transforming raw materials into finished products swiftly. The versatility of laser cutting means you can work with a wide range of materials, from metals to plastics. As the market for laser cutting machines grows, projected to reach USD 22.12 billion by 2031, you stand to benefit from its expanding capabilities. Understanding how a CNC laser cutting machine works can open new possibilities for innovation and creativity.

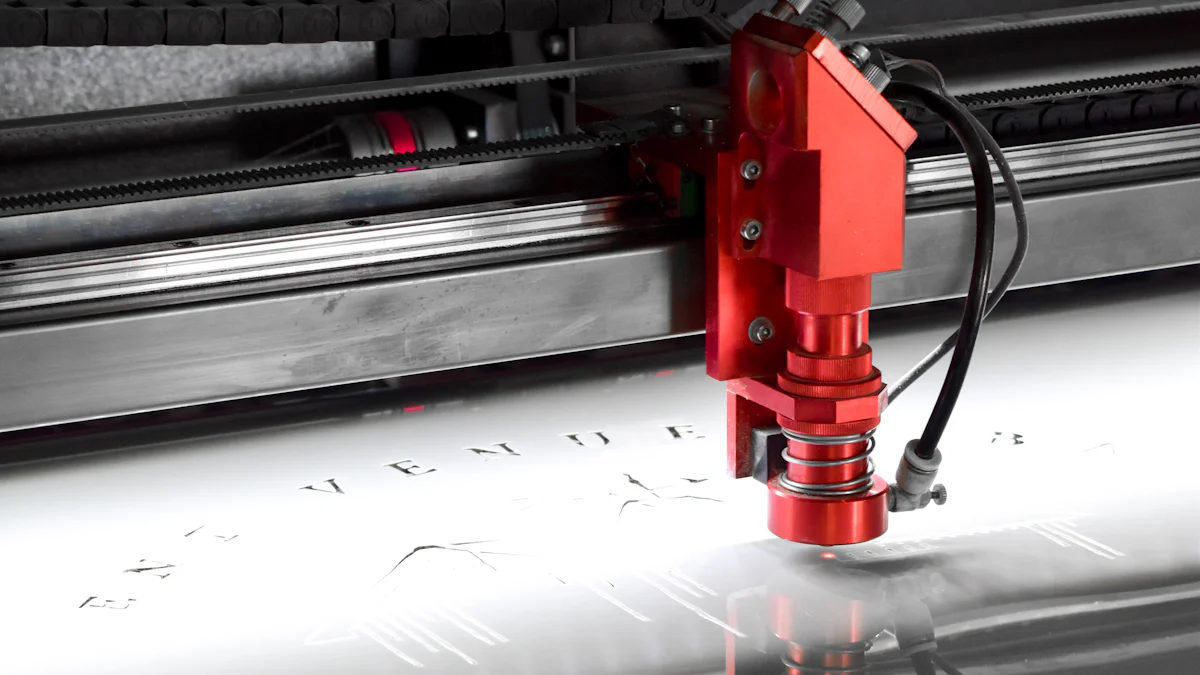

How a CNC Laser Cutting Machine Works

Understanding how a CNC laser cutting machine works can significantly enhance your manufacturing capabilities. These machines utilize a high-power laser beam, guided by precise computer instructions, to cut or engrave materials with exceptional accuracy. This process begins with a design file, which the machine's computer system translates into specific instructions. These instructions control the movement of the laser head and the work table, ensuring that each cut is executed with precision.

Basic Operation

In the basic operation of a CNC laser cutting machine, you start by loading a design file into the machine's computer system. This file contains the blueprint of the shape or pattern you wish to cut. The computer then processes this file and generates a set of instructions. These instructions guide the laser head as it moves over the material. The laser beam, focused to a fine point, cuts through the material by melting, burning, or vaporizing it. This method allows you to achieve intricate designs and clean cuts without the need for additional finishing.

Key Components

A CNC laser cutting machine comprises several key components that work together to deliver precise results:

- Laser Source: This is the heart of the machine, generating the high-power laser beam used for cutting.

- CNC Controller: This component interprets the design file and controls the movement of the laser head and work table.

- Laser Head: It focuses the laser beam onto the material, ensuring accurate cuts.

- Work Table: This is where you place the material to be cut. It moves in coordination with the laser head to facilitate precise cutting.

- Cooling System: It prevents the machine from overheating during operation, ensuring consistent performance.

By understanding these components and their functions, you can better appreciate how a CNC laser cutting machine works. This knowledge empowers you to leverage the full potential of laser cutting technology in your projects.

Advantages of CNC Laser Cutting

When you explore the advantages of CNC laser cutting, you'll discover how it can transform your manufacturing processes. This technology offers several benefits that make it a preferred choice for many industries.

Precision and Accuracy

CNC laser cutting provides a high degree of accuracy, allowing you to achieve intricate designs with ease. The laser beam is incredibly precise, often cutting with tolerances as small as less than 0.0001 inch. This precision ensures that each piece you produce meets exact specifications, reducing waste and improving quality. Compared to traditional methods like CNC milling, laser cutting delivers cleaner cuts without the need for additional finishing.

Efficiency and Speed

The high speed of CNC laser cutting significantly enhances your production efficiency. You can cut through materials swiftly, reducing lead times and increasing throughput. Unlike waterjet cutting, which may require more post-processing, laser cutting leaves smooth edges, minimizing the need for further work. This efficiency allows you to complete projects faster, meeting tight deadlines with ease.

Versatility in Material Cutting

One of the standout features of CNC laser cutting is its versatility. You can work with a wide range of materials, from metals to plastics, without compromising on quality. The laser's adaptability means you can switch between different materials quickly, making it ideal for diverse projects. Whether you're cutting thin sheets or intricate patterns, laser cutting handles it all with precision and ease.

By understanding these advantages, you can leverage CNC laser cutting to enhance your manufacturing capabilities. This technology not only improves the quality of your products but also boosts your overall productivity.

Cost-Effectiveness

CNC laser cutting offers significant cost advantages that can enhance your manufacturing processes. This technology reduces material waste due to its precision, ensuring you use only what is necessary. The clean cuts produced by laser cutting eliminate the need for additional finishing, saving both time and resources. Compared to traditional methods like CNC milling, laser cutting is faster and more precise, which translates into lower labor costs and increased productivity.

Moreover, the maintenance costs of CNC laser cutting machines are relatively low. These machines have fewer mechanical parts, reducing the likelihood of breakdowns and the need for repairs. This reliability ensures consistent performance, allowing you to focus on production without worrying about unexpected expenses. By investing in CNC laser cutting, you can achieve high-quality results while keeping operational costs in check.

Environmental Benefits

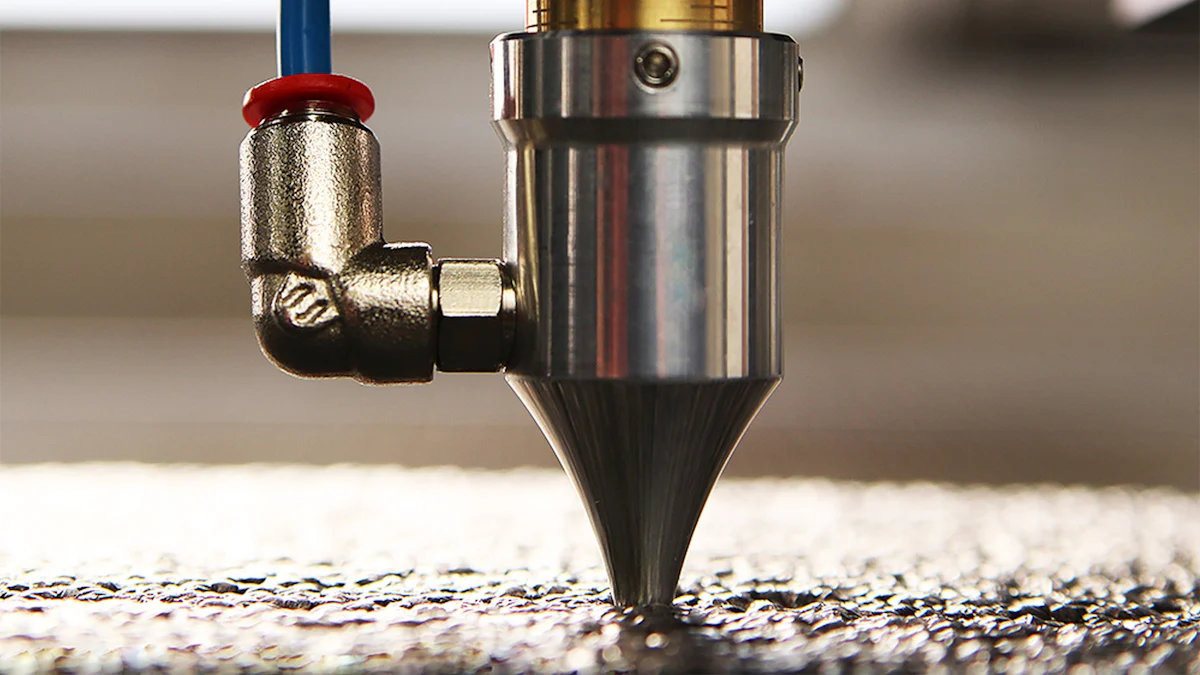

CNC laser cutting also contributes positively to the environment. The precision of laser cutting minimizes material waste, which reduces the environmental impact associated with excess scrap. Unlike waterjet cutting, which requires large amounts of water and can lead to contamination, laser cutting uses a dry process, making it more environmentally friendly.

Additionally, the energy efficiency of CNC laser cutting machines helps lower your carbon footprint. These machines consume less energy compared to traditional cutting methods, making them a sustainable choice for modern manufacturing. By choosing laser cutting, you not only improve your production efficiency but also contribute to a greener planet.

CNC Laser Cutter in Real-World Applications

CNC laser cutters have become indispensable tools across various industries due to their precision and versatility. You can find these machines playing a crucial role in sectors ranging from aerospace to medical device manufacturing. Their ability to handle diverse materials with ease makes them a preferred choice for many applications.

Aerospace and Automotive Industries

In the aerospace and automotive industries, precision is paramount. CNC laser cutters excel in producing intricate components with exact specifications. You can use them to cut lightweight materials like aluminum and titanium, which are essential for building efficient aircraft and vehicles. The high accuracy of laser cutting ensures that each part fits perfectly, reducing the need for adjustments during assembly. This precision not only enhances the performance of the final product but also contributes to safety and reliability.

Medical Device Manufacturing

The medical field demands high standards of accuracy and cleanliness. CNC laser cutters meet these requirements by producing precise cuts without leaving burrs or residues. You can manufacture intricate components for medical devices, such as surgical instruments and implants, with confidence. The clean cuts provided by laser cutting minimize the risk of contamination, ensuring that the devices meet stringent health standards. This technology allows you to innovate and create complex designs that improve patient outcomes.

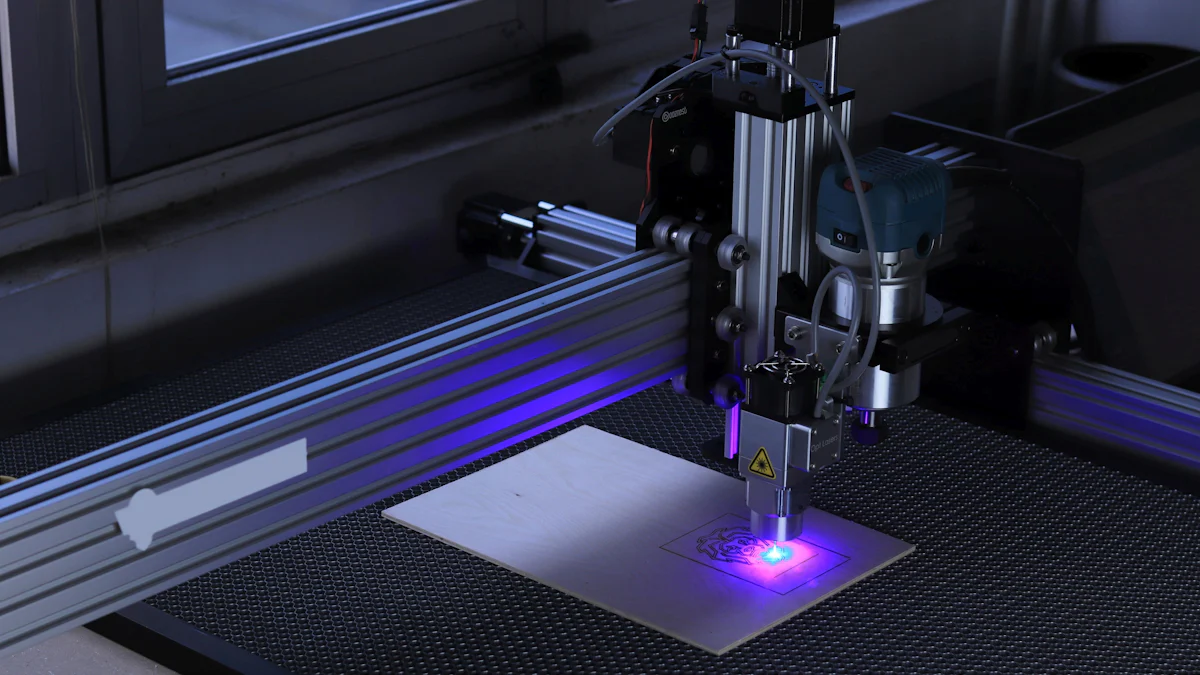

Prototyping and Small Batch Production

For prototyping and small batch production, CNC laser cutters offer unmatched flexibility. You can quickly switch between different designs and materials, making it easy to test new ideas and refine products. The speed and precision of laser cutting enable you to produce prototypes rapidly, reducing the time from concept to market. This capability is invaluable for startups and small businesses looking to innovate and compete in the market. By using a CNC laser cutter, you can efficiently produce high-quality prototypes and small batches without incurring high costs.

Incorporating CNC laser cutting into your operations can significantly enhance your production capabilities. Whether you're in aerospace, medical manufacturing, or prototyping, these machines provide the precision and efficiency needed to succeed in today's competitive landscape.

Comparing CNC Laser Cutting to Traditional Methods

When you compare CNC laser cutting to traditional methods, the differences become clear. This modern technology offers several advantages that can transform your manufacturing processes.

Precision and Clean Cuts

CNC laser cutting excels in precision. The laser beam can cut with tolerances as small as less than 0.0001 inch. This level of accuracy is difficult to achieve with traditional methods. You can create intricate designs that would be challenging or impossible with conventional tools. For example, in the jewelry industry, laser cutting allows for detailed engraving and cutting that enhances the beauty of each piece. The result is cleaner cuts, reducing the need for additional finishing and improving the overall quality of your products.

Speed and Automation

Speed is another area where CNC laser cutting outshines traditional methods. The automation involved in laser cutting means you can produce parts quickly and efficiently. You don't need to manually adjust the machine for each cut, which saves time and reduces errors. In industries like automotive and aerospace, where precision and speed are crucial, laser cutting helps you meet tight deadlines without compromising on quality. The ability to automate the cutting process also means you can focus on other aspects of production, increasing your overall efficiency.

Material Adaptability

CNC laser cutting offers unmatched versatility when it comes to material adaptability. You can work with a wide range of materials, from metals to plastics, without sacrificing quality. Traditional methods often struggle with certain materials, especially those that require precise cuts. In contrast, laser cutting handles these challenges with ease. Whether you're shaping sheet metal parts for vehicles or crafting components for aerospace applications, laser cutting provides the flexibility you need. This adaptability makes it an ideal choice for diverse projects, allowing you to switch between materials seamlessly.

By understanding these advantages, you can see why CNC laser cutting is becoming the preferred choice for many industries. Its precision, speed, and versatility offer significant benefits over traditional methods, enhancing your manufacturing capabilities and opening new possibilities for innovation.

Future of CNC Laser Cutting Technology

The future of CNC laser cutting technology holds exciting possibilities. As you explore the advancements in this field, you'll find innovations that promise to enhance manufacturing processes even further.

Innovations and Trends

-

Increased Automation: Automation continues to transform CNC laser cutting. Machines now integrate with advanced software, allowing you to automate complex tasks. This reduces manual intervention and increases efficiency.

-

Enhanced Precision: New developments focus on improving precision. You can expect laser cutting machines to achieve even finer tolerances, making them ideal for intricate designs and detailed work.

-

Material Versatility: The range of materials compatible with laser cutting is expanding. Innovations enable you to cut thicker and more diverse materials, broadening the scope of applications.

-

Energy Efficiency: Future laser cutting machines aim to reduce energy consumption. This not only lowers operational costs but also aligns with sustainable manufacturing practices.

-

Smart Technology Integration: The integration of IoT and AI in laser cutting machines is on the rise. These technologies provide real-time monitoring and predictive maintenance, enhancing machine performance and longevity.

Potential Industry Impacts

-

Manufacturing Efficiency: As laser cutting technology advances, you can expect significant improvements in manufacturing efficiency. Faster production times and reduced waste will become standard, allowing you to meet increasing demand with ease.

-

Cost Reduction: The cost-effectiveness of laser cutting will improve. With lower energy consumption and reduced material waste, your operational costs will decrease, making laser cutting an attractive option for businesses of all sizes.

-

Innovation in Design: The ability to cut more complex shapes and patterns will spur innovation. Designers and engineers can push the boundaries of creativity, leading to new products and solutions across industries.

-

Environmental Benefits: As energy-efficient machines become more prevalent, the environmental impact of manufacturing will lessen. You can contribute to a greener planet by adopting these advanced technologies.

-

Market Expansion: The growing capabilities of laser cutting will open new markets. Industries that previously relied on traditional methods will transition to laser cutting, recognizing its advantages in precision and speed.

By staying informed about these trends and innovations, you can position yourself to take full advantage of the future of CNC laser cutting technology. This knowledge empowers you to make strategic decisions that enhance your manufacturing processes and drive success.

CNC laser cutting technology offers remarkable advantages that can transform your manufacturing processes. You gain precision, efficiency, and versatility, making it a valuable tool across various industries. From aerospace to medical device manufacturing, laser cutting enhances production quality and speed. As advancements in automation and software integration continue, the potential for innovation grows. Consider incorporating laser cutting into your future projects to stay competitive and efficient. This technology not only improves your output but also aligns with sustainable practices, paving the way for a greener future.

FAQ

What is CNC laser cutting?

CNC laser cutting uses a high-power laser beam to cut or engrave materials. The process involves a computer system that guides the laser with precision, allowing you to create intricate designs and shapes. This technology offers high accuracy and efficiency, making it a popular choice in various industries.

How does CNC laser cutting compare to traditional cutting methods?

CNC laser cutting provides several advantages over traditional methods. It offers higher precision, faster cutting speeds, and cleaner cuts. You can achieve complex designs without additional finishing processes. The technology also reduces material waste and maintenance costs, enhancing production efficiency.

What materials can a CNC laser cutter handle?

A CNC laser cutter can work with a wide range of materials, including metals, plastics, wood, and textiles. Its versatility allows you to switch between different materials easily, making it suitable for diverse projects. The adaptability of laser cutting ensures high-quality results across various applications.

Is CNC laser cutting environmentally friendly?

Yes, CNC laser cutting is environmentally friendly. The precision of the process minimizes material waste, reducing the environmental impact. Unlike some traditional methods, laser cutting uses a dry process, which avoids water contamination. Additionally, the energy efficiency of laser cutting machines helps lower your carbon footprint.

What industries benefit from CNC laser cutting?

Many industries benefit from CNC laser cutting, including aerospace, automotive, medical device manufacturing, and prototyping. The technology's precision and versatility make it ideal for producing intricate components and designs. You can enhance production quality and speed, meeting the demands of competitive markets.

How does CNC laser cutting improve production efficiency?

CNC laser cutting improves production efficiency by offering high-speed cutting and automation. You can produce parts quickly without manual adjustments, reducing lead times. The clean cuts eliminate the need for additional finishing, saving time and resources. This efficiency allows you to meet tight deadlines and increase throughput.

What are the cost benefits of using CNC laser cutting?

CNC laser cutting offers significant cost benefits. The precision of the process reduces material waste, ensuring you use only what is necessary. The clean cuts eliminate the need for additional finishing, saving labor costs. Moreover, the low maintenance requirements of laser cutting machines reduce repair expenses, making it a cost-effective choice.

Can CNC laser cutting handle complex designs?

Yes, CNC laser cutting excels at handling complex designs. The technology supports cutting any intricate graphics with high precision. You can create detailed patterns and shapes that would be challenging with traditional methods. This capability allows you to innovate and push the boundaries of design.

What is the future of CNC laser cutting technology?

The future of CNC laser cutting technology promises exciting advancements. Innovations focus on increased automation, enhanced precision, and expanded material versatility. Energy-efficient machines will reduce operational costs and align with sustainable practices. These developments will enhance manufacturing efficiency and open new possibilities for innovation.

How safe is CNC laser cutting for operators?

CNC laser cutting is safe for operators. The technology involves fewer mechanical parts, reducing the risk of accidents. The automation of the process minimizes manual intervention, enhancing operator safety. By following proper safety protocols, you can ensure a safe working environment while benefiting from the advantages of laser cutting.

See Also

Understanding The Operation Of CNC Laser Cutters

A Simple Explanation Of Laser Cutting Machines

The Functionality Of Fiber Laser Cutting Machines