How CNC Laser Cutting Machine Works and Its Benefits

You might wonder how CNC laser cutting machine works. This technology uses a focused laser beam to cut materials with precision. The machine's computer numerical control (CNC) system guides the laser, ensuring accuracy and consistency. Understanding CNC laser cutting is crucial in modern manufacturing. It plays a vital role in industries like automotive, where precision and intricate designs are essential. The non-contact nature of laser cutting ensures minimal material distortion, making it a preferred choice for creating complex shapes. This technology not only meets sophisticated manufacturing requirements but also enhances production efficiency.

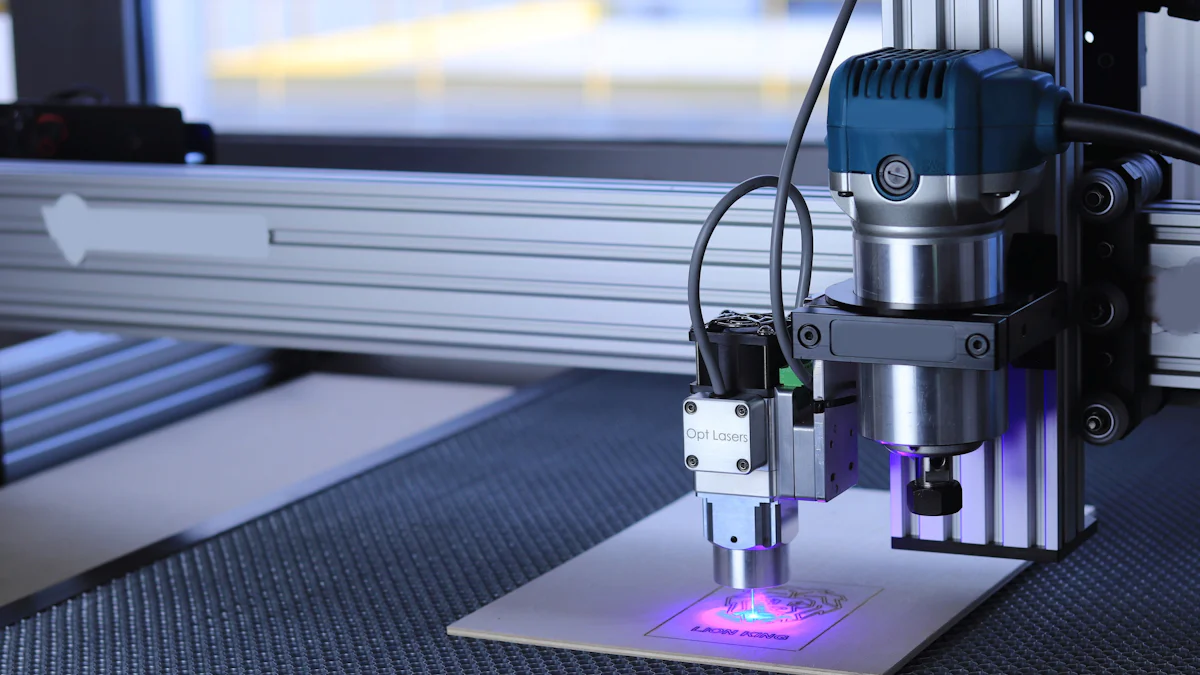

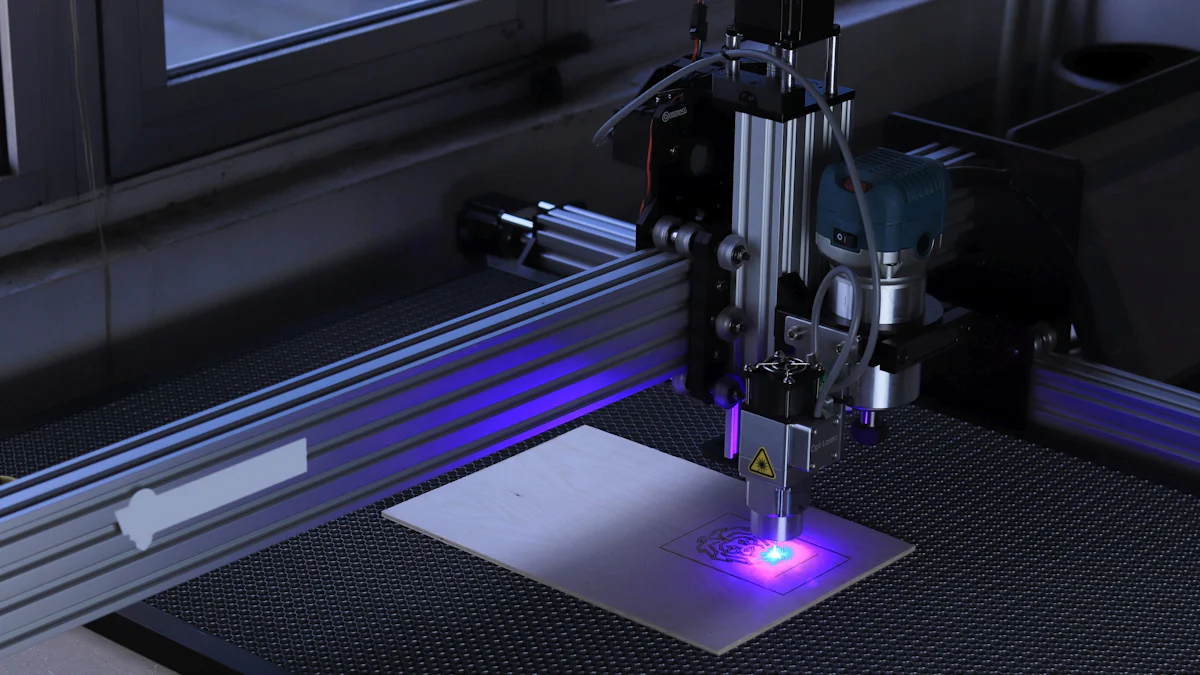

How CNC Laser Cutting Machine Works

Understanding how CNC laser cutting machine works can enhance your appreciation of its precision and efficiency. This technology employs a high-powered laser beam, guided by computer numerical control (CNC) systems, to cut or engrave materials. The CNC system translates design files into precise instructions, ensuring the laser follows the exact path needed for the desired cut. This process allows for the creation of intricate shapes and designs that would be challenging to achieve manually.

Basic Operation

In the basic operation of a CNC laser cutter, you start by inputting a design into the machine's software. The CNC system then interprets this design, dictating the movement of the laser head and work table. The laser beam, focused to a fine point, melts or vaporizes the material along the designated path. This non-contact method ensures minimal wear on the cutting tool, maintaining consistent quality throughout production. The precision of CNC laser cutting allows for detailed cuts, even in complex geometries, with minimal errors.

Key Components

A CNC laser cutter comprises several key components that work together seamlessly:

- Laser Source: This is the heart of the machine, generating the high-powered laser beam used for cutting.

- CNC System: This computer-controlled system manages the movement of the laser head and work table, ensuring accuracy and precision.

- Laser Head: The laser head focuses the beam onto the material, allowing for precise cuts.

- Work Table: This is where the material is placed during cutting. It moves in coordination with the laser head to achieve the desired cut.

- Cooling System: This component prevents the laser and other parts from overheating during operation.

These components work in harmony to deliver the high precision and efficiency that CNC laser cutting is known for. By understanding these elements, you can better appreciate the capabilities of this advanced manufacturing technique.

Types of CNC Laser Cutting Machines

When exploring CNC laser cutting machines, you will encounter various types, each with unique features and applications. Understanding these differences helps you choose the right machine for your specific needs.

CO2 Laser Cutters

CO2 Laser Cutters are among the most common types of laser cutting machines. They use a gas mixture, primarily carbon dioxide, to generate the laser beam. These machines excel in cutting non-metal materials like wood, acrylic, and plastics. You will find them particularly useful for engraving and marking applications due to their ability to produce smooth and precise cuts. CO2 lasers also handle thicker materials effectively, making them versatile tools in industries ranging from signage to packaging.

Fiber Laser Cutters

Fiber Laser Cutters represent a newer technology in the laser cutting world. They use a solid-state laser, which is generated through a seed laser and amplified within a glass fiber. This type of laser cutter is ideal for cutting metals, including stainless steel, aluminum, and brass. You will appreciate their high precision and speed, especially when working with thinner materials. Fiber lasers offer lower maintenance costs and energy efficiency, making them a cost-effective choice for many manufacturing processes.

Crystal Laser Cutters

Crystal Laser Cutters utilize crystals like Nd:YAG (neodymium-doped yttrium aluminum garnet) or Nd:YVO (neodymium-doped yttrium orthovanadate) to produce the laser beam. These machines are suitable for cutting both metals and non-metals, providing flexibility in various applications. You will find crystal lasers beneficial for tasks requiring high power and precision, such as in the aerospace and medical device industries. However, they tend to have higher operational costs due to the need for regular crystal replacement.

By understanding the distinct characteristics of each type of CNC laser cutting machine, you can make informed decisions that align with your manufacturing goals and material requirements.

Laser Cutting Advantages

When you explore the laser cutting advantages, you'll find that this technology offers numerous benefits over traditional methods. These advantages make CNC laser cutting a preferred choice in various industries.

Precision and Accuracy

One of the most significant advantages of laser cutting is its high precision. You can achieve intricate designs and complex shapes with pinpoint accuracy. Unlike traditional mechanical methods, laser cutting excels in creating detailed cuts without material distortion. This precision is particularly beneficial when working with thin materials like acrylics and wood. The non-contact nature of CNC laser cutting ensures no material contamination, maintaining the integrity of the workpiece.

Speed and Efficiency

Laser cutting stands out for its high speed and efficiency. You can complete complex cuts much faster than with traditional methods. This speed enhances productivity, allowing you to meet tight deadlines without compromising quality. The process is less labor-intensive, reducing the need for manual intervention. As a result, you can achieve consistent results with minimal errors, making it a cost-effective solution in the long run.

Versatility

The material versatility of CNC laser cutting is another key advantage. You can cut a variety of materials, including metals, plastics, and wood. This versatility opens up a variety of applications across different industries. Whether you're in automotive, aerospace, or signage, laser cutting provides the flexibility to meet diverse manufacturing needs. Additionally, the process ensures no material contamination, preserving the quality of the final product.

Reduced Need for Post-Processing

When you use laser cutting, you significantly reduce the need for post-processing. This technology provides clean and precise cuts, which means you spend less time on finishing tasks. Traditional cutting methods often leave rough edges or require additional smoothing. Laser cutting, however, delivers a high-quality finish right from the start.

-

Clean Edges: The laser beam melts or vaporizes the material, resulting in smooth edges. You won't need to sand or polish the cut surfaces, saving both time and effort.

-

Minimal Material Distortion: Unlike mechanical cutting methods, laser cutting does not exert physical force on the material. This non-contact process ensures that the material retains its original shape and integrity, eliminating the need for corrective measures.

-

Precision and Accuracy: Laser cutting excels in precision, allowing you to achieve intricate designs without errors. This accuracy reduces the likelihood of needing adjustments or corrections after the initial cut.

-

No Material Contamination: The laser cutting process avoids direct contact with the material, preventing contamination. This feature is particularly beneficial when working with sensitive materials that require a pristine finish.

By choosing laser cutting, you streamline your production process. You can focus on creating complex designs without worrying about extensive post-processing. This efficiency not only enhances productivity but also reduces overall production costs.

You now understand how CNC laser cutting works and its significant advantages. This technology uses a focused laser beam to cut materials with precision and efficiency. Compared to traditional methods, laser cutting offers superior precision, speed, and versatility. It reduces the need for post-processing, saving you time and money. In modern manufacturing, CNC laser cutting plays a crucial role. It meets the demands for intricate designs and high-quality finishes. By embracing this technology, you enhance productivity and maintain a competitive edge in various industries.

FAQ

What is CNC laser cutting?

CNC laser cutting uses a focused laser beam to cut materials with high precision. The machine's computer numerical control (CNC) system guides the laser, ensuring accurate and consistent cuts. This technology is essential in modern manufacturing for creating intricate designs and shapes.

How does CNC laser cutting differ from traditional cutting methods?

CNC laser cutting offers superior precision and speed compared to traditional methods. You can achieve intricate designs without material distortion. The non-contact nature of laser cutting ensures minimal wear on tools and reduces the need for post-processing.

What materials can CNC laser cutting machines handle?

CNC laser cutting machines are versatile. You can cut a wide range of materials, including metals, plastics, and wood. This versatility makes them suitable for various industries, from automotive to signage.

Why is CNC laser cutting popular in manufacturing?

CNC laser cutting is popular due to its numerous benefits. It provides high precision, speed, and versatility. You can meet sophisticated design and manufacturing requirements with ease. This technology enhances productivity and reduces production costs.

Are there different types of CNC laser cutting machines?

Yes, there are different types of CNC laser cutting machines. The main types include CO2 laser cutters, fiber laser cutters, and crystal laser cutters. Each type has unique features and applications, allowing you to choose the best one for your needs.

What are the advantages of using CNC laser cutting?

CNC laser cutting offers several advantages. You can achieve high precision and accuracy, complete tasks quickly, and work with various materials. The process also reduces the need for post-processing, saving you time and effort.

How does CNC laser cutting ensure precision?

The CNC system translates design files into precise instructions for the laser. This ensures the laser follows the exact path needed for the desired cut. You can achieve detailed and complex shapes with minimal errors.

Is CNC laser cutting cost-effective?

Yes, CNC laser cutting is cost-effective. The process reduces material waste and operational costs. You can achieve consistent results with minimal manual intervention, enhancing productivity and reducing labor costs.

Can CNC laser cutting be automated?

CNC laser cutting allows for automation possibilities. You can streamline production processes and reduce labor costs. Automation ensures consistent quality and efficiency in manufacturing.

What industries benefit from CNC laser cutting?

Many industries benefit from CNC laser cutting, including automotive, aerospace, and signage. The technology meets the demands for intricate designs and high-quality finishes, making it a valuable tool in various manufacturing sectors.

See Also

Understanding The Functionality Of CNC Laser Cutters

Exploring The Benefits And Drawbacks Of Laser Cutters

A Simple Explanation Of Laser Cutting Machine Operation