Guide to Choosing the Right Laser Cutting Machine

Understanding how to choose a laser cutting machine is essential for your business's success. The right machine significantly impacts your efficiency and cost-effectiveness. A well-chosen laser cutter can save you both time and money, whereas a poor selection might result in unnecessary expenses. Laser cutting provides a cost-effective solution, with machines priced between $4,000 and $300,000. By knowing how to choose a laser cutting machine, you ensure you receive the best value for your investment. Selecting the appropriate laser cutter enhances your production capabilities and helps you maintain a competitive edge in your industry.

How to Choose Laser Cutting Machine

Choosing the right laser cutting machine involves understanding your specific needs and requirements. This section will guide you through the essential factors to consider when selecting a laser cutter.

Assessing Your Needs

Begin by identifying what you need from a laser cutting machine. Consider the types of projects you plan to undertake. Are you focusing on crafting, manufacturing, or both? For instance, if you're a beginner crafter, a machine like the Aura Laser 3D Printer might suit your needs. It offers a low-power laser suitable for cutting and engraving typical craft materials such as paper, thin wood, and leather. Understanding your primary use will help you narrow down your options.

Evaluating Material Compatibility

Next, evaluate the materials you intend to work with. A comprehensive list of materials that a laser cutting machine can cut includes wood, metal, acrylic, and fabric. Machines like the LaserPecker LP5 are versatile, allowing you to cut and engrave on various materials, including metal. Ensure the machine you choose can handle the materials you frequently use. This step is crucial because different machines have varying capabilities and power levels. For example, CO2 Laser Cutting Machines excel in cutting thicker materials over 10mm.

Considering Workpiece Size

The size of your workpieces plays a significant role in choosing a laser cutter. You must ensure the machine's cutting area accommodates your typical job sizes. If you work with large pieces, opt for a machine with a spacious cutting bed. Conversely, for smaller projects, a compact machine might suffice. The Powerful Laser Cutter can handle large workpieces, cutting up to 20mm thick wood in a single pass, making it ideal for substantial projects.

By carefully assessing your needs, evaluating material compatibility, and considering workpiece size, you can make an informed decision on how to choose a laser cutting machine that best suits your requirements. This approach ensures you select a machine that enhances your production capabilities and meets your specific needs.

Types of Laser Cutters

Understanding the different types of laser cutters is crucial for selecting the right machine for your needs. Each type offers unique features and benefits, making them suitable for various applications.

CO2 Laser Cutters

CO2 laser cutters are among the most popular types of laser cutters. They excel in cutting non-metallic materials like wood, acrylic, and plastics. These machines use a gas mixture to produce a laser beam, which is highly efficient for cutting and engraving. CO2 lasers consume more power compared to other types, but they offer a lower upfront cost. This makes them an attractive option for businesses focusing on non-metallic applications. If you frequently work with thicker materials, CO2 laser cutters provide the power and efficiency needed for such tasks.

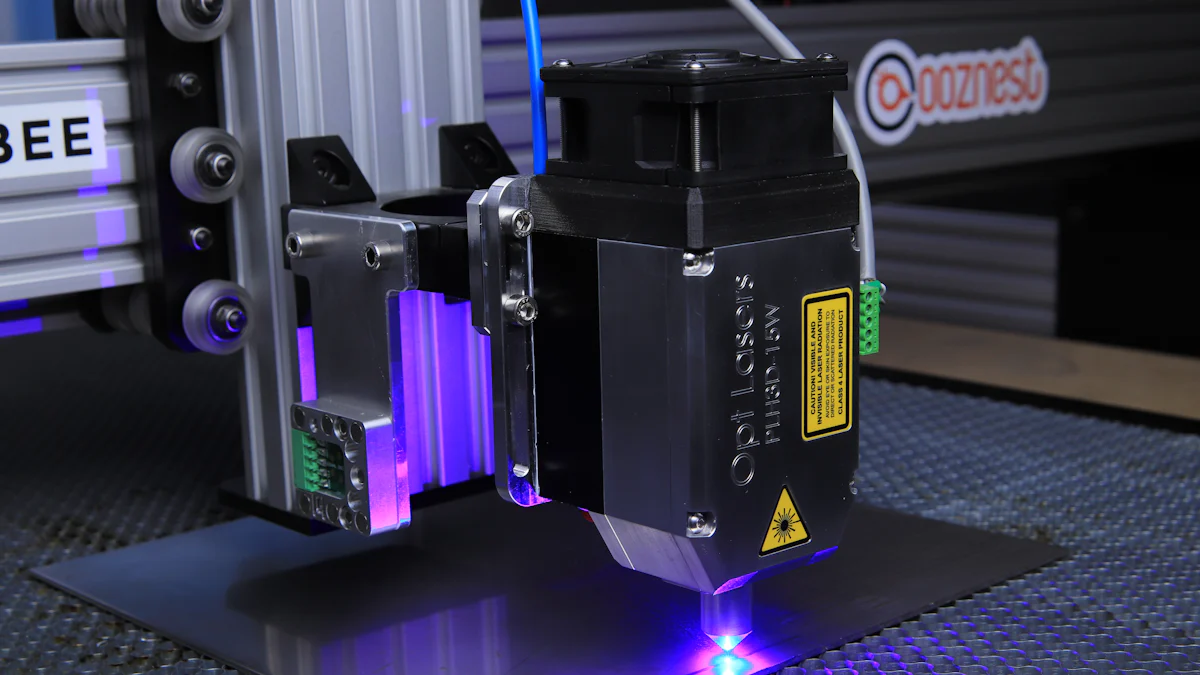

Fiber Laser Cutters

Fiber laser cutters have gained popularity due to their precision and speed. They use optical fibers to amplify the laser beam, resulting in higher cut precision and faster processing times. Fiber lasers are particularly effective for cutting metals and thin sheets, offering speeds three to five times quicker than CO2 lasers. They also have a longer working life, making them a durable choice for industrial applications. Although the initial cost of fiber lasers is higher, their efficiency and longevity often justify the investment. For metal cutting and engraving tasks, fiber lasers are the optimal choice.

Crystal Laser Cutters

Crystal laser cutters, though less common, offer unique advantages for specific applications. They use crystals like Nd:YAG or Nd:YVO to generate the laser beam. These machines are ideal for high-precision tasks and can cut through a variety of materials, including metals and ceramics. Crystal lasers provide excellent beam quality, making them suitable for intricate designs and detailed work. However, they tend to be more expensive and require more maintenance compared to CO2 and fiber lasers. If your projects demand high precision and versatility, crystal laser cutters might be the right fit.

By understanding the distinct features of CO2, fiber, and crystal laser cutters, you can make an informed decision that aligns with your specific needs and applications. Each type offers unique benefits, ensuring you find the best laser cutting solution for your business.

Key Features of a Laser Cutter

When selecting a laser cutter, you must consider several key features that directly impact its performance and suitability for your needs. Understanding these features will help you make an informed decision.

Power and Speed

The laser power and cutting speed are crucial factors in determining the efficiency of a laser cutter. Higher laser power allows you to cut through thicker materials with ease. For instance, a Powerful Laser Cutter with 55W can cut 20mm thick wood in a single pass. This capability is essential for projects requiring high precision and intricate designs. Cutting speed, on the other hand, affects how quickly you can complete tasks. Machines with faster speeds increase productivity, allowing you to handle more projects in less time. Evaluate your typical workload to choose a machine with the right balance of power and speed.

Size and Cutting Area

The size and cutting area of a laser cutter determine the maximum dimensions of the workpieces you can process. If you frequently work with large materials, opt for a machine with a spacious cutting bed. For example, the Aura Laser 3D Printer offers a 39x25x10-inch footprint, making it suitable for crafting projects. Conversely, if your projects involve smaller pieces, a compact machine might suffice. Consider the typical size of your materials to ensure the machine's cutting area meets your requirements.

Safety Features

Safety should always be a top priority when operating a laser cutter. Look for machines equipped with essential safety features to protect both the operator and the equipment. These features may include emergency stop buttons, protective enclosures, and ventilation systems to manage fumes. Ensuring your machine has adequate safety measures not only prevents accidents but also prolongs the life of the equipment. Prioritize safety to maintain a secure working environment.

By focusing on power and speed, size and cutting area, and safety features, you can select a laser cutter that aligns with your specific needs. These options ensure you achieve high-quality results with accuracy and precision, enhancing your production capabilities.

Laser Cutter Buying Guide: Cost Considerations

When purchasing a laser cutter, understanding the cost considerations is crucial. This guide will help you navigate the financial aspects of acquiring a laser cutting machine, ensuring you make a wise investment.

Initial Purchase Price

The initial purchase price of a laser cutter can vary significantly. Prices range from a few thousand dollars for entry-level models to hundreds of thousands for industrial-grade machines. Your budget will play a pivotal role in determining which laser cutter suits your needs. It's essential to balance the price with the features and capabilities you require. For instance, if you need a machine for basic crafting, an affordable laser cutter might suffice. However, for industrial applications, investing in a higher-priced model could offer better performance and durability.

Operating Costs

Beyond the initial price, consider the ongoing operating costs associated with a laser cutter. These include expenses for maintenance, consumables like lenses and mirrors, and power consumption. Regular maintenance helps prevent major breakdowns, saving you from costly repairs or even the need for a new machine. Evaluate the efficiency of the machine to ensure it meets your production requirements without inflating your operational budget. Balancing performance with cost is key to maximizing your investment.

Long-term Investment Value

A laser cutter purchase should be viewed as a long-term investment. Consider the potential for future upgrades and the machine's impact on your manufacturing process. A more expensive machine might offer greater efficiency and longevity, providing better value over time. Assess the reliability and durability of the laser cutter to ensure it can handle continuous operation if needed. By factoring in these elements, you can determine the long-term investment value and make an informed decision that aligns with your business goals.

By carefully considering the initial purchase price, operating costs, and long-term investment value, you can make a financially sound decision when purchasing a laser cutter. This approach ensures you select a machine that not only fits your budget but also enhances your production capabilities.

Maintenance Requirements for a Laser Cutting Machine

Proper maintenance of your laser cutting machine ensures its longevity and optimal performance. Regular upkeep not only prevents costly repairs but also enhances the machine's efficiency. Here, we outline essential maintenance tasks and common troubleshooting tips to keep your laser cutter in top shape.

Routine Maintenance Tasks

Routine maintenance tasks are crucial for the smooth operation of your laser cutter. You can perform many of these tasks yourself, ensuring the machine runs efficiently:

- Cleaning the Optics: Regularly clean the lenses and mirrors to maintain clear laser paths. Dust and debris can obstruct the laser beam, reducing cutting precision.

- Checking the Cooling System: Ensure the cooling system functions properly to prevent overheating. Inspect coolant levels and replace them as needed.

- Lubricating Moving Parts: Apply lubricant to the machine's moving parts to reduce friction and wear. This step helps maintain smooth operation.

- Inspecting Belts and Cables: Check belts and cables for signs of wear or damage. Replace them promptly to avoid disruptions in operation.

While you can handle these tasks, scheduling professional maintenance by qualified technicians is advisable for more advanced tasks. Technicians can identify potential issues early, saving you money by preventing major breakdowns.

Common Issues and Troubleshooting

Even with regular maintenance, you might encounter common issues with your laser cutter. Understanding these problems and how to troubleshoot them can minimize downtime:

- Inconsistent Cutting Quality: If you notice uneven cuts, check the alignment of the laser beam. Misalignment can affect precision. Adjust the mirrors and lenses to correct this issue.

- Laser Not Firing: When the laser fails to fire, inspect the power supply and connections. Loose or damaged cables can disrupt power flow. Secure connections and replace faulty components.

- Overheating: Overheating can occur if the cooling system malfunctions. Ensure the coolant circulates properly and the fans operate efficiently. Clean any blockages in the cooling system.

- Software Errors: Software glitches can halt operations. Restart the machine and update the software to the latest version. If problems persist, consult the manufacturer's support team.

By addressing these routine maintenance tasks and troubleshooting common issues, you ensure your laser cutter operates efficiently. Regular care and timely interventions keep your machine running smoothly, enhancing your production capabilities.

Additional Factors in Choosing a Laser Cutter

When selecting a laser cutter, you should consider several additional factors that can significantly impact your experience and satisfaction with the machine. These factors ensure that the laser cutter not only meets your technical needs but also aligns with your business operations and support requirements.

Brand Reputation

The reputation of the brand plays a crucial role in your decision-making process. A well-established brand often indicates reliability and quality. Brands with a strong reputation have likely been in the industry for a while, providing consistent performance and customer satisfaction. You should research customer reviews and testimonials to gauge the brand's standing in the market. A reputable brand often invests in research and development, ensuring their products incorporate the latest technology and innovations. This commitment to quality can provide you with a laser cutter that delivers excellent results and stands the test of time.

Integration with Existing Systems

Consider how the laser cutter will integrate with your existing systems. Compatibility with your current software and hardware can streamline your workflow and enhance productivity. You should evaluate whether the laser cutter supports the file formats you commonly use and if it can easily connect with your design software. Seamless integration minimizes the learning curve and reduces the need for additional training or equipment. By ensuring compatibility, you can maximize the efficiency of your operations and avoid potential disruptions.

Customer Support and Warranty

Reliable customer support is essential for a smooth experience with your new laser cutter. A responsive support team can assist you with setup, troubleshooting, and maintenance, ensuring your machine operates efficiently. You should look for brands that offer comprehensive customer support, including online resources, phone assistance, and on-site service if needed. Additionally, a robust warranty provides peace of mind, protecting your investment against defects and malfunctions. A good warranty reflects the manufacturer's confidence in their product's durability and performance.

"A reliable customer service team can make all the difference in ensuring a smooth and successful experience with your new laser system."

By considering brand reputation, integration capabilities, and customer support, you can choose a laser cutter that not only meets your technical needs but also provides a reliable and efficient user experience. These factors contribute to a successful investment, enhancing your production capabilities and ensuring long-term satisfaction.

Choosing the right laser cutting machine requires careful evaluation of your needs and budget. Start by assessing what materials you plan to process and the size of your workpieces. Consider the types of laser cutters available and their compatibility with your projects. Evaluate key features like power, speed, and safety to ensure the machine meets your production demands. Finally, balance the initial purchase price with long-term operating costs to make a sound investment. By following these steps, you can select a laser cutter that enhances your efficiency and aligns with your budget.

FAQ

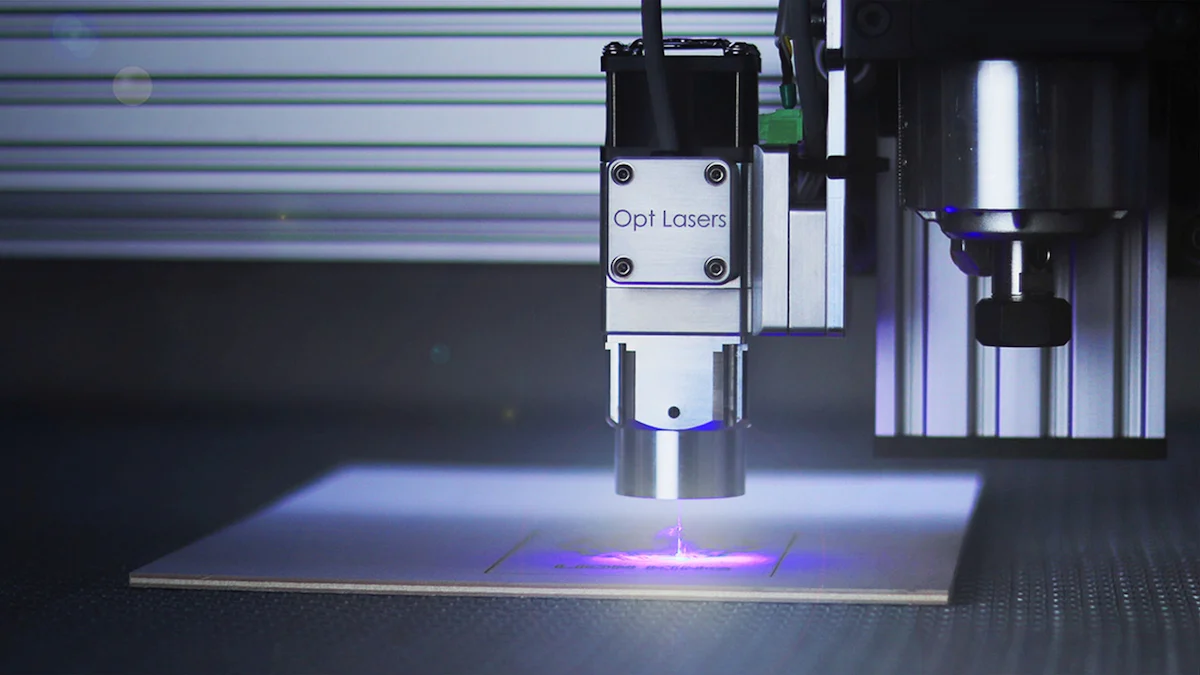

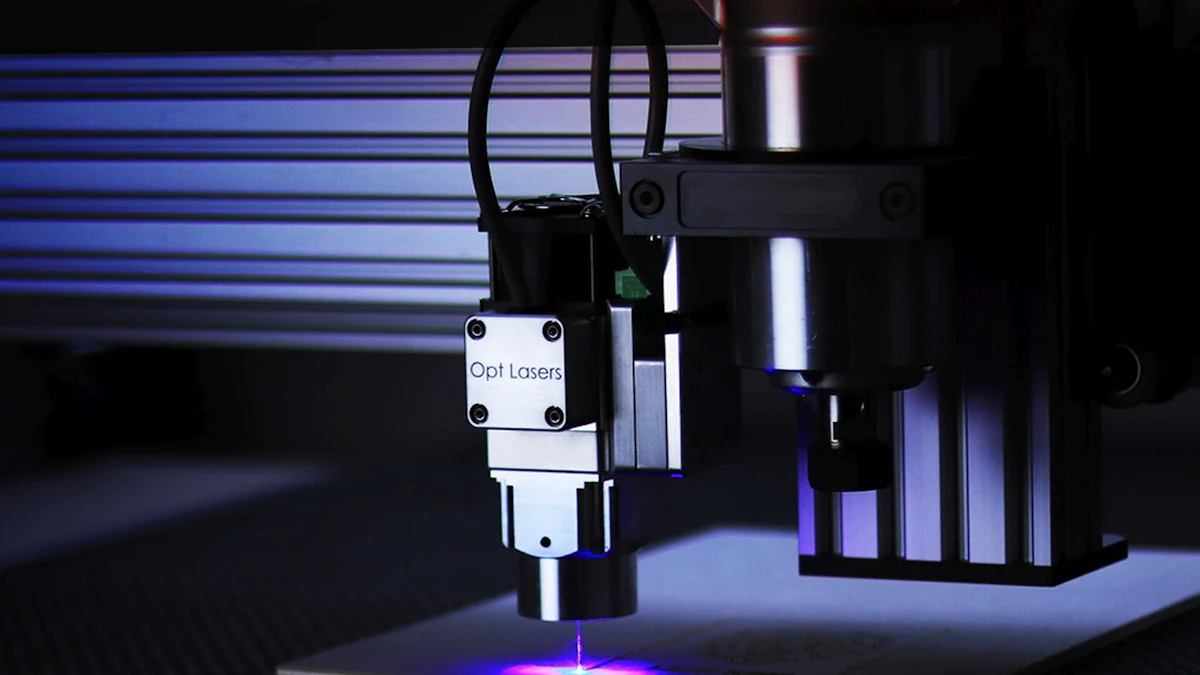

How does a laser cutting machine work?

A laser cutting machine uses a focused laser beam to cut or engrave materials. The laser beam melts, burns, or vaporizes the material, allowing for precise cuts and intricate designs. Different types of laser cutters are suited for various materials and thicknesses, making them versatile tools in industries ranging from manufacturing to crafting.

How long do laser cutters last?

The lifespan of a laser cutter depends on several factors, including usage frequency, maintenance, and the quality of the machine. With proper care and regular maintenance, a laser cutter can last many years. Routine tasks like cleaning optics and checking the cooling system help extend the machine's life.

What materials can lasers cut?

Laser cutters can handle a wide array of materials. Commonly cut materials include wood, acrylic, plastics, paper, and cardboard. More powerful laser cutters can also cut metals and thicker materials. Always check the machine's specifications to ensure compatibility with your chosen materials.

What are the main components of a laser cutting machine?

A laser cutting machine consists of several key components: the laser source, mirrors, lenses, and a cutting bed. The laser source generates the beam, which is directed by mirrors and focused by lenses onto the material. The cutting bed supports the material during the cutting process.

What is a laser cutter best for?

A laser cutter excels in creating precise cuts and detailed engravings. It is ideal for producing prototypes, artwork, and custom designs. Laser cutters are used in various applications, from crafting to industrial manufacturing, due to their versatility and precision.

Do you know the best way to go about purchasing a laser cutting machine?

When purchasing a laser cutting machine, assess your needs and budget. Consider the materials you plan to cut, the size of your workpieces, and the types of laser cutters available. Evaluate key features like power, speed, and safety. Balancing the initial purchase price with long-term operating costs ensures a sound investment.

What is laser cutting?

Laser cutting is a process that uses a high-powered laser beam to cut, engrave, or etch materials. The laser's precision allows for intricate designs and detailed work. This technology is widely used in industries such as manufacturing, crafting, and prototyping.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Essential Advice for Selecting Water Jet Cutting Machines

Maximizing Efficiency with Your Laser Cutting Machine