What Is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is a remarkable tool that revolutionizes how you cut materials. So, what is a fiber laser cutting machine? This device uses advanced laser technology to achieve high precision in cutting tasks. By focusing a high-power laser beam through a fiber optic cable, the fiber laser cutter ensures efficient and accurate results. You will find that fiber laser cutting machines excel in speed and quality, surpassing traditional methods. They offer superior efficiency, reducing both maintenance and operational costs. With a fiber laser cutter, you can achieve faster, high-quality results with lower material consumption, making it an invaluable asset in various applications.

How Does a Fiber Laser Cutting Machine Work?

Understanding how a fiber laser cutting machine operates can enhance your appreciation of its capabilities. This machine uses advanced fiber laser technology to deliver precise cuts on various materials. Let's break down the process into its fundamental components and principles.

Basic Principles of Fiber Lasers

Fiber lasers form the core of a fiber laser cutting machine. They generate a laser beam by using active optical fibers. These fibers amplify the light, creating a powerful beam capable of cutting through tough materials. The laser beam travels through a fiber optic cable, which guides it to the cutting head. This setup ensures that the laser maintains its intensity and focus, crucial for achieving high precision in cutting tasks.

Key Components and Their Functions

A fiber laser cutting machine comprises several key components, each playing a vital role in the cutting process:

-

Laser Source: Often referred to as the power core, the laser source generates the laser beam. It uses diode emission and fiber amplification to produce a highly focused beam.

-

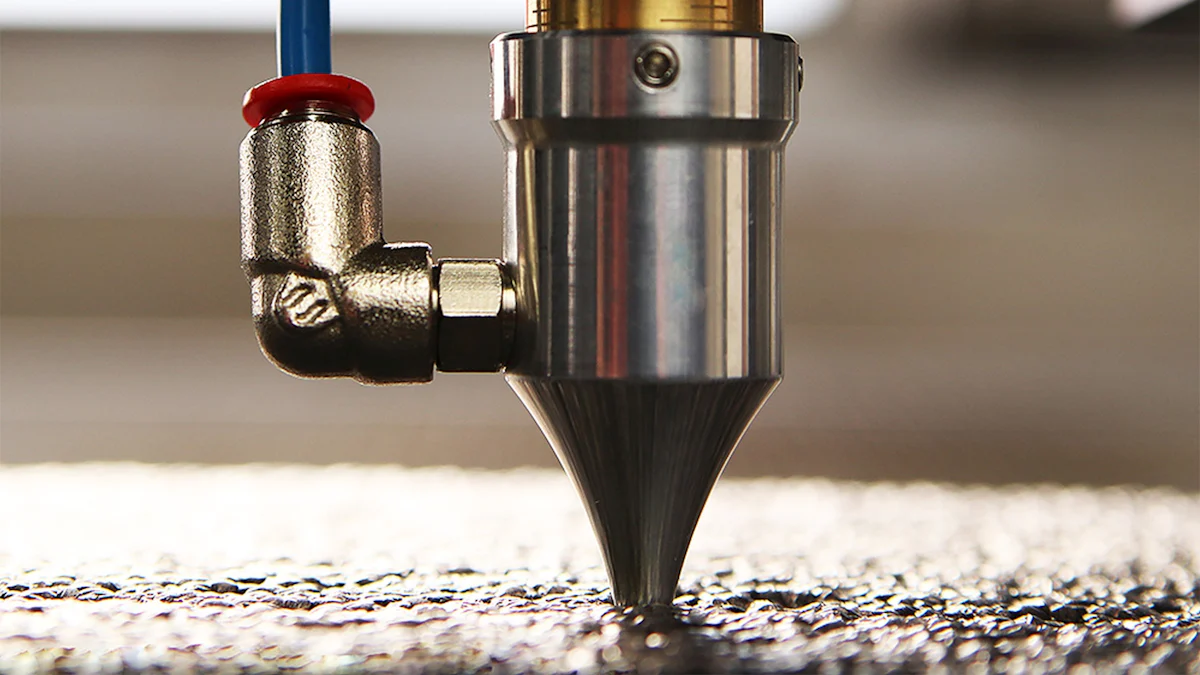

Cutting Head: This intricate assembly delivers and controls the laser beam. It focuses the beam on the material, ensuring precise cuts.

-

Power Supply: Converts electrical power into the precise voltage and current needed to drive the laser generator. This ensures the machine operates at high performance.

-

Air Cutting System: Utilizes a high-pressure air stream to remove debris and cool the cut area. This prevents material warping and reduces thermal impact on the laser head.

-

Stabilizer: Maintains the consistency of the laser beam, ensuring it remains stable and focused even under varying conditions.

The Cutting Process Explained

The fiber laser cutting process begins with the laser beam traveling through the fiber optic cable to the cutting head. The cutting head focuses the beam on a specific spot on the material. The intense heat generated by the laser causes the material to melt, burn away, or vaporize. This results in a sharp, clean cut with high precision. The air cutting system assists by blowing away molten material, ensuring cleaner cuts and protecting the cutting head from debris.

Fiber laser cutting machines excel in delivering precise cuts with minimal material waste. Their efficiency and accuracy make them invaluable in various industrial applications, from metal fabrication to intricate artistic designs.

Benefits of Using Fiber Laser Cutting Machines

When you consider the benefits of fiber laser cutting machines, you'll find they offer remarkable advantages over traditional cutting methods. These machines provide exceptional precision, speed, and efficiency, making them a valuable asset in various industries.

Precision and Accuracy

Fiber laser cutting machines excel in delivering high-quality cuts with unmatched precision. The technology allows you to achieve clean cuts on a wide range of materials, including metals and non-metals. The laser beam's shorter wavelength enhances absorption power, resulting in optimal results even on challenging materials like nickel alloys. This precision ensures that your projects meet exact specifications, reducing material waste and improving overall cutting quality.

Speed and Efficiency

One of the standout benefits of fiber laser cutting is its impressive cutting speed. Compared to other laser cutting technologies, fiber lasers operate at a much faster pace, especially when working with thin sheets of metal. This increased speed translates to higher productivity, allowing you to complete projects more quickly. Additionally, fiber laser cutting machines consume less energy, further enhancing their efficiency. By choosing fiber laser cutting, you can achieve faster turnaround times without compromising on quality.

Low Maintenance Requirements

Fiber laser cutting machines are designed with durability and longevity in mind. They require minimal maintenance compared to other laser cutting machines, such as CO2 lasers. The solid-state design of fiber lasers contributes to their longer working life, reducing downtime and operational costs. This reliability ensures that you can focus on your work without frequent interruptions for repairs or maintenance. As a result, you benefit from lower overall costs and increased uptime, making fiber laser cutting a cost-effective choice for your cutting needs.

By understanding these benefits, you can make informed decisions about incorporating fiber laser cutting machines into your operations. Their precision, speed, and low maintenance requirements make them an ideal choice for achieving high-quality cuts efficiently.

Drawbacks of Fiber Laser Cutting Machines

While fiber laser cutting machines offer numerous advantages, you should also consider some drawbacks before making an investment. Understanding these limitations will help you make informed decisions and set realistic expectations.

Initial Cost

The initial cost of acquiring a fiber laser cutting machine can be quite high. You might find that the price tag is significantly more than that of traditional cutting machines. This upfront investment can be a barrier for small businesses or individuals with limited budgets. However, it's important to weigh this cost against the long-term savings. Experts in fiber laser cutting highlight that despite the higher initial expense, the reduced energy consumption, lower maintenance costs, and increased throughput can lead to substantial savings over time.

"The long-term savings associated with fiber laser cutting are substantial. The initial investment might be higher than that for traditional cutting machines, but the lower maintenance costs, reduced energy consumption, and increased throughput translate into significant cost savings over time."

Limitations in Material Thickness

Fiber laser cutting machines excel in precision and speed, but they do have limitations when it comes to material thickness. You may encounter challenges when cutting very thick materials. These machines are particularly effective for thin to moderately thick materials, such as metals up to a certain thickness. When dealing with thicker materials, the laser's efficiency and precision might decrease, leading to less optimal results. This limitation is crucial to consider if your projects often involve cutting thick materials. Understanding the limitations of laser cutting will ensure you choose the right tool for your specific needs.

Materials That Can Be Cut with Fiber Lasers

Fiber laser cutting machines offer remarkable versatility in the types of materials they can handle. Understanding which materials are suitable for fiber laser cutting will help you maximize the potential of these machines in your projects.

Metals

Fiber laser cutters excel in cutting through metals with precision and efficiency. They are particularly effective for sheet metal cutting, making them a popular choice in industries that require high-quality metal fabrication. Here are some metals you can cut using fiber laser technology:

-

Stainless Steel: Known for its strength and corrosion resistance, stainless steel is a common material for fiber laser cutting. The laser's precision ensures clean cuts without compromising the material's integrity.

-

Carbon Steel: Fiber lasers can easily cut carbon steel, providing smooth edges and reducing the need for additional finishing processes.

-

Aluminum: Although aluminum reflects light, fiber laser cutters can still cut it effectively by using the right settings to prevent reflection issues.

-

Copper and Brass: These metals are challenging to cut with traditional methods due to their reflective surfaces. However, fiber lasers can handle them with ease, delivering precise cuts.

-

Nickel Alloys: Prized for their strength and corrosion resistance, nickel alloys are challenging to cut with traditional methods. Fiber lasers, however, achieve precise, clean cuts, preserving the material’s properties.

Non-Metals

While fiber laser cutting machines are primarily designed for metals, they can also cut certain non-metallic materials. Here are some examples:

-

Acrylic (PMMA): Fiber lasers cut acrylic cleanly, leaving a smooth, flame-polished edge. This makes it ideal for applications requiring clear, precise cuts.

-

Polycarbonate: This material absorbs fiber laser light well, allowing for cuts with minimal discoloration and high precision.

-

Polypropylene and Polyethylene: Both materials can be cut with fiber lasers, though they require careful power management to prevent warping or melting.

-

Nylon: Fiber lasers effectively cut nylon, leaving a clean edge with minimal thermal deformation.

-

Polyester (PET): This material cuts very well with fiber lasers, producing sharp and highly detailed edges.

However, not all non-metals are suitable for fiber laser cutting. For instance, Polyvinyl Chloride (PVC) is not recommended due to the release of harmful fumes during the cutting process. Always ensure that the material you intend to cut is compatible with fiber laser technology to maintain safety and achieve the best results.

By understanding the range of materials that fiber laser cutting machines can handle, you can make informed decisions about their applications in your projects. Whether you're working with metals or select non-metals, fiber laser cutters provide the precision and efficiency needed for high-quality results.

Comparing Fiber Lasers to CO2 Lasers

When you explore the world of laser cutting, you'll encounter two main types: fiber lasers and CO2 lasers. Each has unique characteristics that make them suitable for different applications. Understanding these differences will help you choose the right laser cutting technology for your needs.

Differences in Technology

Fiber lasers and CO2 lasers operate on distinct principles. Fiber lasers use a solid-state technology where the laser beam is generated and amplified within optical fibers. This design results in a more compact and efficient system. You benefit from lower operating costs and higher energy efficiency. Fiber lasers also offer a longer lifespan and require less maintenance compared to CO2 lasers.

On the other hand, CO2 lasers utilize a gas mixture to produce the laser beam. This technology has been around longer and is well-suited for cutting non-metallic materials. However, CO2 lasers consume more power and have higher maintenance requirements. The upfront cost of CO2 laser cutting machines is generally lower, but the long-term expenses can add up due to energy consumption and maintenance needs.

Performance and Application Differences

In terms of performance, fiber lasers excel in cutting speed and precision. They are particularly effective for cutting thin sheets of metal, achieving speeds up to six times faster than CO2 lasers. This makes fiber laser cutting ideal for industries that require high productivity and precision, such as metal fabrication. You will find that fiber lasers handle reflective materials like aluminum and copper with ease, thanks to their greater absorption power.

CO2 lasers, however, shine when it comes to cutting non-metallic materials. They are better suited for applications involving wood, acrylic, and certain plastics. If your projects involve a variety of materials, CO2 lasers offer versatility. Yet, for metallic materials, fiber lasers provide superior cutting quality and efficiency.

Applications of Fiber Laser Cutting Machines

Fiber laser cutting machines have revolutionized various industries with their precision and versatility. You will find these machines in numerous applications, ranging from industrial to artistic endeavors. Understanding these applications can help you appreciate the full potential of fiber laser cutting technology.

Industrial Uses

In the industrial sector, fiber laser cutting machines play a crucial role. They are indispensable in the aerospace industry, where they manufacture aircraft components. You can use them to create intricate shapes and contours for turbine parts, airframe structures, and interior elements. The laser beam effectively cuts through materials like alloys, titanium, stainless steel, and aluminum, ensuring high precision and minimal waste.

Fiber laser cutting also excels in handling composite materials. These materials, often composed of fibers embedded in a resin matrix, present unique challenges. However, fiber lasers manage these challenges adeptly. They finely control the laser beam to minimize damage to the composite structure, making them ideal for industries requiring intricate designs and tight tolerances, such as electronics and medical devices.

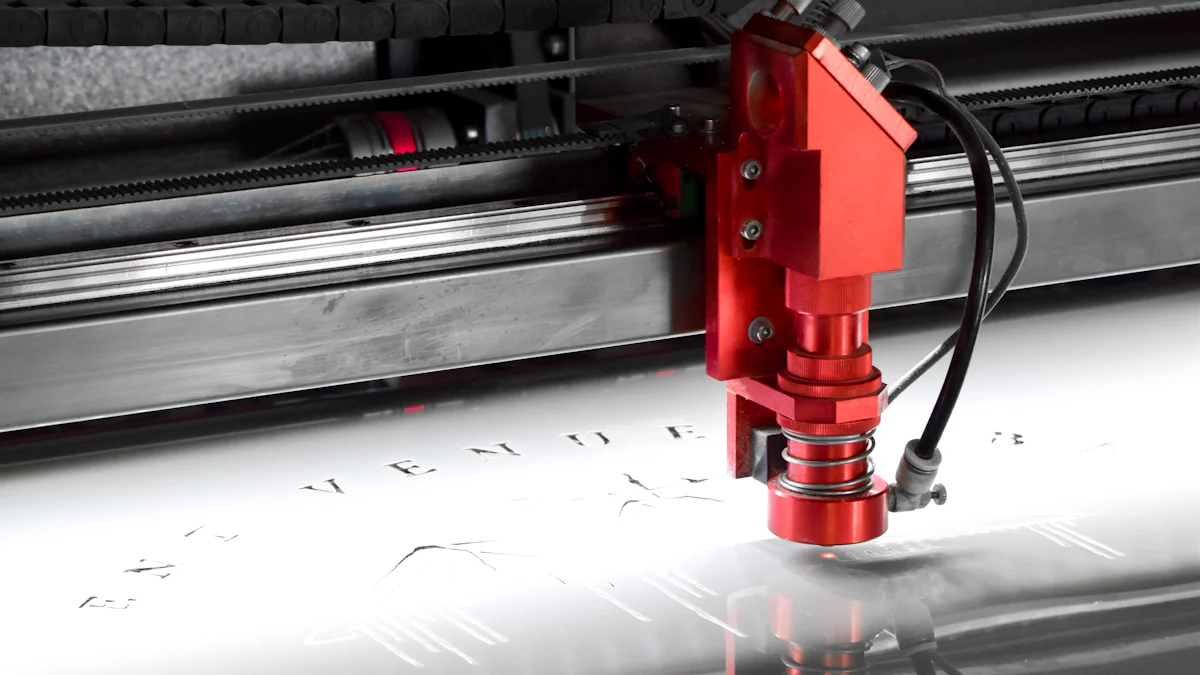

Artistic and Creative Applications

Beyond industrial uses, fiber laser cutting machines have found a place in the world of art and design. You can harness their precision to create stunning decorative pieces and metal art. With computer numerical control, these machines craft graphic designs and patterns in metal sheets. This capability allows for the creation of custom pieces for decoration and metal signs, offering endless possibilities for creativity.

Artists and designers appreciate the ability of fiber laser cutting to produce complex shapes and fine details. Whether you're working on a large-scale installation or a delicate piece of jewelry, these machines provide the precision needed to bring your vision to life. The versatility of fiber laser cutting extends to various materials, enabling you to explore new artistic avenues.

Fiber laser cutting machines offer a wide range of applications, from industrial manufacturing to artistic creation. By understanding these applications, you can leverage the full potential of this technology in your projects, whether you're in an industrial setting or pursuing creative endeavors.

How to Choose a Fiber Laser Cutting Machine

Selecting the right fiber laser cutting machine can significantly impact your projects. You need to consider several factors to ensure you make an informed decision. This guide will help you understand what to look for when choosing a fiber laser cutting machine.

Key Features to Look For

When evaluating fiber laser cutting machines, focus on key features that align with your needs:

-

Power Rating: The power of the laser determines its ability to cut through various materials. A machine with at least a 12kW power rating can handle extremely thick materials, making it suitable for large-scale projects.

-

Cutting Table Size: A large cutting table allows you to work on bigger pieces without repositioning them frequently. This feature is crucial for maintaining precision across extensive projects.

-

Software Integration: Advanced software integration helps manage complex cutting tasks efficiently. Look for machines that offer user-friendly interfaces and compatibility with design software.

-

Automation: Automation features can enhance productivity by reducing manual intervention. Consider machines with automated loading and unloading systems to streamline operations.

-

Safety Standards: Ensure the machine complies with safety standards to protect operators from potential hazards. Features like enclosed cutting areas and emergency stop buttons are essential.

-

Brand Value: Reputable brands often provide better customer support and reliable products. Research the brand's reputation and read reviews from other users.

Budget and Cost Considerations

Budget plays a crucial role in your decision-making process. Here are some cost-related aspects to consider:

-

Initial Investment: Fiber laser cutting machines can be expensive. Assess your budget and determine how much you can invest upfront. Remember, higher initial costs may lead to long-term savings due to reduced maintenance and operational expenses.

-

Operating Costs: Consider the energy consumption and maintenance requirements of the machine. Fiber laser cutting machines generally have lower operating costs compared to other laser cutting technologies.

-

Skill Requirements: Operating a fiber laser cutting machine requires skilled personnel. Factor in the cost of training or hiring experienced operators.

-

Long-term Savings: Despite the high initial cost, fiber laser cutting machines offer long-term savings. Their efficiency and low maintenance needs can offset the initial investment over time.

By carefully considering these factors, you can choose a fiber laser cutting machine that meets your specific needs and budget. This decision will enhance your ability to deliver high-quality results across various applications.

Maintenance of Fiber Laser Cutting Machines

Maintaining your fiber laser cutting machine is essential for ensuring its optimal performance and longevity. Regular maintenance not only enhances the efficiency of the machine but also prevents costly downtime. By following a structured maintenance routine, you can keep your laser cutting machine in top condition.

Routine Maintenance Tasks

To maintain your fiber laser cutting machine effectively, you should perform several routine tasks. These tasks help in preserving the machine's performance and extending its lifespan:

-

Clean Optics Regularly: Dust and debris can accumulate on the optics, affecting the quality of the laser beam. You should clean the lenses and mirrors regularly to ensure clear and precise cuts.

-

Check and Replace Nozzles: Nozzles play a crucial role in directing the laser beam. Inspect them frequently for wear and tear, and replace them as needed to maintain cutting accuracy.

-

Monitor Laser Power: Consistently check the laser power output. A drop in power can indicate issues with the laser source or optics, which may require attention.

-

Inspect and Clean the Cooling System: The cooling system prevents overheating. Regularly inspect it for leaks or blockages and clean it to ensure efficient operation.

-

Check Gas Lines for Leaks: Gas lines are vital for the cutting process. Inspect them for leaks to prevent disruptions in the cutting process.

-

Calibrate Focus Position: Proper focus is essential for precision cutting. Regularly calibrate the focus position to maintain the quality of cuts.

-

Clean and Lubricate Moving Parts: Moving parts require lubrication to function smoothly. Clean and lubricate them to prevent mechanical issues.

-

Update Software and Firmware: Keep the machine's software and firmware up to date. Updates often include improvements and bug fixes that enhance performance.

Troubleshooting Common Issues

Even with regular maintenance, you might encounter issues with your fiber laser cutting machine. Knowing how to troubleshoot these problems can save you time and resources:

-

Inconsistent Cuts: If you notice variations in cut quality, check the alignment of the optics and the condition of the nozzles. Misalignment or worn nozzles can cause inconsistencies.

-

Reduced Cutting Speed: A decrease in cutting speed may result from a drop in laser power. Verify the power settings and inspect the laser source for any issues.

-

Material Warping: Warping can occur if the cooling system is not functioning properly. Ensure the cooling system is clean and operating efficiently.

-

Frequent Shutdowns: If the machine shuts down unexpectedly, check for overheating issues. Inspect the cooling system and ensure all fans are working correctly.

-

Error Messages: Pay attention to error messages displayed by the machine. They often provide clues about the underlying issue. Consult the user manual or contact technical support for guidance.

By adhering to these maintenance practices and troubleshooting tips, you can ensure that your fiber laser cutting machine operates smoothly and efficiently. This proactive approach not only enhances the machine's performance but also maximizes its applications across various industries.

Fiber laser cutting machines have transformed the landscape of modern manufacturing. By understanding fiber laser cutting, you can harness its precision and efficiency to achieve superior results. These machines offer unmatched versatility, making them suitable for a wide range of applications, from industrial to artistic endeavors. As you explore the potential of laser cutting, you'll find that it not only enhances production capabilities but also drives innovation across various industries. Embracing this technology is crucial for staying competitive and achieving sustainable growth in today's fast-paced world.

FAQ

What is a fiber laser cutting machine?

A fiber laser cutting machine is a tool that uses advanced laser technology to cut materials with high precision. It focuses a powerful laser beam through a fiber optic cable, allowing for efficient and accurate cutting. This technology is particularly effective for cutting metals and is widely used in various industries.

How does fiber laser cutting differ from other laser cutting technologies?

Fiber laser cutting differs from other technologies, such as CO2 lasers, in several ways. Fiber lasers use solid-state technology, which makes them more compact and energy-efficient. They excel in cutting thin metals quickly and with high precision. In contrast, CO2 lasers are better suited for cutting non-metallic materials and have higher maintenance requirements.

What materials can be cut with a fiber laser cutting machine?

Fiber laser cutting machines can handle a variety of materials. They are particularly effective for cutting metals like stainless steel, carbon steel, aluminum, copper, and nickel alloys. While primarily designed for metals, they can also cut certain non-metals, such as acrylic and polycarbonate, with the right settings.

Are there any limitations to using fiber laser cutting machines?

Yes, there are some limitations. Fiber laser cutting machines may struggle with very thick materials, as their efficiency and precision can decrease. Additionally, the initial cost of these machines can be high, which might be a barrier for smaller businesses.

What are the benefits of using fiber laser cutting machines?

Fiber laser cutting machines offer several benefits, including high precision and accuracy, fast cutting speeds, and low maintenance requirements. They consume less energy compared to other laser cutting technologies, leading to cost savings over time. These machines are also durable and have a longer lifespan.

How do I choose the right fiber laser cutting machine for my needs?

When choosing a fiber laser cutting machine, consider factors such as power rating, cutting table size, software integration, automation features, and safety standards. Assess your budget and operating costs, and ensure the machine aligns with your specific project requirements.

What maintenance is required for fiber laser cutting machines?

Regular maintenance is essential for optimal performance. Routine tasks include cleaning optics, checking and replacing nozzles, monitoring laser power, inspecting the cooling system, and updating software. Troubleshooting common issues, such as inconsistent cuts or reduced speed, is also important.

Can fiber laser cutting machines be used for artistic applications?

Yes, fiber laser cutting machines are versatile and can be used for artistic and creative applications. They allow artists and designers to create intricate designs and patterns in metal sheets, offering endless possibilities for decorative pieces and metal art.

How do fiber lasers compare to CO2 lasers in terms of performance?

Fiber lasers excel in cutting speed and precision, especially for thin metal sheets. They are more energy-efficient and require less maintenance than CO2 lasers. However, CO2 lasers are better suited for cutting non-metallic materials and offer versatility for projects involving a variety of materials.

Where can I find more information about fiber laser cutting machines?

For comprehensive information about fiber laser cutting machines and their differences from other technologies, you can explore resources like "Fiber Laser FAQ: Everything you need to know!" These resources provide detailed insights into the capabilities and applications of fiber laser cutting technology.

See Also

Understanding The Functionality Of Fiber Laser Cutters

Exploring Laser Cutting Machines And Their Various Types

A Simple Explanation Of Laser Cutting Machine Operation

The Working Mechanism Of CNC Laser Cutting Machines

The Role Of Laser Cutting Machines In Industrial Applications