What is Fiber Laser Cutting Machine Used For?

Fiber laser cutting machines have revolutionized the way you approach material processing. These machines excel in precision cutting, making them indispensable across various industries. From automotive to aerospace, their applications are vast and diverse. The market for laser cutting machines reached a staggering $5.94 billion in 2023, reflecting their growing importance. With a projected growth rate of 7.6% CAGR from 2024 to 2032, the demand for these machines continues to rise. Understanding what is fiber laser cutting machine used for can open up new possibilities for efficiency and innovation in your industry.

Key Takeaways

- Fiber laser cutting machines are essential in various industries, including automotive, aerospace, and medical device manufacturing, due to their precision and efficiency.

- These machines can cut a wide range of materials, from metals to non-metals, making them versatile tools for modern manufacturing processes.

- The technology offers significant advantages such as high-speed operation, minimal waste, and cost-effectiveness, enhancing overall production efficiency.

- Understanding the specific applications of fiber laser cutting can help businesses innovate and stay competitive in their respective markets.

- Future trends in fiber laser technology include increased power, automation, and expanded applications, paving the way for new manufacturing possibilities.

- Investing in fiber laser cutting technology can lead to long-term savings and improved product quality, making it a worthwhile consideration for manufacturers.

Primary Applications of Fiber Laser Cutting Machines

Fiber laser cutting machines have become essential in various industries due to their precision and efficiency. Understanding what is fiber laser cutting machine used for can help you appreciate its versatility and impact on modern manufacturing.

General Manufacturing

In general manufacturing, fiber laser cutting machines offer unmatched precision and speed. You can use them to cut a wide range of materials, from thin sheets to thicker metal plates. Their ability to produce high-quality cuts makes them indispensable tools in creating intricate components. Whether you're working with metals or other materials, these machines streamline production processes and enhance product quality.

Automotive Industry

The automotive industry heavily relies on fiber laser cutting machines for their ability to cut engine parts, body panels, and exhaust systems with high precision. You can achieve superior results when shaping strong metals, ensuring that each component meets stringent quality standards. By embracing this technology, automotive manufacturers can stay competitive and meet the evolving demands of the market.

Aerospace Industry

In the aerospace sector, precision is paramount. Fiber laser cutting machines excel in producing lightweight and complex components required for aircraft. You can rely on these machines to deliver high-precision cuts, ensuring that every part fits perfectly. Their efficiency and adaptability make them a top choice for aerospace manufacturers aiming to maintain high standards and innovate continuously.

Medical Device Manufacturing

In the medical device manufacturing sector, precision and reliability are crucial. Fiber laser cutting machines excel in producing intricate components required for medical devices. You can use these machines to create surgical instruments with precise edges, ensuring they meet stringent medical standards. Their ability to cut with high accuracy makes them ideal for crafting implants and prosthetics. By utilizing fiber laser technology, you enhance the quality and safety of medical products, contributing to better patient outcomes.

Electronics Industry

The electronics industry demands components with fine details and exact specifications. Fiber laser cutting machines offer the precision needed to manufacture circuit boards and micro-components. You can achieve clean cuts and intricate designs, essential for modern electronic devices. These machines streamline production processes, allowing you to meet the fast-paced demands of the electronics market. Their efficiency and adaptability make them indispensable tools in this ever-evolving industry.

Advertising and Signage

In advertising and signage, creativity and detail are paramount. Fiber laser cutting machines enable you to produce intricate designs and fonts in metal advertising products. Whether you're crafting eye-catching signs or detailed logos, these machines provide the precision and versatility needed to bring your creative visions to life. By embracing this technology, you can deliver high-quality, customized signage that stands out in a competitive market.

Metalworking and Sheet Metal Fabrication

In the realm of metalworking and sheet metal fabrication, fiber laser cutting machines have become indispensable tools. You can rely on these machines to deliver precise and efficient cuts, making them a staple in modern manufacturing processes. Their ability to handle various metals, from carbon steel to stainless steel, showcases their versatility and adaptability.

Fiber laser cutting machines offer several advantages in metalworking:

- Precision and Accuracy: You achieve high-quality cuts with minimal waste, ensuring that each piece meets exact specifications.

- Speed and Efficiency: These machines operate at high speeds, allowing you to complete projects faster and increase productivity.

- Versatility: You can cut a wide range of materials, from thin sheets to thicker metal plates, making them suitable for diverse applications.

By embracing this technology, you streamline production processes and enhance product quality. The precision of fiber laser cutting machines allows you to create intricate designs and complex shapes, which are essential in industries like automotive and aerospace. Their efficiency reduces production time and costs, helping you stay competitive in a rapidly evolving market.

Understanding what is fiber laser cutting machine used for in metalworking can open up new possibilities for innovation and efficiency. As you integrate these machines into your operations, you benefit from their advanced capabilities and contribute to the advancement of modern manufacturing.

How Fiber Laser Cutting Machines Work

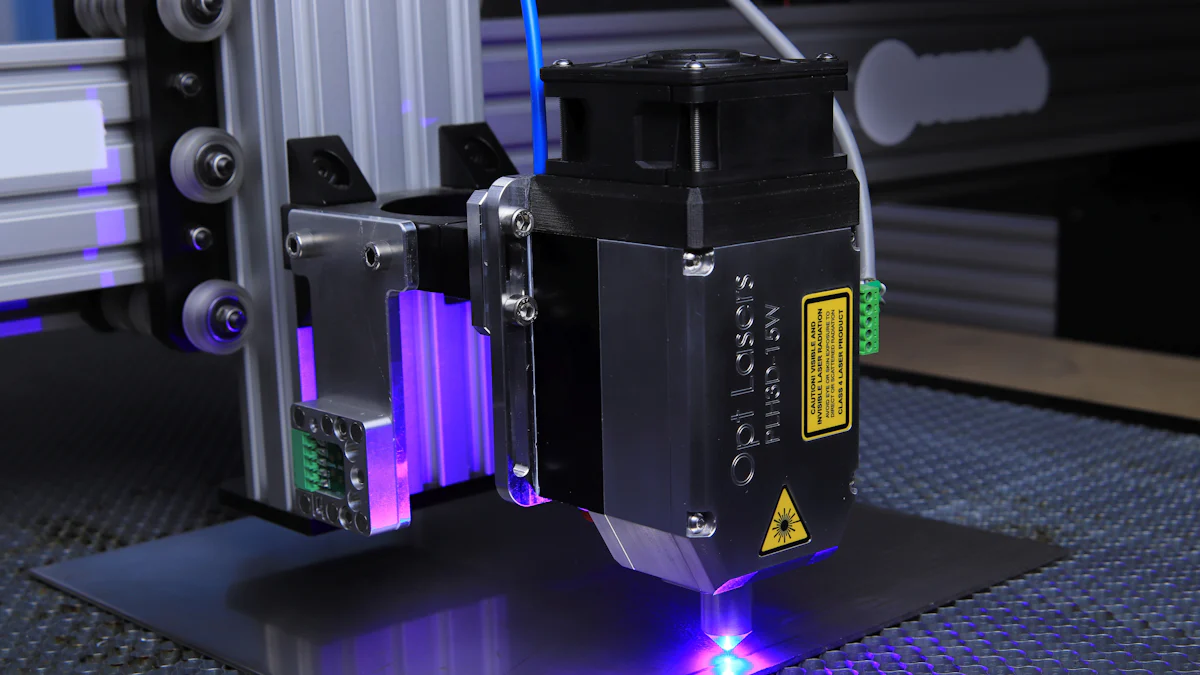

Understanding how fiber laser cutting machines operate can enhance your appreciation of their capabilities and applications. These machines utilize advanced technology to deliver precise and efficient cuts across various materials.

Basic Principles of Fiber Laser Technology

Fiber laser technology relies on the amplification of light through optical fibers. You start with a seed laser, which generates a beam of light. This light travels through a series of optical fibers, where it gets amplified. The fibers contain rare-earth elements like erbium or ytterbium, which enhance the light's intensity. As the light exits the fibers, it forms a powerful laser beam capable of cutting through materials with high precision.

The laser beam's wavelength is typically in the infrared spectrum, making it suitable for cutting metals and other materials. You can adjust the beam's focus to achieve different cutting depths and widths, allowing for versatility in applications. This adaptability makes fiber laser cutting machines valuable in industries ranging from automotive to advertising.

Key Components and Operation

Fiber laser cutting machines consist of several key components that work together to achieve precise cuts:

-

Laser Source: This is the core of the machine, where the laser beam originates. It includes the seed laser and the optical fibers that amplify the light.

-

Cutting Head: The cutting head directs the laser beam onto the material. It contains lenses and mirrors that focus the beam to the desired spot size and intensity.

-

CNC Controller: This component controls the movement of the cutting head and the material. You can program it to follow specific patterns and shapes, ensuring accuracy and repeatability.

-

Cooling System: The cooling system prevents overheating by dissipating excess heat generated during the cutting process. This ensures the machine operates efficiently and prolongs its lifespan.

-

Assist Gas System: Assist gases like nitrogen or oxygen are used to blow away molten material and improve cutting quality. They also help prevent oxidation and enhance the cutting speed.

Operating a fiber laser cutting machine involves setting up the material, programming the CNC controller, and initiating the cutting process. You monitor the machine to ensure it performs optimally and make adjustments as needed. By understanding these components and their functions, you can maximize the machine's efficiency and output.

Types of Materials Cut by Fiber Laser Machines

Fiber laser cutting machines are renowned for their versatility and precision. They can handle a wide array of materials, making them indispensable in various industries. Understanding what is fiber laser cutting machine used for can help you appreciate its adaptability and efficiency.

Metals

Fiber laser cutting machines excel in cutting metals. You can use them to cut through carbon steel, stainless steel, aluminum, brass, and copper. These machines deliver high-quality cuts with minimal waste, making them ideal for industries like automotive, aerospace, and metalworking. The ability to cut metals up to 200mm thick showcases their power and precision. Whether you're working with thin sheets or thick plates, fiber lasers provide consistent results.

Non-metals

Beyond metals, fiber laser cutting machines can also cut non-metal materials. You can use them to process plastics, ceramics, and even some types of glass. This capability expands their application range, allowing you to create intricate designs and components in various industries. The precision of fiber lasers ensures clean cuts, which is essential for products requiring high accuracy.

Composites

Fiber laser cutting machines are also effective in cutting composite materials. These materials, often used in aerospace and automotive industries, require precise cutting to maintain their structural integrity. You can rely on fiber lasers to deliver accurate cuts, ensuring that composite components meet the necessary specifications. This adaptability makes fiber laser cutting machines a valuable asset in modern manufacturing.

Advantages of Fiber Laser Cutting Technology

Fiber laser cutting technology offers numerous advantages that make it a preferred choice in various industries. Understanding these benefits can help you appreciate what is fiber laser cutting machine used for and how it can enhance your manufacturing processes.

Precision and Accuracy

Fiber laser cutting machines provide exceptional precision and accuracy. You can achieve intricate cuts with minimal deviation, ensuring that each piece meets exact specifications. This precision is crucial in industries like aerospace and medical device manufacturing, where even the slightest error can have significant consequences. The high beam quality of fiber lasers allows you to produce clean and smooth edges, reducing the need for additional finishing processes. This capability not only improves product quality but also enhances your overall production efficiency.

Speed and Efficiency

Speed is another significant advantage of fiber laser cutting technology. These machines operate at high speeds, allowing you to complete projects faster and increase your productivity. The efficiency of fiber lasers stems from their ability to cut through materials quickly while maintaining high precision. This speed is particularly beneficial in industries with high-volume production demands, such as automotive and electronics. By reducing production time, you can meet tight deadlines and respond swiftly to market demands. Additionally, the energy efficiency of fiber lasers means you consume less power, contributing to cost savings and environmental sustainability.

Cost-effectiveness

Fiber laser cutting machines offer a cost-effective solution for material processing. Their low maintenance requirements and long lifespan reduce operational costs over time. You benefit from lower energy consumption and minimal material waste, which further enhances cost savings. The versatility of fiber lasers allows you to cut a wide range of materials, eliminating the need for multiple machines and reducing equipment costs. By investing in fiber laser technology, you can optimize your production processes and achieve a higher return on investment.

Industry-Specific Applications

Automotive Industry

Cutting and Shaping Components

In the automotive industry, fiber laser cutting machines play a crucial role in cutting and shaping various components. You can use these machines to cut body panels, engine parts, and exhaust systems with high precision. Their ability to handle different materials, such as steel, aluminum, and other alloys, makes them versatile tools in automotive manufacturing. By using a single machine to cut various materials, you save on space and equipment costs, streamlining your production process.

Customization and Prototyping

Customization and prototyping are essential in the automotive sector. Fiber laser cutting machines allow you to create custom parts and prototypes quickly and accurately. You can adjust the laser power and speed to achieve the desired results, whether you're working with metals or non-metallic materials like plastics and composites. This flexibility enables you to meet specific customer requirements and test new designs efficiently.

Aerospace Industry

Lightweight Material Processing

In aerospace manufacturing, lightweight materials are vital for improving fuel efficiency and performance. Fiber laser cutting machines excel in processing these materials, such as aluminum and titanium. You can rely on these machines to deliver precise cuts, ensuring that each component meets the stringent standards required in the aerospace industry. Their ability to cut reflective materials like aluminum and copper further enhances their utility in this sector.

High-Precision Parts

Precision is paramount in aerospace applications. Fiber laser cutting machines provide the accuracy needed to produce high-precision parts. You can achieve intricate cuts with minimal deviation, ensuring that each piece fits perfectly within the aircraft's design. This precision reduces the need for additional finishing processes, saving you time and resources while maintaining the highest quality standards.

Medical Device Manufacturing

Surgical Instruments

In medical device manufacturing, the precision of fiber laser cutting machines is invaluable. You can use these machines to create surgical instruments with precise edges, ensuring they meet stringent medical standards. The high beam quality of fiber lasers allows you to produce clean and smooth edges, enhancing the safety and effectiveness of surgical tools.

Implants and Prosthetics

The production of implants and prosthetics requires meticulous attention to detail. Fiber laser cutting machines enable you to craft these components with high accuracy, ensuring they fit perfectly and function as intended. By utilizing fiber laser technology, you enhance the quality and safety of medical products, contributing to better patient outcomes.

Electronics Industry

Circuit Board Manufacturing

In the electronics industry, precision is crucial. Fiber laser cutting machines excel in circuit board manufacturing. You can use these machines to achieve precise cuts and intricate designs necessary for modern electronic devices. The high beam quality ensures clean edges, reducing the need for additional processing. This efficiency allows you to meet the fast-paced demands of the electronics market. By integrating fiber laser technology, you enhance the quality and reliability of your circuit boards, ensuring they meet exact specifications.

Micro-component Fabrication

Micro-components require meticulous attention to detail. Fiber laser cutting machines provide the precision needed for fabricating these tiny parts. You can rely on these machines to produce components with exact dimensions, essential for the functionality of electronic devices. The ability to cut with high accuracy minimizes material waste and enhances production efficiency. By utilizing fiber laser technology, you can meet the stringent requirements of micro-component fabrication, contributing to the advancement of electronic products.

Advertising and Signage

Metal Advertising Products

In advertising and signage, creativity and precision are key. Fiber laser cutting machines enable you to create metal advertising products with intricate designs. You can craft eye-catching signs and detailed logos that stand out in a competitive market. The versatility of fiber lasers allows you to work with various metals, from stainless steel to aluminum, ensuring high-quality results. By embracing this technology, you can deliver customized signage that captures attention and communicates your message effectively.

Intricate Design Creation

Creating intricate designs requires precision and flexibility. Fiber laser cutting machines offer the capability to produce detailed patterns and shapes in metal and non-metal materials. You can bring your creative visions to life with high accuracy, ensuring each design meets your specifications. The adaptability of fiber lasers allows you to experiment with different materials and styles, enhancing your creative potential. By integrating fiber laser technology into your design process, you can achieve stunning results that resonate with your audience.

Challenges and Considerations

Initial Investment Costs

When considering fiber laser cutting machines, you must account for the initial investment costs. These machines require a significant upfront expenditure. The advanced technology and precision capabilities contribute to their higher price compared to traditional cutting methods. However, the benefits often outweigh the costs. Fiber lasers offer enhanced efficiency, speed, and accuracy. You can complete more jobs in less time, reducing long-term operational expenses. Despite the initial cost, the return on investment can be substantial due to increased productivity and reduced material waste.

Maintenance and Technical Expertise

Operating fiber laser cutting machines demands regular maintenance and technical expertise. You need to ensure that the machine functions optimally. Routine checks and servicing are essential to prevent downtime and extend the machine's lifespan. Additionally, you must have skilled personnel who understand the intricacies of fiber laser technology. Training your team on machine operation and troubleshooting is crucial. This expertise ensures that you maximize the machine's capabilities and maintain high-quality output. While these considerations may seem daunting, they are necessary for leveraging the full potential of fiber laser cutting technology.

Future Trends in Fiber Laser Cutting Technology

The world of fiber laser cutting technology is constantly evolving, with new advancements and applications emerging regularly. As you explore the future trends in this field, you'll discover how these machines continue to revolutionize industries by enhancing precision, efficiency, and versatility.

Technological Advancements

Fiber laser cutting machines are at the forefront of technological innovation. You can expect several advancements that will further enhance their capabilities:

-

Increased Power and Speed: Manufacturers are developing more powerful lasers that can cut through thicker materials at faster speeds. This improvement allows you to tackle more demanding projects with ease.

-

Enhanced Precision: New technologies are being integrated to improve the accuracy of cuts. You can achieve even finer details, which is crucial for industries like aerospace and medical device manufacturing.

-

Automation and AI Integration: Automation is becoming a key feature in fiber laser cutting machines. With AI integration, you can optimize cutting paths, reduce waste, and increase productivity. This advancement allows you to focus on more complex tasks while the machine handles routine operations.

-

Improved User Interfaces: User-friendly interfaces make it easier for you to operate these machines. Intuitive controls and real-time monitoring systems enhance your ability to manage cutting processes efficiently.

Expanding Applications

The versatility of fiber laser cutting machines means their applications are continually expanding. Here are some areas where you can expect to see growth:

-

Automotive Industry: Fiber laser cutting is revolutionizing automotive manufacturing. You can produce intricate components with high precision, essential for modern vehicle production. The ability to cut complex shapes and designs enhances the efficiency and quality of automotive parts.

-

Aerospace Sector: In aerospace, lightweight yet strong components are crucial. Fiber laser cutting machines excel in creating these parts, ensuring they meet stringent standards. As the demand for advanced aerospace technology grows, so will the use of fiber lasers.

-

Medical Device Manufacturing: Precision is vital in medical device production. Fiber laser cutting machines allow you to create precise and miniature components, improving the quality and safety of medical products.

-

Electronics Industry: The need for detailed and exact components in electronics continues to rise. Fiber laser cutting machines provide the precision required for circuit board manufacturing and micro-component fabrication.

As you look to the future, understanding what is fiber laser cutting machine used for will help you appreciate its expanding role in various industries. These machines are not only enhancing current applications but also paving the way for new possibilities in manufacturing and design.

Fiber laser cutting machines offer numerous benefits across various industries. Their precision and efficiency make them indispensable in sectors like automotive, aerospace, and electronics. You can achieve high-quality cuts with minimal waste, enhancing production processes and product quality. As technology advances, expect even greater capabilities from these machines. Future trends include increased power, automation, and expanded applications. By understanding what is fiber laser cutting machine used for, you can leverage its potential to stay competitive and innovative in your field.

FAQ

What is a fiber laser cutting machine?

A fiber laser cutting machine uses a high-powered laser beam to cut through materials with precision. You can use it for various applications, including metalworking, automotive, and electronics industries. The machine's efficiency and accuracy make it a popular choice for manufacturers.

How does fiber laser cutting differ from other cutting methods?

Fiber laser cutting stands out due to its precision and speed. Unlike traditional methods, it uses a focused laser beam to achieve clean cuts with minimal waste. You benefit from lower maintenance costs because fiber lasers have fewer moving parts and don't require consumables like other methods.

What materials can a fiber laser cutting machine process?

Fiber laser cutting machines can handle a wide range of materials. You can cut metals like steel, aluminum, and copper. They also work well with non-metals such as plastics and ceramics. This versatility makes them suitable for diverse applications across industries.

Are fiber laser cutting machines cost-effective?

Yes, fiber laser cutting machines are cost-effective. They reduce overheads and operating costs due to their low maintenance requirements. You save on energy consumption and material waste, making them a reliable solution for manufacturers.

What are the operational costs associated with fiber laser cutting machines?

Operational costs include energy consumption, maintenance, and consumables like laser gases and lenses. However, fiber lasers generally have lower maintenance costs compared to other cutting methods. You can manage these costs with strategic adjustments and regular maintenance.

How do I maintain a fiber laser cutting machine?

Regular maintenance is crucial for optimal performance. You should conduct routine checks and servicing to prevent downtime. Training your team on machine operation and troubleshooting ensures you maximize the machine's capabilities and maintain high-quality output.

Can small businesses afford fiber laser cutting technology?

While the initial investment may seem high, fiber laser cutting technology offers long-term savings. You benefit from increased productivity and reduced material waste. Many small and medium-sized enterprises find the investment worthwhile due to the machine's efficiency and reliability.

What industries benefit most from fiber laser cutting machines?

Industries like automotive, aerospace, electronics, and medical device manufacturing benefit greatly. You can achieve high-quality cuts with precision, essential for producing intricate components. The versatility of fiber lasers allows you to meet the specific demands of these industries.

How does fiber laser cutting impact production efficiency?

Fiber laser cutting enhances production efficiency by operating at high speeds and delivering precise cuts. You can complete projects faster, reducing production time and costs. This efficiency helps you meet tight deadlines and respond swiftly to market demands.

What future trends can we expect in fiber laser cutting technology?

Expect advancements in power, speed, and precision. Automation and AI integration will optimize cutting paths and increase productivity. As technology evolves, fiber laser cutting machines will continue to expand their applications, offering even greater capabilities for manufacturers.

See Also

Understanding the Functionality of Fiber Laser Cutters

Exploring Different Types of Laser Cutting Machines

Tips for Effective Use of Laser Cutting Machines