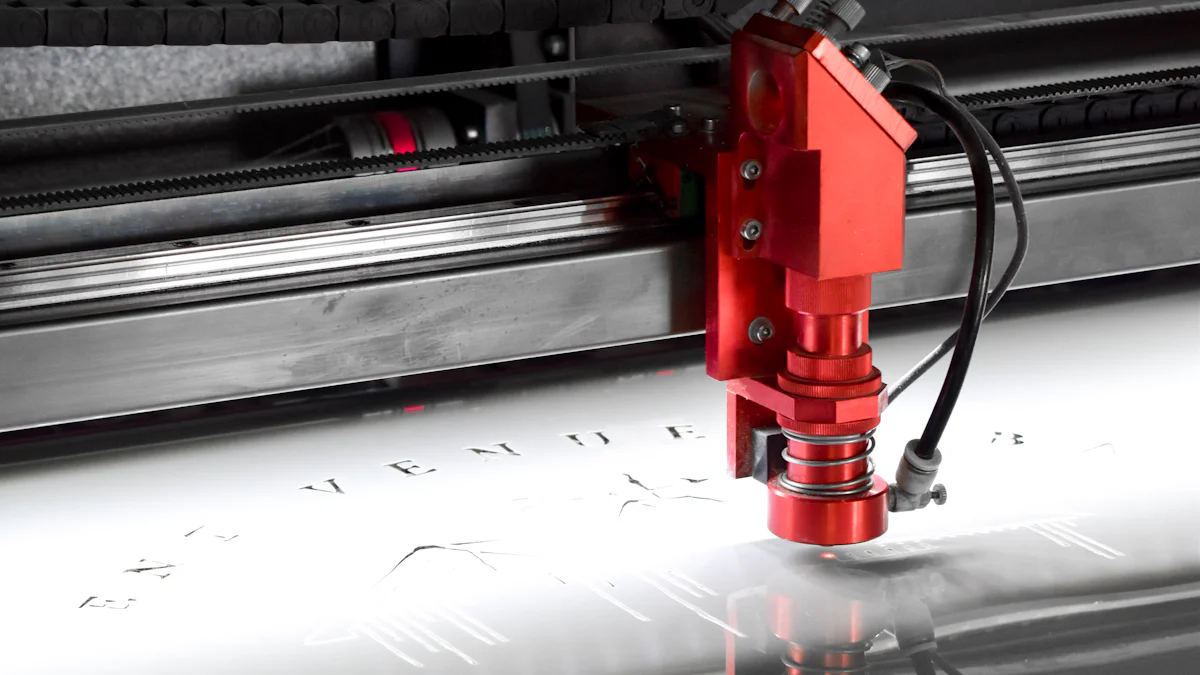

How to Cut with a Laser Using Chinese Machines

Using a Chinese laser cutting machine can transform your crafting or manufacturing process. These machines have gained popularity due to their affordability and efficiency. In 2021, China exported 268,700 laser cutting machines, reflecting a significant rise in demand. To get the best results, you need to focus on setup, operation, and troubleshooting. Proper setup ensures your machine runs smoothly, while understanding its operation helps you achieve precise cuts. Troubleshooting skills are essential for addressing any issues that arise. By mastering these aspects, you can effectively learn how to cut with a laser with Chinese machine technology.

Setting Up Your CNC Laser Cutting Machine

Setting up your laser cutting machine is the first step to achieving precise and efficient cuts. Let's dive into the process, starting with unboxing and initial setup.

Unboxing and Initial Setup

Inspecting the machine for damage

When you receive your laser cutting machine, carefully unbox it. Look for any signs of damage during shipping. Check the exterior for dents or scratches. Ensure all parts are intact. If you notice any issues, contact the supplier immediately. This step ensures your machine functions correctly from the start.

Assembling the components

Once you've inspected the machine, begin assembling the components. Follow the manufacturer's instructions closely. Attach the laser head, connect the power supply, and secure any loose parts. Proper assembly is crucial for the machine's performance. Take your time to ensure everything fits perfectly.

Software Installation

Choosing the right software

Selecting the right software is essential for operating your laser cutting machine. Research different options available. Consider factors like compatibility with your machine and ease of use. Popular choices include LightBurn and RDWorks. Choose software that suits your needs and skill level.

Installing and configuring the software

After selecting the software, proceed with installation. Follow the provided instructions. Configure the settings to match your machine's specifications. This step involves setting the correct parameters for cutting and engraving. Proper configuration ensures smooth operation and accurate results.

Calibration and Testing

Aligning the laser

Calibration is vital for precision. Start by aligning the laser. Adjust the mirrors and lens to ensure the beam hits the intended spot. Use alignment tools if necessary. Proper alignment prevents errors during cutting and enhances the quality of your work.

Performing a test cut

Before diving into projects, perform a test cut. Use a simple design on a scrap material. This test helps verify the machine's settings and alignment. Adjust the speed and power as needed. A successful test cut confirms your laser cutting machine is ready for action.

By following these steps, you set the foundation for successful projects with your cnc laser cutting machine. Proper setup and calibration lead to efficient and precise cuts, making your work easier and more enjoyable.

Addressing Common Faults in Laser Cutting Machines

Even the most advanced laser cutting machine can encounter issues over time. Understanding these common problems and knowing how to address them ensures your machine runs smoothly and efficiently.

Power and Connectivity Problems

Power and connectivity issues often cause a laser cutter fail. Here's how you can tackle these problems:

Checking power supply

First, ensure your laser cutting machine receives adequate power. Check all connections and verify that the power supply functions correctly. A faulty power source can lead to a laser output failure, affecting the machine's performance.

Ensuring proper USB connection

Next, inspect the USB connection. A loose or damaged USB cable can disrupt communication between the machine and the computer. Secure the connection and replace any faulty cables to prevent display panel fail and other connectivity issues.

Laser Not Cutting Properly

When your laser cutting machine doesn't cut as expected, it might be due to misalignment or other factors. Here's what you can do:

Adjusting laser focus

Proper laser focus is crucial for precise cuts. Adjust the focus by moving the laser head closer or further from the material. This adjustment helps prevent cutting misalignment and ensures clean cuts.

Cleaning the lens and mirrors

Dirt and debris on the lens and mirrors can cause the laser tube not emit light effectively. Regularly clean these components with a soft cloth and appropriate cleaning solution. This maintenance step enhances the machine's performance and prevents light output failure.

Material Compatibility

Using the right materials is essential for optimal results. Here's how to ensure compatibility:

Identifying suitable materials

Not all materials work well with a laser cutting machine. Identify materials that are compatible with your machine's specifications. This knowledge helps avoid common faults related to material incompatibility.

Adjusting settings for different materials

Different materials require different settings. Adjust the machine's speed, power, and frequency to match the material you're working with. Proper settings prevent the laser tube not emit light and ensure efficient cutting.

By addressing these common problems, you can maintain the performance and reliability of your laser cutting machine. Regular maintenance and troubleshooting keep your machine running smoothly, allowing you to focus on creating precise and intricate designs.

Solutions of CNC Laser Cutting Machines

When dealing with a laser cutting machine, you might encounter various issues. Understanding the solutions to these common problems can help you maintain your machine's performance and extend its lifespan. Let's explore some practical solutions for your CNC laser cutting machine.

Diagnosing Mechanical Issues

Mechanical issues often arise in laser cutting machines, affecting their efficiency. Here's how you can address them:

Checking for loose belts or gears

Loose belts or gears can lead to cutting shape deformation. Regularly inspect these components to ensure they are tight and secure. If you notice any looseness, tighten them immediately. This simple step can prevent cutting overlap and ensure precise cuts.

Ensuring smooth movement of the laser head

The laser head should move smoothly across the material. Any obstruction or resistance can cause cutting shape deformation. Check the rails and bearings for dust or debris. Clean them regularly to maintain smooth movement. This practice not only enhances performance but also prolongs the machine's life.

Software and Firmware Updates

Keeping your software and firmware up-to-date is crucial for optimal performance. Here's what you need to do:

Updating the machine's firmware

Firmware updates often include solutions to common problems and improve the machine's functionality. Check the manufacturer's website for the latest updates. Follow the instructions carefully to install them. Regular updates ensure your laser cutting machine operates efficiently.

Troubleshooting software glitches

Software glitches can disrupt your workflow. If you experience any issues, restart the software and check for updates. Reinstall the software if necessary. These solutions can resolve most glitches and restore normal operation.

Safety Precautions

Safety should always be a priority when operating a laser cutting machine. Here are some essential precautions:

Ensuring proper ventilation

Laser cutting produces fumes that can be harmful if inhaled. Ensure your workspace has adequate ventilation. Use exhaust fans or air purifiers to remove fumes. Proper ventilation protects your health and maintains a safe working environment.

Using protective gear

Always wear protective gear when operating the machine. Safety goggles protect your eyes from laser beams. Gloves shield your hands from sharp edges. These precautions minimize the risk of injury and ensure safe operation.

By implementing these solutions, you can effectively address common problems with your CNC laser cutting machine. Regular maintenance and updates keep your machine running smoothly, allowing you to focus on creating precise and intricate designs.

Optimizing Performance of Your Laser Cutting Machine

To get the most out of your laser cutting machine, you need to focus on optimizing its performance. This involves regular maintenance and enhancing cutting efficiency. Let's explore how you can achieve this.

Regular Maintenance

Keeping your laser cutting machine in top shape requires consistent care. Regular maintenance ensures that your machine operates smoothly and efficiently.

Cleaning and lubricating moving parts

You should clean and lubricate the moving parts of your laser cutting machine regularly. Dust and debris can accumulate, causing friction and wear. Use a soft cloth to wipe down surfaces and apply lubricant to the rails and gears. This simple routine helps maintain smooth operation and prolongs the life of your machine.

Replacing worn-out components

Over time, some parts of your laser cutting machine may wear out. Inspect your machine regularly for signs of wear and tear. Replace any worn-out components promptly to prevent further damage. Keeping your machine in good condition ensures consistent performance and reduces the risk of breakdowns.

Enhancing Cutting Efficiency

Improving the efficiency of your laser cutting machine can lead to better results and faster production times. Here are some ways to enhance its cutting efficiency.

Optimizing cutting speed and power

Finding the right balance between cutting speed and power is crucial. Too much speed can lead to incomplete cuts, while too little power can result in poor quality. Experiment with different settings to find the optimal combination for your material. This adjustment can significantly improve the quality and precision of your cuts.

Using advanced cutting techniques

Explore advanced cutting techniques to maximize the capabilities of your laser cutting machine. Techniques like nesting and multi-pass cutting can help you achieve more intricate designs and reduce material waste. By mastering these techniques, you can take full advantage of your machine's potential.

Chinese companies produce a wide range of laser cutting machines, including fiber laser cutting machines, catering to various industries and applications. Understanding the specific features and capabilities of your machine can help you optimize its performance.

By focusing on regular maintenance and enhancing cutting efficiency, you can ensure that your laser cutting machine delivers the best possible results. These practices not only improve performance but also extend the lifespan of your machine, making it a valuable asset for your projects.

Mastering how to cut with a laser with Chinese machine technology involves several key steps. First, ensure proper setup and calibration of your laser cutting machine. This foundation is crucial for achieving precise cuts. Regular maintenance plays a vital role in keeping your machine in top condition. By addressing minor issues early, you prevent major breakdowns and save money in the long run. Troubleshooting skills are essential for minimizing downtime and maintaining productivity. Embrace these practices to enhance your experience with Chinese laser cutting machines and enjoy efficient, high-quality results.

FAQ

What is a laser cutting machine and how does it work?

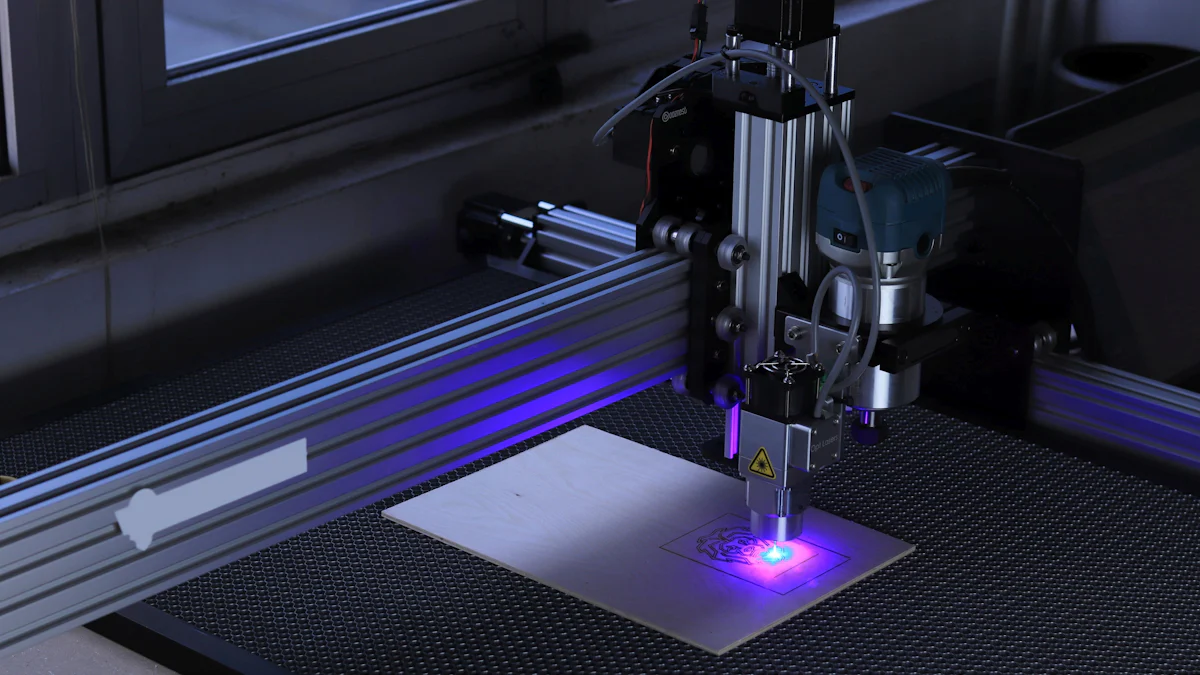

A laser cutting machine uses a high-powered laser beam directed through optics to cut materials. The focused laser burns or melts the material, leaving a clean edge. This allows you to create precise designs. The process is controlled by computer numerical control (CNC), which lets you repeat those designs with accuracy.

What materials can laser cutting machines work on?

Laser cutter machines can work on a wide variety of materials. These include wood, acrylic, fabric, leather, metal, paper, and cardboard. This versatility makes laser cutters ideal for enhancing products in various businesses. Whether you create or sell, there's likely a way a laser machine can help.

How do I choose the right laser cutting machine for my needs?

Consider the materials you plan to cut and the thickness you need. Look at the machine's power and speed capabilities. Evaluate the software compatibility and ease of use. Research different models and read reviews. This helps you find a machine that fits your specific requirements.

How often should I perform maintenance on my laser cutting machine?

Regular maintenance is crucial for optimal performance. Clean and lubricate moving parts weekly. Inspect and replace worn-out components as needed. Check the alignment and calibration monthly. Following a consistent maintenance schedule ensures your machine runs smoothly and efficiently.

Can I use a laser cutting machine for engraving?

Yes, you can use a laser cutting machine for engraving. Adjust the settings to lower power and speed for engraving. This allows you to create detailed designs on various materials. Experiment with different settings to achieve the desired depth and clarity.

What safety precautions should I take when using a laser cutting machine?

Always wear protective gear like safety goggles and gloves. Ensure proper ventilation in your workspace to avoid inhaling fumes. Keep flammable materials away from the machine. Follow the manufacturer's safety guidelines to minimize risks and ensure safe operation.

How do I troubleshoot common issues with my laser cutting machine?

Start by checking the power supply and USB connections. Ensure the laser focus is adjusted correctly. Clean the lens and mirrors regularly. If problems persist, consult the user manual or contact customer support for assistance.

Is it possible to upgrade my laser cutting machine?

Yes, you can upgrade certain components of your laser cutting machine. Consider upgrading the laser tube for more power or the software for better functionality. Check with the manufacturer for compatible upgrades and follow their instructions for installation.

How can I improve the efficiency of my laser cutting machine?

Optimize cutting speed and power settings for different materials. Use advanced cutting techniques like nesting to reduce waste. Regular maintenance and software updates also enhance efficiency. By focusing on these areas, you can achieve better results and faster production times.

What are the benefits of using a Chinese laser cutting machine?

Chinese laser cutting machines offer affordability and efficiency. They provide a cost-effective solution for businesses looking to enhance their production capabilities. With proper setup and maintenance, these machines deliver precise cuts and reliable performance.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding the Functionality of CNC Laser Cutters

A Simple Explanation of Laser Cutting Machine Operation