What to Consider When Buying a Laser Cutting Machine

When you decide to purchase a laser cutting machine, you face a crucial decision. This investment can significantly impact your business or hobby. The global market for these machines is booming, with a valuation of $7.12 billion in 2023 and an expected growth rate of 5.7% annually until 2030. To make a wise choice, you must evaluate several factors to consider. These include the machine's power, size, and compatibility with your needs. Understanding how much is a laser cutting machine and its capabilities ensures you select the right tool for your projects, whether it's cutting or engraving.

Cutting Area Size

When selecting a laser cutting machine, the size of the cutting area plays a pivotal role. It determines the maximum dimensions of the materials you can work with, directly impacting your project's scope and efficiency.

Importance of Cutting Area

Matching Size to Project Needs

You must align the cutting area size with your specific project requirements. For instance, if you frequently work with large format materials like billboards or metal sheets, a Large Format Laser Cutter with a cutting area of 47" x 95" or even 59" x 118" would be ideal. These machines accommodate extensive projects, ensuring you don't face limitations due to size constraints.

Space Considerations in Your Workshop

Consider the available space in your workshop before deciding on a machine. A Desktop Laser Cutting Machine might be more suitable if you have limited space. These machines offer a compact design while still providing a decent cutting capability for materials like wood, acrylic, and fabric. Ensure that the machine fits comfortably in your workspace, allowing for safe and efficient operation.

Versatility and Limitations

Handling Different Material Sizes

A versatile cutting area allows you to handle various material sizes. Machines with larger cutting areas can process both small and large materials, offering flexibility in your projects. For example, a machine with a 51" x 51" cutting area can accommodate a wide range of materials, from small intricate designs to larger pieces.

Future Expansion Possibilities

Think about future expansion possibilities when choosing a cutting area size. If you anticipate scaling up your operations or taking on larger projects, investing in a machine with a larger cutting area now can save you from needing an upgrade later. This foresight ensures that your machine remains relevant and useful as your needs evolve.

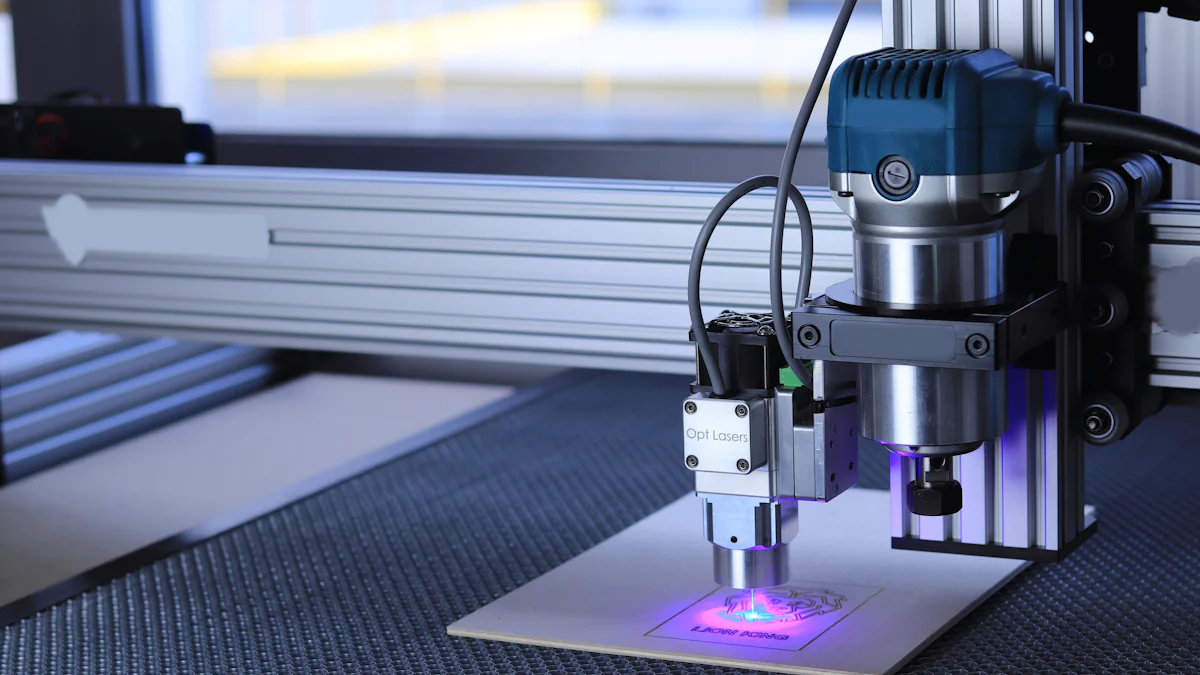

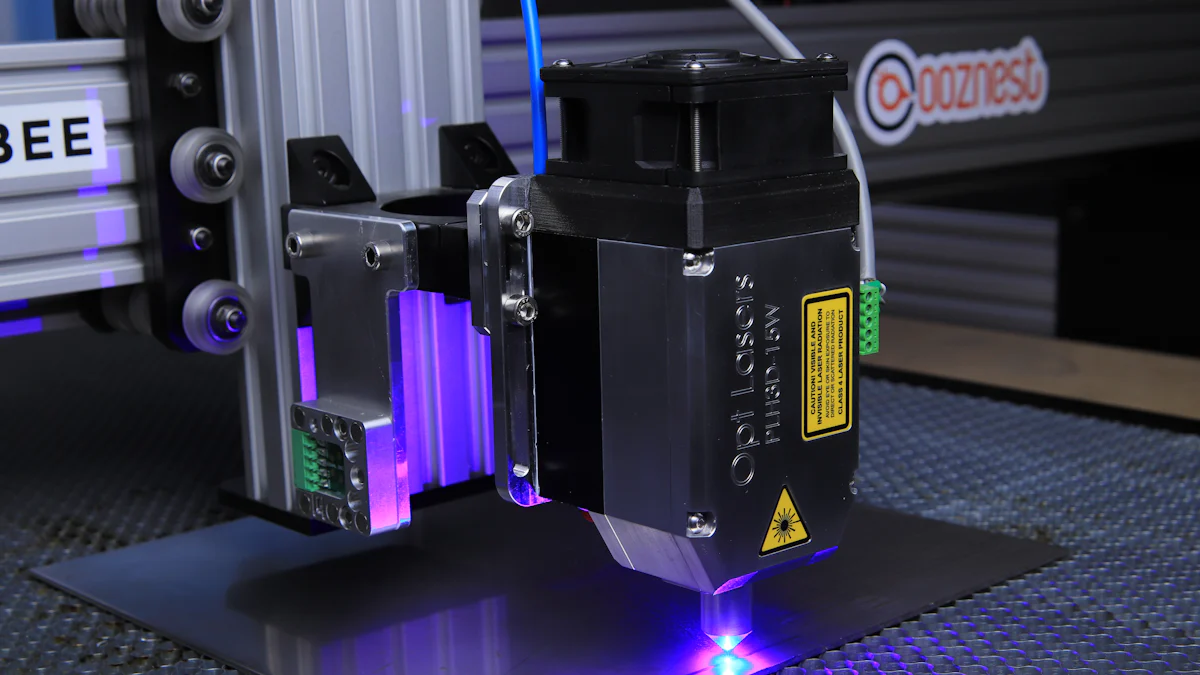

Laser Power and Type

When choosing a laser cutting machine, understanding the laser power and type is crucial. These factors directly influence the machine's performance and suitability for your projects.

Understanding Laser Power

Laser power determines how effectively a machine can cut through materials. It affects both the speed and thickness of the materials you can process.

Power Levels for Different Materials

Different materials require varying power levels for optimal cutting. For instance, a higher-powered laser can cut through thicker materials more quickly. If you frequently work with dense materials like metal, you might need a powerful fiber laser cutting machine. This type of machine excels in cutting metals due to its high power and efficiency. On the other hand, for lighter materials like wood or acrylic, a lower power setting on a laser engraving machine might suffice.

Balancing Power and Precision

Balancing power and precision is essential for achieving the desired results. While higher power allows for faster cutting, it can sometimes compromise the cutting quality of the laser. You must find a balance that maintains high precision without sacrificing speed. The quality and power of laser source play a significant role here. A well-calibrated laser source ensures that you achieve both precision and speed in your projects.

Types of Lasers

The type of laser you choose impacts the machine's capabilities and the range of materials it can handle.

CO2 vs. Fiber Lasers

CO2 lasers and fiber lasers are the most common types used in cutting machines. CO2 lasers are versatile and can cut a variety of materials, including wood, acrylic, and some metals. However, if you need to cut metals specifically, a fiber laser cutting machine is more suitable. Fiber lasers offer high precision and are particularly effective for metal cutting due to their focused beam and efficiency.

Application-Specific Laser Types

Consider the specific applications you intend to use the machine for. If your projects involve intricate designs or require high precision, a cnc fiber laser machine might be the best choice. These machines provide excellent control and accuracy, making them ideal for detailed work. Always review the machine specifications to ensure they align with your project needs.

Software Compatibility

When purchasing a laser cutting machine, software compatibility is a crucial factor to consider. The software acts as the brain of your machine, guiding its operations and ensuring precision in every cut.

Importance of Software in Laser Cutting

User Interface and Learning Curve

The user interface of the software significantly impacts your experience with the laser cutting machine. A well-designed interface simplifies the process, making it easier for you to navigate and operate the machine. Look for software that offers intuitive controls and clear instructions. This reduces the learning curve, allowing you to start creating designs and executing cuts more quickly. Laser Cutter Control Software often provides precise control over cutting, engraving, and scoring processes, which enhances your ability to produce high-quality results.

Integration with Design Software

Seamless integration with design software is essential for efficient workflow. You should ensure that the laser cutting machine's software can easily import designs from popular design programs. This compatibility allows you to create intricate designs and transfer them directly to the machine for cutting. Desktop Laser Cutting Machines often emphasize this feature, enabling you to work with a variety of design formats without hassle. This integration not only saves time but also ensures that your designs are accurately translated into physical cuts.

Updates and Support

Access to Software Updates

Regular software updates are vital for maintaining the performance and security of your laser cutting machine. These updates often include new features, bug fixes, and improvements that enhance the machine's capabilities. Ensure that the manufacturer provides easy access to these updates. Staying up-to-date with the latest software versions ensures that your machine operates efficiently and remains compatible with new design software.

Availability of Technical Support

Technical support is an invaluable resource when you encounter issues or have questions about your laser cutting machine. Before purchasing, verify that the manufacturer offers reliable customer support. This support can include online resources, tutorials, and direct assistance from experts. Having access to technical support ensures that you can resolve problems quickly, minimizing downtime and maximizing productivity. Laser Cutting Software often comes with comprehensive support options, providing you with the guidance needed to make the most of your machine.

Ease of Use

When selecting a laser cutting machine, ease of use becomes a critical factor. You want a machine that simplifies your workflow and enhances productivity. Let's explore the features and resources that contribute to a user-friendly experience.

User-Friendly Features

Intuitive Controls and Interfaces

A laser cutting machine with intuitive controls and interfaces can significantly improve your experience. You should look for machines that offer straightforward navigation and clear instructions. This simplicity allows you to focus on your projects rather than struggling with complex settings. For instance, some machines come equipped with touchscreens that provide easy access to various functions, making it easier for you to adjust settings and monitor progress.

Setup and Calibration Processes

The setup and calibration processes should be as seamless as possible. A machine that requires minimal effort to set up and calibrate saves you time and reduces frustration. Look for models that offer guided setup procedures or automatic calibration features. These elements ensure that your machine operates at optimal performance from the start, allowing you to begin cutting or engraving without unnecessary delays.

Training and Resources

Availability of Tutorials and Guides

Access to comprehensive tutorials and guides is essential for mastering your laser cutting machine. Manufacturers often provide detailed manuals and video tutorials that walk you through various processes. These resources help you understand the machine's capabilities and teach you how to achieve the best results. By utilizing these materials, you can quickly become proficient in using your machine, whether it's a laser engraving machine or a more advanced model.

Community and Manufacturer Support

Community and manufacturer support play a vital role in your overall experience. Engaging with a community of users allows you to share tips, troubleshoot issues, and learn from others' experiences. Many manufacturers also offer dedicated support teams to assist you with technical questions or concerns. This support network ensures that you have the guidance needed to overcome challenges and make the most of your investment.

"The technology of Cutlite machines has revolutionized their business and future prospects." - LaserJet

This quote highlights the transformative impact that user-friendly technology can have on your operations. By choosing a machine with intuitive features and robust support, you position yourself for success in your laser cutting endeavors.

Safety Features

When you operate a laser cutting machine, prioritizing safety features is essential. These features protect you and your workspace from potential hazards. Let's explore the critical safety mechanisms and standards you should consider.

Essential Safety Mechanisms

Enclosures and Shields

Enclosures and shields serve as the first line of defense in laser cutting machines. They prevent accidental exposure to laser beams, which can cause severe injuries. You should ensure that your machine has robust enclosures that completely cover the laser area. Shields made from appropriate materials can block harmful radiation, protecting your eyes and skin. These components are crucial, especially when working with Class-3B or Class-4 lasers, which pose significant risks if viewed directly.

Emergency Stop Functions

An emergency stop function is a vital safety feature in any laser cutting machine. This mechanism allows you to halt the machine's operation immediately in case of an emergency. You should look for machines with easily accessible emergency stop buttons. This feature can prevent accidents and minimize damage during unexpected situations. Quick access to this function ensures that you can respond promptly to any issues that arise during operation.

Compliance with Safety Standards

Certifications and Regulations

Compliance with safety standards is non-negotiable when selecting a laser cutting machine. Various regulations, such as ANSI B11.21 and ISO 11553-1, outline the safety requirements for laser processing machines. These standards ensure that manufacturers incorporate protective measures to mitigate hazards. You should verify that your machine meets these certifications, as they guarantee adherence to industry safety norms. Additionally, in the EU, compliance with specific regulations protects workers from laser radiation hazards.

Importance of Regular Safety Checks

Regular safety checks are crucial for maintaining a safe working environment. You should conduct routine inspections to ensure that all safety mechanisms function correctly. This practice helps identify potential issues before they escalate into serious problems. Following a checklist of best practices for safe operation can enhance your machine's safety. Regular maintenance not only increases the machine's durability but also ensures that it operates safely and efficiently.

"Safety is not a gadget but a state of mind." - Eleanor Everet

This quote underscores the importance of adopting a safety-first mindset when using laser cutting machines. By prioritizing safety features and adhering to standards, you create a secure environment for your laser engraving machine operations.

Cost and Budget

When purchasing a laser cutting machine, understanding the cost and budget is crucial. You need to evaluate both the initial purchase price and the long-term costs to make an informed decision.

Initial Purchase Price

Comparing Models and Brands

The initial purchase price of a laser cutting machine varies significantly across different models and brands. High-end brands often come with a higher price tag. They offer excellent performance, reliability, and after-sale services. These machines are ideal if you prioritize quality and long-term investment. On the other hand, economic machines might attract you with their lower initial costs. However, they may incur higher maintenance expenses over time. When comparing models, consider the laser power, as it directly affects cutting speed and material thickness.

Evaluating Cost vs. Features

Evaluating the cost versus features is essential in determining the best value for your investment. A higher-priced machine might offer advanced features that enhance productivity and precision. For instance, a laser engraving machine with a robust build and superior technology can justify a higher price. Conversely, a lower-priced model might lack certain features but still meet your basic needs. Assess your project requirements and budget constraints to find a machine within your desired price range that offers the necessary features.

Long-Term Costs

Maintenance and Consumables

Long-term costs include maintenance and consumables, which can impact your overall budget. Regular maintenance ensures the machine operates efficiently and prolongs its lifespan. You should factor in the cost of replacement parts and routine servicing. Additionally, consider the consumables required, such as lenses and filters, which need periodic replacement. These costs can add up over time, so it's important to budget for them when calculating the total cost of a laser engraving machine.

Energy Consumption and Efficiency

Energy consumption and efficiency also play a role in the long-term costs of operating a laser cutting machine. Machines with higher energy efficiency can reduce your electricity bills, making them more cost-effective in the long run. Evaluate the machine's energy consumption ratings and compare them with other models. An energy-efficient machine not only saves money but also contributes to a more sustainable operation.

"Investing in a machine with a higher initial price can lead to savings in maintenance and energy costs over time."

By carefully considering both the initial purchase price and long-term costs, you can make a wise investment that aligns with your budget and project needs.

Maintenance and Reliability

Ensuring the longevity and optimal performance of your laser cutting machine requires regular maintenance and attention to reliability. By adhering to a consistent maintenance schedule, you can prevent unexpected breakdowns and extend the life of your equipment.

Routine Maintenance Requirements

Routine maintenance is essential for keeping your laser cutting machine in top condition. Regular checks and servicing help maintain its efficiency and prevent costly repairs.

Cleaning and Part Replacement

You should regularly clean your laser cutting machine to ensure it operates smoothly. Dust and debris can accumulate on lenses and mirrors, affecting the quality of cuts. Use a soft cloth and appropriate cleaning solutions to keep these components clear. Additionally, inspect parts for wear and replace them as needed. Worn parts can lead to inefficiencies and potential damage to the machine. Following the manufacturer's guidelines for cleaning and part replacement ensures your machine remains in optimal working order.

Scheduled Servicing Needs

Scheduled servicing is crucial for maintaining the reliability of your laser cutting machine. Manufacturers often provide a recommended maintenance schedule that includes routine inspections and servicing. Adhering to this schedule helps identify potential issues before they become major problems. Regular servicing may involve checking for loose parts, calibrating the machine, and updating software. By following these guidelines, you can minimize downtime and ensure your machine operates efficiently.

Reliability and Longevity

The reliability and longevity of your laser cutting machine depend on several factors, including build quality and user feedback. Investing in a reliable machine ensures consistent performance and reduces the likelihood of unexpected failures.

Build Quality and Durability

When selecting a laser cutting machine, consider its build quality and durability. Machines constructed with high-quality materials tend to last longer and withstand regular use. Look for features such as sturdy frames and robust components that can handle the demands of your projects. A well-built machine not only enhances reliability but also provides a stable platform for precise cutting and engraving tasks.

User Reviews and Testimonials

User reviews and testimonials offer valuable insights into the reliability of a laser cutting machine. Reading feedback from other users helps you gauge the machine's performance and identify any common issues. Pay attention to reviews that highlight the machine's reliability and maintenance requirements. Positive testimonials often indicate a machine's ability to meet user expectations and deliver consistent results. By considering user experiences, you can make an informed decision and choose a machine that aligns with your needs.

"Investing in a reliable laser engraving machine ensures consistent performance and reduces the likelihood of unexpected failures."

By prioritizing maintenance and reliability, you can maximize the lifespan of your laser cutting machine and ensure it continues to meet your project needs effectively.

Manufacturer Support and Warranty

When purchasing a laser cutting machine, you should consider the level of manufacturer support and the warranty offered. These factors can significantly impact your experience and satisfaction with the machine.

Importance of Manufacturer Support

Manufacturer support plays a crucial role in ensuring that your laser cutting machine operates smoothly. Reliable support can help you resolve issues quickly and efficiently.

Access to Customer Service

Access to customer service is vital when you encounter problems with your machine. Companies like Boss Laser provide free lifetime tech support via phone and email to the original purchaser. This support ensures that you can get assistance whenever you need it, minimizing downtime and keeping your projects on track. You should look for manufacturers that offer responsive and knowledgeable customer service teams.

Availability of Spare Parts

The availability of spare parts is another important aspect of manufacturer support. If your machine requires repairs, having access to replacement parts is essential. Thunder Laser USA offers a generous 2-year warranty that covers all parts and components, ensuring that you can obtain the necessary parts if any issues arise. This availability gives you peace of mind, knowing that your machine can be repaired promptly.

Warranty Considerations

A comprehensive warranty provides protection and assurance for your investment. It reflects the manufacturer's confidence in their product's quality and reliability.

Coverage and Duration

The coverage and duration of a warranty are key factors to consider. Focused Laser Systems offers a 24-month warranty on their Vision Laser range, while refurbished machines come with a 12-month warranty. This coverage period allows you to address any defects or malfunctions that may occur during normal use. A longer warranty period often indicates a higher level of trust in the product's durability.

Terms and Conditions

Understanding the terms and conditions of a warranty is essential. Some warranties, like those from Boss Laser, require the client to cover replacement parts and shipping charges after a certain period. You should carefully review the warranty details to know what is included and any potential costs you might incur. This knowledge helps you make an informed decision and avoid unexpected expenses.

"Quality warranties are often an indicator of a company’s confidence in its products." - Thunder Laser USA

By considering manufacturer support and warranty options, you can ensure that your laser engraving machine remains a valuable and reliable tool for your projects.

When buying a laser cutting machine, consider several key factors to ensure a wise investment. Evaluate the cutting area size, laser power, and software compatibility. Assess your specific needs and budget to determine how much is a laser cutting machine that suits your requirements. Consider the machine's ease of use, safety features, and long-term costs. Research and compare options thoroughly. This approach helps you find a laser engraving machine that aligns with your projects and financial constraints. By understanding these aspects, you make an informed decision that enhances your productivity and creativity.

FAQ

What is the primary use of a laser cutting machine?

You use a laser cutting machine to cut, engrave, or mark various materials with precision. These machines excel in creating intricate designs on materials like wood, metal, acrylic, and fabric. They are popular in industries such as manufacturing, crafting, and signage.

How do I determine the right laser power for my projects?

You should consider the materials you plan to work with most frequently. Higher laser power allows you to cut thicker materials quickly. For metals, a powerful fiber laser is ideal. For lighter materials like wood or acrylic, a lower power setting suffices. Balance power with precision to achieve the best results.

What safety features should I look for in a laser cutting machine?

Ensure your machine has enclosures and shields to protect against laser exposure. An emergency stop function is crucial for halting operations in emergencies. Verify compliance with safety standards like ANSI and ISO. Regular safety checks help maintain a safe working environment.

How important is software compatibility in a laser cutting machine?

Software compatibility is vital for seamless operation. You should choose a machine with user-friendly software that integrates well with popular design programs. This ensures efficient workflow and accurate translation of designs into cuts. Regular software updates and technical support enhance performance.

What factors affect the cost of a laser cutting machine?

The cost depends on the machine's features, brand, and model. High-end machines offer advanced features and reliability but come at a higher price. Consider initial purchase price, maintenance, consumables, and energy efficiency. Evaluate cost versus features to find the best value for your investment.

How can I ensure the longevity of my laser cutting machine?

Regular maintenance is key. Clean lenses and mirrors to prevent debris buildup. Replace worn parts as needed. Follow the manufacturer's maintenance schedule for inspections and servicing. Choose a machine with high build quality and durability for long-term reliability.

What should I consider regarding manufacturer support and warranty?

Look for manufacturers offering responsive customer service and easy access to spare parts. A comprehensive warranty provides protection and assurance. Check the coverage, duration, and terms of the warranty. Reliable support and warranty options ensure your machine remains a valuable tool.

Can a laser engraving machine handle different materials?

Yes, a laser engraving machine can work with various materials. It excels in engraving wood, acrylic, leather, and some metals. The machine's versatility allows you to create detailed designs on different surfaces. Ensure the machine's specifications match your material requirements.

See Also

Comparative Guide to Laser Cutting Machine Prices

Maximizing Efficiency with Your Laser Cutting Machine

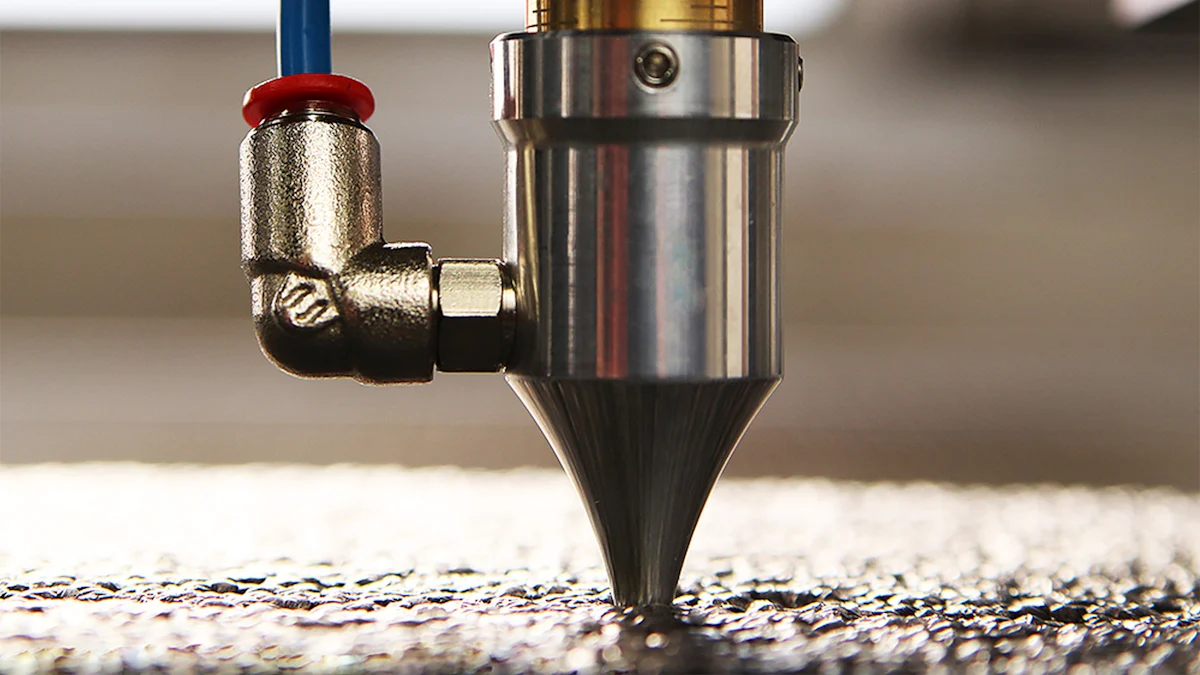

Guidelines for Selecting the Ideal Water Jet Cutter