What Is CNC Laser Cutting Machine Pros and Cons

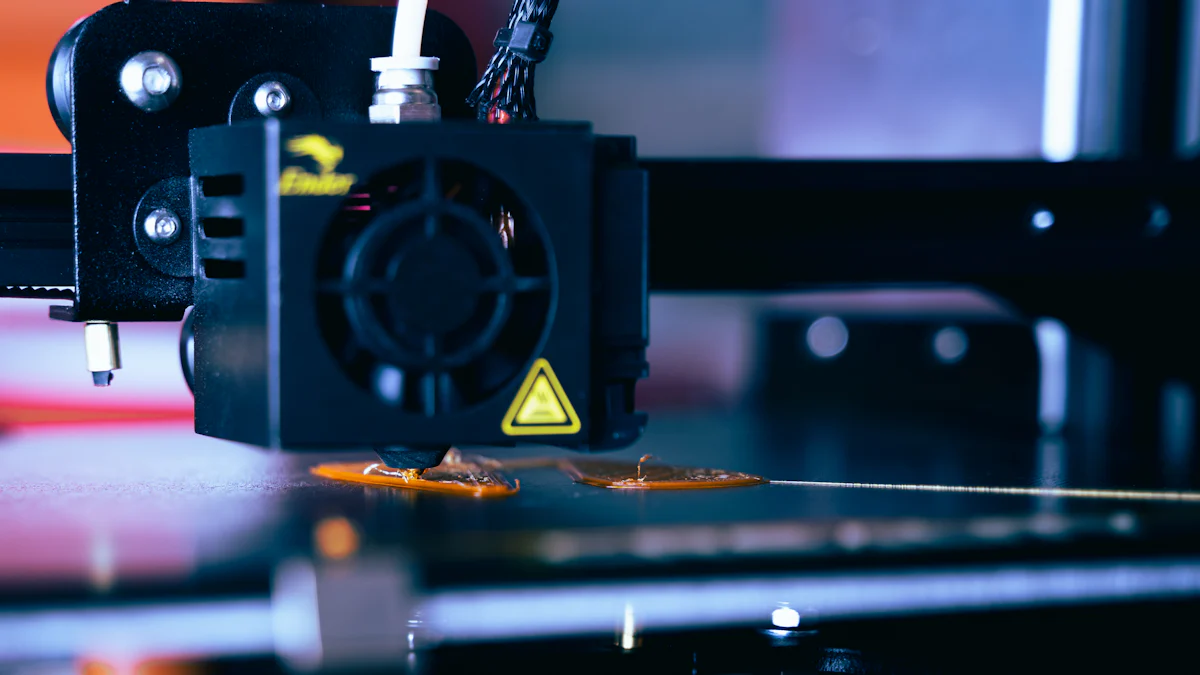

CNC laser cutting machines, which are defined as advanced tools that utilize high-powered lasers to cut materials with precision and accuracy, have revolutionized the manufacturing industry. You can achieve intricate designs without the need for additional finishing processes. The market for these machines is growing rapidly, with sales increasing by an average of 10% per year. This growth highlights their importance in modern production. However, like any technology, what is CNC laser cutting machine also comes with both advantages and disadvantages. Understanding these pros and cons will help you make informed decisions about their use in your projects.

Key Takeaways

- CNC laser cutting machines provide exceptional precision and accuracy, making them ideal for intricate designs and reducing the need for additional finishing.

- These machines are cost-effective, minimizing material waste and labor costs, which can lead to significant savings over time.

- CNC laser cutting machines are versatile and can handle a wide range of materials, allowing for diverse project capabilities without needing multiple machines.

- The speed and efficiency of CNC laser cutting significantly reduce production times, enabling businesses to meet tight deadlines and increase productivity.

- Operating CNC laser cutting machines requires skilled operators due to the complexity of the software and the need for precise adjustments.

- Initial investment costs can be high, but the long-term benefits often justify the expense, especially when considering reduced labor and material costs.

- Safety is paramount; proper ventilation and protective gear are essential to mitigate risks associated with fumes and potential injuries during operation.

Advantages of CNC Laser Cutting Machines

Precision and Accuracy

CNC laser cutting machines excel in delivering precision and accuracy. You can achieve a high level of detail in cuts, which is crucial for intricate designs. Unlike traditional cutting methods, laser cutting offers superior precision. This precision ensures that each cut is clean and sharp, reducing the need for additional finishing processes. Moreover, when you need to perform repeated tasks, these machines provide consistency. Each cut remains identical to the last, ensuring uniformity across your projects.

Cost-Effectiveness

When considering what is CNC laser cutting machine, cost-effectiveness stands out as a significant advantage. These machines reduce material waste by making precise cuts, which means you use only what you need. This efficiency translates into savings on materials. Additionally, the automated nature of CNC laser cutting reduces labor costs. You require fewer operators, and the machine handles complex tasks with minimal supervision. This reduction in manual labor further enhances cost savings.

Material Compatibility

CNC laser cutting machines offer remarkable versatility with different materials. Whether you're working with metals, plastics, or non-ferrous materials, these machines handle them with ease. This versatility allows you to expand your range of projects without needing multiple machines. Furthermore, the ability to cut complex shapes sets CNC laser cutting apart from conventional methods. You can create intricate patterns and designs that would be challenging with other cutting techniques.

Speed and Efficiency

CNC laser cutting machines excel in speed and efficiency, making them a valuable asset in any production environment.

Faster Production Times

You will notice a significant reduction in production times when using CNC laser cutting machines. These machines operate at high speeds, allowing you to complete projects much faster than traditional methods. For instance, laser cutting is generally faster than conventional cutting techniques, which means you can meet tight deadlines with ease. This speed advantage becomes particularly evident in large-scale production runs, where time savings translate into increased productivity and profitability.

Minimal Setup Time

Another benefit you will appreciate is the minimal setup time required for CNC laser cutting machines. Unlike traditional cutting methods that often involve lengthy preparation, laser cutting machines require little setup. You can quickly transition from one project to another without significant downtime. This efficiency not only saves time but also reduces the overall cost of production. By minimizing setup time, you can focus more on the actual cutting process, enhancing your workflow and maximizing output.

Disadvantages of CNC Laser Cutting Machines

Technical Expertise Required

Operating a CNC laser cutting machine demands skilled operators. You need to understand the complex software that controls these machines. This software optimizes part paths, machine speed, and material utilization. Without proper training, you might struggle to achieve the precision these machines offer. New users often face a learning curve. Mastering the intricacies of programming and operating the machine takes time. You must invest in training to ensure efficient and safe operation.

Need for Skilled Operators

You require skilled operators to manage CNC laser cutting machines effectively. These operators must possess a deep understanding of the machine's capabilities and limitations. They should know how to adjust settings for different materials and designs. Skilled operators ensure that each cut meets the required specifications, maintaining the high standards expected in manufacturing.

Learning Curve for New Users

For new users, the learning curve can be steep. You must familiarize yourself with the machine's software and controls. This process involves understanding how to program intricate designs and adjust laser settings. Patience and practice are essential as you develop the skills needed to operate the machine efficiently.

Initial Investment Cost

Investing in a CNC laser cutting machine involves significant upfront costs. The purchase price can be high, especially for advanced models with enhanced features. You must consider these costs when planning your budget. However, the long-term benefits often outweigh the initial expense.

High Purchase Price

The high purchase price of CNC laser cutting machines can be a barrier for some businesses. You need to evaluate whether the investment aligns with your production needs. While the cost may seem daunting, the machine's efficiency and precision can lead to increased profitability over time.

Maintenance Expenses

Maintenance expenses add to the overall cost of owning a CNC laser cutting machine. Regular maintenance ensures optimal performance and extends the machine's lifespan. You must budget for these expenses to avoid unexpected downtime and costly repairs.

Safety Concerns

Safety is a critical consideration when using CNC laser cutting machines. You must implement proper safety measures to protect operators and maintain a safe working environment.

Risk of Burns or Injuries

The risk of burns or injuries exists when operating CNC laser cutting machines. You must follow safety protocols to minimize these risks. Operators should wear appropriate protective gear and remain vigilant during operation.

Need for Proper Ventilation

Proper ventilation is essential when using CNC laser cutting machines. The cutting process can produce fumes and particles that pose health risks. You must ensure adequate ventilation to maintain air quality and protect workers' health.

Limitations with Certain Materials

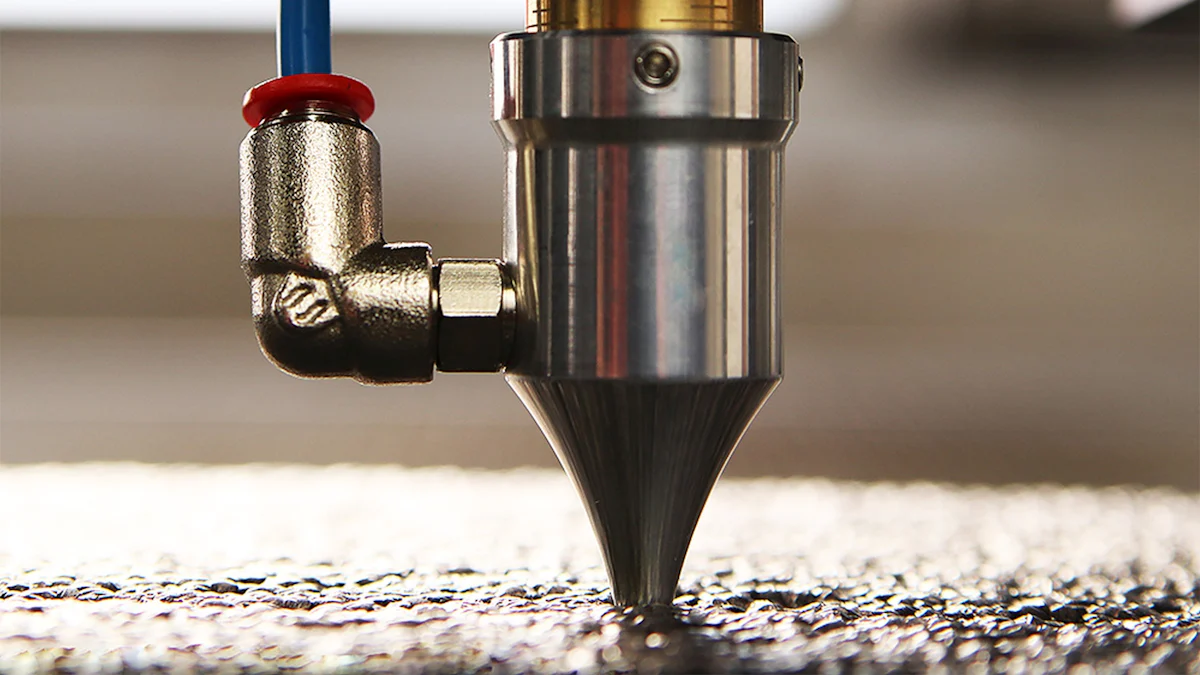

Difficulty with Reflective Materials

When using CNC laser cutting machines, you might encounter challenges with reflective materials. These materials, such as certain metals, can reflect the laser beam, which disrupts the cutting process. This reflection can lead to inconsistent cuts and may even damage the machine. You need to take extra precautions when working with reflective surfaces. Special coatings or adjustments to the laser settings can help mitigate these issues, but they require additional time and expertise.

Thickness Limitations

Another limitation you should consider is the thickness of the material. CNC laser cutting machines excel at cutting thin to moderately thick materials. However, when you work with very thick materials, the laser's effectiveness decreases. The laser may struggle to penetrate thicker materials, leading to incomplete cuts or rough edges. You must evaluate the material's thickness before starting a project to ensure the laser can handle it effectively. In some cases, alternative cutting methods might be more suitable for thicker materials.

In summary, CNC laser cutting machines offer numerous advantages. You benefit from precision, cost-effectiveness, material versatility, and speed. However, challenges exist. You need skilled operators and face high initial costs. Safety concerns and material limitations also require attention. Understanding what is CNC laser cutting machine helps you weigh these pros and cons effectively. By considering your specific needs and resources, you can make informed decisions about integrating this technology into your projects.

FAQ

What is a CNC laser cutting machine?

A CNC laser cutting machine uses a high-powered laser to cut materials with precision. You can use it for intricate designs and detailed cuts. The machine operates through computer numerical control (CNC), which ensures accuracy and consistency in every cut.

How does laser cutting compare to traditional cutting methods?

Laser cutting offers superior precision and speed compared to traditional methods. You will find that it produces cleaner cuts with less material waste. Unlike conventional techniques, laser cutting requires minimal setup time, allowing for faster production cycles.

What materials can I cut with a CNC laser cutting machine?

You can cut a wide range of materials, including metals, plastics, and non-ferrous materials. The machine's versatility allows you to work on various projects without needing different equipment. However, some materials, like reflective metals, may pose challenges.

Are there any limitations on material thickness?

Yes, CNC laser cutting machines are more effective for thin to moderately thick materials. For very thick materials, you might encounter difficulties in achieving clean cuts. In such cases, CNC milling might be a better option.

What safety measures should I take when using a CNC laser cutting machine?

You must ensure proper ventilation and wear protective gear to minimize risks. The cutting process can produce fumes and particles, so maintaining air quality is crucial. Following safety protocols helps prevent burns and injuries.

How can I optimize the laser cutting process?

Optimizing cutting parameters can enhance the effectiveness of the laser cutting process. You should experiment with different settings to achieve the best surface quality. Selecting materials that are easier to cut can also improve efficiency and reduce costs.

What are the initial costs involved in purchasing a CNC laser cutting machine?

The initial investment includes the purchase price of the machine and potential maintenance expenses. Advanced models with enhanced features may have higher costs. You should evaluate whether the investment aligns with your production needs.

Do I need technical expertise to operate a CNC laser cutting machine?

Yes, operating a CNC laser cutting machine requires skilled operators. You need to understand the software and controls to achieve precision. Training is essential to ensure efficient and safe operation.

How does laser cutting impact the automotive industry?

Laser cutting allows for the production of intricate components with exceptional accuracy in the automotive industry. It reduces waste and operational costs, enabling the development of lightweight, fuel-efficient vehicles.

Can laser cutting affect the quality of certain materials?

Yes, the material's chemical composition can impact laser-cutting quality. Some plastics may release hazardous gases when exposed to high-powered heat. You should consider these factors when selecting materials for laser cutting.

See Also

Understanding Laser Cutting Machines: Benefits and Drawbacks

Advantages and Disadvantages of Cricut Machines for Plastic

Benefits and Limitations of DE TECH Fabric Cutting Machines