How Much Does a CNC Laser Cutting Machine Cost?

When considering a CNC laser cutting machine, you might wonder, "How much does a CNC laser cutting machine cost?" The price can vary significantly, ranging from as low as $1,500 to over $1 million. This wide range depends on factors like machine type and features. For instance, a basic CO2 laser cutter might start at $2,600, while high-end industrial models can exceed $100,000. Understanding these price components is crucial. It helps you make informed decisions and ensures you get the best value for your investment.

Understanding CNC Laser Cutting Machine Costs

When you explore the world of CNC laser cutting machines, understanding the factors that influence their cost is crucial. These machines come with a wide range of features and specifications, which directly impact their price.

Factors Influencing Cost

Machine Size

The size of a CNC laser cutting machine plays a significant role in determining its price. Larger machines often accommodate bigger materials and offer more versatility. However, they also require more space and resources, which can increase the overall cost. If you need to cut large sheets of material, investing in a bigger machine might be necessary.

Power and Wattage

Power and wattage are critical factors in laser cutter pricing. Machines with higher wattage can cut through thicker materials more efficiently. For instance, a high-power fiber laser machine offers greater versatility and productivity but comes at a higher price. Consider your specific needs when evaluating the power requirements of a laser cutting machine.

Features and Capabilities

The features and capabilities of a CNC laser cutting machine significantly affect its price. Advanced features like automated systems, enhanced cooling systems, and safety features can add to the cost. Machines with built-in air assist or powerful exhaust systems, like the xTool P2, provide additional functionalities that might justify a higher price tag. Evaluate which features are essential for your operations to make an informed decision.

What is Included in the Price?

Standard Accessories

When purchasing a CNC laser cutting machine, you should consider what standard accessories are included in the price. These might include lenses, mirrors, and other essential components that ensure the machine operates effectively. Knowing what comes with the machine helps you avoid unexpected expenses later.

Software Packages

Software compatibility is another important aspect of laser cutting machine pricing. Many machines come with software packages that allow you to design and execute cutting tasks efficiently. Ensure that the software meets your needs and is compatible with your existing systems.

Warranty and Support

A comprehensive warranty and support package can add value to your purchase. It provides peace of mind and ensures that you have assistance if any issues arise. Check the warranty terms and the level of support offered by the manufacturer before making a decision.

Understanding these factors will help you answer the question, "How much does a CNC laser cutting machine cost?" By considering machine size, power, features, and what's included in the price, you can make a well-informed purchase that meets your needs and budget.

Comparing CNC Laser Cutting Machine Models

When you explore CNC laser cutting machines, you'll find a variety of models to choose from. Each model caters to different needs and budgets. Let's delve into the specifics of entry-level, mid-range, and high-end models to help you make an informed decision.

Entry-Level Models

Specifications

Entry-level laser cutting machines are perfect for beginners or small businesses. These machines typically offer basic features suitable for simple projects. They often come with lower power and smaller work areas. Despite their limitations, they provide a great starting point for those new to laser cutting.

Price Range

The price for entry-level models usually ranges from $2,600 to $5,600. This affordability makes them accessible to hobbyists and small enterprises. While they may lack advanced features, they still deliver reliable performance for basic tasks.

Mid-Range Models

Specifications

Mid-range laser cutting machines offer a balance between cost and functionality. They come with enhanced features like increased power and larger workspaces. These machines can handle more complex projects and materials, making them ideal for growing businesses.

Price Range

Expect to pay between $6,000 and $20,000 for a mid-range laser cutting machine. This investment provides you with better precision and versatility. It's a suitable choice if you need more capabilities without breaking the bank.

High-End Models

Specifications

High-end laser cutting machines are designed for industrial use. They boast advanced features, such as high wattage and extensive cutting capabilities. These machines can handle large-scale projects and a wide range of materials, including metals.

Price Range

The price for high-end models can exceed $100,000, with some reaching up to $1,000,000. These machines are a significant investment but offer unmatched precision and efficiency. If you require an industrial laser cutting machine for demanding applications, this is the category to consider.

Understanding these pricing comparisons helps you choose the right laser cutting machine for your needs. Whether you're looking for a basic laser engraving machine or a powerful metal laser cutting machine, knowing the specifications and price ranges ensures you make a wise investment.

Additional Costs and Considerations

When purchasing a laser cutting machine, you must consider additional costs beyond the initial purchase price. These expenses can impact your budget and influence your decision-making process.

Maintenance and Repairs

Regular Maintenance Costs

Regular maintenance keeps your laser cutting machine in optimal condition. You should budget for routine tasks like cleaning lenses and mirrors, checking alignment, and replacing worn parts. These activities prevent breakdowns and extend the machine's lifespan. Regular maintenance costs vary based on the machine's complexity and usage frequency.

Potential Repair Expenses

Unexpected repairs can occur despite regular maintenance. You might face expenses for replacing damaged components or fixing mechanical issues. Understanding potential repair costs helps you prepare financially. Consider setting aside funds for these unforeseen expenses to avoid disruptions in your operations.

Software and Training

Software Updates

Software plays a crucial role in operating your laser cutting machine efficiently. Manufacturers often release updates to improve performance and add new features. You should stay informed about these updates and budget for any associated costs. Keeping your software current ensures compatibility with new technologies and enhances productivity.

Training Programs

Proper training maximizes the benefits of your laser cutting machine. Investing in training programs helps you and your team operate the machine safely and effectively. Training costs vary depending on the program's depth and duration. Prioritize training to enhance skills and reduce the risk of errors during operation.

Operational Costs

Energy Consumption

Operating a laser cutting machine requires energy, which contributes to your overall costs. Machines with higher power and wattage consume more electricity. You should calculate the operating costs per hour to understand the financial impact. Energy-efficient models might have a higher upfront cost but save money in the long run.

Material Costs

Materials are essential for laser cutting projects. You need to consider the type and quantity of material required for your operations. Different materials have varying costs, affecting your budget. Efficient material usage reduces waste and lowers expenses. Evaluate your material needs carefully to optimize costs.

Understanding these additional costs and considerations helps you make informed decisions when purchasing a laser cutting machine. By planning for maintenance, software, training, and operational expenses, you ensure a smooth and cost-effective operation.

Understanding how much a CNC laser cutting machine costs involves considering various factors. These include machine size, power, features, and additional expenses like maintenance and software. By evaluating these aspects, you can determine the total price and make an informed decision. Choose a machine that aligns with your budget and specific needs. Whether you opt for an entry-level model or a high-end industrial machine, knowing the price range and features ensures you invest wisely in a laser cutting machine that meets your requirements.

FAQ

What are CNC laser cutters used for?

CNC laser cutters serve a variety of purposes. You can use them to create personalized signs, business logos, and advertisements. These machines offer high accuracy, making them ideal for detailed work. They are also safe to operate, providing peace of mind during use.

What is a CNC Laser Cutter?

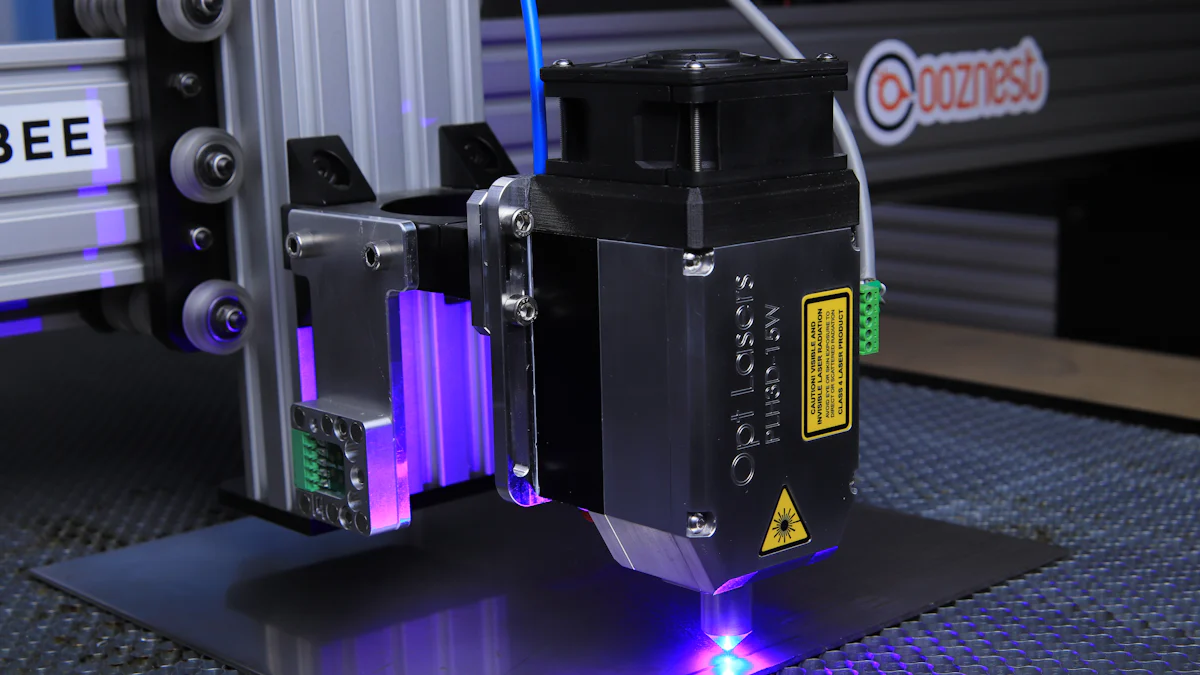

A CNC laser cutter is a technologically advanced device that uses a highly concentrated beam of light to cut materials. It operates through a computerized manufacturing process, using G-Code commands to guide the laser. This precision tool can be mounted on a CNC machine or come as a standalone unit with a laser head installed.

How does a CNC Laser Cutter work?

CNC laser cutters work by vaporizing or melting materials with a focused beam of light. The process is controlled by computer software, which ensures high manufacturing precision. This method allows you to achieve intricate designs and cuts that other tools might not handle as effectively.

What materials can a CNC laser cutter process?

You can use CNC laser cutters on a wide range of materials. These include metals, plastics, wood, and textiles. The versatility of these machines makes them suitable for various industries, from automotive to fashion.

Are CNC laser cutters user-friendly?

Yes, CNC laser cutters are designed to be user-friendly. They come with intuitive software interfaces that make it easy for you to operate them. Even if you're new to laser cutting, you can quickly learn how to use these machines effectively.

What are the safety features of CNC laser cutters?

CNC laser cutters include several safety features to protect you during operation. These may include enclosed cutting areas, emergency stop buttons, and safety interlocks. Always follow the manufacturer's guidelines to ensure safe use.

How do I maintain a CNC laser cutter?

Regular maintenance is crucial for keeping your CNC laser cutter in optimal condition. You should clean lenses and mirrors, check alignment, and replace worn parts as needed. Routine maintenance helps prevent breakdowns and extends the machine's lifespan.

Can I upgrade my CNC laser cutter?

Yes, many CNC laser cutters offer upgrade options. You can enhance features like power, software, and additional accessories. Upgrading allows you to expand the machine's capabilities as your needs grow.

What should I consider when buying a CNC laser cutter?

When purchasing a CNC laser cutter, consider factors like machine size, power, features, and budget. Evaluate what you need for your specific applications to make an informed decision. Understanding these aspects ensures you choose a machine that meets your requirements.

How do CNC laser cutters compare to other cutting tools?

CNC laser cutters provide higher precision and versatility compared to many other cutting tools. They can handle complex designs and a variety of materials with ease. This makes them a preferred choice for industries requiring detailed and accurate cuts.

See Also

Understanding The Price Of Water Jet Cutting Machines

Comparative Guide To The Cost Of Laser Cutters

The Functionality Of CNC Laser Cutting Machines Explained