What Is a CNC Cutting Machine vs Laser Cutting

When you explore cutting technologies, understanding what a CNC cutting machine is and how it differs from laser cutting becomes crucial. CNC cutting machines excel in intricate and detailed cutting tasks, making them ideal for complex designs. On the other hand, laser cutting offers speed and precision, especially with fragile metals and intricate shapes. Choosing the right technology depends on your specific needs. Whether you require the detailed craftsmanship of CNC or the swift accuracy of laser cutting, selecting the appropriate method ensures optimal results for your projects.

Key Takeaways

- CNC cutting machines are ideal for intricate designs and thicker materials, making them versatile for various industries.

- Laser cutting excels in precision and speed, particularly for thin materials and complex shapes, ensuring high-quality results.

- Understanding material compatibility is crucial; CNC machines handle a wider range of materials, while laser cutting is best for delicate and thin materials.

- Consider your budget carefully; laser cutting machines often have higher initial costs but lower maintenance, while CNC machines may have lower upfront costs but higher long-term maintenance due to tool wear.

- Evaluate your project's precision needs; laser cutting offers exceptional accuracy, often within +/-0.1 mm, while CNC cutting is better for larger parts.

- Operational ease varies; laser cutting is generally more user-friendly, requiring less technical skill compared to CNC machines, which need programming knowledge.

- Both technologies can complement each other; using CNC for versatility and laser cutting for precision can optimize your production process.

What is a CNC Cutting Machine?

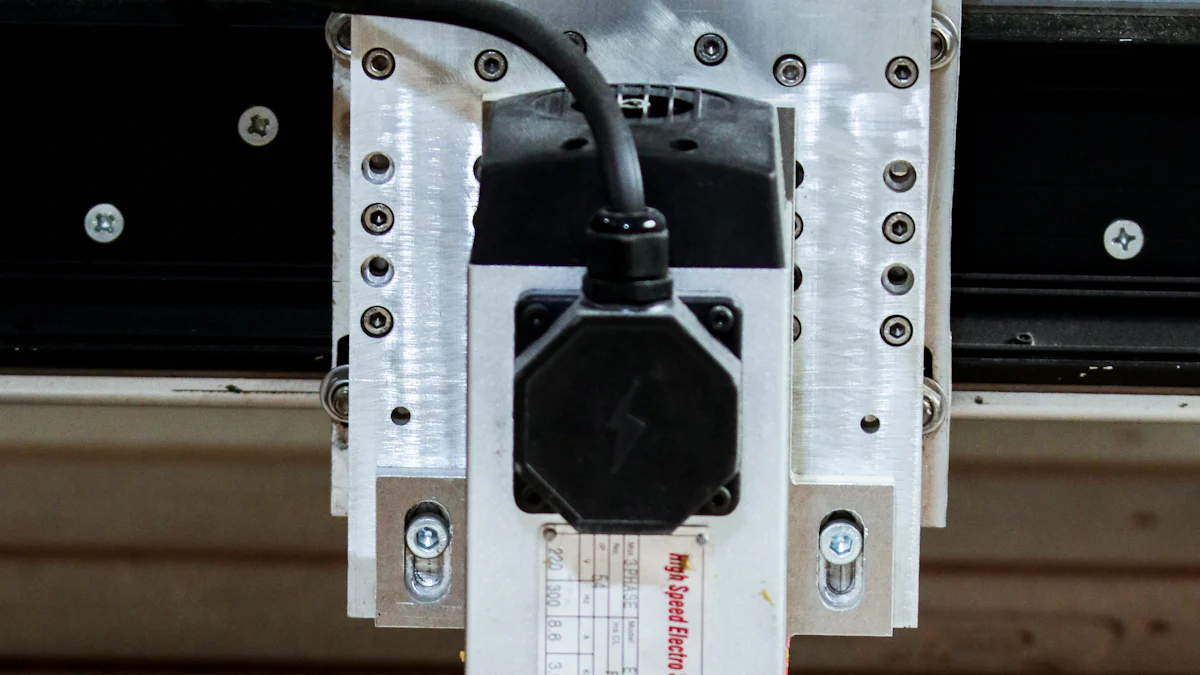

Understanding what a CNC cutting machine is can greatly enhance your ability to choose the right tool for your projects. CNC, or Computer Numerical Control, machines automate the cutting process through precise programming. This technology allows you to achieve consistent and accurate results across various materials.

Definition and Functionality

A CNC cutting machine operates by following programmed instructions to cut materials with precision. You input the design specifications into the computer, which then controls the cutting tool's movement. This automation ensures high-speed operation and minimizes errors, making CNC machines ideal for complex and detailed tasks. They are often referred to as "perfect workers" due to their efficiency and reliability.

Types of CNC Cutting Machines

CNC cutting machines come in several types, each suited for different applications:

CNC Milling Machines

CNC milling machines are versatile tools that excel in metalworking. They use rotary cutters to remove material from a workpiece, allowing you to create intricate designs and shapes. These machines are particularly useful in industries like aviation and manufacturing, where precision is crucial.

CNC Plasma Cutters

CNC plasma cutters use a high-velocity jet of ionized gas to cut through electrically conductive materials. They offer enhanced safety and automation, making them a popular choice for cutting metals. With their fast cutting times and precise, clean cuts, plasma cutters are both efficient and cost-effective.

CNC Waterjet Cutters

CNC waterjet cutters utilize a high-pressure stream of water mixed with abrasive particles to cut materials. This method is ideal for cutting heat-sensitive materials, as it does not generate heat during the process. Waterjet cutters can handle a wide range of materials, from metals to composites, providing versatility in various industries.

Common Applications

CNC cutting machines find applications in numerous fields due to their versatility and precision. You can use them in the defense industry for crafting complex parts, in the oil and gas sector for cutting pipes and container caps, and in healthcare for creating precise components. Additionally, smaller businesses and hobbyists can benefit from stationery CNC milling machines for personal projects.

By understanding what a CNC cutting machine is and exploring its various types and applications, you can make informed decisions about incorporating this technology into your work.

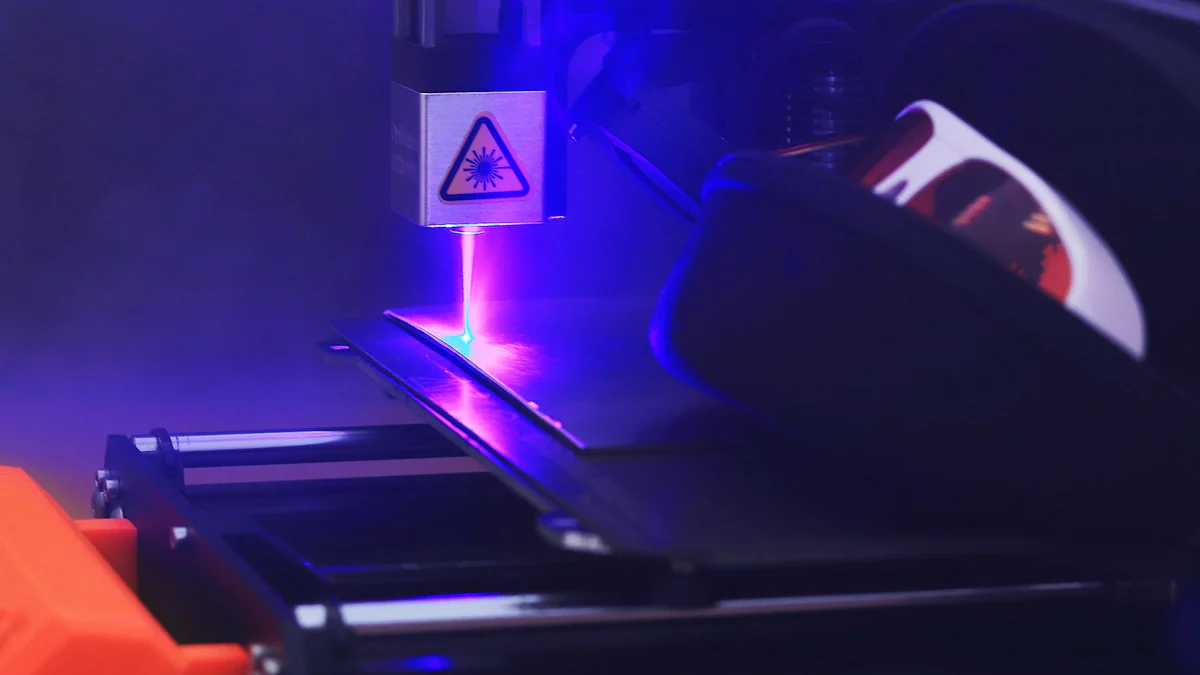

What is Laser Cutting?

Laser cutting stands as a powerful and precise method for shaping materials. You can achieve intricate designs with remarkable accuracy using this technology. The process involves directing a high-powered laser beam onto the material, which melts, burns, or vaporizes it to create the desired shape.

Definition and Functionality

Laser cutting operates through an automated process. You upload your design to the laser cutter software, which then guides the laser beam based on your specifications. This software simplifies the task, allowing you to adjust power, speed, and focus settings according to the material. The laser beam moves swiftly and efficiently, ensuring clean and precise cuts. Unlike CNC programming, laser design software uses vector files, which maintain quality even when resized.

Types of Laser Cutting Machines

Laser cutting machines come in various types, each offering unique capabilities:

CO2 Laser Cutters

CO2 laser cutters are popular for their versatility. You can use them to cut a wide range of materials, including wood, paper, textiles, and some plastics. These machines excel in applications requiring smooth edges and intricate details.

Fiber Laser Cutters

Fiber laser cutters provide high-speed cutting and are particularly effective for metals. You benefit from their efficiency and precision, making them ideal for industries like automotive and aerospace. Fiber lasers offer excellent energy efficiency and require minimal maintenance.

Nd:YAG Laser Cutters

Nd:YAG laser cutters specialize in cutting metals and ceramics. You can achieve deep penetration and high-quality cuts with these machines. They are often used in applications where precision and strength are paramount, such as in medical device manufacturing.

Common Applications

Laser cutting finds applications across various industries due to its versatility and precision:

- Metal Fabrication: You can use laser cutting to create complex metal parts with high accuracy.

- Art and Craft: Artists and crafters favor laser cutting for its ability to produce detailed designs in materials like wood and acrylic.

- Textile Industry: You can cut intricate patterns in fabrics quickly and efficiently.

- Electronics: Laser cutting helps in manufacturing components with precise dimensions.

By understanding laser cutting and its various machine types, you can harness this technology for diverse applications, ensuring high-quality results in your projects.

Comparing CNC Cutting Machines and Laser Cutting

When deciding between CNC cutting machines and laser cutting, understanding their differences can guide you to the right choice for your projects. Both technologies offer unique advantages, but they excel in different areas.

Precision and Accuracy

Laser cutting stands out for its exceptional precision. You can achieve intricate designs with a high degree of accuracy, often within +/-0.1 mm. This makes laser cutting ideal for detailed work, especially with thin materials and complex shapes. In contrast, CNC cutting machines, while precise, may not match the fine detail achievable with lasers. However, CNC machines excel in cutting thicker materials and larger parts, where laser cutting might struggle.

Speed and Efficiency

Speed is another critical factor. Laser cutting generally operates faster than CNC cutting machines. The laser's ability to cut without physical contact means it can move swiftly across the material, reducing cutting time. This efficiency makes laser cutting suitable for high-volume production runs. On the other hand, CNC machines, which rely on physical cutting tools, may take longer, especially when dealing with intricate designs or harder materials. However, CNC machines offer versatility across a broader range of materials, which can be beneficial for diverse projects.

Cost Considerations

Cost plays a significant role in choosing between these technologies. Laser cutting machines often come with higher initial costs due to their advanced technology and precision capabilities. However, they require less maintenance since they don't rely on physical cutting tools that wear out. CNC cutting machines might have lower upfront costs, but the tools can wear out quickly, leading to additional expenses over time. When considering cost, you should also factor in the material type and project scale, as these can influence the overall expense of using either technology.

By weighing these factors, you can determine which cutting method aligns best with your needs. Whether you prioritize precision, speed, or cost, understanding these differences will help you make an informed decision.

Material Compatibility

When choosing between CNC cutting machines and laser cutting, understanding material compatibility is crucial. Each technology excels with different materials, impacting your project's outcome.

-

CNC Cutting Machines:

- CNC machines handle a wide range of materials, including wood, plastic, and metal. They are particularly effective for thicker materials and larger parts. CNC routers, for example, excel in cutting wood and other dense materials. This versatility makes CNC cutting machines suitable for various industries, from construction to manufacturing.

- However, CNC cutting may not achieve the same level of precision as laser cutting, especially with intricate designs or thin materials. The physical cutting tools can wear out quickly, affecting the quality of the cut over time.

-

Laser Cutting:

- Laser cutting shines when working with thin materials and intricate shapes. It offers superior precision and produces less waste, making it ideal for delicate metals and detailed designs. Laser cutters can handle materials like paper, textiles, and certain plastics with ease.

- Despite its precision, laser cutting may struggle with thicker materials. The laser's effectiveness decreases as material thickness increases, which can limit its application in projects requiring deep cuts.

By understanding these material compatibility factors, you can select the right technology for your specific needs. Whether you prioritize versatility with CNC cutting or precision with laser cutting, aligning your choice with the material requirements ensures optimal results.

Operational Ease and Maintenance

Operational ease and maintenance are key considerations when deciding between CNC cutting machines and laser cutting. Each technology presents unique challenges and benefits in these areas.

-

CNC Cutting Machines:

- Operating a CNC machine requires programming skills and an understanding of the machine's mechanics. You must input precise instructions to achieve the desired cuts. This process can be complex for beginners but offers flexibility once mastered.

- Maintenance involves regular tool replacement due to wear and tear. The physical cutting tools degrade over time, necessitating frequent checks and replacements to maintain cutting quality. This can increase operational costs and downtime.

-

Laser Cutting:

- Laser cutting offers a more straightforward operation. You upload your design to the software, which guides the laser beam automatically. This ease of use makes laser cutting accessible to users with varying skill levels.

- Maintenance is minimal compared to CNC machines. Since laser cutting doesn't rely on physical tools, there's no need for frequent replacements. This reduces maintenance costs and ensures consistent performance over time.

Understanding these operational and maintenance aspects helps you make an informed decision. Whether you value the flexibility of CNC cutting or the simplicity of laser cutting, considering these factors will guide you to the best choice for your projects.

Advantages and Disadvantages

CNC Cutting Machines

Advantages

-

Versatility: CNC cutting machines handle a wide range of materials, including wood, plastic, and metal. This versatility makes them suitable for various industries, from construction to manufacturing.

-

Precision in Thick Materials: You can rely on CNC machines for cutting thicker materials and larger parts. They excel in applications where laser cutting might struggle, such as metalworking and woodworking.

-

Complex Designs: CNC routers excel at creating intricate designs with straight lines, curves, and diagonal cuts. This capability is beneficial for projects requiring detailed craftsmanship.

-

Cost-Effective for Large Parts: CNC machines often have lower initial costs compared to laser cutters. They are cost-effective for projects involving large parts or thick materials.

Disadvantages

-

Tool Wear and Maintenance: Physical cutting tools in CNC machines wear out quickly. You need to replace them regularly, which increases maintenance costs and downtime.

-

Slower Speed: CNC cutting machines generally operate slower than laser cutters. The physical removal of material takes more time, especially with intricate designs or harder materials.

-

More Waste Material: CNC routers may produce more waste material compared to laser cutters. The precision of laser beams results in less waste, making CNC less efficient in this regard.

Laser Cutting

Advantages

-

High Precision: Laser cutting offers exceptional precision, often achieving accuracy within +/-0.1 mm. This makes it ideal for detailed work, especially with thin materials and complex shapes.

-

Speed and Efficiency: You benefit from the swift operation of laser cutters. The laser's ability to cut without physical contact reduces cutting time, making it suitable for high-volume production runs.

-

Minimal Waste: Laser cutting generates less waste due to its precise beams. This efficiency is advantageous for projects requiring intricate designs and minimal material loss.

-

Low Maintenance: Laser cutters require minimal maintenance. Since they don't rely on physical tools, there's no need for frequent replacements, reducing operational costs over time.

Disadvantages

-

Higher Initial Costs: Laser cutting machines often come with higher initial costs due to their advanced technology and precision capabilities. This can be a barrier for small businesses or hobbyists.

-

Limited Thickness: Laser cutting may struggle with thicker materials. The laser's effectiveness decreases as material thickness increases, limiting its application in projects requiring deep cuts.

-

Material Limitations: While laser cutters excel with thin materials, they may not handle all types of materials effectively. You need to consider material compatibility when choosing laser cutting for your projects.

By understanding these advantages and disadvantages, you can make informed decisions about which cutting technology best suits your needs. Whether you prioritize versatility with CNC cutting or precision with laser cutting, aligning your choice with project requirements ensures optimal results.

Decision-Making Guide

Choosing between CNC cutting machines and laser cutting requires careful consideration of several factors. This guide will help you make an informed decision based on your specific needs.

Assessing Material Type

Understanding the material you plan to work with is crucial. CNC cutting machines excel with a wide range of materials, including wood, plastic, and metal. They are particularly effective for thicker materials and larger parts. For instance, CNC routers are widely used in woodworking and cabinetry due to their versatility and reliability. On the other hand, laser cutting shines when working with thin materials and intricate shapes. It offers superior precision and produces less waste, making it ideal for delicate metals and detailed designs. From stainless steel to brass, laser cutting can create precise cuts with minimal distortion, enabling the production of high-quality metal components.

Evaluating Desired Precision

Precision plays a significant role in selecting the right cutting technology. Laser cutting stands out for its exceptional precision, often achieving accuracy within +/-0.1 mm. This makes it ideal for detailed work, especially with thin materials and complex shapes. Laser cutting utilizes CNC machining to produce complex designs and shapes with smooth finishes. It can create more intricate parts with high tolerances and exceptionally smooth finishes. In contrast, CNC cutting machines, while precise, may not match the fine detail achievable with lasers. However, they excel in cutting thicker materials and larger parts, where laser cutting might struggle.

Budget Considerations

Budget is another critical factor in your decision-making process. Laser cutting machines often come with higher initial costs due to their advanced technology and precision capabilities. However, they require less maintenance since they don't rely on physical cutting tools that wear out. CNC cutting machines might have lower upfront costs, but the tools can wear out quickly, leading to additional expenses over time. CNC cutting provides a cost-effective and efficient option for projects that don’t require intricate details or extremely fine tolerances. When considering cost, you should also factor in the material type and project scale, as these can influence the overall expense of using either technology.

By evaluating these aspects, you can determine which cutting method aligns best with your needs. Whether you prioritize material compatibility, precision, or budget, understanding these differences will help you make an informed decision.

Operational Requirements

When choosing between CNC cutting machines and laser cutting, understanding the operational requirements is essential. Each technology demands different levels of expertise, setup, and maintenance, which can impact your workflow and productivity.

-

Skill Level: Operating a CNC machine requires a solid understanding of programming and mechanics. You must input precise instructions to achieve the desired cuts. This process can be complex for beginners but offers flexibility once mastered. In contrast, laser cutting provides a more user-friendly experience. You simply upload your design to the software, which guides the laser beam automatically. This ease of use makes laser cutting accessible to users with varying skill levels.

-

Setup and Calibration: CNC machines need careful setup and calibration. You must ensure that the cutting tools are correctly aligned and that the machine is properly configured for the material. This setup process can be time-consuming but is crucial for achieving accurate results. Laser cutting, on the other hand, involves minimal setup. The software handles most of the calibration, allowing you to focus on the design and material selection.

-

Maintenance: Regular maintenance is vital for both technologies, but the requirements differ. CNC machines require frequent tool replacements due to wear and tear. You need to check and replace cutting tools regularly to maintain cutting quality. This can increase operational costs and downtime. Laser cutters, however, require less maintenance. Since they don't rely on physical tools, there's no need for frequent replacements. This reduces maintenance costs and ensures consistent performance over time.

-

Safety Considerations: Safety is a critical aspect of any cutting operation. CNC machines involve physical cutting tools, which can pose safety risks if not handled properly. You must follow strict safety protocols to prevent accidents. Laser cutting offers greater operator safety. The process involves no physical contact with the material, reducing the risk of injury. However, you should still take precautions to protect against laser exposure.

By understanding these operational requirements, you can make an informed decision about which cutting technology best suits your needs. Whether you value the flexibility and versatility of CNC cutting or the simplicity and precision of laser cutting, aligning your choice with your operational capabilities ensures optimal results.

Choosing between CNC cutting machines and laser cutting requires careful consideration of your project's needs. Laser cutting excels in precision and speed, making it ideal for intricate designs and thin materials. It offers high accuracy without direct contact, reducing waste and ensuring consistent results. CNC cutting machines, however, provide versatility across a broader range of materials, especially thicker ones. They are cost-effective for larger parts and complex designs. Evaluate your material type, desired precision, and budget to determine the best technology for your projects. By aligning your choice with these factors, you ensure optimal outcomes.

FAQ

What are the main differences between CNC cutting machines and laser cutting?

CNC cutting machines and laser cutting differ primarily in their method of operation and material compatibility. CNC machines use physical tools to cut, drill, or mill materials, making them versatile for various shapes and sizes. Laser cutting, however, uses a high-powered laser beam for precision and speed, especially with thin materials and intricate designs.

Which technology should I choose for my project?

Your choice depends on your project's specific requirements. If you need versatility across different materials and the ability to create three-dimensional shapes, a CNC router might be ideal. However, if precision, speed, and intricate cuts on thin materials are crucial, a laser cutter could be more suitable.

Can CNC machines handle all types of materials?

CNC machines can work with a wide range of materials, including wood, plastic, and metal. They excel in cutting thicker materials and larger parts. However, they may not be as efficient as laser cutting for certain materials or shapes, especially when high precision is required.

How precise is laser cutting compared to CNC cutting?

Laser cutting offers exceptional precision, often achieving accuracy within +/-0.1 mm. This makes it superior for detailed work, especially with thin materials and complex shapes. CNC cutting, while precise, may not match the fine detail achievable with lasers but excels in thicker materials.

What factors should I consider when choosing between CNC and laser cutting?

Consider the following factors:

- Material type and thickness

- Desired precision and accuracy

- Production volume and size

- Complexity of the design

- Budget constraints

These factors will help you determine which technology aligns best with your needs.

Are there any limitations to using laser cutting?

Laser cutting may struggle with thicker materials, as its effectiveness decreases with increased thickness. Additionally, it may not handle all types of materials effectively, particularly reflective metals unless specialized lasers are used.

How does the cost of CNC and laser cutting compare?

Laser cutting machines often have higher initial costs due to their advanced technology and precision capabilities. However, they require less maintenance. CNC machines might have lower upfront costs, but the tools can wear out quickly, leading to additional expenses over time.

Is laser cutting safer than CNC cutting?

Laser cutting generally offers greater operator safety since it involves no physical contact with the material, reducing the risk of injury. However, you should still take precautions to protect against laser exposure. CNC machines involve physical cutting tools, which can pose safety risks if not handled properly.

Can CNC and laser cutting be used together?

Yes, CNC machining complements laser cutting. While CNC machines handle a wide range of applications in terms of material type and thickness, laser cutting excels in precision and speed for intricate designs. Using both technologies can optimize your production process.

What are the standard tolerances for CNC laser cutting?

The standard tolerances for CNC laser cutting typically range from +/- 0.1 mm to +/- 0.01 mm. This depends on the machine, material, and the complexity of the part, ensuring high precision and quality in the final product.

See Also

Understanding The Functionality Of CNC Laser Cutters

Exploring Different Types Of CNC Cutting Machines

Comparing CNC Machines And Laser Cutters For Acrylic