CNC Cutting Machine: A Simple Definition

A CNC cutting machine, or Computer Numerical Control cutting machine, automates the cutting process using computer programming. To understand what a CNC cutting machine is, imagine it as a tool that transforms digital designs into precise cuts on various materials. Its primary function is to enhance productivity and accuracy in manufacturing. By reducing human error, CNC machines ensure high-quality and reliable parts across industries like aerospace, automotive, and electronics. This technology not only boosts efficiency but also supports cost-effective operations, making it indispensable in modern manufacturing.

Key Takeaways

- CNC cutting machines automate the cutting process, transforming digital designs into precise cuts, which enhances productivity and accuracy in manufacturing.

- These machines operate continuously, significantly speeding up production times and reducing labor costs by minimizing human error.

- Different types of CNC cutting machines, such as laser, plasma, and waterjet cutters, are designed for specific materials and applications, offering versatility in manufacturing.

- CNC technology is invaluable across industries like aerospace, automotive, and custom fabrication, providing high-quality and reliable parts.

- When choosing a CNC cutting machine, consider factors like material type, cutting speed, precision, and software compatibility to ensure it meets your manufacturing needs.

- Investing in CNC cutting machines can lead to cost savings through reduced material waste, lower maintenance costs, and increased production speed.

- Understanding the core functionalities and benefits of CNC cutting machines empowers businesses to enhance their manufacturing capabilities and maintain high-quality standards.

What is CNC Cutting Machine?

Definition and Purpose

When you ask, "what is a CNC cutting machine?" you're delving into a world where precision meets automation. A CNC cutting machine, or Computer Numerical Control cutting machine, uses computer programming to automate the cutting process. This technology transforms digital designs into precise cuts on various materials. The primary purpose of a CNC cutting machine is to enhance productivity and accuracy in manufacturing. By reducing human error, these machines ensure high-quality and reliable parts across industries like aerospace, automotive, and electronics. They support cost-effective operations, making them indispensable in modern manufacturing.

Core Functionality

Understanding the core functionality of a CNC cutting machine involves recognizing its ability to execute complex tasks with minimal human intervention. You start by designing a part using computer-aided design (CAD) software. This design is then converted into a format suitable for CNC machines. The machine interprets the coded instructions and puts them into action, directing every move to replicate the CAD design in the specified material with precision.

CNC machines operate 24/7 with quick program changes, significantly speeding up production times. They can handle high-volume runs efficiently, making them ideal for industries that require rapid production. Unlike manual machining, which involves frequent tool changes and downtime, CNC machines maintain consistent operation, ensuring faster production times and reduced labor costs.

These machines are equipped with safety features like guards and emergency stops to protect operators. They also offer a high degree of automation, allowing for faster production times and reduced labor costs. Whether you're working with hard metals or softer materials like wood and plastic, CNC cutting machines provide the versatility needed to meet diverse manufacturing demands.

How Does a CNC Cutting Machine Work?

Basic Operation

To grasp how a CNC cutting machine operates, you need to understand its basic process. You begin by creating a digital design using computer-aided design (CAD) software. This design serves as a blueprint for the machine. Once you finalize the design, you convert it into a machine-readable code, often referred to as G-code. This code instructs the CNC machine on how to move and cut the material.

The machine follows these instructions with precision. It moves the cutting tool along the specified paths, ensuring each cut matches the digital design. You can rely on CNC machines to perform repetitive tasks with high accuracy, reducing the chances of errors. This automation allows you to focus on other aspects of production, enhancing overall efficiency.

Key Components

Understanding the key components of a CNC cutting machine helps you appreciate its functionality. Here are the essential parts:

-

Control Unit: This is the brain of the CNC machine. It interprets the G-code and sends commands to the machine's components. You can think of it as the central processing unit that ensures everything runs smoothly.

-

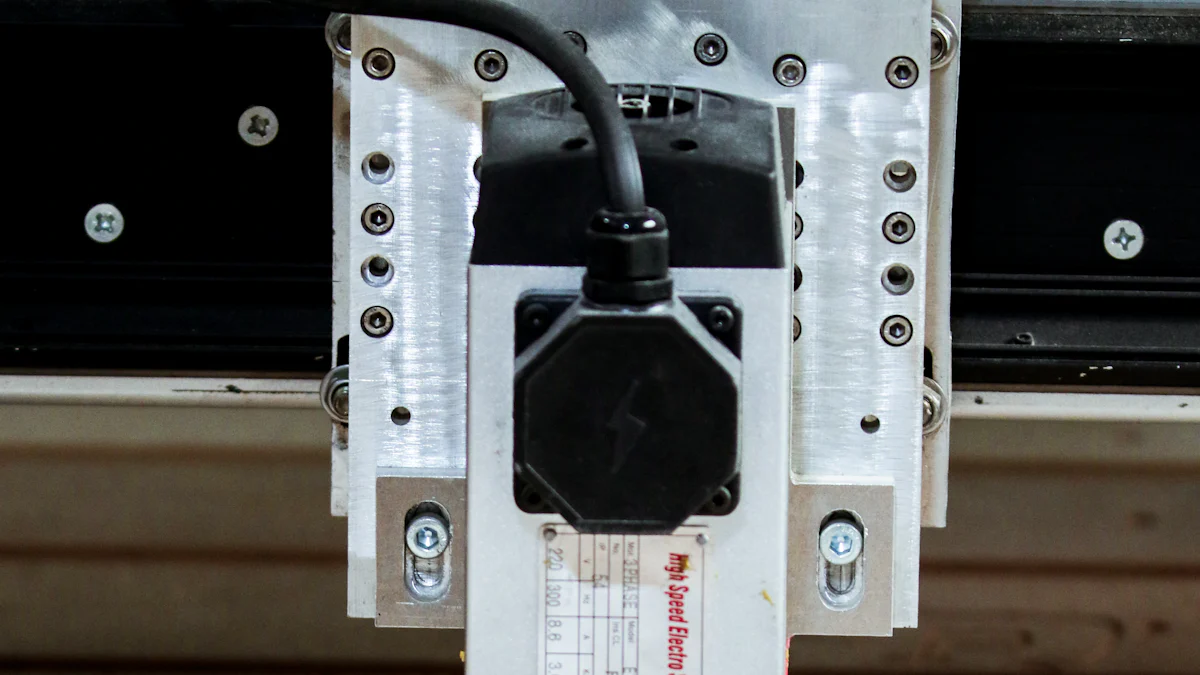

Cutting Tool: Depending on the type of CNC machine, this could be a laser, plasma torch, or waterjet. The cutting tool is responsible for executing the actual cuts on the material. You select the tool based on the material and the desired outcome.

-

Drive System: This system moves the cutting tool along the X, Y, and Z axes. It ensures precise positioning and movement, allowing the machine to follow the design accurately. You can adjust the speed and direction to suit different materials and designs.

-

Bed or Table: This is where you place the material to be cut. The bed provides a stable surface, ensuring the material remains in place during the cutting process. You can find beds of various sizes to accommodate different material dimensions.

-

Feedback System: This component monitors the machine's operations and provides real-time data. It helps you ensure the machine performs as expected, allowing for adjustments if necessary.

By understanding these components, you gain insight into what makes CNC cutting machines efficient and reliable. They work together seamlessly to transform digital designs into tangible products, making them invaluable in modern manufacturing.

Types of CNC Cutting Machines

When exploring the world of CNC cutting machines, you will encounter various types, each designed for specific tasks and materials. Understanding these types helps you choose the right machine for your needs.

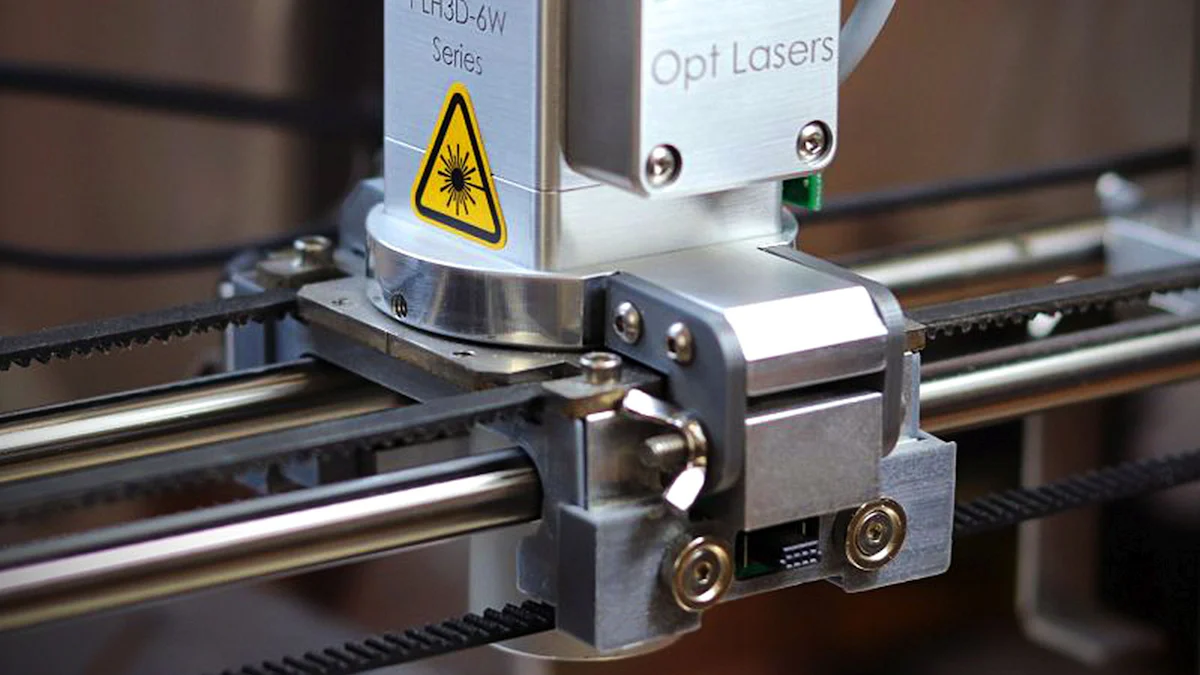

CNC Laser Cutters

CNC laser cutters use highly focused laser beams to cut through materials with exceptional precision. You will find these machines ideal for tasks requiring intricate designs and fine details. The laser's precision ensures smooth edges and high-quality finishes, making it perfect for engineering applications and accurate component cutting. Laser cutters excel in working with metals, plastics, and even wood, offering versatility across different industries. Their ability to produce complex shapes with minimal waste makes them a valuable asset in manufacturing.

CNC Plasma Cutters

CNC plasma cutters employ ionized gas, or plasma, to cut through electrically conductive materials. You will appreciate their efficiency in cutting thick metals like steel and aluminum. Plasma cutters are known for their speed and ability to handle large-scale projects. While they may not match the precision of laser cutters, they offer a cost-effective solution for heavy-duty cutting tasks. These machines are commonly used in industries such as automotive and construction, where robust and rapid cutting is essential.

CNC Waterjet Cutters

CNC waterjet cutters use a high-pressure stream of water, often mixed with abrasive materials, to cut through a wide range of materials. You will find them particularly useful for cutting materials sensitive to heat, such as stone, glass, and certain metals. Waterjet cutters provide a clean cut without altering the material's properties, making them ideal for applications where maintaining material integrity is crucial. Their versatility allows you to work with both soft and hard materials, offering flexibility in various manufacturing processes.

By understanding the different types of CNC cutting machines, you can make informed decisions about which machine best suits your specific needs. Whether you require the precision of a laser cutter, the power of a plasma cutter, or the versatility of a waterjet cutter, each type offers unique advantages that enhance your manufacturing capabilities.

Applications of CNC Cutting Machines

CNC cutting machines have revolutionized various industries by providing precision, efficiency, and versatility. You will find these machines indispensable in sectors that demand high-quality and reliable parts. Let's explore some key applications of CNC cutting machines.

Industrial Manufacturing

In industrial manufacturing, CNC cutting machines play a crucial role. You can automate the cutting and shaping of materials, which enhances productivity and reduces manual labor. These machines handle complex manufacturing tasks with ease, allowing you to produce intricate designs that would be challenging or impossible to achieve manually. By using CNC technology, you ensure consistency and repeatability in your production processes, which is vital for maintaining quality standards.

Automotive Industry

The automotive industry relies heavily on CNC cutting machines for producing precision metal parts. You will appreciate their ability to cut and shape materials like steel and aluminum with high accuracy. CNC machines help you create components that meet the stringent specifications required in automotive manufacturing. By automating routine tasks, these machines increase efficiency and reduce production time, enabling you to meet the demands of the fast-paced automotive market.

Aerospace Industry

In the aerospace industry, precision is paramount. CNC cutting machines provide the accuracy needed to produce parts with narrow tolerances. You can use these machines to cut exotic metals and composites, which are common in aerospace applications. The ability to reproduce high-quality parts consistently makes CNC machines invaluable in this field. By employing CNC technology, you contribute to the development of efficient and size-reducing products and machines, which are essential in aerospace engineering.

"CNC laser cutting machines are employed in the aerospace industry for producing accurate parts with narrow tolerances."

By understanding the applications of CNC cutting machines, you can appreciate their impact across various industries. Whether you're involved in industrial manufacturing, automotive production, or aerospace engineering, CNC technology offers the tools you need to enhance your manufacturing capabilities.

Custom Fabrication

In the realm of custom fabrication, CNC cutting machines stand out as indispensable tools. You can harness their precision and versatility to create unique and intricate designs tailored to specific needs. Whether you're working with metal, wood, or plastic, CNC machines offer the flexibility required to bring your creative visions to life.

-

Versatility in Material Handling: CNC machines excel in processing a wide range of materials. You can cut, shape, and engrave metals, plastics, and even wood with remarkable accuracy. This versatility allows you to tackle diverse projects, from crafting custom furniture to designing bespoke metal components.

-

Precision and Detail: When it comes to custom fabrication, precision is key. CNC machines provide the accuracy needed to produce detailed and complex parts. You can achieve intricate patterns and fine details that would be challenging to replicate manually. This capability is particularly valuable in industries like woodworking, where precise cuts and intricate designs are essential.

-

Efficiency and Consistency: CNC technology streamlines the fabrication process. You can automate repetitive tasks, ensuring consistency across multiple pieces. This efficiency not only saves time but also reduces the likelihood of errors. By maintaining uniformity in your creations, you enhance the quality and reliability of your products.

-

Innovation and Creativity: With CNC machines, you have the freedom to explore innovative designs and push the boundaries of creativity. You can experiment with new materials and techniques, opening up possibilities for unique and groundbreaking projects. This innovation is evident in industries like aerospace and automotive, where CNC technology enables the production of advanced and efficient components.

"CNC routers automate cutting and shaping of materials in various industries like manufacturing, woodworking, and small businesses, improving productivity and creativity."

By leveraging the capabilities of CNC cutting machines, you can elevate your custom fabrication projects to new heights. Whether you're crafting one-of-a-kind pieces or producing high-quality components, CNC technology provides the tools you need to succeed in the competitive world of custom fabrication.

Benefits of Using CNC Cutting Machines

Precision and Accuracy

When you work with CNC cutting machines, you achieve unparalleled precision and accuracy. These machines follow digital designs with exactness, ensuring each cut matches the intended specifications. In industries like aerospace, where precision is crucial, CNC laser cutting machines excel. They produce parts with narrow tolerances, cutting exotic metals and composites with ease. This level of precision reduces material waste and enhances the quality of the final product. You can rely on CNC machines to deliver consistent results, making them indispensable in fields that demand high accuracy.

Efficiency and Speed

CNC cutting machines significantly boost efficiency and speed in manufacturing processes. You can automate repetitive tasks, allowing the machine to operate continuously without fatigue. This automation leads to faster production times compared to manual methods. CNC machines handle high-volume runs efficiently, making them ideal for industries that require rapid production. By minimizing downtime and tool changes, you maximize productivity. The ability to quickly switch between programs further enhances their efficiency, enabling you to meet tight deadlines and increase output.

Versatility in Material Cutting

The versatility of CNC cutting machines allows you to work with a wide range of materials. Whether you're cutting metals, plastics, or wood, these machines adapt to different materials with ease. CNC laser cutters, for example, handle intricate designs on metals and plastics, while CNC waterjet cutters excel in cutting heat-sensitive materials like stone and glass. This adaptability makes CNC machines suitable for various applications, from custom fabrication to industrial manufacturing. You can tackle diverse projects with confidence, knowing that CNC technology provides the flexibility needed to meet your specific requirements.

Cost-Effectiveness

When you consider CNC cutting machines, cost-effectiveness stands out as a significant advantage. These machines streamline production processes, reducing the need for manual labor. By automating tasks, you minimize human error and increase efficiency. This leads to lower labor costs and higher productivity.

-

Reduced Material Waste: CNC machines cut materials with precision, ensuring minimal waste. You can optimize material usage, which translates to cost savings. In industries like aerospace, where materials such as exotic metals and composites are expensive, this precision is invaluable. CNC laser cutting machines excel in producing accurate parts with narrow tolerances, maximizing material efficiency.

-

Lower Maintenance Costs: CNC machines require less maintenance compared to traditional machinery. Their automated nature reduces wear and tear, extending the lifespan of components. You spend less on repairs and replacements, further enhancing cost-effectiveness.

-

Increased Production Speed: With CNC technology, you can achieve faster production times. The machines operate continuously, handling high-volume runs efficiently. This speed allows you to meet tight deadlines and increase output without compromising quality. The ability to quickly switch between programs also contributes to faster turnaround times.

-

Scalability: As your business grows, CNC machines can easily scale to meet increased demand. You can adjust production levels without significant additional costs. This scalability ensures that you remain competitive in the market, adapting to changing customer needs.

By investing in CNC cutting machines, you gain a cost-effective solution that enhances your manufacturing capabilities. You benefit from reduced waste, lower maintenance expenses, and increased production speed, all of which contribute to a more efficient and profitable operation.

Choosing the Right CNC Cutting Machine

Selecting the appropriate CNC cutting machine is crucial for optimizing your manufacturing processes. You need to consider several factors to ensure the machine meets your specific needs and enhances productivity.

Consider Material Type

When choosing a CNC cutting machine, you must first consider the type of material you will be working with. Different machines excel with different materials. For instance, CNC laser cutters are ideal for metals and plastics, while CNC waterjet cutters handle heat-sensitive materials like stone and glass. Understanding the material's properties helps you select a machine that delivers precise cuts and maintains the material's integrity.

Evaluate Cutting Speed and Precision

Cutting speed and precision are vital factors in your decision-making process. You should evaluate the machine's ability to perform tasks quickly without compromising accuracy. CNC machines offer varying speeds and precision levels. For industries like aerospace, where precision is paramount, you might prioritize machines that provide narrow tolerances and high accuracy. Faster machines can increase production rates, but you must ensure they maintain the quality standards required for your projects.

Assess Software Compatibility

Software compatibility plays a significant role in the functionality of CNC cutting machines. You need to ensure that the machine's software integrates seamlessly with your existing systems. This compatibility allows for smooth operation and efficient workflow. Modern CNC machines often come with advanced software that supports complex designs and automates processes. By assessing software compatibility, you can leverage these features to enhance your manufacturing capabilities.

Tramar Industries, experts in CNC machining, emphasize the importance of selecting the right machine for your industry. They highlight that CNC machines are vital for producing high-quality and reliable parts across various sectors, including medical, aerospace, and electronics.

By considering these factors, you can choose a CNC cutting machine that aligns with your manufacturing goals. Whether you prioritize material handling, speed, precision, or software integration, making an informed decision ensures that your investment enhances productivity and efficiency.

Budget Considerations

When selecting a CNC cutting machine, budget considerations play a crucial role in your decision-making process. You need to balance the cost of the machine with its features and capabilities to ensure you make a wise investment.

-

Initial Purchase Cost: The upfront cost of a CNC cutting machine can vary significantly based on its type, size, and features. You should evaluate your budget and determine how much you are willing to spend on the initial purchase. Keep in mind that more advanced machines with additional features may come at a higher price, but they can offer greater efficiency and precision.

-

Operating Costs: Beyond the initial purchase, consider the ongoing operating costs of the machine. These include energy consumption, maintenance, and the cost of consumables like cutting tools or abrasives. You should assess how these costs fit into your overall budget and whether the machine's efficiency can offset them over time.

-

Return on Investment (ROI): It's essential to calculate the potential ROI when investing in a CNC cutting machine. Consider how the machine will enhance your production capabilities and whether it will lead to increased revenue or cost savings. A machine that offers a high ROI can justify a higher initial investment.

-

Financing Options: If the upfront cost is a concern, explore financing options that may be available. Leasing or financing plans can help you acquire the machine without a significant initial outlay. You should weigh the terms and interest rates to ensure they align with your financial goals.

-

Long-term Value: Consider the long-term value of the CNC cutting machine. A durable and reliable machine may have a higher initial cost but can provide value over many years. You should prioritize machines from reputable manufacturers known for quality and longevity.

Tramar Industries, experts in CNC machining, emphasize the importance of selecting the right machine for your industry. They highlight that CNC machines are vital for producing high-quality and reliable parts across various sectors, including medical, aerospace, and electronics.

By carefully considering your budget, you can choose a CNC cutting machine that meets your needs without compromising financial stability. Balancing cost with functionality ensures that your investment supports your manufacturing goals and contributes to long-term success.

Understanding what is CNC cutting machine and its various types is crucial for making informed decisions in manufacturing. These machines enhance precision, efficiency, and cost-effectiveness across industries. By selecting the right machine type, you can optimize material handling and reduce machining costs. Consider factors like machinability and design optimization to further cut expenses. Different CNC machines offer unique benefits, impacting the overall machining process. With this knowledge, you can leverage CNC technology to improve productivity and maintain high-quality standards in your operations.

FAQ

What is a CNC cutting machine?

A CNC cutting machine automates the cutting process using computer programming. It transforms digital designs into precise cuts on various materials, enhancing productivity and accuracy in manufacturing.

How does a CNC cutting machine work?

You start by creating a digital design using CAD software. The design converts into a machine-readable code, instructing the CNC machine on how to move and cut the material. The machine follows these instructions with precision, ensuring each cut matches the digital design.

What materials can CNC cutting machines handle?

CNC cutting machines work with a wide range of materials. You can cut metals, plastics, wood, stone, and glass. The type of CNC machine determines the materials it can handle effectively.

What are the benefits of using CNC cutting machines?

CNC cutting machines offer precision, efficiency, and versatility. They reduce human error, enhance production speed, and adapt to various materials. These machines also lower labor costs and minimize material waste.

How do I choose the right CNC cutting machine?

Consider the material type, cutting speed, precision, and software compatibility. Evaluate your budget and the machine's features. Ensure the machine aligns with your manufacturing goals and enhances productivity.

Are CNC cutting machines cost-effective?

Yes, CNC cutting machines are cost-effective. They streamline production processes, reduce manual labor, and minimize material waste. The initial investment often leads to long-term savings and increased efficiency.

What industries use CNC cutting machines?

Industries like aerospace, automotive, electronics, and custom fabrication rely on CNC cutting machines. These machines provide the precision and efficiency needed for high-quality and reliable parts.

Can CNC cutting machines handle custom designs?

Absolutely. CNC cutting machines excel in custom fabrication. They allow you to create unique and intricate designs with precision, making them ideal for bespoke projects.

What safety features do CNC cutting machines have?

CNC cutting machines include safety features like guards and emergency stops. These features protect operators and ensure safe operation during the cutting process.

How do CNC cutting machines improve manufacturing?

CNC cutting machines enhance manufacturing by automating tasks, reducing errors, and increasing production speed. They provide consistent results, improve material handling, and support cost-effective operations.

See Also

Exploring Different Types of CNC Cutting Machines

Understanding the Functionality of CNC Laser Cutters

A Simple Explanation of Laser Cutting Machine Operation