Guide to Choosing Acrylic Cutting Machines

Acrylic cutting machines have transformed how you cut acrylic sheets, offering unmatched precision and efficiency. These machines are essential in industries like advertising, sign-making, woodworking, and metalworking. They allow you to cut through various materials, including acrylic, wood, and metal, with remarkable accuracy. By using these machines, you can achieve clean and precise cuts, which are crucial for high-quality production. So, what machine can cut acrylic effectively? The answer lies in the advanced technology of acrylic cutting machines, which have become indispensable tools in modern manufacturing.

Key Takeaways

- Understand the different types of acrylic cutting machines—laser cutters, CNC routers, and traditional machines—to choose the best fit for your needs.

- Prioritize power and speed when selecting a machine; higher power allows for cutting thicker materials, while speed is essential for efficiency in larger projects.

- Evaluate the materials and thickness you plan to cut; ensure the machine is optimized for acrylic and can handle the required thickness.

- Consider your budget carefully, factoring in both the initial cost and ongoing maintenance expenses to find a machine that offers good value.

- Research brand reputation and customer support; established brands with positive reviews and strong warranties provide peace of mind.

- Follow essential safety measures and maintenance tips to ensure safe operation and longevity of your acrylic cutting machine.

- Explore the diverse applications of acrylic cutting machines in industrial, creative, and educational settings to maximize their potential in your projects.

Types of Acrylic Cutting Machines

When you're diving into the world of acrylic cutting, understanding the different types of machines available can make a huge difference. Each type has its own set of features, advantages, and disadvantages. Let's explore these options to help you decide what machine can cut acrylic most effectively for your needs.

Laser Cutters

Laser cutters are a popular choice for cutting acrylic due to their precision and efficiency.

Features of Laser Cutters

- High Precision: Laser cutters use a focused beam of light to cut through acrylic, ensuring clean and accurate cuts.

- Versatility: These machines can handle intricate designs and are suitable for various materials, not just acrylic.

- Software Integration: Most laser cutters come with software that allows you to design and control the cutting process.

Advantages of Laser Cutters

- Precision and Accuracy: You get consistent results, which is crucial for detailed projects.

- Speed: Laser cutters work quickly, making them ideal for high-volume production.

- Minimal Waste: The precision of laser cutting reduces material waste.

Disadvantages of Laser Cutters

- Cost: Laser cutters can be expensive, both in terms of initial investment and maintenance.

- Safety Concerns: You need to follow strict safety protocols to prevent accidents.

- Complexity: Operating a laser cutter requires some technical knowledge and training.

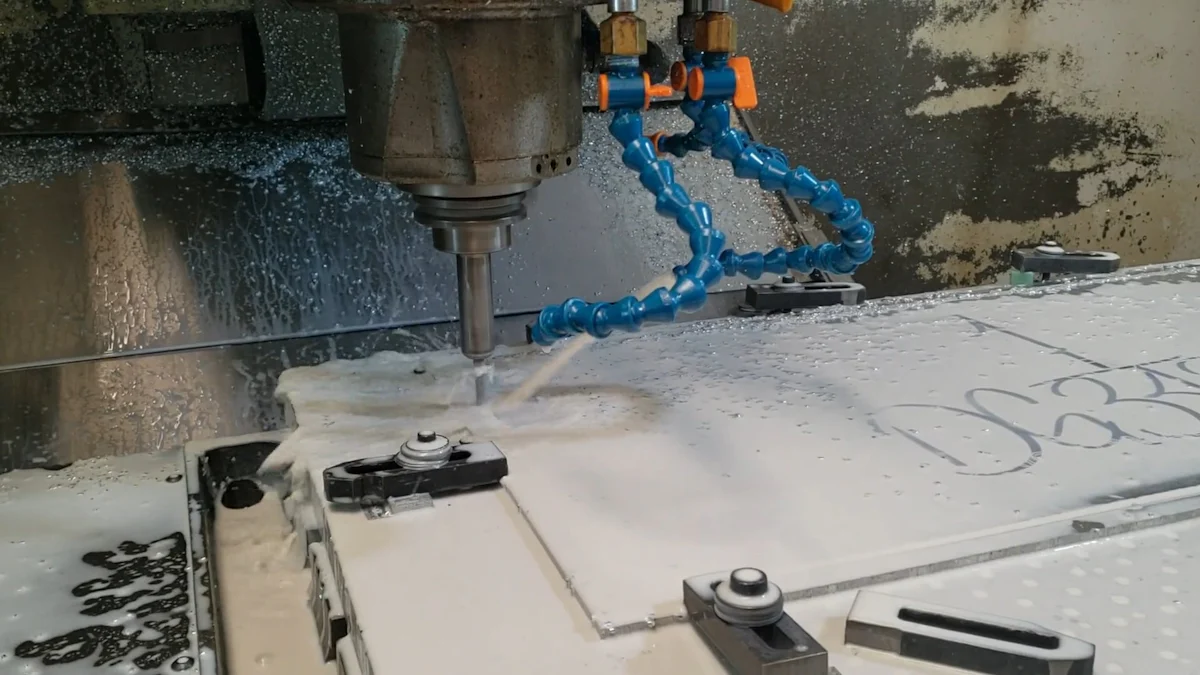

CNC Routers

CNC routers offer another effective solution for cutting acrylic, especially for larger projects.

Features of CNC Routers

- Robust Design: CNC routers are built to handle heavy-duty tasks and can cut through thicker materials.

- Automated Operation: These machines use computer numerical control for precise cutting.

- Multi-Tool Capability: You can equip CNC routers with various tools for different cutting needs.

Advantages of CNC Routers

- Durability: CNC routers are designed for long-term use and can handle large-scale projects.

- Flexibility: They can cut a wide range of materials, including wood and metal.

- Customization: You can easily adjust settings for different projects.

Disadvantages of CNC Routers

- Size: CNC routers are often large and require significant space.

- Noise: They can be quite loud during operation.

- Setup Time: Initial setup and calibration can be time-consuming.

Other Types of Cutting Machines

Besides laser cutters and CNC routers, there are traditional cutting machines that might suit your needs.

Features of Traditional Cutting Machines

- Manual Operation: These machines often require manual input and control.

- Simple Design: They are generally less complex than their automated counterparts.

- Cost-Effective: Traditional machines are usually more affordable.

Advantages of Traditional Cutting Machines

- Affordability: Lower cost makes them accessible for small businesses or hobbyists.

- Ease of Use: Simpler operation means less training is needed.

- Portability: Many traditional machines are compact and easy to move.

Disadvantages of Traditional Cutting Machines

- Limited Precision: Manual operation can lead to less accurate cuts.

- Time-Consuming: Cutting can take longer compared to automated machines.

- Additional Finishing: You might need extra steps like polishing to achieve smooth edges.

Choosing the right machine depends on your specific needs, budget, and the complexity of your projects. Whether you opt for a laser cutter, CNC router, or a traditional machine, understanding their features will guide you in making an informed decision about what machine can cut acrylic best for you.

How to Choose the Right Acrylic Cutting Machine

Choosing the right acrylic cutting machine can feel overwhelming, but breaking it down into key considerations makes it manageable. Let's dive into what you should look for when selecting the perfect machine for your needs.

Considerations for Power and Speed

When you're picking an acrylic cutting machine, power and speed are crucial factors. The power of the machine directly impacts how quickly and cleanly it can cut through acrylic. Machines with higher power levels can handle thicker materials and provide smoother edges. For instance, a CO2 laser cutter with robust power can significantly enhance cutting speed and edge quality.

Speed matters too. If you're working on large projects or need quick turnaround times, a machine with a high cutting speed will be beneficial. However, remember that faster isn't always better if it compromises the quality of the cut. Balancing speed with precision ensures you get the best results without sacrificing quality.

Evaluating Cutting Material and Thickness

Not all machines are created equal when it comes to handling different materials and thicknesses. You need to evaluate what materials you'll be cutting most often. If acrylic is your primary material, ensure the machine is optimized for it. Some machines, like laser cutters, excel at cutting acrylic due to their specific wavelength that interacts well with the material.

Thickness is another consideration. Machines vary in their ability to cut through different thicknesses of acrylic. A machine with an auto-sinking cutting function, for example, can increase cutting depth by a significant margin, making it ideal for thicker materials. Always check the specifications to ensure the machine can handle the thickness you require.

Budget and Cost Considerations

Your budget plays a big role in determining what machine can cut acrylic effectively for you. Acrylic cutting machines come in a range of prices, from affordable traditional machines to high-end laser cutters. It's important to consider both the initial investment and ongoing costs, such as maintenance and potential upgrades.

Mid-range machines often offer a good balance between performance and cost. They provide decent power and features without breaking the bank. However, if you have a larger budget, investing in a high-quality machine can pay off in terms of efficiency and precision.

Assessing Brand Reputation and Support

When you're in the market for an acrylic cutting machine, brand reputation and support play a crucial role. You want a machine that not only performs well but also comes from a reliable manufacturer. Here's how you can assess these factors effectively:

-

Research Brand History: Start by looking into the history of the brand. Established brands often have a track record of producing high-quality machines. They have built their reputation over time, which can give you confidence in their products.

-

Customer Reviews and Testimonials: Check out what other users are saying. Customer reviews and testimonials provide real-world insights into the machine's performance and the company's customer service. Look for patterns in feedback—consistent praise or complaints can be telling.

-

Warranty and Support Services: A good warranty is a sign that the company stands behind its product. Make sure to understand what the warranty covers and for how long. Additionally, consider the support services offered. Does the company provide easy access to technical support? Are there resources like manuals and online tutorials available?

-

Community and Forums: Some brands have active user communities or forums. These can be invaluable for troubleshooting and tips. Engaging with other users can give you a sense of the brand's support network and the machine's capabilities.

-

Innovation and Updates: Brands that invest in innovation and regularly update their machines tend to stay ahead in the market. This commitment to improvement can mean better features and performance for you.

Choosing the right brand ensures you get a machine that meets your needs and offers reliable support. Whether you're looking for what machine can cut acrylic with precision or seeking robust customer service, assessing brand reputation and support is key to making an informed decision.

Safety Precautions and Maintenance Tips

When working with acrylic cutting machines, safety and maintenance are crucial. These practices not only protect you but also extend the life of your machine. Let's explore some essential safety measures and maintenance tips to keep your operations smooth and safe.

Essential Safety Measures

-

Wear Protective Gear: Always wear safety goggles and gloves. They protect your eyes from debris and your hands from sharp edges.

-

Ensure Proper Ventilation: Acrylic cutting can produce fumes. Make sure your workspace is well-ventilated to avoid inhaling harmful substances.

-

Follow Manufacturer Guidelines: Each machine comes with specific safety instructions. Follow these guidelines to prevent accidents and ensure optimal performance.

-

Regularly Inspect Equipment: Before each use, check for any signs of wear or damage. This includes inspecting the laser or cutting tool for any irregularities.

-

Emergency Protocols: Familiarize yourself with emergency shutdown procedures. Knowing how to quickly stop the machine can prevent accidents.

Routine Maintenance Practices

-

Clean the Machine Regularly: Dust and debris can accumulate, affecting performance. Use a soft brush or cloth to clean the machine after each use.

-

Lubricate Moving Parts: Regular lubrication reduces friction and wear. Check the manufacturer's recommendations for the right type of lubricant.

-

Check Alignment and Calibration: Ensure that the cutting tools are properly aligned and calibrated. Misalignment can lead to inaccurate cuts and increased wear on the machine.

-

Replace Worn Parts: Over time, parts like blades and belts may wear out. Replace them promptly to maintain efficiency and safety.

-

Software Updates: If your machine uses software, keep it updated. Manufacturers often release updates to improve performance and fix bugs.

Troubleshooting Common Issues

-

Inconsistent Cuts: If you notice uneven cuts, check the alignment and calibration of the machine. Ensure that the cutting tool is sharp and properly installed.

-

Machine Overheating: Overheating can occur if the machine is overworked. Allow it to cool down and check for any blockages in the ventilation system.

-

Software Glitches: Restart the machine and check for software updates. If problems persist, consult the manufacturer's support team.

-

Power Fluctuations: Ensure that the machine is connected to a stable power source. Use a surge protector to prevent damage from power surges.

By following these safety precautions and maintenance tips, you can ensure that your acrylic cutting machine operates efficiently and safely. Whether you're using a laser cutter or another type of machine, these practices help you get the most out of your equipment.

Applications of Acrylic Cutting Machines

Acrylic cutting machines have revolutionized various fields by offering precise and efficient cutting solutions. Let's explore how these machines are utilized across different sectors.

Industrial Applications

In the industrial sector, acrylic cutting machines play a pivotal role. You find them in manufacturing settings where precision is crucial. These machines cut acrylic sheets into specific shapes and sizes, which is essential for creating components in electronics, automotive parts, and construction materials. Their ability to handle large volumes with consistent accuracy makes them indispensable in mass production environments. By using these machines, industries can maintain high standards of quality while optimizing production time.

Creative and Artistic Uses

Acrylic cutting machines aren't just for industrial use; they also open up a world of possibilities for artists and designers. If you're in the creative field, these machines allow you to bring intricate designs to life. Whether you're crafting custom jewelry, designing unique home decor, or creating signage, the precision of acrylic cutting machines ensures your vision is realized with clarity and detail. The versatility of these machines means you can experiment with various shapes and patterns, pushing the boundaries of your creativity.

Educational and Prototyping Applications

In educational settings, acrylic cutting machines serve as valuable tools for learning and innovation. Schools and universities use them in workshops and labs to teach students about design and engineering principles. If you're involved in prototyping, these machines enable you to quickly create models and test ideas. This hands-on approach enhances understanding and fosters creativity among students. By incorporating acrylic cutting machines into educational programs, institutions can provide practical experience that prepares students for future careers in technology and design.

Choosing the right acrylic cutting machine can transform your projects. You’ve learned about different machines, their features, and how they fit various needs. Now, it's time to assess what suits you best. Consider your specific applications and budget. Remember, an acrylic cutting machine offers versatility and precision, whether you're crafting jewelry or designing intricate products. For further guidance, explore online resources or consult professionals in the field. This way, you ensure that your investment aligns perfectly with your creative and industrial goals.

FAQ

What should I consider when choosing an acrylic cutting machine?

When selecting an acrylic cutting machine, focus on the machine's power, cutting area size, and features. These factors should align with your specific needs. Also, think about the initial investment and ongoing costs. Finding a machine that matches your business goals can improve efficiency and productivity.

How do I determine the right machine for my budget?

Your budget plays a crucial role in your decision. Consider both the upfront cost and the long-term expenses like maintenance and upgrades. Mid-range machines often provide a good balance between cost and performance. If you have a larger budget, investing in a high-quality machine can enhance precision and efficiency.

Are there any safety precautions I should follow?

Yes, safety is paramount. Always wear protective gear like goggles and gloves. Ensure your workspace has proper ventilation to avoid inhaling fumes. Follow the manufacturer's safety guidelines and regularly inspect your equipment for wear or damage. Knowing emergency shutdown procedures can prevent accidents.

How can I maintain my acrylic cutting machine?

Routine maintenance keeps your machine running smoothly. Clean it regularly to remove dust and debris. Lubricate moving parts to reduce friction. Check alignment and calibration to ensure accurate cuts. Replace worn parts promptly and keep software updated for optimal performance.

What are the common issues with acrylic cutting machines?

Common issues include inconsistent cuts, overheating, software glitches, and power fluctuations. To address these, check machine alignment, allow cooling periods, restart the machine, and ensure a stable power source. Using a surge protector can prevent damage from power surges.

How do I choose a reliable brand?

Research the brand's history and read customer reviews. Look for consistent feedback on performance and customer service. A good warranty and support services are essential. Brands with active user communities and regular updates often offer better features and support.

Can acrylic cutting machines handle other materials?

Yes, many acrylic cutting machines can cut various materials like wood and metal. Laser cutters and CNC routers are particularly versatile. However, always check the machine's specifications to ensure it can handle the materials and thicknesses you plan to work with.

What are the benefits of using laser cutters for acrylic?

Laser cutters offer high precision and speed, making them ideal for detailed projects. They minimize material waste and provide consistent results. However, they can be costly and require strict safety protocols. Their versatility allows for intricate designs across different materials.

Are traditional cutting machines still useful?

Traditional cutting machines can be useful, especially for small businesses or hobbyists. They are more affordable and easier to use. However, they may lack the precision and speed of automated machines and often require additional finishing steps for smooth edges.

How do acrylic cutting machines benefit creative projects?

Acrylic cutting machines open up endless possibilities for artists and designers. They allow you to create intricate designs with precision. Whether crafting jewelry or designing home decor, these machines help bring your creative visions to life with clarity and detail.

See Also

Ten Precision Machines Perfect for Cutting Acrylic

Guidelines for Selecting the Ideal Wood Cutting Machine

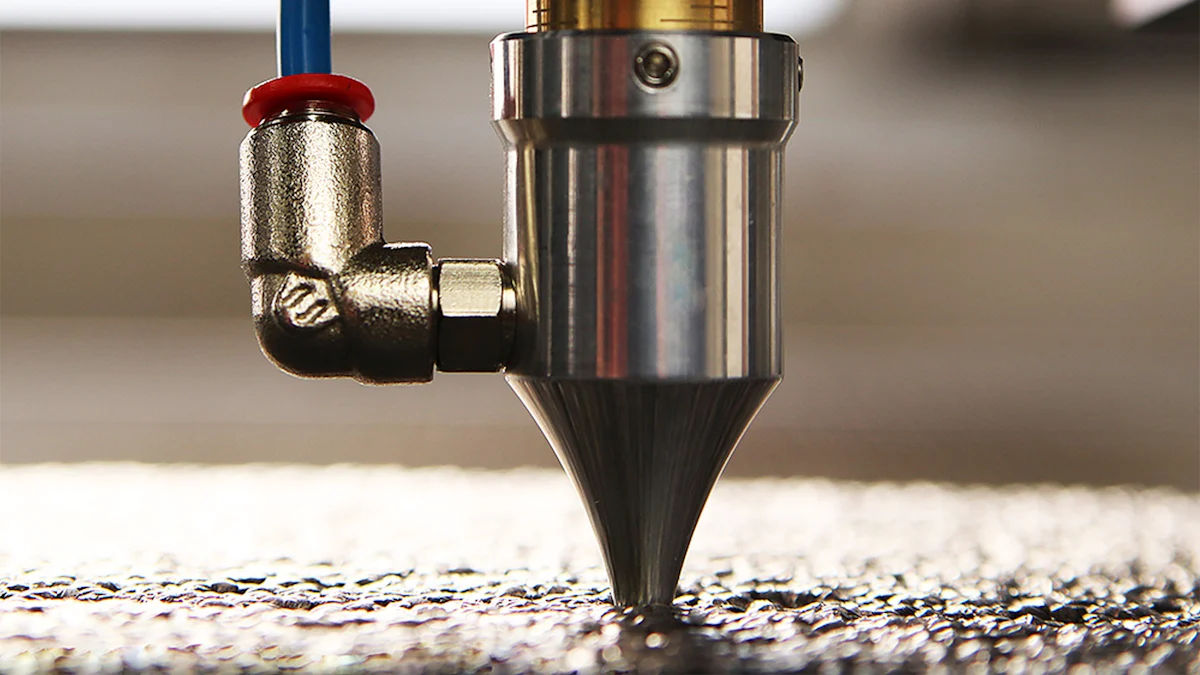

Advice on Picking the Optimal Water Jet Cutter