Choosing the Right 4K CNC Laser for Wood

Selecting the right 4K CNC laser machine that can cut wood may seem daunting, but it doesn't have to be. It's crucial to focus on understanding the machine's specifications and the support available. The market for CNC laser cutting machines is expanding rapidly, with projections indicating a significant rise in demand. This growth underscores the importance of choosing a machine that meets your needs. By considering factors such as laser power, bed size, and precision, you ensure that your investment is worthwhile. Remember, the right choice will enhance your woodworking projects and offer long-term value.

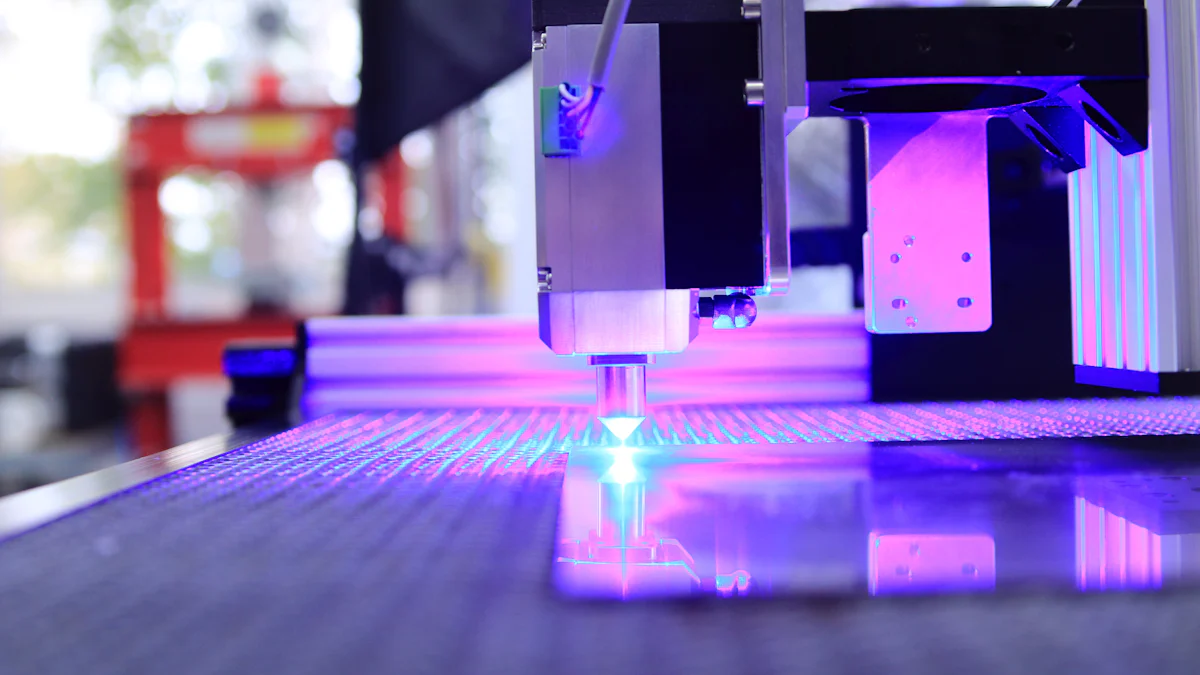

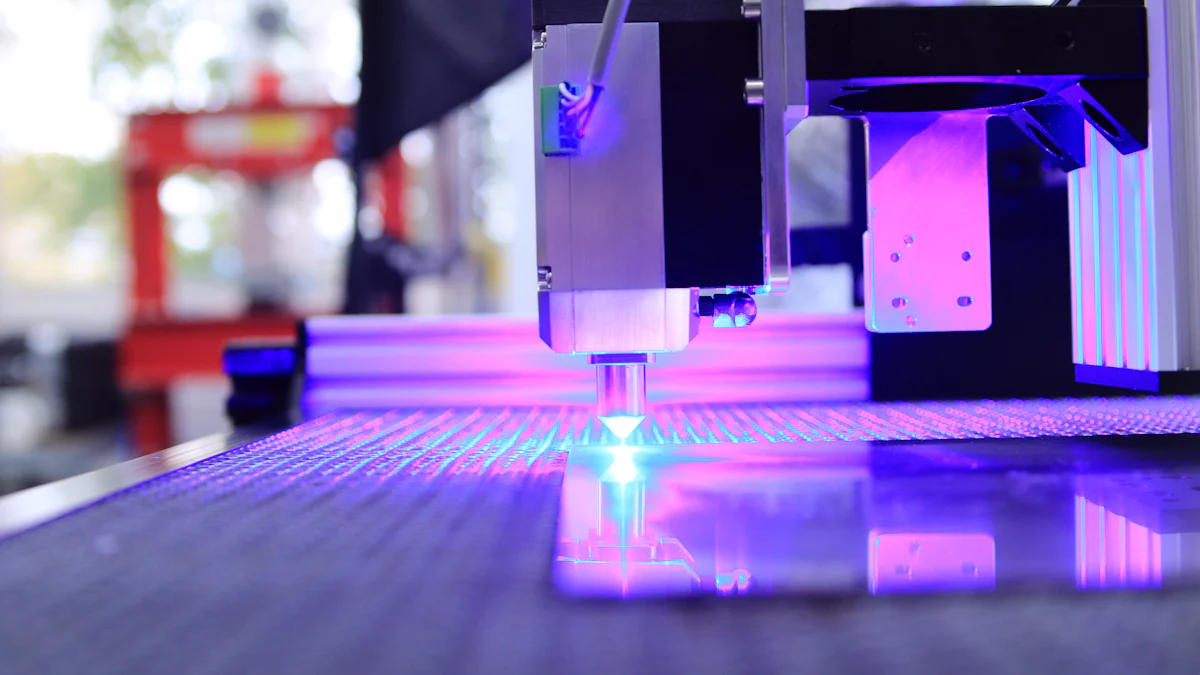

Can a 4K CNC Laser Machine Cut Wood?

When you're diving into the world of woodworking with a 4K CNC laser machine, understanding its capabilities is crucial. Let's break down the key factors that determine whether a 4K CNC laser machine can cut wood effectively.

Understanding Laser Power

The power of the laser is a critical factor in determining how well your machine can cut through wood. For woodworking, you typically need a laser with a wattage between 60w to 100w. This range ensures that the laser has enough strength to slice through various types of wood efficiently.

Recommended Power Levels for Cutting Wood

You might wonder what power levels work best for cutting wood. Generally, a laser with at least 60 watts is recommended for most woodworking projects. This level of power allows you to cut through thicker materials without compromising on speed or quality.

Impact of Laser Power on Cutting Efficiency

The strength of the laser directly impacts cutting efficiency. A higher wattage laser not only cuts faster but also produces cleaner edges. This means less time spent on post-processing and more time creating intricate designs.

Bed Size Considerations

The size of the bed in your CNC laser machine plays a significant role in your woodworking projects. It determines the maximum size of the material you can work with.

Importance of Bed Size for Woodworking Projects

A larger bed size offers more flexibility. You can work on bigger pieces without needing to cut them down to fit the machine. This is particularly useful for large-scale projects or when you want to maximize material usage.

Choosing the Right Bed Size for Your Needs

Consider the typical size of your projects. If you often work with large panels, opt for a machine with a bigger bed. However, if your projects are smaller, a compact bed might suffice, saving you space and cost.

Precision and Resolution

Precision and resolution are vital for achieving detailed designs. A high-resolution laser ensures that even the smallest details are captured accurately.

Achieving Detailed Designs with High Resolution

High resolution in a laser machine allows you to create intricate patterns and designs. This is especially important for decorative pieces where detail is key. Look for machines that offer resolutions of at least 3100 DPI for the best results.

Comparing Resolution Capabilities

Different machines offer varying resolution capabilities. When comparing, focus on the DPI (dots per inch) rating. A higher DPI means better detail and smoother edges, which is essential for professional-grade woodworking.

By understanding these aspects, you can confidently answer the question: can a 4K CNC laser machine cut wood? Yes, it can, provided you choose the right specifications that align with your woodworking needs.

Buying a Laser Cutter: Support and Customer Service

When you're buying a laser cutter, support and customer service play a crucial role in your overall experience. Let's explore why these aspects matter and how they can impact your decision.

Manufacturer Support

Choosing a reliable manufacturer is essential. You want a company that stands by its product and offers robust support services. Imagine investing in a laser machine only to find out that getting help is a hassle. That's not a situation you want to be in.

Evaluating Support Services and Customer Service Quality

To evaluate support services, consider the following:

- Response Time: How quickly does the company respond to inquiries or issues? Fast response times indicate a commitment to customer satisfaction.

- Availability: Is support available 24/7, or only during specific hours? Knowing when you can reach out for help is important.

- Expertise: Are the support staff knowledgeable about the laser machine and its components? You need experts who can provide accurate solutions.

- Warranty and Repairs: Check if the company offers a comprehensive warranty and how they handle repairs. Some companies might require you to ship the machine back, which can be costly and time-consuming.

A good manufacturer will offer clear communication and effective solutions, ensuring that your laser cutter remains in top condition.

Community and Online Resources

Beyond manufacturer support, community and online resources can be invaluable. They provide additional layers of assistance and learning opportunities.

Benefits of User Communities and Online Tutorials

User communities and online tutorials offer several benefits:

- Shared Experiences: Engaging with other users allows you to learn from their experiences. You can discover tips and tricks that aren't in the manual.

- Problem Solving: Communities often have forums where users discuss common issues and solutions. This can be a quick way to troubleshoot problems.

- Learning Resources: Online tutorials can guide you through setup, operation, and maintenance. They often include step-by-step videos that make complex tasks easier to understand.

- Innovation and Inspiration: Seeing what others create with their laser machines can inspire your projects and push your creativity.

By tapping into these resources, you enhance your understanding and skills, making the most of your laser engraver.

Recommendations for Purchasing a Laser

When you're in the market for a laser, making the right choice involves several key considerations. Let's dive into what you should keep in mind to ensure you get the best value for your investment.

Budget Considerations

Balancing cost with features and quality is crucial when choosing a laser. You might find yourself tempted by high-end models with all the bells and whistles, but it's essential to weigh these against your actual needs and budget.

-

Cost vs. Features: High-power fiber laser cutters can cost over $2 million, offering state-of-the-art technology. However, CO2 lasers, which require less maintenance, might be more budget-friendly while still providing sufficient power for most woodworking tasks.

-

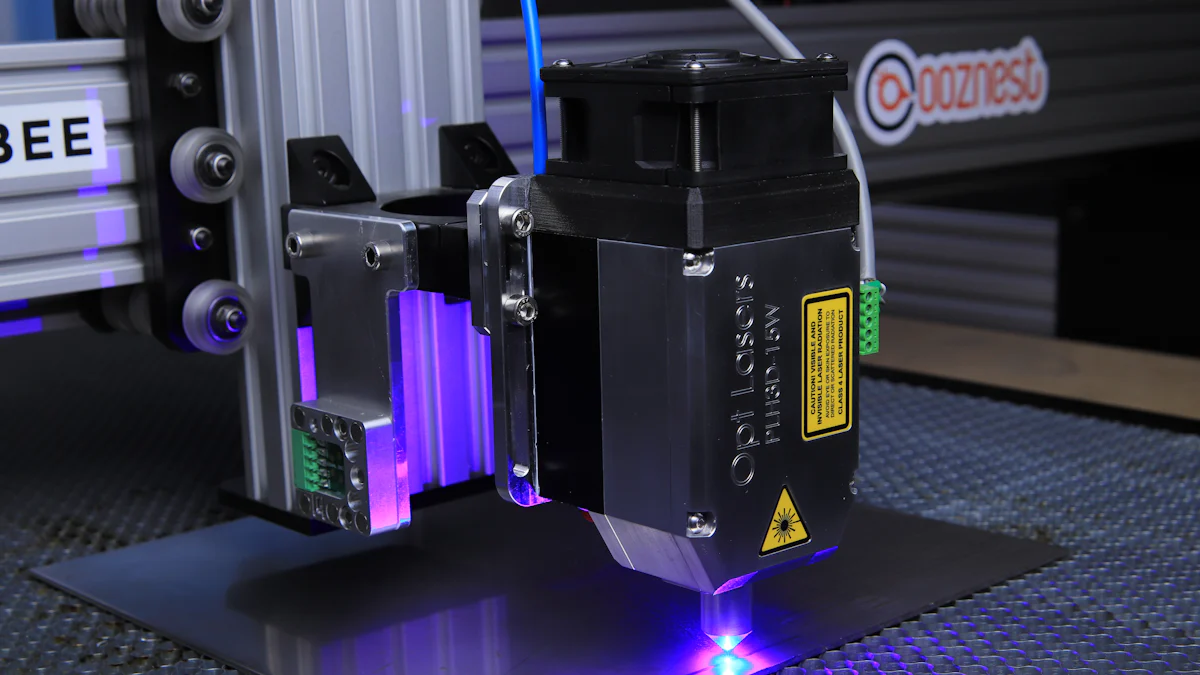

Quality and Longevity: Investing in a laser with high-quality components can save you money in the long run. Opt Lasers' Blue CNC Laser kits, for example, are known for their precise cutting capabilities and excellent customer support, making them a worthwhile consideration.

Trusted Brands and Models

Choosing a reputable brand ensures reliability and support. Here are some brands and models that stand out:

-

Opt Lasers: Known for their Blue CNC Laser kits, they offer high power output and compatibility with almost all materials. Their customer support is also highly rated, which can be a significant advantage.

-

Other Reputable Brands: While Opt Lasers is a standout, other brands also offer reliable models. Researching user reviews and expert opinions can help you identify which models have a track record of performance and durability.

Warranty and Return Policies

Understanding warranty terms and return processes is vital before making a purchase. A good warranty can provide peace of mind and protect your investment.

-

Warranty Terms: Look for warranties that cover a reasonable period and include parts and labor. Some manufacturers might offer extended warranties for an additional cost, which can be beneficial if you plan to use the laser extensively.

-

Return Processes: Familiarize yourself with the return policy. Knowing how returns are handled can save you from potential headaches if the laser doesn't meet your expectations or if you encounter issues.

By considering these factors, you can make an informed decision when purchasing a laser. Remember, the right choice will not only enhance your woodworking projects but also provide long-term satisfaction.

Choosing the right 4K CNC laser for wood involves several key factors. You need to consider the laser's power, bed size, and precision to ensure it meets your woodworking needs. Evaluate the support and customer service offered by manufacturers, as these can significantly impact your experience. Don't forget to research trusted brands and models, and understand warranty and return policies. By focusing on these aspects, you make an informed decision that enhances your projects and provides long-term satisfaction. Remember, the right laser engraver can transform your woodworking endeavors into masterpieces.

FAQ

What is a CNC laser cutter?

A CNC laser cutter is a high-tech device that uses a concentrated beam of light to cut materials. It operates through computerized commands, often referred to as G-Code, to precisely vaporize or melt materials like wood. You can think of it as a tool that combines the precision of CNC technology with the power of laser cutting. This makes it ideal for achieving intricate designs and high manufacturing precision.

Can a CNC machine cut wood?

Absolutely! CNC machines excel at cutting wood with precision and efficiency. They utilize specialized tools, such as routers and milling machines, to carve, shape, and engrave various types of wood. With CNC technology, you gain automated control over the cutting process, ensuring accurate results that meet your design specifications.

What is the best CNC machine for woodworking?

When choosing a CNC machine for woodworking, consider CNC routers and milling machines specifically designed for wood. Look for machines with robust construction, precise control systems, adequate spindle power, and a spacious work area. Brands known for reliability and customer support are often a good choice. Ultimately, the best machine will align with your project needs, whether you're into furniture making, cabinetry, or intricate carvings.

How does laser power affect cutting efficiency?

Laser power plays a crucial role in cutting efficiency. A higher wattage laser cuts faster and produces cleaner edges. This means you spend less time on post-processing and more time creating detailed designs. For woodworking, a laser with a wattage between 60w to 100w is typically recommended to ensure efficient cutting through various types of wood.

Why is bed size important in a CNC laser machine?

The bed size of a CNC laser machine determines the maximum size of the material you can work with. A larger bed size offers more flexibility, allowing you to work on bigger pieces without needing to cut them down. This is particularly useful for large-scale projects or when you want to maximize material usage. Consider your typical project sizes when choosing the right bed size for your needs.

How do I evaluate manufacturer support for a laser cutter?

Evaluating manufacturer support involves looking at several factors:

- Response Time: Quick responses to inquiries or issues indicate a commitment to customer satisfaction.

- Availability: Check if support is available 24/7 or only during specific hours.

- Expertise: Ensure the support staff is knowledgeable about the laser machine and its components.

- Warranty and Repairs: Look for comprehensive warranties and understand how repairs are handled.

A reliable manufacturer will offer clear communication and effective solutions, ensuring your laser cutter remains in top condition.

What are the benefits of user communities and online resources?

User communities and online resources provide additional layers of assistance and learning opportunities. Engaging with other users allows you to learn from their experiences and discover tips and tricks not found in manuals. Online tutorials can guide you through setup, operation, and maintenance, often with step-by-step videos. These resources can inspire your projects and enhance your understanding and skills with your laser engraver.

See Also

Essential Advice for Selecting the Right Wood Cutter

Is CNC Machinery Capable of Efficient Wood Cutting?

Does CNC Outperform Laser Cutters for Acrylic Cutting?