Can You Cut Foam on a Laser Machine? A Comparison

Can you cut foam on a laser machine? Absolutely, and it's a game-changer for foam materials. Laser machines offer precision, speed, and minimal waste, making them the top choice for foam processing. You can achieve clean and smooth edges that traditional methods can't match. The demand for laser-cut foam materials continues to rise, highlighting the importance of selecting the right laser machine. With options like automatic CNC controllers, you can efficiently cut various foam materials. Understanding the capabilities of different laser machines ensures you make the best choice for your foam cutting needs.

Overview of Laser Cutting for Foam

Laser cutting has revolutionized the way you can work with foam materials. This technology offers precision, efficiency, and versatility, making it a preferred choice in various industries. Let's delve into how laser cutting works and its feasibility for foam materials.

How Laser Cutting Works

Laser cutting machines use a focused beam of light to cut through materials. When you operate a laser cutter, it emits a high-powered laser beam that melts, burns, or vaporizes the material along a specified path. This process allows for intricate designs and precise cuts. The laser's intensity and speed can be adjusted to suit different types of foam, ensuring optimal results.

Scientific Research Findings:

- Laser Cutting Foam Benefits and Applications: Laser cutting foam is safe for the environment and energy efficient. It reduces material wastage and provides immaculate cuts, transforming foam processing across industries.

Feasibility of Foam Cutting

Foam cutting with laser machines is not only feasible but also highly effective. You can achieve clean and smooth edges that traditional methods often struggle to provide. The precision of laser cutting machines ensures that you can create detailed and complex shapes without compromising on quality.

Advantages of Laser Cutting Foam:

- Unparalleled precision and versatility.

- Ability to craft intricate designs consistently.

- Emphasis on safety considerations.

Laser cutting machines, especially CO2 lasers, are superbly suited for processing various foams. They can be equipped with filter systems to manage emissions, making them environmentally friendly. Material testing and detailed reports are available in application laboratories, ensuring you choose the right setup for your needs.

By understanding how laser cutting works and its feasibility for foam, you can make informed decisions about incorporating this technology into your projects. Whether you're in manufacturing, design, or any other field, laser cutting machines offer a reliable and efficient solution for foam processing.

Comparison of Different Laser Machines

When it comes to cutting foam, choosing the right laser cutter is crucial. Let's explore the differences between three popular types of laser machines: CO2 laser machines, Fiber laser machines, and Diode laser machines. Each has unique features that make them suitable for specific applications.

CO2 Laser Machines

CO2 laser machines are among the best laser cutters for foam. They use a gas mixture of carbon dioxide, helium, and nitrogen to produce a powerful laser beam. This type of laser cutter excels in cutting non-metal materials like foam, wood, and acrylic. The CO2 laser machine provides clean and precise cuts, making it ideal for intricate designs.

-

Advantages:

- High precision and smooth edges.

- Versatile for various non-metal materials.

- Cost-effective for foam cutting.

-

Limitations:

- Struggles with high reflectivity materials.

- Requires regular maintenance to ensure optimal performance.

Fiber Laser Machines

Fiber laser machines use flexible fiber optic cables infused with rare earth elements to generate the laser beam. These machines are known for their efficiency and low maintenance requirements. While they are excellent for cutting metals, they are not the best choice for foam due to their wavelength and power characteristics.

-

Advantages:

- Low maintenance and high efficiency.

- Best suited for cutting reflective materials like metals.

-

Limitations:

- Not ideal for foam cutting.

- Higher initial cost compared to CO2 laser machines.

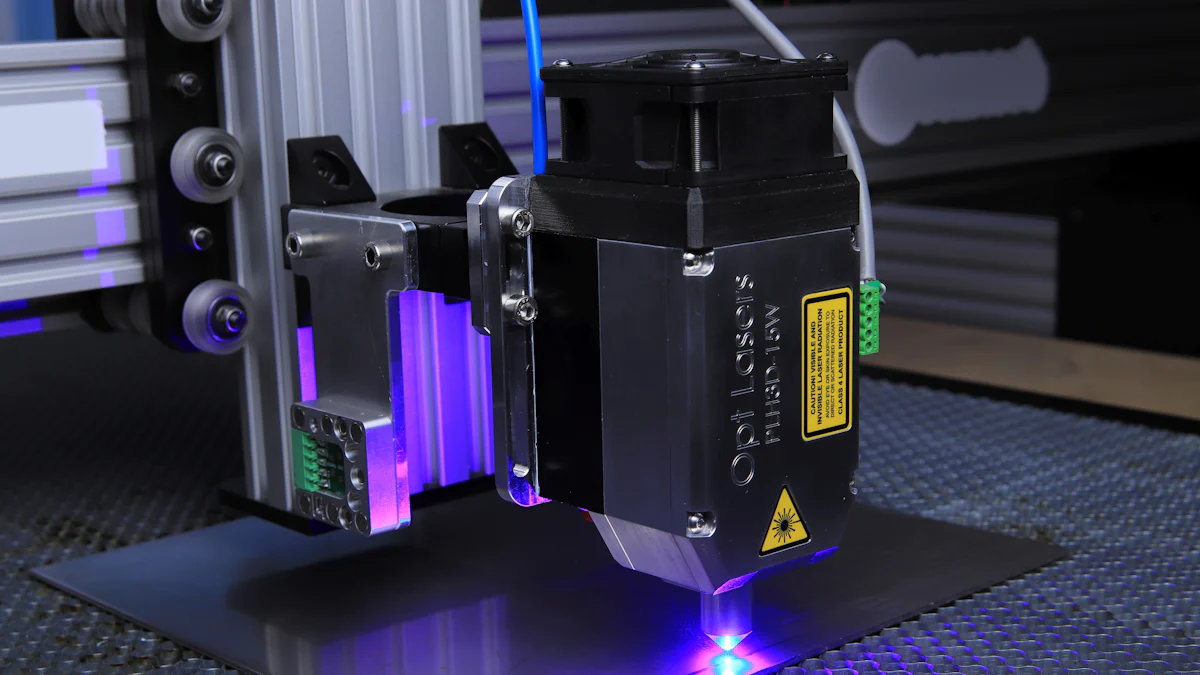

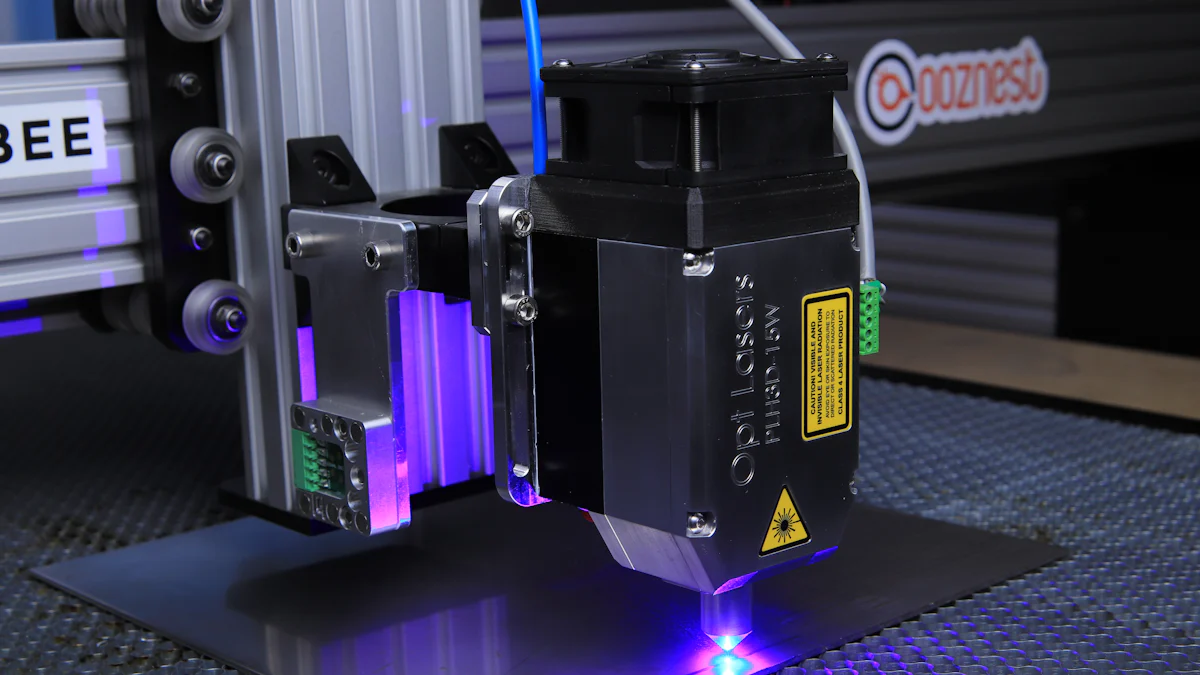

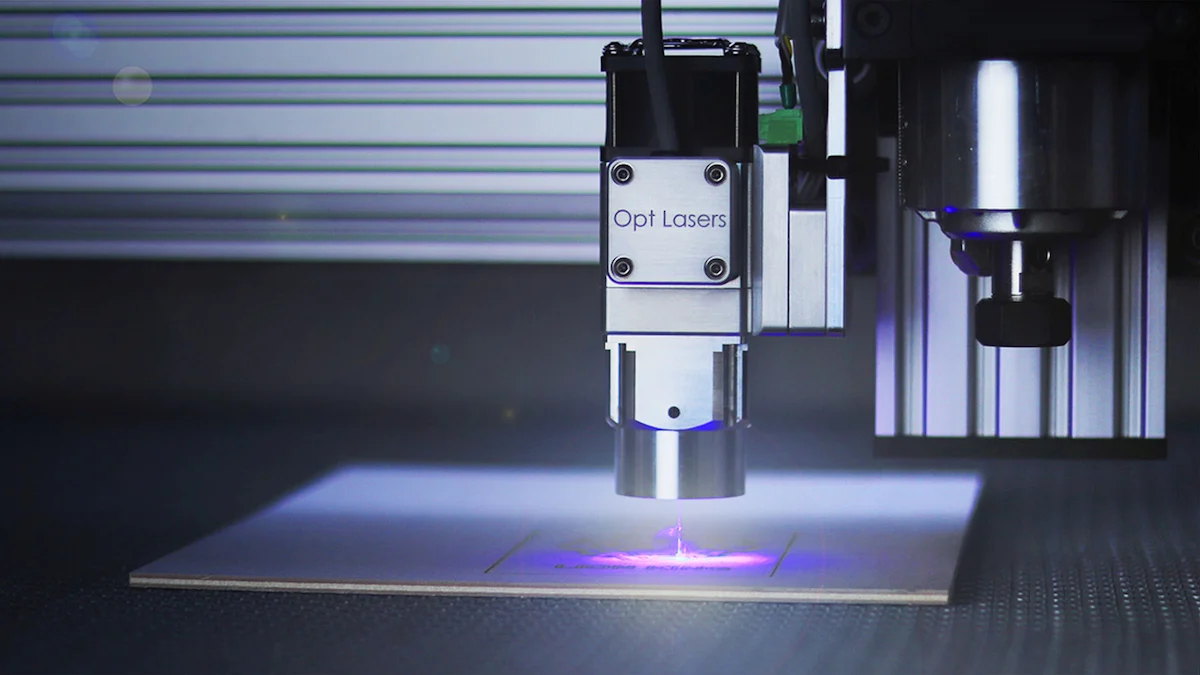

Diode Laser Machines

Diode laser machines use semiconductors to amplify light, making them compact and energy-efficient. They are suitable for engraving and cutting thin materials. However, they may not provide the same level of precision and power as CO2 laser machines when it comes to foam cutting.

-

Advantages:

- Compact and energy-efficient.

- Suitable for engraving and cutting thin materials.

-

Limitations:

- Limited power for cutting thicker foam.

- Less precision compared to CO2 laser machines.

Advantages and Disadvantages

Advantages of Laser Cutting Foam

When you choose laser cutting for foam, you unlock a host of benefits that enhance your projects. One of the primary advantages of laser cutting foam is its unparalleled precision. The technology allows you to achieve intricate designs with remarkable accuracy, ensuring each cut meets your exact specifications. This precision is crucial for applications where detail matters, such as in custom packaging or artistic creations.

Laser cutting also offers significant efficiency. The process minimizes material wastage, making it an environmentally friendly option. You can produce clean cuts without the need for additional finishing, saving both time and resources. Moreover, laser cutting machines operate with high performance, allowing you to complete projects faster compared to traditional methods.

Another advantage is the consistency in results. Whether you're working on a single piece or a large batch, laser cutting ensures uniformity across all items. This consistency is vital for maintaining quality standards in mass production.

Additionally, laser cutting foam is safe for the environment. The process is energy-efficient and reduces emissions, aligning with sustainable practices. You can also customize designs easily, offering flexibility in creating unique products tailored to specific needs.

Disadvantages of Laser Cutting Foam

Despite its many benefits, laser cutting foam does have some limitations. One of the main disadvantages of laser cutting is the initial cost of acquiring a laser cutting machine. These machines can be expensive, which might be a barrier for small businesses or hobbyists.

Another challenge is the learning curve associated with operating laser cutting equipment. You need to invest time in understanding the machine's settings and capabilities to maximize its performance. This requirement might deter those who prefer straightforward tools.

Laser cutting also has limitations in terms of material thickness. While it excels at cutting thin to medium foam sheets, it may struggle with thicker materials. You might need to explore alternative methods for cutting dense foam.

Maintenance is another consideration. Regular upkeep is necessary to ensure optimal performance and prolong the machine's lifespan. This maintenance includes cleaning lenses and checking alignment, which can be time-consuming.

Lastly, while laser cutting is excellent for engraving and cutting, it may not be suitable for all types of foam. Some foams might emit harmful fumes when cut, requiring proper ventilation and safety measures.

By weighing these advantages and disadvantages, you can make informed decisions about incorporating laser cutting into your foam processing projects. Understanding both sides helps you optimize the use of this technology to meet your specific needs.

Safety and Maintenance Considerations

When working with a laser CNC machine, safety and maintenance are crucial. These machines offer precision and efficiency, but they also require careful handling to ensure safe operation and longevity.

Safety Precautions

Operating a laser CNC machine involves certain risks. You must follow safety guidelines to protect yourself and others. Here are some key precautions:

-

Wear Protective Gear: Always wear safety goggles to shield your eyes from the laser beam. The intensity of the laser can cause serious eye damage.

-

Ensure Proper Ventilation: Laser cutting can produce fumes and particles. Make sure your workspace has adequate ventilation to prevent inhalation of harmful substances.

-

Follow Manufacturer Guidelines: Each laser CNC machine comes with specific instructions. Adhere to these guidelines to minimize risks. The ANSI B11.21 standard outlines safety requirements for machines using lasers, emphasizing the importance of following provided information.

-

Regular Training: Stay updated with training on laser safety. The NFPA 115 standard provides criteria for training and responding to fire emergencies involving lasers. Regular training ensures you know how to handle emergencies.

-

Emergency Procedures: Familiarize yourself with emergency shutdown procedures. Quick action can prevent accidents from escalating.

Maintenance Tips

Proper maintenance of your laser CNC machine ensures it operates efficiently and safely. Here are some maintenance tips:

-

Routine Cleaning: Regularly clean the machine's lenses and mirrors. Dust and debris can affect the laser's performance and precision.

-

Check Alignment: Ensure the laser beam is properly aligned. Misalignment can lead to inaccurate cuts and potential damage to the machine.

-

Inspect Components: Regularly inspect the machine's components for wear and tear. Replace any damaged parts promptly to maintain optimal performance.

-

Software Updates: Keep the machine's software up to date. Manufacturers often release updates to improve functionality and safety features.

-

Document Maintenance: Maintain a log of all maintenance activities. This record helps track the machine's condition and schedule future maintenance.

By adhering to these safety and maintenance practices, you can maximize the efficiency and lifespan of your laser CNC machine. Understanding these considerations not only enhances your safety but also ensures the machine delivers consistent, high-quality results.

Laser cutting foam offers precision and efficiency, making it a valuable tool for various applications. When selecting a laser machine, consider your specific needs and budget. For those new to the process, CO2 laser machines are often the best for beginners due to their versatility and ease of use. If you enjoy crafting, these machines are also the best for crafters, providing the ability to create intricate designs with ease. Always evaluate your requirements to choose the most suitable laser cutter for your projects.

FAQ

Can any type of foam be laser cut?

Not all foams are suitable for laser cutting. You can successfully cut common types like polyurethane foam, polyethylene foam, and EVA foam. The foam's composition and density determine its suitability for laser cutting. Always test a small piece first to ensure the material responds well to the laser.

Can intricate designs be laser cut on foam?

Absolutely! Laser cutting excels at creating intricate designs on foam. The precision of laser technology allows you to craft detailed patterns and shapes that would be challenging with traditional methods. This capability makes laser cutting an excellent choice for projects requiring high detail and accuracy.

Is laser-cut foam suitable for creating prototypes?

Yes, laser-cut foam is ideal for prototyping. Its precision and speed make it a valuable tool for quickly iterating designs. You can efficiently create prototypes across various industries, from packaging solutions to artistic creations. The ability to shape foam with laser precision opens new possibilities for customization and innovation.

What are the benefits of using laser cutting technologies for foam?

Laser cutting technologies offer several benefits for foam processing. You achieve clean and smooth edges without additional finishing. The process minimizes material wastage, making it environmentally friendly. Additionally, laser cutting provides consistent results, ensuring uniformity in mass production.

Are there any safety concerns when laser cutting foam?

Yes, safety is crucial when laser cutting foam. Always wear protective gear, such as safety goggles, to protect your eyes from the laser beam. Ensure proper ventilation in your workspace to avoid inhaling fumes. Follow the manufacturer's guidelines and stay updated with training on laser safety to minimize risks.

How does laser cutting compare to other cutting technologies for foam?

Laser cutting stands out for its precision and efficiency compared to other cutting technologies. It offers cleaner cuts and greater accuracy than methods like hot knives or waterjets. While other methods may have their advantages, laser cutting remains a top choice for projects requiring detailed and precise work.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Comparing CNC Machines and Laser Cutters for Acrylic

Maximizing Efficiency with Your Laser Cutting Machine

Understanding Laser Cutting Machines: Benefits and Drawbacks