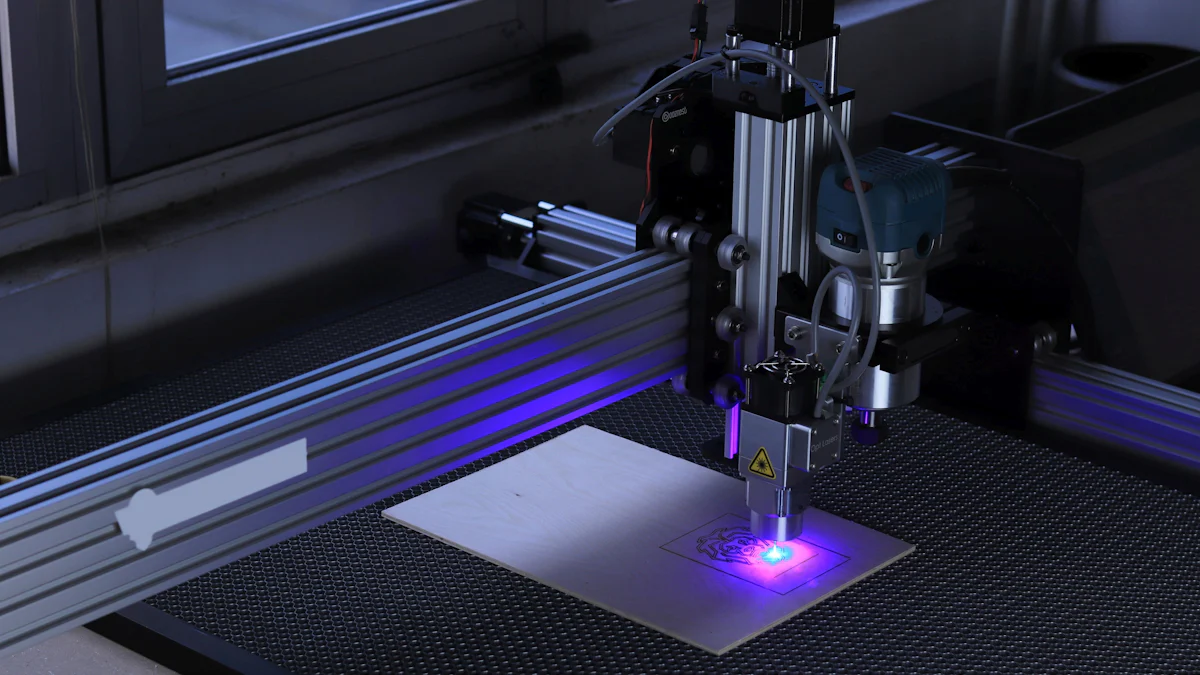

Can Laser Cutting Machine Be Used Indoors Safely?

You might wonder, can laser cutting machine be used indoor safely? The answer is yes, but only with the right precautions. Laser cutting machines offer precision and efficiency, yet they come with risks. Fire hazards and harmful emissions are primary concerns. To ensure laser cutter safety, you must manage indoor air quality. Proper ventilation and personal protective equipment like goggles and facemasks are essential. Additionally, understanding the potential for fires and taking steps to prevent them is crucial. By implementing these safety measures, you can safely enjoy the benefits of laser cutting indoors.

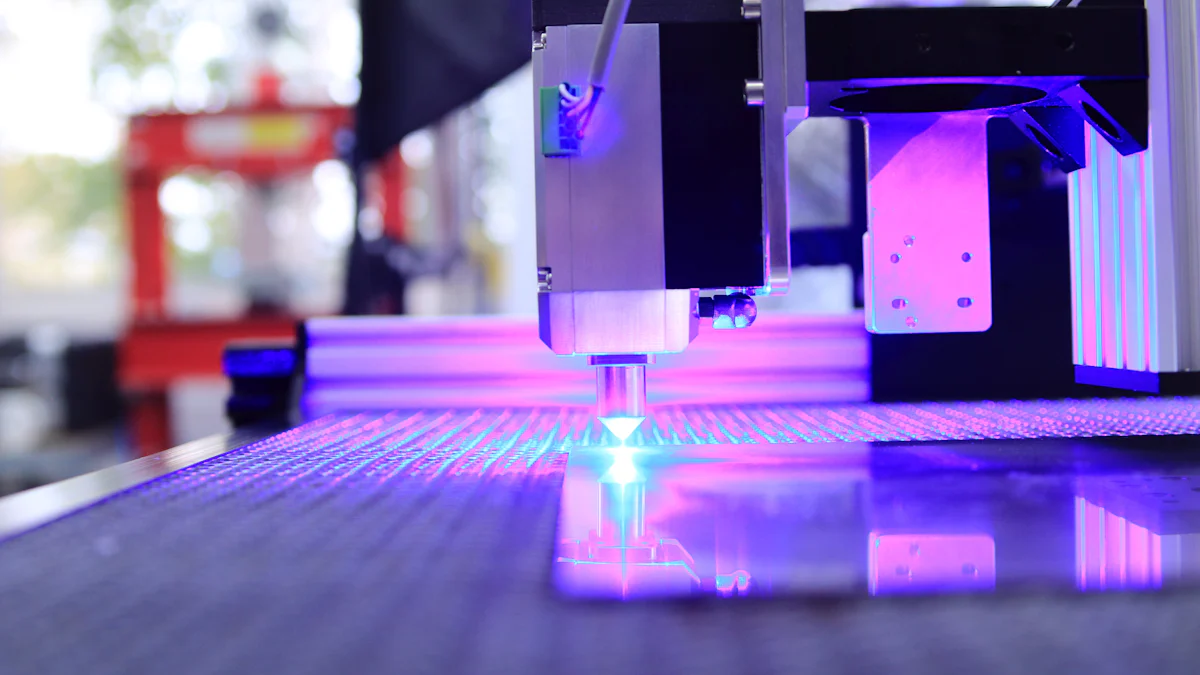

Ventilation and Air Quality

Ensuring proper ventilation is crucial when using a laser cutting machine indoors. Without it, you risk exposure to harmful fumes and potential fire hazards. Let's explore why ventilation is so important and how you can implement effective systems.

Importance of Proper Ventilation

Preventing Inhalation of Fumes

When you operate a laser cutting machine, it generates fumes that can be harmful if inhaled. These fumes often contain toxic substances that pose health risks. Proper ventilation helps remove these fumes from the air, reducing your exposure and keeping the environment safe. Studies emphasize that ventilation is essential to avoid exposure to harmful fumes and dust during laser cutting processes. By ensuring that your workspace is well-ventilated, you protect yourself and others from inhaling these dangerous emissions.

Ensuring Adequate Airflow

Adequate airflow is another critical aspect of maintaining a safe environment. You need to ensure that fresh air circulates continuously in the workspace. This circulation helps disperse fumes and prevents them from accumulating. A well-designed ventilation system will facilitate this airflow, ensuring that the air quality remains high and that you can work safely.

Air Filtration Systems

To further enhance safety, consider installing air filtration systems. These systems play a vital role in capturing and filtering out toxic fumes before they can spread.

Types of Filters

Different types of filters are available for air filtration systems. HEPA filters, for example, are highly effective at trapping small particles, including those found in laser cutting fumes. Activated carbon filters can also be used to absorb volatile organic compounds (VOCs) and other harmful gases. Choosing the right filter depends on the specific materials you are working with and the level of filtration required.

Installation and Maintenance

Proper installation and regular maintenance of your air filtration system are essential. Ensure that the system is correctly set up to capture fumes directly at the source. Regularly check and replace filters to maintain their effectiveness. A well-maintained fume exhaust system will significantly reduce the presence of toxic fumes, contributing to a safer working environment.

By prioritizing ventilation and air quality, you create a safer space for laser cutting activities. Implementing these measures not only protects your health but also enhances the overall safety of your operations.

Fire Safety

When using a laser cutting machine indoors, understanding fire safety is crucial. You must identify potential fire hazards and implement strategies to prevent them. This section will guide you through recognizing risks and adopting effective safety features.

Identifying Fire Risks

Laser cutting machines can pose significant fire hazards if not managed properly. Recognizing these risks is the first step in ensuring a safe working environment.

Flammable Materials

You should always be aware of the materials you are working with. Many materials used in laser cutting, such as wood, paper, and certain plastics, are highly flammable. These materials can ignite easily when exposed to the laser beam. To minimize fire hazards, store flammable materials away from the laser cutter and only bring them into the workspace when needed. Keeping your work area clean and free of unnecessary flammable items is a key safety feature.

Electrical Hazards

Electrical components of laser cutting machines can also present fire risks. Faulty wiring or overloaded circuits can lead to sparks and fires. Regularly inspect the machine's electrical systems to ensure they are in good condition. Avoid using extension cords or power strips that may not handle the machine's power requirements. By maintaining the electrical integrity of your equipment, you reduce the risk of fire hazards.

Fire Prevention Strategies

Implementing fire prevention strategies is essential for safe laser cutting operations. These strategies include having the right equipment and following safe operating procedures.

Fire Extinguishers and Alarms

Always have fire extinguishers and alarms readily accessible in your workspace. Fire extinguishers should be suitable for the types of fires that could occur, such as those involving electrical equipment or flammable materials. Ensure that you and your team know how to use them effectively. Fire alarms provide an early warning system, allowing you to respond quickly in case of a fire. Regularly check and maintain these safety features to ensure they function correctly.

Safe Operating Procedures

Adhering to safe operating procedures is vital in preventing fires. Never leave the laser cutter unattended while it is running. Monitor the machine closely to detect any signs of overheating or malfunction. Follow the manufacturer's guidelines for safe operation and maintenance. Establish clear emergency procedures so everyone knows what to do in case of a fire. Training and preparedness are key components of fire safety.

By understanding and addressing fire hazards, you can create a safer environment for laser cutting. Implementing these safety features and strategies will help protect you from injury and ensure that your operations run smoothly.

Protective Equipment

When operating a laser cutting machine, using the right protective equipment is crucial for your safety. This section will guide you through the necessary personal protective equipment (PPE) and additional safety gear to ensure a secure working environment.

Necessary Personal Protective Equipment (PPE)

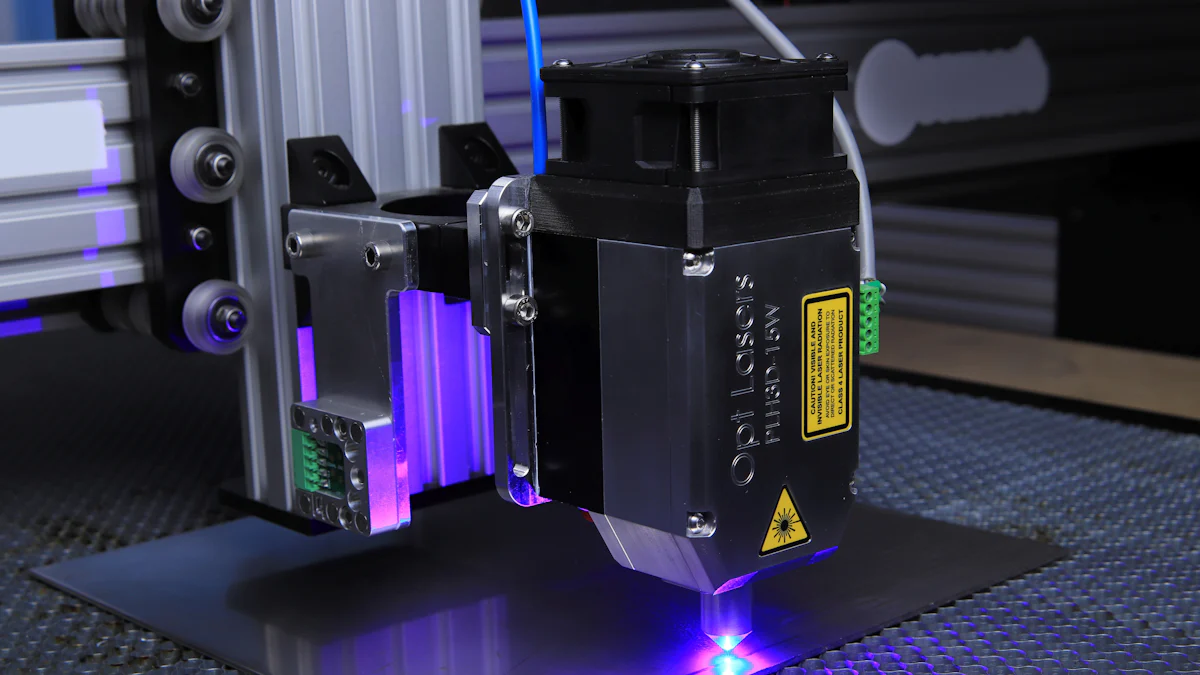

Eye Protection

Your eyes are particularly vulnerable when using a laser cutter. Laser beams can cause serious eye injury if you do not take proper precautions. Wearing goggles specifically designed for laser safety is essential. These goggles have lenses that absorb the laser's light, preventing it from reaching your eyes. The type of goggles you need depends on the laser's wavelength. For instance, blue or green goggles are suitable for diode lasers, while gray ones are ideal for CO2 lasers. Always ensure that your eye protection matches the laser type you are using.

Respiratory Protection

Laser cutting can produce toxic and corrosive fumes. To protect yourself from inhaling these harmful substances, you should wear a mask or respirator. This respiratory protection is vital, especially when cutting materials that emit dangerous fumes. Proper ventilation in your workspace complements the use of masks, ensuring that you breathe clean air while working.

Additional Safety Gear

Gloves and Clothing

Wearing thick gloves is another important safety measure. They protect your hands from potential burns and cuts. Additionally, wearing protective clothing shields your skin from sparks and debris. Choose clothing made from non-flammable materials to reduce fire risks. This gear forms a barrier between you and the hazards associated with laser cutting.

Hearing Protection

While laser cutters are not excessively loud, prolonged exposure to their noise can affect your hearing. Using earplugs or earmuffs provides the necessary hearing protection. This simple step ensures that your hearing remains intact, even after extended periods of operation.

By equipping yourself with the appropriate PPE and safety gear, you significantly reduce the risks associated with laser cutting. Prioritizing safety through these measures allows you to focus on your work without compromising your well-being.

Machine Maintenance

Regular maintenance of your laser cutting machine is crucial to ensure its optimal performance and longevity. By dedicating time to routine checks and professional servicing, you can prevent unexpected breakdowns and maintain the machine's efficiency.

Regular Maintenance Checks

Performing regular maintenance checks helps keep your laser cutting machine in top condition. These checks involve cleaning, inspecting, and replacing worn parts.

Cleaning and Inspection

You should clean your laser cutting machine regularly to prevent the buildup of dirt and debris. This buildup can affect the machine's performance and lead to malfunctions. Boss Laser emphasizes the importance of minimizing contaminants to maintain peak performance. Clean the lens and mirrors to ensure clear laser paths, and inspect the drive belts and guiderails for any signs of wear. Regular cleaning and inspection maximize the machine's output and extend its lifespan.

Replacing Worn Parts

Over time, certain parts of your laser cutting machine may wear out. Replacing these parts promptly is essential to avoid further damage. Check components like the laser tube and focus lens for signs of wear. If you notice any deterioration, replace the parts immediately to maintain the machine's efficiency. Rabbit Laser USA advises regular checks on these components to ensure optimal performance and save money in the long run.

Importance of Professional Servicing

While regular maintenance checks are vital, professional servicing provides an additional layer of care for your laser cutting machine. Scheduled maintenance and troubleshooting by experts ensure the machine runs smoothly.

Scheduled Maintenance

Scheduling professional maintenance at regular intervals keeps your laser cutting machine in excellent condition. Experts can perform detailed inspections and address any underlying issues that may not be apparent during routine checks. Thunder Laser highlights that regular maintenance increases the machine's durability and productivity. By adhering to a maintenance schedule, you reduce the likelihood of unexpected breakdowns.

Troubleshooting and Repairs

Professional servicing also involves troubleshooting and repairs. If your laser cutting machine encounters any issues, experts can diagnose and fix the problem efficiently. They have the knowledge and tools to address complex issues that may arise. By relying on professional servicing, you ensure that your machine receives the best care possible, enhancing its performance and lifespan.

Incorporating regular maintenance checks and professional servicing into your routine ensures that your laser cutting machine operates safely and efficiently. By taking these steps, you protect your investment and enjoy the benefits of a well-maintained machine.

Training and Supervision

Training and supervision are vital components in ensuring the safe operation of laser cutting machines. By equipping operators with the necessary knowledge and skills, you can significantly reduce the risks associated with laser cutting.

Operator Training Programs

Proper training programs are essential for anyone operating a laser cutting machine. These programs should cover all aspects of machine operation and safety protocols.

Understanding Machine Operation

Understanding how to operate a laser cutting machine is crucial for safety. Training programs should teach you about the machine's components, functions, and controls. You need to know how to start, stop, and adjust the machine safely. Familiarity with the machine's operation helps prevent accidents and ensures efficient use.

Safety Protocols

Safety protocols are a critical part of any training program. You must learn about the potential hazards associated with laser cutting, such as fire risks and harmful emissions. Training should include pre-operational checks to identify and mitigate these hazards. By understanding and following safety protocols, you can create a safer working environment.

Importance of Supervision

Supervision plays a key role in maintaining safety standards in laser cutting operations. It ensures that all operators adhere to established safety guidelines.

Monitoring New Operators

New operators require close monitoring to ensure they follow safety procedures correctly. Supervisors should observe their work and provide guidance as needed. This oversight helps new operators gain confidence and competence in using the machine safely.

Ensuring Compliance with Safety Standards

Supervisors must ensure that all operators comply with safety standards. Regular checks and audits can help identify any deviations from established protocols. By enforcing compliance, supervisors maintain a safe working environment and prevent accidents.

Incorporating comprehensive training and effective supervision into your laser cutting operations enhances safety and efficiency. These measures protect operators from hazards and ensure that laser cutting machines are used responsibly.

In conclusion, ensuring the safe use of laser cutting machines indoors requires a commitment to key safety precautions. You must adhere to safety guidelines, such as maintaining proper ventilation, using protective equipment, and conducting regular machine maintenance. Comprehensive training for all operators is essential, equipping them with the knowledge to handle potential hazards effectively. By prioritizing safety in every aspect of laser cutting operations, you not only protect yourself but also create a secure environment for everyone involved. Remember, safety is not just a guideline—it's a necessity.

FAQ

What are the important safety precautions for laser cutting?

When using a laser cutter, you must prioritize safety. The high-powered laser can cause permanent eye damage if exposed. Proper training and wearing the correct safety gear are essential. Never bypass any interlocks on the machine. Fire safety precautions are also critical due to the constant risk of fire during laser cutting. Here are some key safety precautions:

- Always wear laser safety goggles.

- Ensure proper ventilation to avoid inhaling fumes.

- Keep a fire extinguisher nearby.

- Regularly inspect the machine for any electrical hazards.

- Follow the manufacturer's guidelines for safe operation.

What are the potential risks associated with laser cutting machines?

Laser cutting machines come with several potential risks:

- Laser Radiation: High-intensity laser beams can cause severe eye injuries and skin burns.

- Fire Hazard: The heat generated can ignite flammable materials.

- Fumes and Gases: Harmful fumes and gases released can be toxic if inhaled.

- Electrical Hazards: Significant power usage poses risks of electric shock.

- Mechanical Risks: Moving parts can lead to physical injuries.

Understanding these risks helps you take necessary precautions.

Can laser cutting machines be used safely in schools?

Yes, laser cutting machines can be used safely in schools with proper safety measures. Educators must understand the potential hazards and implement protocols to mitigate risks. Training students on machine operation and safety protocols is crucial. Supervision ensures compliance with safety standards, creating a safe learning environment.

How does proper ventilation impact laser cutting safety?

Proper ventilation is vital for laser cutting safety. It helps remove harmful fumes and gases generated during the process. Without adequate ventilation, you risk inhaling toxic substances. Installing air filtration systems and ensuring continuous airflow in the workspace enhances safety and air quality.

Why is personal protective equipment (PPE) necessary for laser cutting?

Personal protective equipment (PPE) is necessary to protect you from potential hazards. Eye protection prevents laser beams from causing eye injuries. Respiratory protection shields you from inhaling toxic fumes. Gloves and protective clothing protect your skin from burns and cuts. Using PPE minimizes risks and ensures a safer working environment.

What role does machine maintenance play in laser cutting safety?

Regular machine maintenance is crucial for safety and performance. Cleaning and inspecting the machine prevent dirt buildup and malfunctions. Replacing worn parts ensures optimal operation. Scheduled professional servicing addresses underlying issues and enhances the machine's durability. Maintenance protects your investment and ensures safe operations.

How important is training for laser cutting machine operators?

Training is essential for laser cutting machine operators. It equips them with knowledge of machine operation and safety protocols. Understanding potential hazards and following safety guidelines reduce risks. Comprehensive training programs ensure operators handle the machine responsibly and safely.

What should you do in case of a fire during laser cutting?

In case of a fire, remain calm and follow these steps:

- Turn off the laser cutter immediately.

- Use a fire extinguisher to put out small fires.

- Evacuate the area if the fire is uncontrollable.

- Call emergency services for assistance.

- Ensure everyone is safe and accounted for.

Having a clear emergency plan and knowing how to use fire extinguishers effectively is crucial.

How can supervision enhance laser cutting safety?

Supervision ensures that operators adhere to safety standards. Monitoring new operators helps them follow procedures correctly. Regular checks and audits identify deviations from protocols. Supervision maintains a safe working environment and prevents accidents.

What are the benefits of using laser cutting machines indoors?

Using laser cutting machines indoors offers several benefits:

- Precision and Efficiency: Achieve accurate cuts with minimal waste.

- Versatility: Cut various materials like wood, acrylic, and metal.

- Cost-Effectiveness: Reduce material waste and production costs.

- Creative Freedom: Explore intricate designs and patterns.

By implementing safety measures, you can enjoy these benefits while ensuring a safe indoor environment.

See Also

Maximizing Efficiency With Your Laser Cutting Machine

Understanding Laser Cutting Machines in Industrial Applications

Comparing CNC Machines and Laser Cutters for Acrylic