Can a CNC Machine Cut Acrylic Better Than a Laser Cutter

When working with acrylic, the tools you choose can significantly impact the results. Laser cutters stand out for their unmatched precision, achieving tolerances as tight as 0.1 mm. They create smooth, polished edges by evaporating material particles during the cutting process. On the other hand, CNC machines excel in versatility, and many wonder, can a CNC machine cut acrylic? The answer is yes; they handle thicker acrylic sheets with ease and allow for intricate 3D carving. While laser cutters offer speed and accuracy, CNC machines provide flexibility and cost-effectiveness. Your decision depends on the specific needs of your project, including material thickness, desired finish, and budget.

Key Takeaways

Laser cutters provide unmatched precision, achieving tolerances as tight as 0.1 mm, making them ideal for intricate designs and smooth edges. CNC machines excel in cutting thicker acrylic sheets and allow for complex 3D carvings, offering versatility for various project needs.

- When speed is a priority, laser cutters are the faster option for thin acrylic, while CNC machines may take longer due to their physical cutting process.

- Consider your budget: CNC machines typically have a lower initial cost but may incur higher maintenance expenses, whereas laser cutters require a higher upfront investment but less ongoing upkeep.

- Safety is crucial; CNC machines generate debris that can pose fire hazards, while laser cutters produce fumes that require proper ventilation.

- Choose a laser cutter for detailed work on thin materials, and opt for a CNC machine for projects involving thicker materials or diverse material types.

- Evaluate your expertise level; laser cutters are generally easier for beginners, while CNC machines require more technical knowledge and experience.

Can a CNC Machine Cut Acrylic? Understanding the Basics

When deciding between tools for acrylic cutting, understanding the fundamentals of each machine is essential. Both CNC machines and laser cutters have unique capabilities that cater to different project needs. Let’s explore what makes each tool distinct.

What is a CNC Machine?

A CNC (Computer Numerical Control) machine is a versatile tool that uses a computer-controlled system to guide a cutting tool along precise paths. This machine operates by rotating a cutting bit at high speeds to carve, mill, or cut materials. You can use it on a variety of materials, including wood, metal, and acrylic.

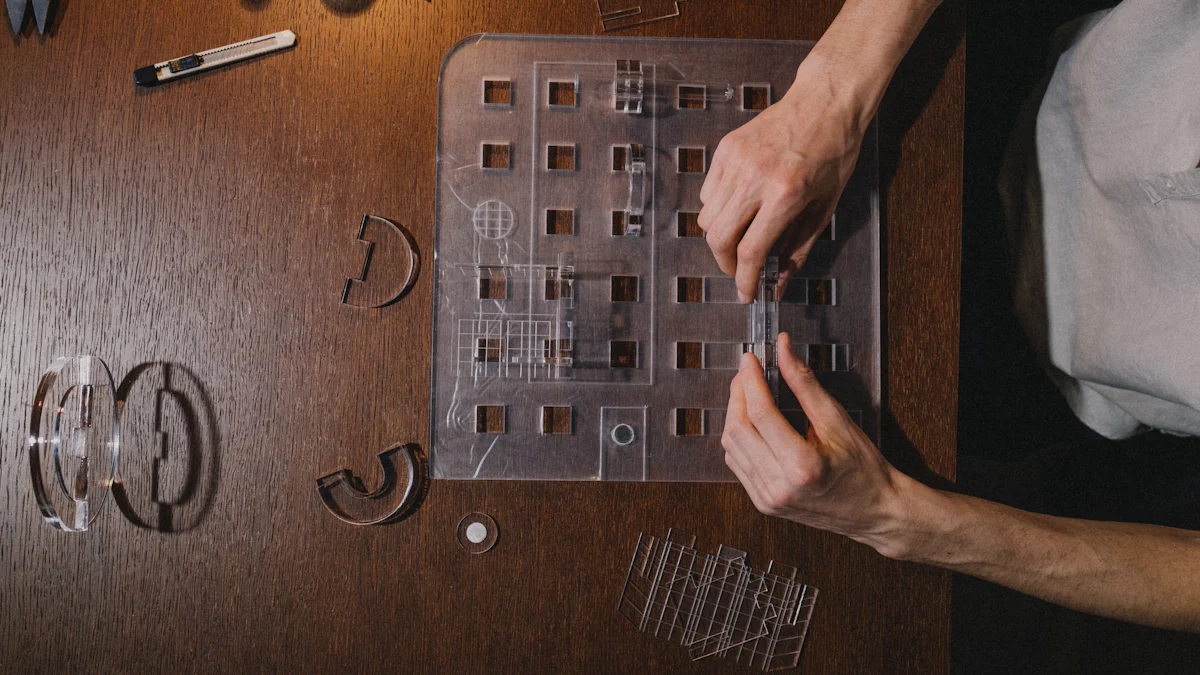

CNC machines excel in handling thicker acrylic sheets. They allow you to create intricate 3D carvings and designs that are difficult to achieve with other tools. For example, if you need to engrave patterns or shapes into a thick acrylic block, a CNC machine provides the flexibility to do so. However, the cutting process involves physical contact between the tool and the material, which may leave rough edges that require additional finishing.

Modern CNC machines automate most of the cutting process. Once you input the design specifications, the machine follows the programmed instructions to complete the task. This automation reduces manual effort and ensures consistent results. While CNC machines are highly capable, they require some expertise to operate effectively, especially when working with delicate materials like acrylic.

What is a Laser Cutter?

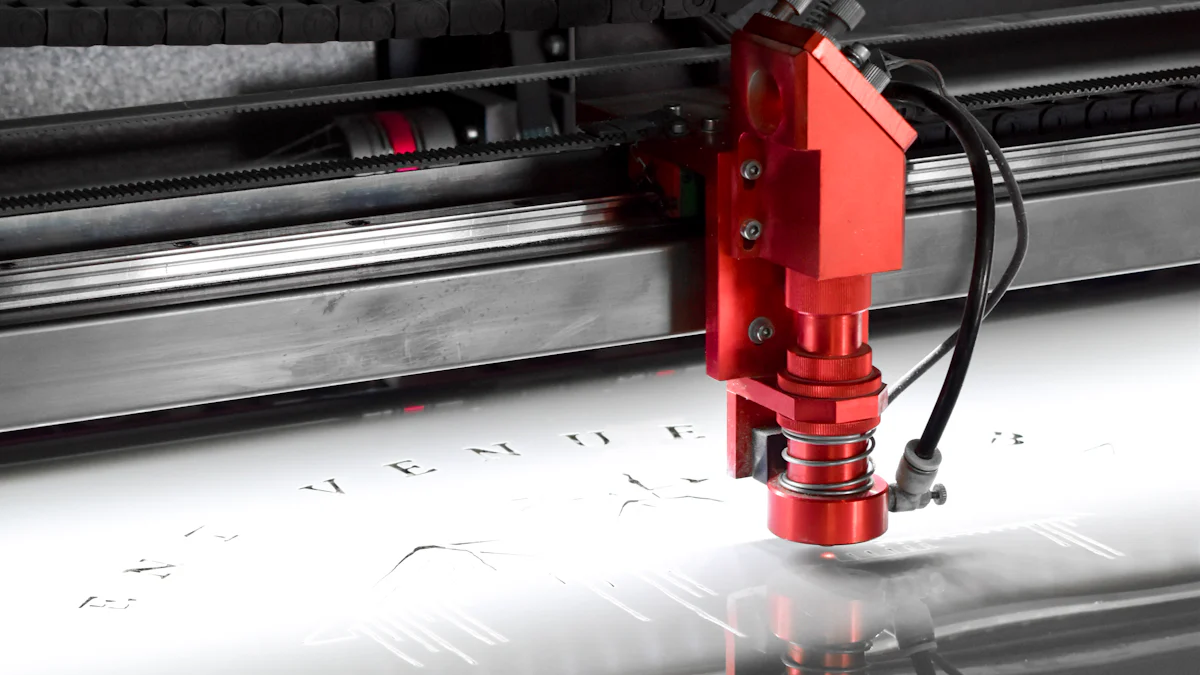

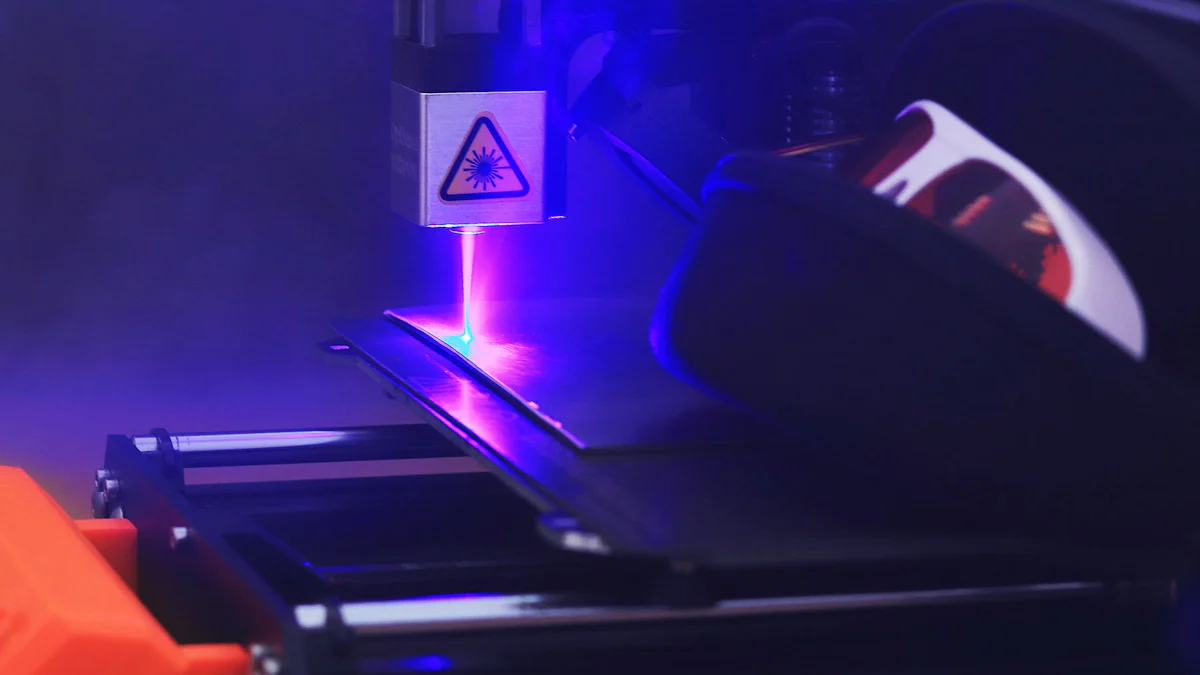

A laser cutter uses a focused beam of light to cut or engrave materials with exceptional precision. The laser beam, generated by sources like CO2 or fiber lasers, melts or vaporizes the material along the cutting path. This process creates smooth, polished edges without the need for post-processing.

Laser cutters are ideal for projects that demand high accuracy. For instance, they can achieve a cutting tolerance of +/-0.1 mm, making them perfect for intricate designs or detailed patterns on acrylic sheets. Unlike CNC machines, laser cutters do not require physical contact with the material. This non-contact method minimizes the risk of damage and ensures clean cuts.

Operating a laser cutter is relatively straightforward. After uploading your design, the machine handles the rest, including adjusting the laser’s speed and intensity. This simplicity makes laser cutters user-friendly, even for beginners. Additionally, they work well with thinner acrylic sheets, producing professional-grade results in less time compared to CNC machines.

Pro Tip: If your project involves cutting large acrylic sheets or creating personalized signs, a laser cutter can save time and deliver consistent quality.

Comparing CNC Machines and Laser Cutters for Acrylic Cutting

Precision and Edge Quality

When it comes to precision, laser cutters take the lead. They use a focused beam of light to achieve cutting tolerances as tight as 0.1 mm. This level of accuracy ensures smooth, polished edges, making laser cutters ideal for intricate designs or detailed patterns on acrylic sheets. The non-contact nature of laser cutting also eliminates the risk of tool marks or rough edges, which often require additional finishing.

CNC machines, on the other hand, rely on a rotating cutting tool to carve through materials. While they can deliver high accuracy, their precision depends on the size of the cutting bit and the complexity of the operation. For example, smaller bits can achieve finer details but may struggle with thicker acrylic. CNC machines often leave rough edges that need sanding or polishing to achieve a clean finish. However, they excel in creating 3D carvings and designs, offering versatility that laser cutters cannot match.

Quick Tip: If your project demands flawless edges and intricate details, a laser cutter is the better choice. For thicker acrylic or 3D designs, a CNC machine provides more flexibility.

Cutting Speed and Efficiency

Laser cutters are known for their speed. They can cut through thin acrylic sheets quickly, making them a time-efficient option for projects requiring high precision. The automated process of laser cutting reduces setup time, as there’s no need to secure the material with clamps or fixtures. This efficiency makes laser cutters a popular choice for mass production or repetitive tasks.

CNC machines, while slower, offer a different kind of efficiency. They can handle a wide range of materials and thicknesses, allowing you to complete diverse projects without switching tools. However, the cutting process involves physical contact, which can slow down operations, especially when working with thicker acrylic. Additionally, CNC machines require more setup time, as you need to secure the material and adjust the cutting tool for each project.

Did You Know? Laser cutters can save you time on thin acrylic projects, but CNC machines shine when versatility and material variety are priorities.

Material Compatibility and Thickness

Material compatibility is another key factor to consider. Laser cutters work best with thinner acrylic sheets, typically up to 12-13 mm thick. Some advanced models can handle materials up to 30 mm, but this is less common. Laser cutters also struggle with certain materials, such as PVC or leather, due to the risk of harmful fumes or damage to the machine.

CNC machines, however, excel in cutting thicker acrylic and a broader range of materials. They can easily handle acrylic blocks several inches thick, making them suitable for heavy-duty projects. Unlike laser cutters, CNC machines can process materials like wood, metal, and even soft plastics, offering unmatched versatility.

Pro Tip: Choose a CNC machine if your project involves thick acrylic or multiple material types. For thinner acrylic sheets and clean cuts, a laser cutter is the way to go.

Cost and Maintenance

When choosing between a CNC machine and a laser cutter, understanding the cost and maintenance requirements is crucial. Both machines represent significant investments, but their long-term expenses differ.

CNC machines generally have a lower upfront cost compared to laser cutters. This affordability makes them an attractive option for small businesses or hobbyists. However, the ongoing maintenance of CNC machines can add to the overall expense. The cutting tools wear out over time and need regular replacement. Additionally, you must frequently clean and lubricate the mechanical components to ensure smooth operation. Neglecting maintenance can reduce accuracy and lead to costly repairs.

Laser cutters, while more expensive initially, often have lower maintenance demands. The primary upkeep involves cleaning the laser lens and replacing the laser tube when it wears out. High-quality laser tubes can last thousands of hours, making them a durable choice for frequent use. Laser cutters also require less manual intervention during operation, which reduces wear and tear on the machine. Despite the higher purchase price, the reduced maintenance effort can make laser cutters a cost-effective option in the long run.

Quick Tip: If you prioritize a lower initial investment, a CNC machine might suit your needs. For reduced maintenance and long-term reliability, consider a laser cutter.

Safety and Environmental Considerations

Safety should always be a top priority when working with cutting tools. Both CNC machines and laser cutters come with unique safety challenges that you need to address.

CNC machines involve physical contact between the cutting tool and the material. This contact generates debris, such as acrylic shavings, which can pose a fire hazard if not managed properly. You should always use protective eyewear and ensure proper ventilation to minimize risks. Additionally, securing the material firmly is essential to prevent accidents caused by shifting during operation.

Laser cutters, on the other hand, use a focused beam of light to cut materials. This process produces fumes and gases, especially when cutting acrylic or other plastics. Without adequate ventilation or an air filtration system, these emissions can harm your health and the environment. Laser cutters also pose a risk of burns or eye damage if the laser beam is mishandled. Always follow safety guidelines, such as wearing protective glasses and keeping the machine’s enclosure closed during operation.

Pro Tip: Install a dust collection system for CNC machines and an air filtration unit for laser cutters to maintain a safe and clean workspace.

Environmentally, CNC machines generate more physical waste, such as chips and shavings, which require proper disposal. Laser cutters produce less waste but may release harmful fumes depending on the material. Choosing eco-friendly materials and maintaining your equipment can help reduce the environmental impact of both machines.

Did You Know? Laser cutters are more environmentally friendly when paired with a high-quality filtration system, while CNC machines require careful waste management to minimize their ecological footprint.

Practical Considerations for Choosing Between CNC and Laser

When deciding between a CNC machine and a laser cutter, you need to evaluate several practical factors. These considerations will help you choose the right tool for your specific needs.

Type of Projects

The type of project you plan to undertake plays a significant role in your decision. Laser cutters excel in projects that require intricate designs, fine details, or smooth edges. For example, if you are creating custom signs, jewelry, or decorative pieces from thin acrylic sheets, a laser cutter delivers professional results with minimal effort. Its precision ensures clean cuts and polished edges without additional finishing.

CNC machines, however, shine in projects involving thicker acrylic or 3D carving. If your work includes engraving patterns into thick acrylic blocks or creating complex three-dimensional designs, a CNC machine offers the flexibility you need. It can also handle a wider range of materials, making it ideal for diverse projects. For instance, you can use a CNC machine to cut wood, metal, or even soft plastics alongside acrylic.

Quick Tip: Choose a laser cutter for detailed designs on thin acrylic. Opt for a CNC machine if your project involves thicker materials or requires versatility.

Budget and Long-Term Investment

Your budget and long-term investment goals are critical when selecting between these tools. CNC machines typically have a lower initial cost compared to laser cutters. This affordability makes them a popular choice for small businesses or hobbyists. However, CNC machines require regular maintenance, including replacing cutting tools and calibrating moving parts. These ongoing expenses can add up over time.

Laser cutters, on the other hand, come with a higher upfront cost but demand less maintenance. You only need to clean the laser lens and occasionally replace the laser tube. High-quality laser tubes last thousands of hours, reducing the frequency of replacements. While the initial investment may seem steep, the lower maintenance requirements make laser cutters a cost-effective option in the long run.

Expert Insight: According to experts, "CNC machines typically have a lower initial cost but may incur higher maintenance expenses due to the numerous moving parts." This highlights the importance of considering both upfront and ongoing costs.

Pro Tip: If you prioritize a lower initial investment, a CNC machine might suit your needs. For reduced maintenance and long-term reliability, consider a laser cutter.

User Expertise and Learning Curve

The level of expertise required to operate each machine varies. Laser cutters are generally easier to use, even for beginners. Once you upload your design, the machine handles most of the process, including adjusting the laser’s speed and intensity. This simplicity reduces the learning curve and allows you to focus on your creative projects.

CNC machines, however, demand more technical knowledge. You need to understand how to secure the material, select the appropriate cutting tools, and program the machine for precise operations. While modern CNC machines automate many tasks, achieving consistent results still requires practice and experience. If you are new to machining, you may need additional training to operate a CNC machine effectively.

Did You Know? Laser cutters are less dependent on human labor, making them easier to manage for beginners. CNC machines, while versatile, require more expertise to achieve high-quality results.

Quick Tip: If you are a beginner, start with a laser cutter for its user-friendly operation. For advanced users seeking flexibility, a CNC machine offers greater control and customization.

When cutting acrylic, your choice between a CNC machine and a laser cutter depends on your project’s specific needs. Laser cutters excel in delivering precise cuts with smooth, polished edges, making them ideal for intricate designs. CNC machines, however, handle thicker acrylic with ease and allow for detailed 3D carving.

Expert Insight: Specialists from CAMaster emphasize that CNC routers work best for heavy-duty projects, while laser cutters shine in precision tasks.

Consider your budget, expertise, and material requirements. Both tools offer unique strengths. Understanding these differences ensures you select the right machine to achieve the best results for your projects.

FAQ

Can a CNC machine cut acrylic as precisely as a laser cutter?

No, CNC machines cannot match the precision of laser cutters. Laser cutters achieve cutting tolerances as tight as +/-0.1 mm, delivering smooth and polished edges. CNC machines rely on rotating cutting tools, which often leave rough edges that require additional finishing. If your project demands intricate details or flawless edges, a laser cutter is the better choice.

Which machine is better for cutting thicker acrylic?

CNC machines excel at cutting thicker acrylic. They can handle acrylic blocks several inches thick with ease, making them ideal for heavy-duty projects. Laser cutters, on the other hand, work best with thinner acrylic sheets, typically up to 12-13 mm thick. For projects involving thick materials, a CNC machine provides better results.

Are laser cutters easier to use than CNC machines?

CNC machines require more technical knowledge, such as securing the material, selecting the right cutting tools, and programming the machine.

Which machine is more cost-effective for small businesses?

For small businesses, the choice depends on your needs. CNC machines have a lower initial cost, making them a budget-friendly option for startups. However, they require regular maintenance, such as replacing cutting tools and lubricating components. Laser cutters have a higher upfront cost but demand less maintenance over time. If you plan to use the machine frequently, a laser cutter may offer better long-term value.

Can I use both machines for different projects?

Yes, having both machines can expand your capabilities. Laser cutters excel in precision tasks, such as creating intricate designs on thin acrylic sheets. CNC machines handle thicker materials and allow for 3D carving. Owning both tools lets you tackle a wider range of projects, from detailed decorative pieces to heavy-duty industrial tasks.

What safety precautions should I take when using these machines?

Both machines require proper safety measures. For CNC machines, wear protective eyewear and ensure good ventilation to manage debris like acrylic shavings. Secure the material firmly to prevent accidents. For laser cutters, use protective glasses and keep the machine’s enclosure closed during operation. Install an air filtration system to handle fumes produced during cutting.

Pro Tip: Always follow the manufacturer’s safety guidelines and maintain a clean workspace to minimize risks.

Which machine is better for eco-friendly projects?

Laser cutters are more environmentally friendly when paired with a high-quality filtration system. They produce less physical waste compared to CNC machines, which generate chips and shavings. However, CNC machines can process a wider range of materials, allowing you to choose eco-friendly options like recycled acrylic or sustainable wood.

Can I use these machines for materials other than acrylic?

Yes, both machines work with various materials. CNC machines are highly versatile and can cut wood, metal, and soft plastics in addition to acrylic. Laser cutters excel with non-metallic materials like wood, paper, and fabric. However, avoid using laser cutters on materials like PVC, as they release harmful fumes.

How do I decide which machine to buy?

Consider your project needs, budget, and expertise. If you work with thin materials and need precise cuts, a laser cutter is ideal. For thicker materials or 3D designs, a CNC machine offers more flexibility. Evaluate the types of projects you plan to undertake and the materials you’ll use. This decision ensures you invest in the right tool for your goals.

Quick Tip: If you’re starting a small business or working from home, a desktop laser cutter can be a cost-effective option for creating DIY items or specialized parts.

Is it worth investing in a machine for personal use?

Yes, investing in a machine can be worthwhile if you frequently work on creative or DIY projects. A laser cutter is perfect for crafting intricate designs, while a CNC machine offers versatility for diverse materials. For home use or small shops, a compact or desktop model provides excellent functionality without taking up too much space.

See Also

10 Best Acrylic Cutting Machines For Accurate Results

Effective Techniques For Utilizing Laser Cutting Machines

Understanding CNC Cutting Machines And Their Varieties