Guide to Buying a Paper Laser Cutting Machine

Choosing the right paper laser cutting machine can transform your creative projects. Laser cutting technology offers precision and efficiency, making it an essential tool for artists and businesses alike. The U.S. market for laser cutting machines is projected to grow significantly, reaching USD 1.95 billion by 2030. This growth highlights the increasing demand for these machines. When considering how much is a paper laser cutting machine, it's crucial to weigh factors like budget and material compatibility. A well-informed decision ensures you harness the full potential of this innovative technology for cutting paper.

Types of Laser Cutting Machines

When exploring laser cutting equipment, you will encounter various types, each with unique capabilities. Understanding these differences helps you choose the right laser cutter machine for your needs.

CO2 Laser Cutting Machines

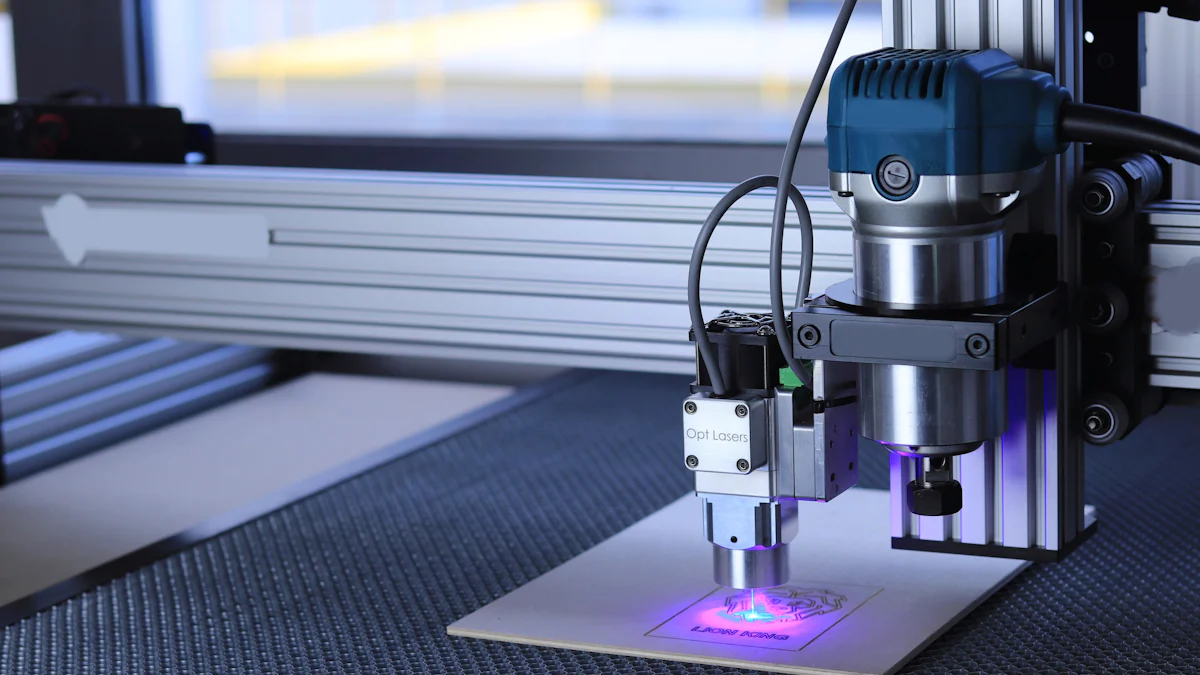

CO2 laser cutting machines are among the most popular choices for cutting a wide range of materials. These machines use CO₂ gas to generate a laser beam, which is then focused onto the material's surface. The wavelength of the CO2 laser cutter, typically around 10.6μm, makes it ideal for cutting non-metal materials like wood, plastic, and paper. You will find CO2 laser cutters particularly effective for intricate designs and detailed work due to their precision.

These machines are widely used in industries such as textiles, woodworking, and even in artistic applications. Their versatility and affordability make them a go-to option for many users. However, if you plan to cut metals, you might need to consider other types of laser cutting equipment.

Fiber Laser Cutting Machines

Fiber laser cutting machines represent a more advanced technology compared to CO2 lasers. They use a fiber optic cable to produce the laser beam, which allows for faster cutting speeds and higher efficiency. Fiber laser cutters excel in cutting metals, including steel and aluminum, due to their high power output, which can range from 500W to 8000W.

The speed of a fiber laser cutter can exceed 30 meters per minute, making it significantly faster than CO2 laser cutting machines. This speed and power make fiber lasers suitable for industrial applications where time and precision are critical. Although they are more expensive, the investment can be worthwhile if you require high-speed cutting of thicker materials.

Key Considerations When Buying

When you decide to purchase a laser cutting machine, several factors come into play. Understanding these elements ensures you make an informed decision that aligns with your needs and expectations.

Budget

Your budget plays a crucial role in determining the type of laser cutter you can afford. Setting a clear budget helps you narrow down your options and focus on machines that fit within your financial constraints. While more affordable options exist, they might require significant tinkering and modifications for optimal performance. These budget-friendly machines often lack customer support and may have quality control issues. Investing in a higher-quality machine might save you from future headaches and additional costs.

Material Compatibility

Consider the types of materials you plan to cut. Different laser cutting machines excel with specific materials. For instance, CO2 laser cutters are ideal for non-metal materials like paper, wood, and plastic. If you intend to work with metals, a fiber laser cutter might be more suitable. Ensuring your machine is compatible with the materials you use most frequently will enhance your cutting speed and precision, leading to better results.

Machine Power

The power of a laser cutting machine directly affects its cutting speed and precision. Machines with higher power can cut through thicker materials more efficiently. However, for thin materials like paper, a lower-wattage machine might suffice. Assess your needs based on the thickness and type of materials you plan to work with. This assessment will guide you in selecting a machine that offers the right balance of power and accuracy for your projects.

Size and Workspace Requirements

When selecting a paper laser cutting machine, consider the size and workspace requirements. The machine's dimensions should fit comfortably in your designated area. Measure your available space before purchasing to ensure a proper fit. A compact machine might be ideal for small workshops or home studios, while larger models suit industrial settings.

Evaluate the cutting area of the machine. A larger cutting area allows you to work on bigger projects without repositioning the material. This feature enhances efficiency and precision. However, larger machines often require more space and may come with higher costs. Balance your workspace constraints with your project needs to find the right machine size.

Safety Features

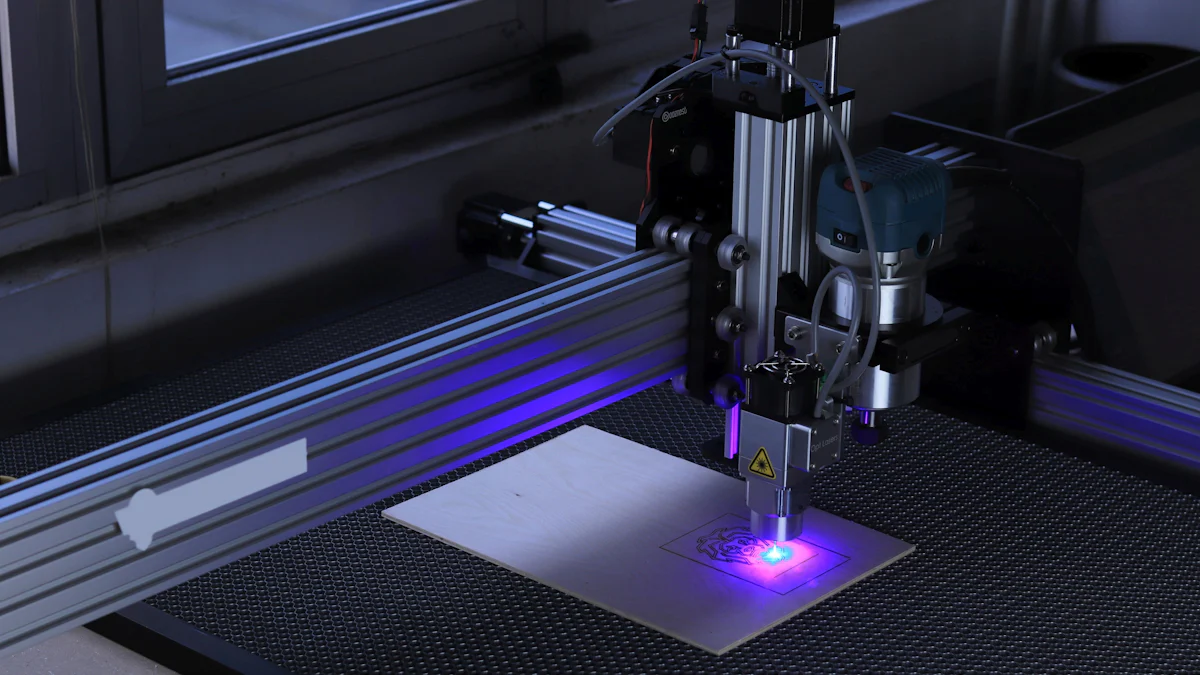

Safety is paramount when operating a laser cutting machine. Look for machines equipped with essential safety features to protect you and your workspace. A reliable machine should have an emergency stop button. This feature allows you to halt operations immediately in case of an emergency.

Consider machines with safety enclosures or covers. These components prevent accidental exposure to the laser beam. They also help contain debris and fumes generated during cutting. Machines with built-in ventilation systems enhance safety by reducing harmful fumes and maintaining air quality.

Some machines offer safety interlocks. These mechanisms disable the laser if the enclosure is open, preventing accidental exposure. Additionally, look for machines with clear safety instructions and user manuals. Understanding how to operate the machine safely is crucial for preventing accidents.

Prioritize machines with robust customer support. Access to technical assistance ensures you can address safety concerns promptly. Investing in a machine with comprehensive safety features not only protects you but also prolongs the machine's lifespan.

Cost Analysis

When considering a laser cutter purchase, understanding the cost dynamics is crucial. The price of a paper laser cutting machine varies widely based on several factors, including the type, power, and additional features. Let's delve into how much is a paper laser cutting machine and what you can expect for your budget.

How Much is a Paper Laser Cutting Machine

The price of a paper laser cutting machine can range from a few hundred dollars to several thousand. Entry-level models, often referred to as affordable laser cutters, start around $300 to $500. These machines are suitable for hobbyists or small-scale projects. They offer basic functionality but may lack advanced features and robust customer support.

Mid-range laser cutters, priced between $1,000 and $3,000, provide a balance of quality and cost-effectiveness. These machines often include enhanced safety features, such as enclosed cutting areas and emergency stop buttons, ensuring safe operation. For instance, the OMTech K40 model prioritizes safety with its enclosed design and fire detection systems, making it a reliable choice for working with combustible materials like paper.

High-end laser cutting machines, which can exceed $5,000, cater to professional and industrial needs. These machines boast superior power, precision, and durability. They often come with advanced features like software compatibility and extensive warranties, ensuring long-term reliability and performance.

What to Expect for Your Budget

When planning your laser cutter purchase, it's essential to align your budget with your needs and expectations. Here's a breakdown of what you can expect at different price points:

-

Under $500: Basic models with limited features. Suitable for simple projects and occasional use. Expect minimal customer support and potential quality control issues.

-

$1,000 - $3,000: Mid-range options offering a good balance of price and quality. These machines typically include safety features and better material compatibility. They are ideal for small businesses or serious hobbyists.

-

Above $5,000: High-end machines designed for professional use. These models provide exceptional precision, speed, and durability. They often include comprehensive warranties and robust customer support, ensuring peace of mind.

When evaluating the cost, consider not only the initial price but also the long-term cost-effectiveness. Investing in a higher-quality machine might save you from frequent repairs and replacements, ultimately proving more economical. Additionally, factor in potential additional costs such as maintenance, materials, and safety equipment.

Understanding how much is a paper laser cutting machine and what to expect for your budget will help you make an informed decision. By aligning your financial plan with your project requirements, you can choose a laser cutter that offers the best value for your investment.

Additional Features

When selecting a laser cutter, you should consider additional features that enhance the machine's functionality and user experience. These features can significantly impact your satisfaction and the machine's performance over time.

Software Compatibility

Software compatibility plays a crucial role in the operation of a laser cutter. You need to ensure that the machine you choose works seamlessly with the design software you prefer. Many laser cutters come with proprietary software, which might limit your design capabilities. However, some models offer compatibility with popular design programs like Adobe Illustrator or CorelDRAW. This flexibility allows you to create intricate designs with ease.

Additionally, look for machines that support various file formats. This feature ensures you can import and export designs without hassle. A user-friendly interface in the software can also enhance your experience, making it easier to navigate and execute your projects efficiently.

Customer Support and Warranty

Customer support and warranty are vital considerations when purchasing a laser cutter. A robust support system ensures you receive timely assistance if you encounter issues with your machine. Manufacturers that offer comprehensive customer support often provide resources like tutorials, troubleshooting guides, and direct contact options for technical help.

The warranty is another critical aspect to evaluate. A good warranty protects your investment by covering repairs or replacements for defective parts. Most laser cutters come with a standard warranty period, but some manufacturers offer extended warranties for added peace of mind. You should check the warranty terms carefully to understand what is covered and for how long.

"A reliable warranty can save you from unexpected expenses and downtime," says industry expert John Doe. "It's essential to choose a machine backed by a strong warranty and excellent customer support."

When buying a laser cutting machine, focus on key factors to make an informed choice. Consider the type of laser cutter that suits your material needs, whether it's a CO2 or fiber laser. Evaluate your budget and ensure the machine offers the necessary power and safety features. Software compatibility is crucial; choose a laser cutter that works with popular design software like Adobe Illustrator. Prioritize machines with robust customer support and warranties. By understanding these elements, you can select a laser cutting machine that enhances your projects and provides long-term value.

FAQ

What should I consider before buying a paper laser cutting machine?

Before purchasing a paper laser cutting machine, you should consider several factors. Think about the types of materials you plan to cut and the laser type that suits your needs. Evaluate the machine's power and accuracy. Consider environmental protection features and cost-effectiveness. Listing your demands helps you compare options across various aspects.

How important is it to understand the technical aspects of laser cutting machines?

Understanding the technical aspects of laser cutting machines is crucial. It helps you make an informed decision. Knowledge about laser types, power requirements, and material compatibility ensures you choose a machine that meets your needs. Researching these aspects can prevent costly mistakes and enhance your cutting projects.

How does my budget affect my choice of a laser cutting machine?

Your budget significantly influences your choice of a laser cutting machine. Establishing a budget upfront helps narrow down your options. It allows you to prioritize essential features. Knowing your budget also enables you to explore financing options or consider purchasing a refurbished machine. This approach ensures you get the best value for your investment.

What are the differences between CO2 and fiber laser cutting machines?

CO2 and fiber laser cutting machines differ in their applications and capabilities. CO2 lasers are ideal for cutting non-metal materials like paper, wood, and plastic. They offer precision for intricate designs. Fiber lasers excel in cutting metals due to their high power output. They provide faster cutting speeds and are suitable for industrial applications.

How do I determine the right machine power for my projects?

To determine the right machine power, assess the thickness and type of materials you plan to cut. Higher power machines cut thicker materials more efficiently. For thin materials like paper, a lower-wattage machine might suffice. Balancing power and accuracy ensures optimal performance for your specific projects.

What safety features should I look for in a laser cutting machine?

When choosing a laser cutting machine, prioritize safety features. Look for machines with an emergency stop button and safety enclosures. These features protect you from accidental exposure to the laser beam. Machines with built-in ventilation systems reduce harmful fumes. Safety interlocks prevent operation if the enclosure is open, enhancing overall safety.

Can I use any design software with my laser cutter?

Not all laser cutters are compatible with every design software. Ensure the machine you choose works with your preferred software. Some models offer compatibility with popular programs like Adobe Illustrator or CorelDRAW. This flexibility allows you to create intricate designs easily. Check for support of various file formats to ensure seamless design import and export.

How does customer support and warranty impact my purchase decision?

Customer support and warranty play vital roles in your purchase decision. A robust support system provides timely assistance for any issues. Manufacturers offering comprehensive support often provide tutorials and troubleshooting guides. A good warranty protects your investment by covering repairs or replacements for defective parts. Evaluate warranty terms carefully to understand coverage and duration.

What are the long-term costs associated with owning a laser cutting machine?

Owning a laser cutting machine involves long-term costs beyond the initial purchase price. Consider maintenance expenses, replacement parts, and materials. Investing in a higher-quality machine might save you from frequent repairs. Factor in safety equipment costs to ensure safe operation. Understanding these costs helps you plan your budget effectively.

How can I ensure I make the right choice when buying a laser cutting machine?

To ensure you make the right choice, consider your needs and budget. Evaluate the materials you plan to cut and the type of laser that suits your projects. Research technical aspects and prioritize essential features. Compare different models and read reviews. Making an informed decision ensures you select a machine that enhances your creative endeavors.

See Also

Comparative Analysis of Laser Cutting Machines Explained

Maximizing Efficiency with Your Laser Cutting Machine

Guidelines for Selecting the Ideal Water Jet Cutter

Understanding Laser Cutting Machines and Their Varieties

Comprehensive Instructions for Operating Hair Cutting Machines