Tips for Buying a Laser Cutting Machine

When you're in the market for a laser cutting machine, knowing the essential tips can make all the difference. The global laser cutting machines market is booming, with a projected growth from *USD 5,736.4 million in 2024 to USD 10,192.50 million by 2032*. This growth highlights the importance of making an informed decision. You need to consider factors like budget, material compatibility, and where to buy a laser cutting machine. By understanding these elements, you ensure that your investment aligns with your needs and future goals.

Budget Considerations

When you're buying a laser cutting machine, budget considerations play a crucial role. You need to weigh the initial cost against the long-term investment. Let's break it down:

Initial Cost vs. Long-term Investment

The initial cost of a laser cutting machine can be substantial. You might feel the pinch when you first see the price tag. However, think of it as an investment. A high-quality machine often pays for itself over time. It offers durability and efficiency, reducing the need for frequent replacements or repairs. Consider the machine's longevity and how it aligns with your business goals. A more expensive model might offer better features, like higher power or larger cutting areas, which can enhance productivity and profitability in the long run.

Financing Options and Leasing

If the upfront cost seems daunting, explore financing options. Many manufacturers and dealers offer flexible payment plans. Leasing is another viable option. It allows you to use the machine without the hefty initial investment. Leasing can also provide tax benefits and the flexibility to upgrade to newer models as technology advances. Evaluate these options carefully to find what suits your financial situation best.

Hidden Costs to Consider

Don't overlook hidden costs. Beyond the purchase price, consider operational expenses. Energy consumption, maintenance, and consumables like lenses and nozzles add up over time. Some machines may require specific software or additional equipment, increasing the overall cost. Also, factor in the cost of training your team to operate the machine efficiently. Understanding these hidden costs helps you budget more accurately and avoid unpleasant surprises.

When deciding where to buy a laser cutting machine, research thoroughly. Look for reputable dealers who offer comprehensive support and service agreements. This ensures you get the best value for your investment.

Material Compatibility

When choosing a laser cutting machine, material compatibility is a key factor. You want a machine that can handle the materials you plan to work with. Let's dive into the details.

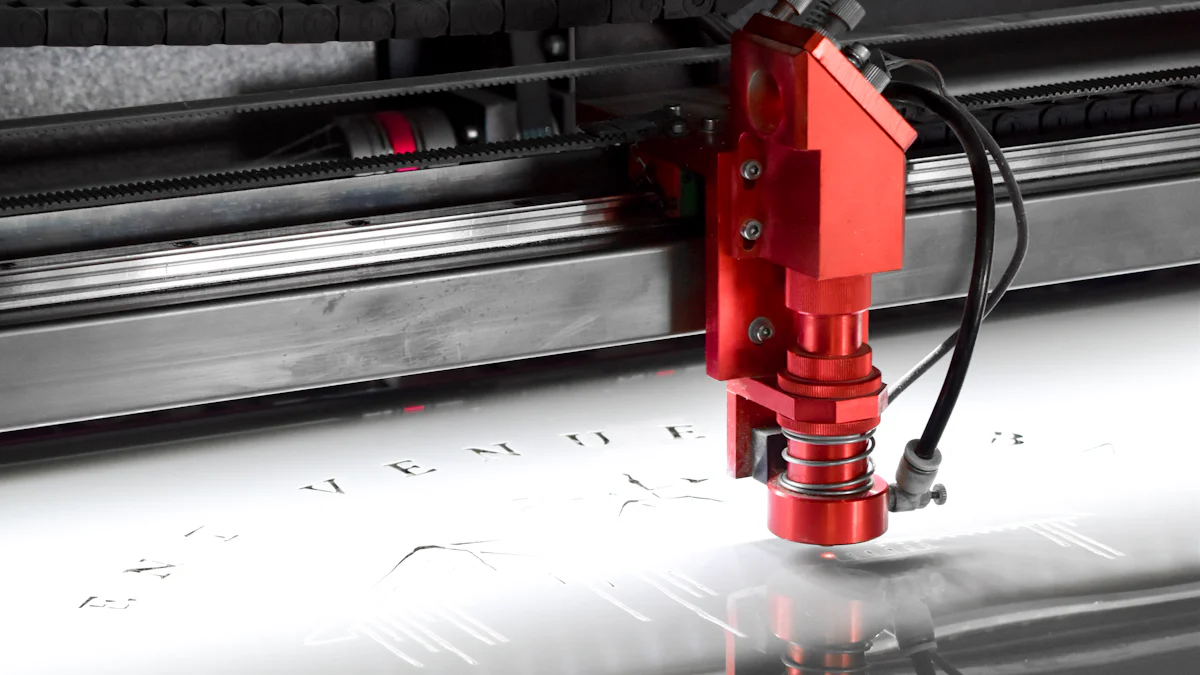

Types of Materials

Laser cutting machines can cut a wide range of materials. These include metal, wood, plastic, fabric, acrylic, leather, and glass. Each material requires specific settings for optimal results. For instance, cutting metal might need a different laser power compared to cutting wood or acrylic. Knowing the types of materials you will work with helps you select a machine that meets your needs.

Versatility and Flexibility

Versatility is a major advantage of laser cutting machines. They offer high accuracy and speed, making them suitable for various applications. Whether you're creating personalized parts, signs, or decorations, a versatile machine can handle it all. Flexibility in a machine allows you to switch between different materials and projects with ease. This adaptability can be a game-changer, especially if your business involves diverse projects.

Future Needs and Expansion

Think about your future needs. As your business grows, you might want to expand your offerings. A machine that supports a wide range of materials and applications can accommodate this growth. Consider the potential for new projects or materials you might explore in the future. Investing in a machine with expansion capabilities ensures you won't outgrow it quickly. This foresight can save you from needing another machine down the line.

Machine Accuracy

When you're choosing a laser cutting machine, accuracy is a big deal. It affects the quality of your work and can make or break your projects. Let's explore why precision matters and how you can ensure your machine stays accurate.

Precision Levels

Laser cutting machines are known for their precision. They can make ultra-precise cuts that are hard to achieve with other tools. This precision comes from advanced engineering and technology. You need to know the precision level of the machine you're considering. Higher precision means cleaner cuts and less material waste. If your projects require tight tolerances, look for a machine with high precision levels. This ensures your work meets the highest standards.

Impact on Quality

Precision directly impacts the quality of your finished products. A machine with high accuracy produces clean edges and intricate details. This is crucial for industries like aerospace, automotive, and electronics, where quality standards are strict. Even if you're in a creative field, like crafting or design, precision enhances the aesthetic appeal of your work. Investing in a precise machine boosts your reputation for quality and reliability.

Calibration and Adjustments

To maintain accuracy, regular calibration and adjustments are necessary. Over time, even the best machines can drift out of alignment. Routine calibration ensures your machine continues to perform at its best. Some machines come with automatic calibration features, making this process easier. If not, you'll need to schedule regular maintenance checks. Proper calibration keeps your machine accurate and extends its lifespan. It also minimizes downtime, keeping your production line running smoothly.

Maintenance Requirements

When you own a laser cutting machine, keeping it in top shape is crucial. Regular maintenance ensures your machine runs smoothly and efficiently. Let's dive into what you need to know about maintaining your laser cutting machine.

Routine Maintenance Tasks

Routine maintenance tasks are essential for the longevity of your machine. You should perform these tasks regularly to prevent issues. Clean the machine's lenses and mirrors to ensure optimal performance. Dust and debris can affect the laser's accuracy. Check the cooling system to prevent overheating. Lubricate moving parts to reduce wear and tear. Equipment Operator emphasizes that daily maintenance should be carried out by the operator who uses the equipment. This person knows the machine best and can spot potential problems early.

Cost of Spare Parts

Spare parts can add up over time. It's important to budget for these costs. Some parts, like lenses and nozzles, may need frequent replacement. Others, like motors or belts, might last longer but cost more. Consider the availability and cost of spare parts when choosing a machine. Brands with Convenient Maintenance suggest selecting brands that offer easy access to spare parts and quick service. This can save you time and money in the long run.

Availability of Technicians

Having access to qualified technicians is vital. They can help with repairs and more complex maintenance tasks. Qualified Technicians note that regular professional maintenance can identify and fix issues before they lead to major breakdowns. Look for manufacturers or dealers that offer reliable technical support. Certified Entity recommends scheduling preventive maintenance with a certified entity. This ensures your machine stays in peak condition and minimizes downtime.

Company Support and Where to Buy Laser Cutting Machine

When you're on the hunt for a laser cutting machine, company support is a crucial factor to consider. Knowing where to buy a laser cutting machine that offers excellent support can save you a lot of headaches down the road. Let's dive into what you should look for.

Warranty and Service Agreements

A solid warranty and service agreement can give you peace of mind. Companies like Focused Laser Systems offer a 24-month warranty on their Vision Laser range and a 12-month warranty on refurbished machines. This kind of coverage ensures that you're protected against defects and malfunctions. Always ask about the specifics of the warranty. Does it cover parts and labor? How long does it last? A comprehensive service agreement can also include regular maintenance checks, which keep your machine running smoothly.

Customer Support and Training

Reliable customer support is invaluable. You want to know that help is just a call or click away if you encounter any issues. Epilog Laser provides tech support Monday through Friday, while AP Lazer offers 24/7/365 support in the US and Canada. This level of availability means you can get assistance whenever you need it. Training is another critical aspect. Companies like StyleCNC emphasize the importance of a professional training system to help you get started quickly. Whether it's through online resources, training videos, or direct communication with experts, make sure the company provides the support you need to operate your machine effectively.

Reputation and Reviews

Before deciding where to buy a laser cutting machine, check the company's reputation. Look for reviews and testimonials from other customers. Kern Laser Systems prides itself on excellent customer service, and their testimonials reflect this commitment. Reading about others' experiences can give you insight into the company's reliability and the quality of their machines. A company with a strong reputation is more likely to provide a positive buying experience and ongoing support.

When you know where to buy a laser cutting machine that meets these criteria, you're setting yourself up for success. A company that stands behind its products with robust support and service agreements can make all the difference in your laser cutting journey.

You've explored the essential tips for buying a laser cutting machine. Remember, it's not just about finding the cheapest option. Consider it a long-term investment. Focus on key technical features like power and cutting area. Establish your budget upfront to avoid overspending. Think about where to buy a laser cutting machine that offers excellent support and service agreements. By understanding these factors, you can make a wise purchase decision. Always align your choice with your specific needs and future goals. This approach ensures you get the best value for your investment.

FAQ

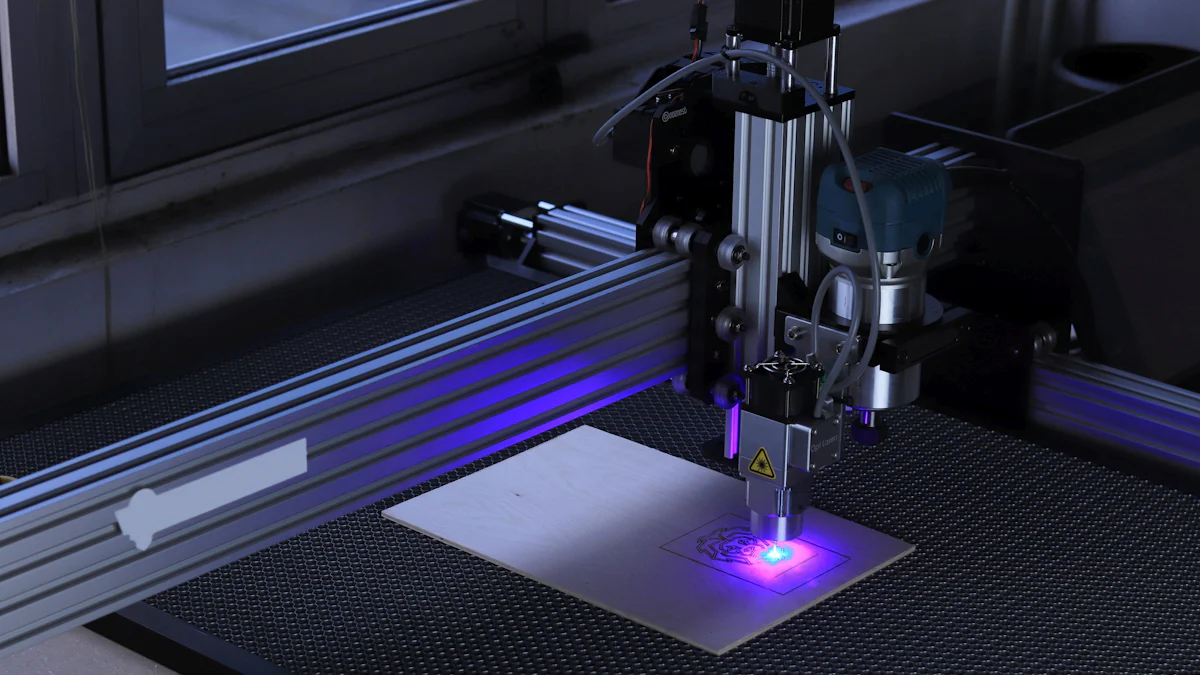

How do laser cutting machines work?

Laser cutting machines use a focused beam of light to cut through materials. This method is highly precise and versatile. You can use it to cut various materials like metal, wood, and plastic. The laser's precision allows for intricate designs and clean edges, making it ideal for manufacturing and creative projects.

What materials can I cut with a laser cutting machine?

You can cut a wide range of materials with a laser cutting machine. Common materials include metal, wood, acrylic, fabric, and leather. Each material may require different settings for optimal results. Always check your machine's specifications to ensure compatibility with the materials you plan to use.

How do I choose the right laser power for my needs?

The right laser power depends on the thickness and type of material you plan to cut. Higher wattage is necessary for thicker materials. For example, cutting metal might require more power than cutting wood. Consider your specific applications and consult with the manufacturer to determine the appropriate laser power.

Is it difficult to learn how to operate a laser cutting machine?

Operating a laser cutting machine can be straightforward, especially with proper training. Many manufacturers offer training resources, such as manuals, videos, and workshops. Start with simple projects to build your confidence. As you gain experience, you can tackle more complex designs.

What should I consider when budgeting for a laser cutting machine?

When budgeting, consider the initial purchase price and long-term costs. These include maintenance, spare parts, and energy consumption. Financing options and leasing can help manage upfront costs. Don't forget to factor in any additional equipment or software you might need.

How often should I perform maintenance on my laser cutting machine?

Regular maintenance is crucial for optimal performance. You should clean lenses and mirrors, check the cooling system, and lubricate moving parts regularly. Follow the manufacturer's guidelines for routine maintenance tasks. Scheduling professional maintenance checks can also help prevent major issues.

Can I upgrade my laser cutting machine as my business grows?

Yes, many laser cutting machines offer upgrade options. You can expand capabilities by adding new features or increasing power. Consider your future needs when purchasing a machine. Investing in a model with expansion potential can save you from needing a new machine as your business grows.

What kind of customer support should I expect from the manufacturer?

Look for manufacturers that offer comprehensive customer support. This includes warranty coverage, technical assistance, and training resources. Reliable support ensures you can resolve issues quickly and keep your machine running smoothly. Check reviews and testimonials to gauge the quality of a company's support.

Where is the best place to buy a laser cutting machine?

Research reputable dealers and manufacturers. Look for those with strong reputations and positive customer reviews. Consider companies that offer robust support and service agreements. A reliable seller can provide valuable guidance and ensure you get the best value for your investment.

How can I ensure my laser cutting machine remains accurate?

To maintain accuracy, perform regular calibration and adjustments. Some machines feature automatic calibration, simplifying this process. Regular maintenance checks can also help keep your machine aligned. Accurate machines produce high-quality cuts, enhancing the overall quality of your projects.

See Also

A Comprehensive Guide to Laser Cutting Machine Costs

Maximizing Efficiency with Your Laser Cutting Machine

Essential Advice for Selecting a Water Jet Cutter