Understanding Bevel Cuts with Laser Engraving Machines

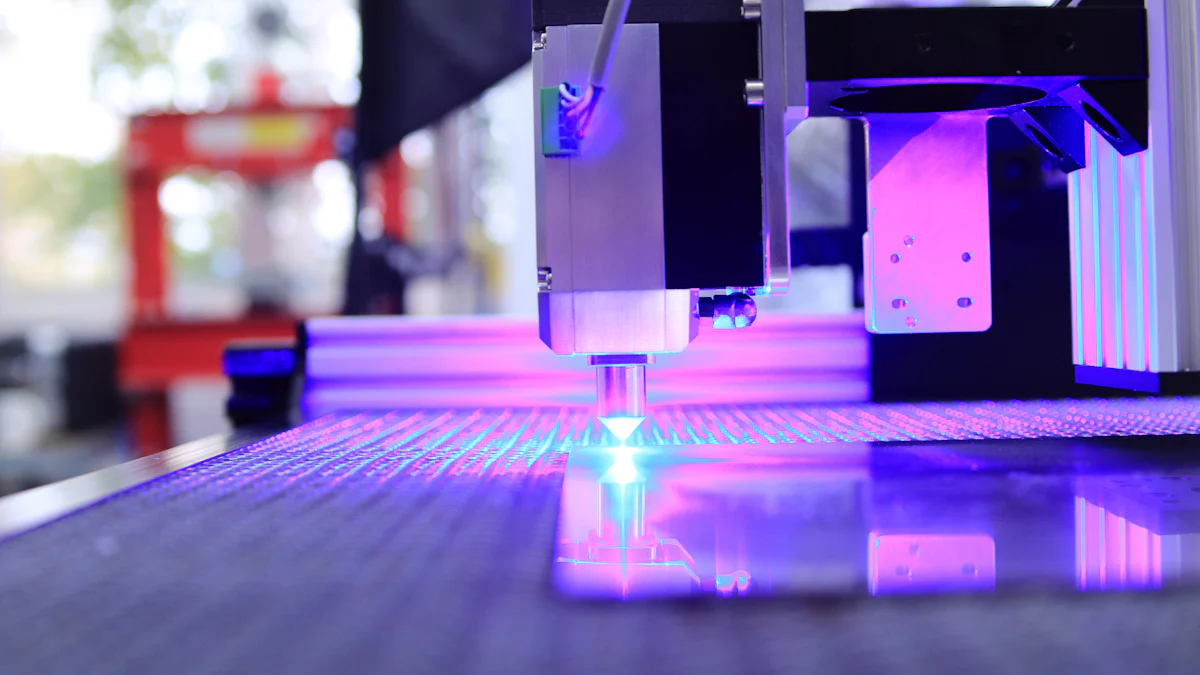

Bevel cutting involves creating edges at angles other than 90 degrees, offering a unique aesthetic and functional advantage. You can achieve precise bevel cuts using a laser cutting machine by adjusting the laser beam angle to the desired inclination. This method provides high precision and versatility, making it superior to traditional techniques. With the right software and expertise, you can efficiently learn how to do bevel cuts with a laser engraving machine. This approach not only enhances productivity but also ensures smooth and accurate results across various materials.

Types of Bevel Cuts with Laser Technology

When you explore the world of laser technology, you'll discover various types of bevel cuts that enhance both functionality and aesthetics. Each type serves a unique purpose and can be achieved with precision using a laser cutting machine.

Straight Bevel Cuts

Straight bevel cuts are the most common type. You create these by cutting the material at a consistent angle along a straight line. This type of bevel cut is ideal for applications requiring clean, linear edges. For instance, in metal fabrication, straight bevel cuts prepare parts for welding by providing a sloped edge that improves joint fit and strength. The Laser Bevel Cutting Machine excels in this area, offering high precision and fast cutting speeds. This machine can cut angles ranging from 1° to 45°, forming bevels in one go, which significantly boosts efficiency and resource savings.

Curved Bevel Cuts

Curved bevel cuts add an artistic touch to your projects. You achieve these by cutting the material at an angle along a curved path. This type of bevel cut is perfect for designs that require smooth, flowing lines. The Laser Beveling Machine is versatile enough to handle these intricate cuts. It operates with an additional axis of rotation, allowing the laser to move in three dimensions and pivot along the z-axis. This capability enables you to create complex shapes with ease, making it suitable for industries like furniture and interior design.

Compound Bevel Cuts

Compound bevel cuts combine multiple angles in a single cut, offering a sophisticated edge profile. You often use these in advanced applications where multiple angled surfaces meet. The Bevel Laser Cutting Machine supports this complexity with its automatic nesting feature, which saves materials and allows for rapid product iterations. This machine's ability to apply 45° chamfers on both inside and outside contours during profiling makes it a valuable tool for industries such as aerospace and automotive, where precision and versatility are paramount.

By understanding these types of bevel cuts, you can better utilize laser technology to meet your specific needs. Whether you're aiming for straight, curved, or compound cuts, the right laser cutting machine can transform your ideas into reality with unmatched precision and efficiency.

Applications of Bevel Cuts in Various Industries

Bevel cutting plays a crucial role across various industries, enhancing both functionality and aesthetics. By using a laser cutting machine, you can achieve precise bevel cuts that meet the specific needs of different sectors. Let's explore how different industries benefit from this advanced technology.

Automotive Industry

In the automotive industry, bevel cutting is essential for creating components that require precise angles and smooth edges. You often use bevel cuts to prepare parts for welding, which enhances joint strength and adaptability. This process not only improves the structural integrity of vehicles but also contributes to their aesthetic appeal. By employing laser cutting machines, you can achieve high precision and efficiency, which are vital in the fast-paced automotive sector.

Aerospace Industry

The aerospace industry demands high precision and reliability, making bevel cutting an indispensable technique. You use bevel cuts to create complex components that fit together seamlessly, ensuring the safety and performance of aircraft. Laser bevel cutting applications in this field allow for intricate designs and precise angles, which are crucial for maintaining the structural strength of aerospace components. The versatility of laser cutting machines enables you to work with various materials, meeting the stringent requirements of the aerospace industry.

Furniture and Interior Design

In furniture and interior design, bevel cuts add a touch of elegance and sophistication. You can use bevel cutting to create unique designs and intricate patterns that enhance the visual appeal of furniture pieces. Laser cutting technology allows you to achieve smooth and precise cuts, enabling you to bring your creative ideas to life. Whether you're working with wood, metal, or other materials, a laser cutting machine provides the flexibility and accuracy needed to produce high-quality designs.

By understanding the application scope of laser bevel cutting, you can leverage this technology to meet the diverse needs of different industries. Whether you're in automotive, aerospace, or design, bevel cuts offer a range of possibilities that enhance both functionality and aesthetics.

Signage and Advertising

In the world of signage and advertising, bevel cuts play a pivotal role in creating eye-catching designs. You can use bevel cutting to add depth and dimension to signs, making them more visually appealing. This technique enhances the overall aesthetic, drawing attention to the message or brand being promoted.

1. Enhanced Visual Appeal

Bevel cuts provide a unique edge profile that stands out. By incorporating angled edges, you create a three-dimensional effect that captures the viewer's attention. This is particularly effective in outdoor signage, where visibility and impact are crucial. The precision of laser cutting ensures that each bevel cut is clean and sharp, contributing to a professional appearance.

2. Versatility in Design

Laser technology allows you to experiment with various materials and designs. Whether you're working with acrylic, metal, or wood, bevel cuts can be applied to achieve the desired look. This versatility opens up endless possibilities for creative expression in advertising. You can tailor your designs to fit specific themes or branding requirements, ensuring that your signage aligns with your marketing goals.

3. Durability and Quality

Signs with bevel cuts not only look good but also last longer. The precise cutting process minimizes material waste and reduces the need for additional finishing. This results in durable signs that withstand environmental factors, maintaining their quality over time. By investing in laser-cut bevel signage, you ensure that your advertising efforts remain effective and impactful.

"Bevel cutting increases structural strength, joint adaptability, cutting precision, and design possibilities in various industrial applications."

Incorporating bevel cuts into your signage and advertising strategy can significantly enhance the effectiveness of your campaigns. By leveraging the precision and versatility of laser technology, you create compelling visuals that resonate with your audience.

How to Make Bevel Cuts with Laser Machines

Creating bevel cuts with a laser cutting machine involves several key steps. By understanding these steps, you can achieve precise and efficient results. Here's a guide on how to do bevel cuts with a laser engraving machine.

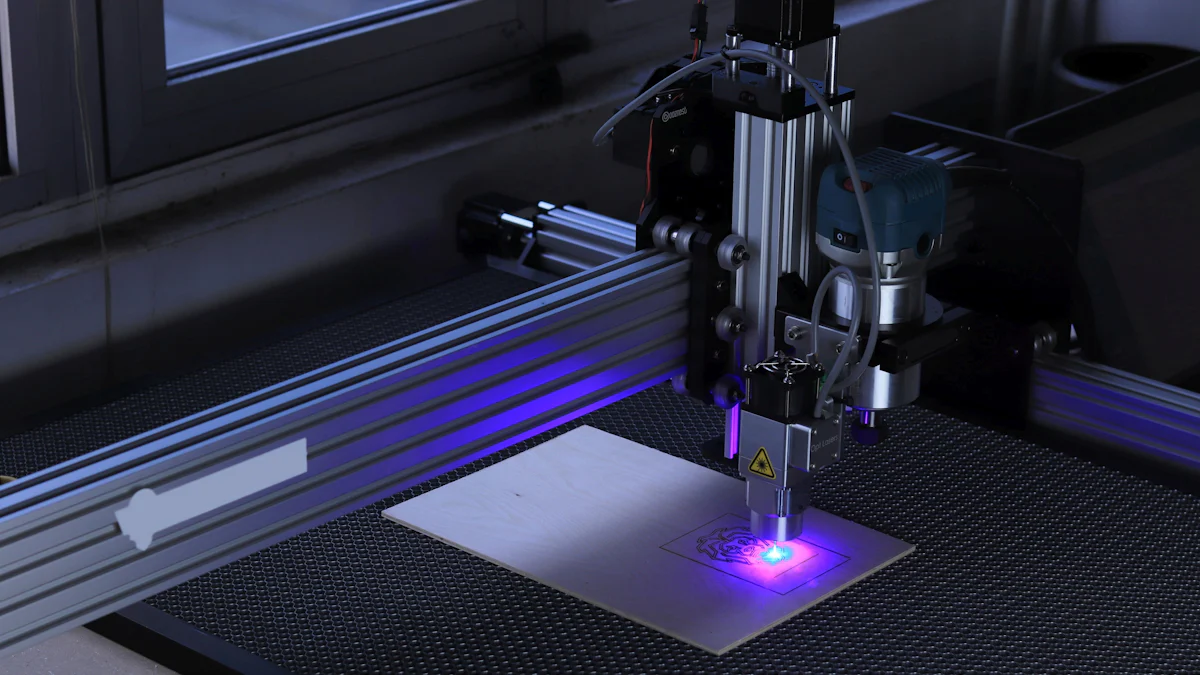

Setting Up the Laser Machine

-

Positioning the Machine: Place your laser cutting machine on a stable surface. Ensure it is level to maintain accuracy during the cutting process. Proper positioning prevents vibrations that could affect the quality of the bevel cut.

-

Configuring the Software: Use the machine's software to input the desired bevel angle. Automated laser beveling systems often come with user-friendly interfaces that allow you to set angles with precision. This step is crucial for achieving the exact cut you need.

-

Adjusting the Laser Beam: Align the laser beam to the correct angle. The angle should be less than 90 degrees to create a bevel cut. This adjustment is vital for ensuring the laser cuts at the right inclination.

Material Selection and Preparation

-

Choosing the Right Material: Select materials compatible with laser cutting. Common choices include metals, plastics, and wood. Each material reacts differently to the laser, so choose one that suits your project needs.

-

Preparing the Material: Clean the material surface to remove any debris or coatings. A clean surface ensures a smooth cut and reduces the risk of imperfections. Proper preparation enhances the overall quality of the bevel cut.

-

Securing the Material: Fix the material firmly in place. Use clamps or a vacuum table to prevent movement during cutting. Stability is essential for maintaining precision throughout the process.

Calibration and Precision Techniques

-

Calibrating the Machine: Regularly calibrate your laser cutting machine. Calibration ensures the laser beam maintains its focus and alignment. This step is crucial for achieving consistent and accurate bevel cuts.

-

Precision Settings: Adjust settings such as feed rate, tilt angle, and kerf offset. These parameters influence the quality of the cut. For successful laser bevel cutting, keep these settings within tight tolerances.

-

Testing and Adjusting: Perform test cuts on scrap material. Testing allows you to fine-tune the machine settings before working on the final piece. Make necessary adjustments to achieve the desired bevel cut quality.

By following these steps, you can master how to make bevel cuts with a laser engraving machine. This process not only enhances the aesthetic appeal of your projects but also improves their structural integrity. Whether you're using fiber laser cutting or automated laser beveling, understanding these techniques will help you achieve professional results.

Benefits of Laser Bevel Cutting

Laser bevel cutting offers numerous benefits that enhance both the quality and efficiency of your projects. By understanding these advantages, you can make informed decisions about incorporating this technology into your work.

Precision and Accuracy

Laser bevel cutting provides unmatched precision and accuracy. You can achieve exact angles and clean edges by adjusting the angle between the laser beam and the original surface. This precision is crucial for applications requiring intricate designs and tight tolerances. The ability to rotate the laser cutter head at specific angles ensures that each bevel cut meets your exact specifications. This level of accuracy reduces material waste and minimizes the need for additional finishing processes.

Versatility in Material Use

One of the significant advantages of laser cutting is its versatility in handling various materials. Whether you're working with metals, plastics, or wood, a laser cutting machine can accommodate your needs. This flexibility allows you to experiment with different materials and designs, expanding your creative possibilities. You can tailor your projects to meet specific requirements, ensuring that the final product aligns with your vision. The adaptability of laser cutting technology makes it an invaluable tool across multiple industries.

Efficiency and Speed

Laser bevel cutting significantly enhances efficiency and speed in your projects. The process allows for rapid cutting without compromising quality. You can complete tasks faster, increasing productivity and reducing lead times. The automated nature of laser cutting machines streamlines operations, allowing you to focus on other aspects of your work. This efficiency translates to cost savings and improved project timelines, making laser bevel cutting a smart investment for any business.

"The precision and efficiency of laser bevel cutting make it a preferred choice for industries seeking high-quality results."

By leveraging the benefits of laser bevel cutting, you can elevate the quality and efficiency of your projects. Whether you're aiming for precision, versatility, or speed, this technology offers a range of advantages that meet your needs.

Limitations of Laser Bevel Cutting

While laser bevel cutting offers numerous advantages, you should be aware of its limitations. Understanding these constraints will help you make informed decisions when using a laser cutting machine for your projects.

Material Thickness Constraints

Laser bevel cutting excels in precision and speed, but it faces challenges with thicker materials. The laser's ability to penetrate and cut through material decreases as thickness increases. This limitation can affect the quality of the bevel cut, especially when working with dense or thick materials. You might need to consider alternative methods or additional processing steps for thicker materials to achieve the desired results.

Initial Cost and Maintenance

Investing in a laser cutting machine involves significant initial costs. These machines require a substantial financial commitment, which can be a barrier for small businesses or individual users. Additionally, maintaining a laser cutting machine demands regular upkeep and potential repairs. You must factor in these ongoing costs when considering laser bevel cutting for your projects. Proper maintenance ensures the machine operates efficiently and prolongs its lifespan.

Technical Skill Requirements

Operating a laser cutting machine requires a certain level of technical expertise. You need to understand the machine's software, settings, and calibration processes to achieve precise bevel cuts. This technical skill requirement can pose a challenge for beginners or those unfamiliar with laser technology. Investing time in training and gaining experience is essential to mastering the art of laser bevel cutting. With practice, you can overcome this limitation and fully leverage the capabilities of your laser cutting machine.

"Laser bevel cutting simplifies processing workflow, reduces costs, and provides high precision and fast cutting speeds compared to traditional methods."

By recognizing these limitations, you can better prepare for the challenges associated with laser bevel cutting. Whether you're dealing with material thickness, cost considerations, or technical skills, understanding these factors will help you optimize your use of laser cutting technology.

How to Do Bevel Cuts with Laser Engraving Machine

Mastering bevel cuts with a laser engraving machine requires attention to detail and understanding of the process. By focusing on key aspects like calibration, software, and operator expertise, you can achieve precise and efficient results.

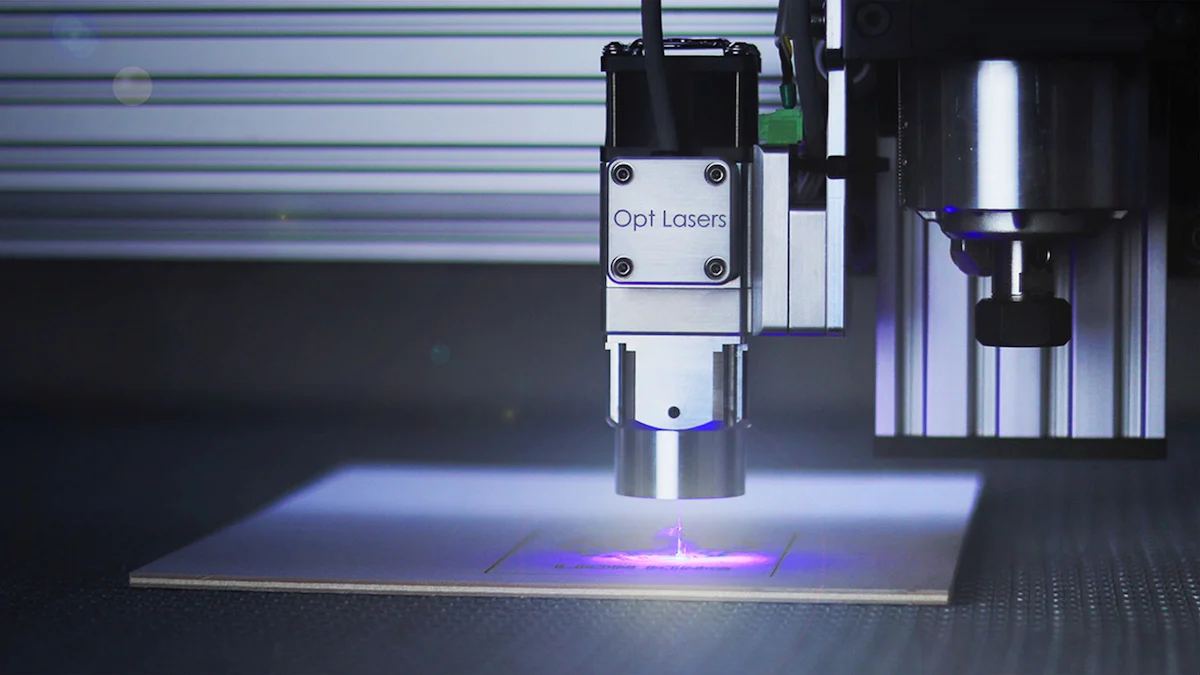

Importance of Calibration

Calibration plays a crucial role in ensuring the accuracy of your bevel cuts. You must regularly calibrate your laser cutting machine to maintain its precision. This involves adjusting the laser beam's focus and alignment to match the desired angle. Proper calibration ensures that the laser cuts at the correct inclination, resulting in clean and precise bevel edges. Regular checks and adjustments prevent errors and enhance the overall quality of your projects.

Software and Design Considerations

The software you use significantly impacts the success of your bevel cuts. You should choose software that allows for precise angle settings and design flexibility. This enables you to create intricate patterns and achieve the exact bevel angles needed for your project. When designing, consider the material's properties and how they interact with the laser. This understanding helps you optimize the cutting process and achieve the best results. By leveraging advanced software features, you can enhance the efficiency and creativity of your laser cutting endeavors.

Operator Expertise

The skill level of the operator directly influences the quality of bevel cuts. You need to understand the machine's functions and settings to achieve optimal results. Training and experience are essential for mastering the art of laser cutting. As you gain expertise, you'll become more adept at handling different materials and adjusting settings for various projects. This knowledge allows you to fully utilize the capabilities of your laser cutting machine, ensuring precise and high-quality bevel cuts every time.

"Bevel cutting is a versatile technique with limitations."

By focusing on calibration, software, and operator expertise, you can effectively perform bevel cuts with a laser engraving machine. This approach not only enhances the aesthetic appeal of your projects but also improves their structural integrity. Understanding these elements will help you achieve professional results and maximize the potential of your laser cutting technology.

Bevel cuts with laser technology offer you a world of precision and versatility. By mastering this technique, you can enhance the aesthetic and functional aspects of your projects. Whether you're working with metals or non-metallic materials, laser bevel cutting provides high accuracy and efficiency. Explore these solutions to meet your specific needs and elevate your craftsmanship. If you have questions or need further guidance, feel free to reach out. Engaging with experts can help you make informed decisions and achieve exceptional results in your laser cutting endeavors.

FAQ

What is bevel laser cutting?

Bevel laser cutting is a specialized technique that creates angled or beveled edges on materials. Unlike standard vertical cuts, bevel cuts add an angled edge, which is crucial for parts that need to fit together at specific angles for welding, assembly, or fabrication. This method enhances both the structural strength and aesthetic appeal of components.

How does a laser beveling machine work?

A laser beveling machine operates by adjusting the angle between the laser beam and the material surface to be less than 90 degrees. This adjustment allows the machine to cut precise bevels at various angles, such as 15, 30, or 45 degrees. The machine's automated, computer-controlled operations ensure high accuracy and efficiency in producing bevel cuts.

What are the advantages of using a bevel cutting machine?

Using a bevel cutting machine offers several advantages. It provides high precision and accuracy, allowing for intricate designs and tight tolerances. The machine's ability to perform on-machine beveling reduces the need for additional machining processes, such as milling and grinding, thereby increasing productivity. Additionally, it supports a wide range of materials, making it versatile for various applications.

How does laser cutting technology enhance bevel cut accuracy?

Laser cutting technology enhances bevel cut accuracy by utilizing precise control over the laser beam's angle and intensity. This control ensures that each cut meets exact specifications, reducing material waste and minimizing the need for further finishing. The technology's precision is particularly beneficial in industries requiring high-quality results, such as aerospace and automotive.

What are the common applications of bevel cuts?

Bevel cuts are commonly used in industries like automotive, aerospace, furniture, and interior design. In the automotive industry, they prepare parts for welding, enhancing joint strength. In aerospace, they create complex components that fit seamlessly together. In furniture and interior design, bevel cuts add elegance and sophistication to designs.

Can laser bevel cutting handle thick materials?

While laser bevel cutting excels in precision, it faces challenges with thicker materials. The laser's ability to penetrate and cut decreases as material thickness increases. For thicker materials, you might need to consider alternative methods or additional processing steps to achieve the desired results.

What skills are required to operate a laser beveling machine?

Operating a laser beveling machine requires technical expertise. You need to understand the machine's software, settings, and calibration processes to achieve precise bevel cuts. Training and experience are essential to mastering the art of laser cutting and fully leveraging the machine's capabilities.

How does laser bevel cutting improve productivity?

Laser bevel cutting improves productivity by reducing the need for manual weld preparation, which is resource-intensive. The automated nature of laser cutting machines streamlines operations, allowing engineers to focus on more complex tasks. This efficiency translates to cost savings and faster project completion times.

What factors affect bevel cut accuracy?

Several factors affect bevel cut accuracy, including the laser beam's angle, the material's properties, and the machine's calibration. Regular calibration ensures the laser maintains its focus and alignment, while understanding the material's interaction with the laser helps optimize the cutting process.

Why is laser cutting technology preferred over traditional methods?

Laser cutting technology is preferred over traditional methods due to its precision, speed, and versatility. It allows for rapid cutting without compromising quality, accommodates various materials, and reduces the need for additional finishing processes. These advantages make it a smart investment for industries seeking high-quality results.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding the Functionality of CNC Laser Cutters

A Simple Explanation of Laser Cutting Machine Operation