Choosing the Best Laser Cutting Machine Guide

Choosing the right laser cutting machine is a pivotal decision that can significantly impact your projects. With the laser cutting machines market projected to grow from USD 5.94 billion in 2023 to USD 12.65 billion by 2032, understanding the different types of machines becomes crucial. You need to consider machine types, features, and their suitability for various materials. Whether you work with metals, plastics, or organic materials, knowing what is the best laser cutting machine for your needs ensures precision and efficiency in your work.

What is the Best Laser Cutting Machine for Your Needs?

Choosing the best laser cutting machine depends on your specific needs and the materials you plan to work with. Understanding the different types of laser cutters will help you make an informed decision.

Understanding CO2 Laser Cutters

CO2 laser cutters are among the most popular choices for many users. They utilize a carbon dioxide laser tube to produce a powerful beam. This beam is directed through mirrors and a focal lens to cut or engrave materials.

Applications and Materials

CO2 laser cutters excel in versatility. You can use them to cut a wide range of materials, including:

- Wood

- Plastics

- Glass

- Metals

These machines are ideal for projects that require precision and clean cuts.

Advantages and Limitations

Advantages:

- Versatile in material handling

- Available in various sizes and power levels

- Capable of both cutting and engraving

Limitations:

- May not be as effective on thicker metals

- Requires regular maintenance of mirrors and lenses

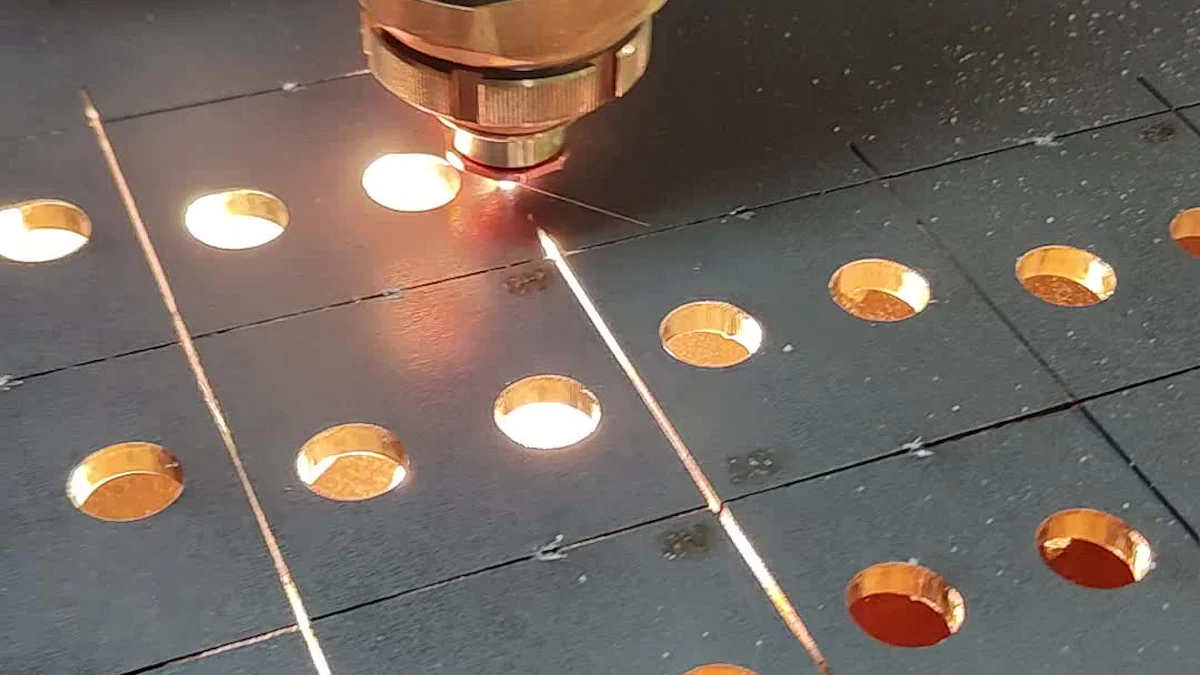

Exploring Fiber Laser Cutters

Fiber laser cutters are another excellent option, especially for those working with metals. They use a different technology compared to CO2 lasers, which makes them more efficient for certain applications.

Applications and Materials

Fiber laser cutters are particularly suited for:

- Metals

- Plastics

They are often used in industries where precision and speed are crucial.

Advantages and Limitations

Advantages:

- High efficiency and speed

- Excellent for metal cutting

- Lower maintenance compared to CO2 lasers

Limitations:

- Higher initial cost

- Limited effectiveness on non-metal materials

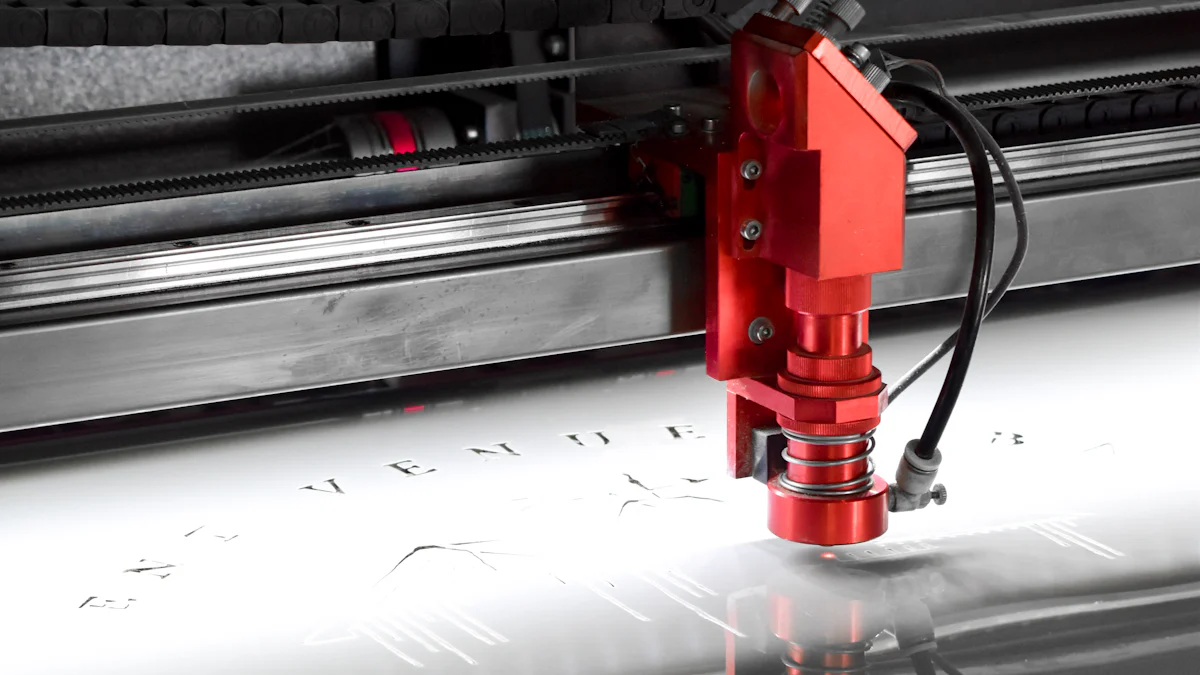

Discovering Diode Laser Cutters

Diode laser cutters are known for their compact size and affordability. They are perfect for hobbyists and small businesses.

Applications and Materials

Diode laser machines can easily cut:

- Wood

- Plywood

- Acrylic (opaque)

- Cardboard

- Paper

- Leather

These materials are commonly used in crafting and small-scale production.

Advantages and Limitations

Advantages:

- Affordable and compact

- Suitable for a variety of organic materials

- Easy to operate

Limitations:

- Limited power compared to CO2 and fiber lasers

- Not suitable for cutting metals

By understanding these different types of laser cutters, you can determine what is the best laser cutting machine for your specific needs. Each type offers unique benefits and limitations, so consider your material requirements and project goals when making your choice.

Laser Cutter Buying Guide: Key Considerations

When selecting a laser cutting machine, several factors come into play. This laser cutter buying guide will help you navigate through the essential considerations to ensure you make an informed decision.

Budget and Cost Analysis

Understanding your budget is crucial when purchasing a laser cutter. Prices can vary significantly based on the type and features of the machine.

Initial Purchase Cost

The initial cost of a laser cutter can range from $500 for basic models to over $100,000 for advanced industrial laser cutting machines. Desktop models are more affordable, starting around $500, while industrial machines can reach half a million dollars. Consider what you can afford and what features are essential for your needs.

Long-term Operating Costs

Beyond the initial purchase, consider the long-term costs. These include energy consumption, maintenance, and consumables. Laser cutters consume between 1.5 kW and 10 kW per hour, depending on their configuration and cutting process. Regular maintenance ensures efficiency and longevity, so factor these into your budget.

Evaluating Power and Performance

Power and performance are critical in determining the effectiveness of a laser cutter.

Power Requirements for Different Materials

The power of a laser cutter dictates the thickness of materials it can handle. For thin materials, lower wattage suffices, but thicker materials require higher power. Fiber laser cutters, known for their efficiency, are ideal for metals, while CO2 lasers work well with organic materials.

Speed and Precision

Cutting speed and precision are vital for achieving high-quality results. Laser cutting technology has advanced to offer remarkable accuracy and precision. Evaluate the speed and precision levels of different models to match your project requirements.

Assessing Size and Workspace Requirements

The size of the machine and your workspace setup are important considerations.

Machine Footprint

Laser cutters come in various sizes, from small desktop models to large industrial machines. Assess the available space in your workspace to accommodate the machine's footprint. Ensure you have enough room for safe operation and maintenance.

Workspace Setup

A well-organized workspace enhances efficiency. Consider the layout and setup of your workspace to facilitate smooth operations. Ensure proper ventilation and safety measures are in place to handle the laser cutting process effectively.

By considering these key factors, you can choose a laser cutting machine that aligns with your budget, power needs, and workspace requirements. This guide aims to provide clarity and direction as you explore the world of laser cutting technology.

Safety Features and Maintenance Essentials

When selecting a laser cutting machine, prioritizing safety is crucial. Understanding the essential safety features and maintenance requirements ensures not only the longevity of your machine but also the well-being of everyone involved in its operation.

Essential Safety Features

-

Enclosures and Shields: Most laser cutters, including fiber laser cutters, come with protective enclosures. These enclosures prevent accidental exposure to the laser beam, which can cause serious injuries. Always ensure that your machine has a robust enclosure to protect users from direct laser exposure.

-

Emergency Stop Button: An emergency stop button is a critical safety feature. It allows you to immediately halt the machine's operation in case of an emergency. This feature is especially important when working with high-power machines like fiber laser cutters.

-

Ventilation Systems: Proper ventilation is necessary to remove fumes and particles generated during the cutting process. Ensure your workspace has adequate ventilation to maintain air quality and prevent respiratory issues.

-

Laser Safety Glasses: Wearing laser safety glasses is essential when operating a laser cutter. These glasses protect your eyes from harmful laser radiation, ensuring safe operation.

-

Interlock Systems: Interlock systems automatically shut down the laser if the enclosure is opened during operation. This feature prevents accidental exposure to the laser beam, enhancing overall safety.

Maintenance and Longevity

Regular maintenance is key to ensuring your laser cutter operates efficiently and lasts for years. Here are some maintenance tips:

-

Routine Cleaning: Dust and debris can accumulate on the machine's components, affecting performance. Regularly clean the mirrors, lenses, and other parts to maintain excellent beam quality and high precision.

-

Check Alignment: Misalignment can lead to poor cutting results. Periodically check and adjust the alignment of the laser beam to ensure optimal performance.

-

Inspect Cooling Systems: Laser cutters, especially fiber laser cutters, generate heat during operation. Ensure the cooling systems are functioning properly to prevent overheating and damage to the machine.

-

Replace Consumables: Parts like lenses and mirrors may wear out over time. Replace them as needed to maintain the machine's efficiency and cutting quality.

-

Software Updates: Keep the machine's software up to date. Updates often include improvements and bug fixes that enhance performance and safety.

By focusing on these safety features and maintenance practices, you can ensure that your laser cutting machine remains a reliable and safe tool in your workshop. Whether you choose affordable laser cutters or high-end models, maintaining safety and performance should always be a priority.

Best Laser Cutting Options Available in the Market

When you decide to invest in a laser cutter, exploring the best options available in the market becomes essential. This section will guide you through some of the top recommended models and provide insights into the next steps for making a purchase.

Top Recommended Models

Choosing the right model involves understanding the features and specifications that align with your needs. Here are some top models that stand out in the market:

Features and Specifications

-

CO2 Laser Cutters: These machines are versatile and suitable for cutting a wide range of materials, including wood, plastics, and glass. They come in various sizes and power levels, allowing you to select one that fits your workspace and project requirements. Look for models with adjustable power settings and high precision for detailed work.

-

Fiber Laser Cutters: Known for their efficiency in cutting metals, fiber laser cutters offer high speed and precision. They require less maintenance compared to CO2 laser cutters, making them a reliable choice for industrial applications. Consider models with advanced cooling systems to prevent overheating during prolonged use.

-

Diode Laser Cutters: Ideal for hobbyists and small businesses, diode laser cutters are compact and affordable. They excel in cutting organic materials like wood and leather. Choose models with user-friendly interfaces and safety features like enclosures and emergency stop buttons.

User Reviews and Ratings

User reviews provide valuable insights into the performance and reliability of different laser cutter models. Look for models with high ratings for quality and durability. Pay attention to feedback on ease of use, maintenance requirements, and customer support. A model with positive reviews across these aspects is likely to meet your expectations.

Next Steps for Making a Purchase

Once you've identified potential models, it's time to evaluate your needs and consult with experts to make an informed decision.

Evaluating Needs and Priorities

-

Material Requirements: Determine the types of materials you plan to work with. This will help you choose a suitable industrial laser machine that meets your cutting needs. Consider the thickness and size of the materials to ensure the machine's power and workspace are adequate.

-

Budget Considerations: Set a realistic budget for your laser cutter purchase. Factor in the initial cost, long-term operating expenses, and potential maintenance costs. Remember that investing in a high-quality machine can save you money in the long run by reducing downtime and repair costs.

-

Warranty and Support: Check the warranty offered by the manufacturer. A comprehensive warranty provides peace of mind and protects your investment. Ensure that the manufacturer offers reliable customer support and access to replacement parts if needed.

Consulting with Experts

Engage with professionals who have experience with different types of laser cutting machines. Qualified Technicians emphasize the importance of regular maintenance to prevent unexpected failures and ensure optimal performance. Consulting with experts can help you understand the technical aspects and maintenance requirements of your chosen model.

Highly Qualified Technician: "Preventive maintenance ensures the optimal performance and durability of the machine. It's about fixing things before they break."

By following these steps, you can confidently navigate the process of purchasing a laser cutter that aligns with your needs and priorities. Whether you opt for CO2 laser cutters, fiber laser cutters, or diode laser cutters, making an informed decision will enhance your projects' quality and efficiency.

You've explored the essential aspects of choosing the best laser cutting machine. From understanding different types like CO2, fiber, and diode lasers to evaluating key considerations such as budget, power, and safety features, this guide equips you with valuable insights. Now, it's your turn to assess your specific needs. Conduct thorough research and consult with experts to make an informed decision. Remember, the right laser cutter can significantly enhance your projects' quality and efficiency. Take the time to choose wisely and invest in a machine that aligns with your goals.

FAQ

What factors should I consider when choosing a laser cutting machine?

When selecting a laser cutting machine, consider the materials you plan to work with, your budget, and the machine's power and size. Evaluate the types of projects you will undertake and the precision required. Understanding these factors helps you make an informed decision that aligns with your needs.

How do I determine the right laser cutter for my materials?

Identify the materials you will frequently cut or engrave. CO2 lasers work well with organic materials like wood and glass, while fiber lasers excel with metals. Diode lasers are suitable for small-scale projects involving materials like cardboard and leather. Match the laser type to your material needs for optimal results.

Is it better to buy a new or refurbished laser cutter?

Buying a new laser cutter ensures you get the latest technology and warranty support. However, refurbished machines can be a cost-effective option if you're on a budget. Ensure the refurbished machine has been thoroughly inspected and comes with a warranty to safeguard your investment.

How important is the power of a laser cutter?

The power of a laser cutter determines the thickness and type of materials it can handle. Higher wattage allows for cutting thicker materials and increases cutting speed. Assess your material requirements to choose a machine with adequate power for your projects.

What safety features should I look for in a laser cutter?

Prioritize machines with enclosures, emergency stop buttons, and ventilation systems. These features protect users from laser exposure and harmful fumes. Laser safety glasses and interlock systems further enhance safety during operation.

How can I maintain my laser cutter for longevity?

Regular maintenance is crucial for optimal performance. Clean mirrors and lenses, check alignment, and inspect cooling systems. Replace consumables like lenses and mirrors as needed. Keeping software updated also ensures the machine runs efficiently.

What are the long-term costs associated with owning a laser cutter?

Consider energy consumption, maintenance, and consumables. Laser cutters vary in power usage, affecting electricity costs. Regular maintenance prevents costly repairs. Budget for these expenses to ensure your machine remains a valuable asset.

Can I finance a laser cutter purchase?

Yes, many manufacturers and retailers offer financing options. Establish your budget upfront to explore these options. Financing can make high-quality machines more accessible, allowing you to invest in a model that meets your needs without overspending.

How do user reviews help in choosing a laser cutter?

User reviews provide insights into the performance and reliability of different models. Look for feedback on ease of use, maintenance, and customer support. Positive reviews indicate a model's quality and can guide your purchasing decision.

Why is consulting with experts recommended before buying?

Experts offer valuable advice on technical aspects and maintenance requirements. They can help you understand the nuances of different models and ensure you choose a machine that fits your needs. Engaging with professionals enhances your decision-making process.

See Also

Comparative Guide to Laser Cutting Machine Costs

Guidelines for Selecting the Ideal Water Jet Cutter

Advice on Selecting the Best Wood Cutting Machine