How to Choose the Best Laser Cutting Machine for Home

Finding what is the best laser cutting machine for home use starts with understanding your needs. Are you cutting wood, engraving metal, or working with acrylic? Each material demands specific capabilities. Your budget also plays a big role. Some machines offer advanced features, but they come at a higher cost. Safety and ease of use matter too, especially for home setups. For example, enclosed laser cutting machines are becoming popular due to their safety and comfort. Whether you're a hobbyist or a DIY enthusiast, choosing the right laser cutting machine ensures precision and efficiency for your projects.

Types of Laser Cutting Machines: What is the Best Laser Cutting Machine for Home?

When choosing the best laser cutter for home use, understanding the different types of laser cutting machines is essential. Each type offers unique features and capabilities, making it easier to find the right fit for your needs. Let’s explore the three main types of home laser cutters and what they bring to the table.

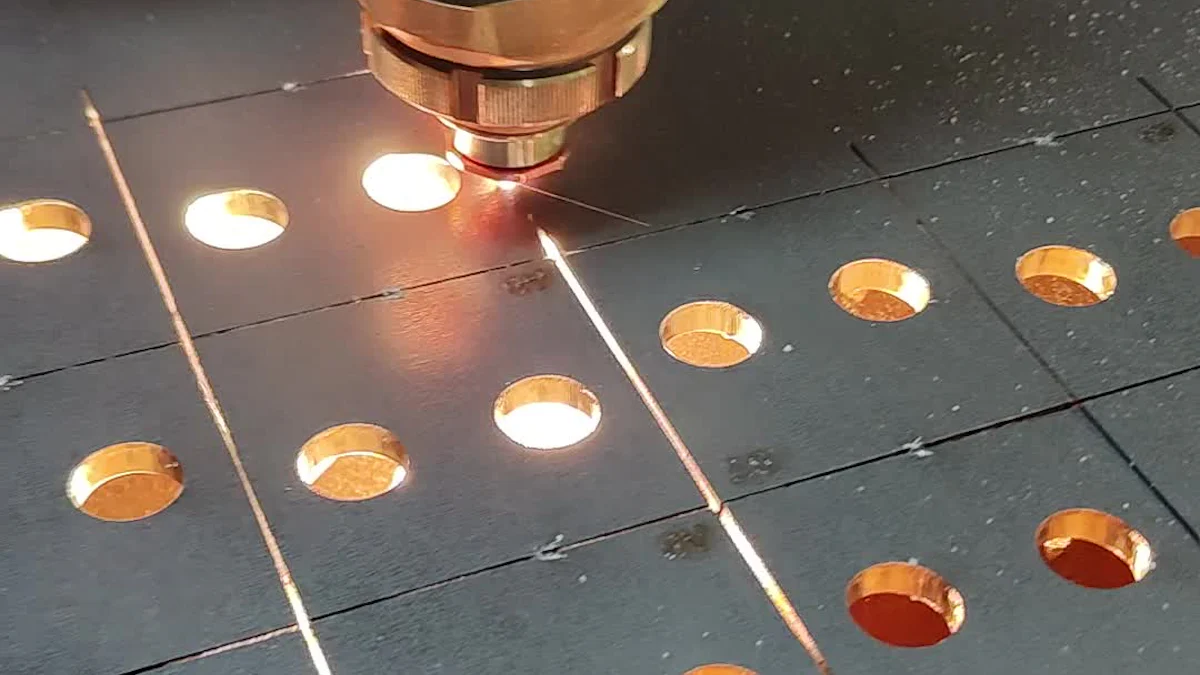

CO2 Laser Cutting Machines

CO2 laser cutters are a popular choice for home users. These machines use a carbon dioxide gas laser to cut and engrave materials with precision. They work well with wood, acrylic, leather, and even some fabrics. If you’re looking for versatility, a CO2 laser cutter is a solid option.

For beginners, models like the Glowforge Plus or xTool D1 Pro stand out. They combine ease of use with advanced functionality, making them ideal for hobbyists. CO2 machines also tend to be cost-effective, offering a balance between price and features. Whether you’re crafting intricate designs or starting small-scale production, this type of laser cutting machine delivers reliable results.

Pro Tip: If safety is a priority, consider an enclosed laser cutter. These machines come with protective covers that reduce exposure to laser beams and fumes, ensuring a safer workspace at home.

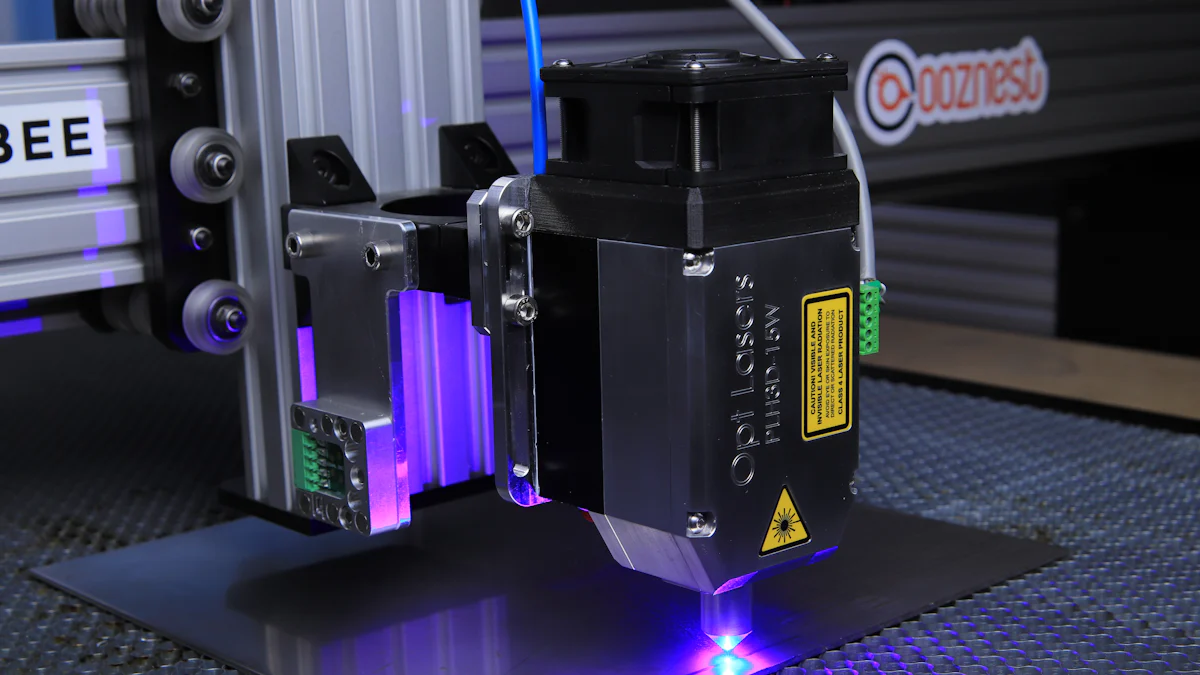

Diode Laser Cutting Machines

Diode lasers are compact and user-friendly, making them another great option for home use. These machines excel at engraving and can handle a variety of materials like wood, plastic, and metal. While they may not cut as deeply as CO2 lasers, they are perfect for detailed engraving projects.

If you’re into crafting or running a small business, a diode laser cutter could be your go-to tool. It’s lightweight, portable, and easy to set up. Plus, its affordability makes it a great entry point for those new to laser engraving machines.

Fiber Laser Cutting Machines

Fiber lasers are the powerhouse of laser cutting machines. They specialize in cutting and engraving metals, including stainless steel, aluminum, and brass. If your projects involve metalwork, a fiber laser cutter is the best choice. These machines offer unmatched precision and speed, making them ideal for professional-grade results.

However, fiber lasers are often more expensive than CO2 or diode lasers. They also require more expertise to operate. For most home users, this type of laser cutter might be overkill unless metal engraving is your primary focus.

Choosing the best home laser cutter depends on your specific needs. CO2 lasers offer versatility, diode lasers provide affordability and ease of use, and fiber lasers excel in metalwork. If you’re still wondering what is the best laser cutting machine for home, start by identifying the materials you’ll work with and the level of precision you need. And don’t forget to prioritize safety by opting for the best enclosed laser cutter for your workspace.

Comparing the Types: How to Choose a Home Laser Cutter

Choosing the right laser cutter for your home can feel overwhelming with so many options available. To make the decision easier, let’s compare the three main types—CO2, diode, and fiber laser cutters—and see how they stack up based on your needs.

1. CO2 Laser Cutters: Versatility Meets Precision

If you’re looking for a machine that can handle a variety of materials, CO2 laser cutters are a fantastic choice. These machines excel at cutting and engraving wood, acrylic, leather, and even some fabrics. They strike a balance between affordability and functionality, making them ideal for hobbyists and beginners. Models like the Glowforge Plus or xTool D1 Pro are user-friendly and packed with features to help you create intricate designs or even start small-scale production at home.

Why Choose CO2?

- Works well with non-metal materials.

- Offers precision and versatility.

- Great for crafting and DIY projects.

2. Diode Laser Cutters: Compact and Affordable

For those who prioritize portability and ease of use, diode laser cutters are worth considering. These machines are perfect for engraving and can handle materials like wood, plastic, and even some metals. While they may not cut as deeply as CO2 lasers, they shine in detailed engraving tasks. Their compact size and lower price point make them a great entry-level option for crafters or small business owners.

Why Choose Diode?

- Lightweight and portable.

- Affordable for beginners.

- Ideal for engraving projects.

3. Fiber Laser Cutters: The Metalwork Specialist

If your projects involve metal, fiber laser cutters are the way to go. These machines are designed to cut and engrave metals like stainless steel, aluminum, and brass with unmatched precision. However, they come with a higher price tag and require more expertise to operate. For most home users, fiber lasers might be unnecessary unless metalwork is your primary focus.

Why Choose Fiber?

- Best for metal engraving and cutting.

- Delivers professional-grade results.

- High speed and precision.

When deciding how to choose a home laser cutter, start by identifying the materials you’ll work with most often. If versatility is key, go for a CO2 laser cutter. If you’re focused on engraving and need something portable, a diode laser cutter is a great fit. For metal-focused projects, a fiber laser cutter will deliver the best results. By understanding the strengths of each type, you can confidently pick the machine that aligns with your goals.

Key Features to Look For in the Best Home Laser Cutter

When choosing a home laser cutter, understanding the key features can help you make the right decision. These features determine how well the machine performs and whether it fits your specific needs. Let’s dive into the most important aspects you should consider.

Laser Power and Cutting Speed

The power of a laser cutting machine directly impacts its cutting and engraving capabilities. Higher wattage means the machine can cut through thicker materials and work faster. For instance, a high-power home laser cutter with over 80 watts is ideal for cutting dense materials like wood or acrylic. On the other hand, lower-power machines, such as those with 25 to 40 watts, are better suited for engraving or working with thinner materials.

Cutting speed also plays a crucial role, especially if you plan to use the machine frequently. Faster speeds allow you to complete projects more efficiently. However, speed often depends on the material and the laser’s power. If you’re looking for precision and speed, fiber lasers are known for their unmatched performance, particularly with metals. For non-metals, CO2 lasers strike a balance between speed and accuracy.

Tip: If you’re a beginner, start with a mid-range machine that offers adjustable power settings. This flexibility lets you experiment with different materials without overwhelming you.

Work Area Size

The size of the work area determines the dimensions of the materials you can cut or engrave. A larger work area provides more versatility, allowing you to handle bigger projects. For example, if you’re creating custom signs or large decorative pieces, a spacious work area is essential. Smaller machines, however, are more compact and fit better in limited spaces, making them ideal for hobbyists or those with smaller workshops.

When considering the work area, think about the types of projects you’ll tackle most often. If portability matters, look for a compact enclosed laser cutter that’s easy to store and move around. These machines not only save space but also enhance safety by containing the laser beam and fumes within the enclosure.

Pro Tip: Measure your workspace before purchasing a home laser cutter. Ensure the machine fits comfortably while leaving room for ventilation and maintenance.

Material Compatibility

Not all laser engraving machines can handle every material. Understanding material compatibility ensures you get the most out of your investment. CO2 lasers are versatile and work well with non-metals like wood, acrylic, leather, and fabric. Diode lasers excel at engraving but may struggle with cutting thicker materials. Fiber lasers, on the other hand, are the go-to choice for metalwork, offering precision and speed for materials like stainless steel and aluminum.

If you plan to work with a variety of materials, a CO2 laser might be your best bet. For detailed engraving projects, a diode laser is a great option. If metal is your primary focus, invest in a fiber laser. Always check the machine’s specifications to ensure it supports the materials you intend to use.

Note: Avoid using materials like PVC or polycarbonate, as they release harmful fumes when cut. An enclosed laser cutter with an air filtration system can help manage fumes and keep your workspace safe.

By focusing on these key features, you can find a laser cutter that meets your needs and enhances your creative projects. Whether you’re a beginner or an experienced user, understanding the features to look for in a home laser cutter ensures you make an informed choice. Remember to prioritize safety, versatility, and ease of use when selecting your machine.

Software and Connectivity

The software and connectivity options of a laser cutting machine can significantly impact your overall experience. A user-friendly interface and seamless connectivity make it easier to bring your creative ideas to life. Let’s break down what you should look for in this area.

Software Compatibility

The software that comes with your laser cutter determines how you design and execute your projects. Some machines include proprietary software, while others are compatible with popular third-party design programs like Adobe Illustrator or CorelDRAW. If you’re already familiar with specific design tools, choosing a machine that supports them can save you time and effort.

Tip: Look for software that offers features like layer management, adjustable power settings, and preview modes. These tools help you fine-tune your designs before cutting or engraving.

For beginners, intuitive software with preloaded templates can be a game-changer. It simplifies the learning curve and allows you to start creating right away. Advanced users, on the other hand, may prefer software that provides more customization and control over the cutting process.

Connectivity Options

Modern laser cutters come with various connectivity options to suit different workflows. USB connections are standard, but many machines now offer Wi-Fi or Bluetooth capabilities. Wireless connectivity allows you to send designs directly from your computer or even your smartphone, adding convenience to your setup.

Why It Matters: Wireless options reduce the clutter of cables and make it easier to position your machine in tight spaces. They also enable remote operation, which can be especially useful for home users.

Some high-end models even support cloud-based platforms, letting you access your designs from anywhere. This feature is particularly handy if you collaborate with others or switch between multiple devices.

Updates and Support

Regular software updates ensure your machine stays compatible with new operating systems and design tools. Before purchasing, check if the manufacturer provides ongoing updates and technical support. A strong community of users can also be a valuable resource for troubleshooting and sharing tips.

Pro Tip: Machines with open-source software often have active online communities. These forums can help you learn new techniques and solve issues quickly.

By prioritizing software compatibility and connectivity, you can streamline your workflow and focus on your projects. Whether you’re a tech-savvy creator or a beginner, choosing a machine with the right tools and features will make your laser cutting experience more enjoyable.

Safety Features

Safety should always be a top priority when working with laser cutting machines. These powerful tools can pose risks if not used properly. Let’s explore the essential safety features you should look for to ensure a secure and worry-free experience.

Enclosed Design

An enclosed laser cutter provides a protective barrier between you and the laser beam. This design minimizes the risk of accidental exposure to harmful laser radiation. It also helps contain fumes and debris, keeping your workspace cleaner and safer.

Did You Know? Enclosed machines often include built-in ventilation systems to filter out smoke and harmful particles. This feature is especially important when cutting materials like acrylic or wood.

Emergency Stop Button

An emergency stop button is a must-have feature for any laser cutter. It allows you to immediately halt the machine in case of a malfunction or unexpected issue. This quick action can prevent accidents and protect both you and your equipment.

Air Filtration Systems

Laser cutting generates fumes and particles that can be hazardous if inhaled. Machines with integrated air filtration systems help maintain good air quality in your workspace. Look for models with HEPA filters or activated carbon filters for optimal performance.

Tip: If your machine doesn’t include a filtration system, consider investing in an external air purifier. Proper ventilation is crucial for a safe and comfortable working environment.

Safety Sensors

Some advanced laser cutters come equipped with safety sensors that detect obstructions or overheating. These sensors automatically pause the machine to prevent damage or accidents. While not all models include this feature, it’s worth considering if safety is a top concern.

Protective Gear

Even with built-in safety features, using protective gear is essential. Safety goggles designed for laser use shield your eyes from harmful radiation. Gloves and masks can also provide additional protection, especially when handling certain materials.

By choosing a laser cutter with robust safety features, you can enjoy peace of mind while working on your projects. Always follow the manufacturer’s guidelines and take extra precautions to create a safe and efficient workspace.

Budget Considerations: Laser Cutter Buying Guide

When buying a laser cutter for your home, understanding the cost and value of different models is essential. Whether you're a hobbyist or running a small business, balancing your budget with the features you need ensures you make a smart investment. Let’s explore the price ranges and how to weigh cost against functionality.

Price Ranges for Home Laser Cutting Machines

The price of a home laser cutter can vary widely depending on its power, features, and capabilities. Entry-level models, like the Aura Laser 3D Printer, start at around $999. These machines are perfect for beginners, offering a compact design and the ability to cut and engrave materials like paper, thin wood, and faux leather. If you're just starting out, this type of machine provides an affordable way to explore laser cutting without breaking the bank.

Mid-range options, such as the Snapmaker Ray, offer more power and versatility. With interchangeable laser modules, you can choose between a 20W or 40W laser, depending on your needs. The 40W module, for instance, can cut through 20mm wood with ease, making it ideal for more demanding projects. These machines typically range from $1,500 to $3,000, striking a balance between cost and performance.

High-end models, like the LaserPecker LP5, cater to professionals and advanced users. This device combines a 20W diode and a 20W fiber laser, allowing you to work on both metal and non-metal materials with precision. Its compact design and high-speed capabilities make it a favorite for those who need portability and power. These machines often exceed $3,000 but deliver unmatched quality and functionality.

Pro Tip: If you're on a tight budget, look for sales or refurbished models. Many manufacturers offer discounts on older versions, giving you access to reliable machines at a lower cost.

Balancing Cost and Features

When evaluating the cost of a laser cutting machine, it's important to consider the features that matter most to you. Start by identifying your primary use case. Are you focusing on crafting, engraving, or metal cutting? For general crafting, affordable laser cutters like the Aura or mid-range CO2 models provide excellent value. If you're working with metals, investing in a fiber laser like the LaserPecker LP5 might be worth the higher price.

Think about the maintenance requirements as well. Machines with higher power often need more upkeep, which can add to the overall cost. Look for models with a good warranty to protect your investment. For example, many manufacturers offer extended warranties that cover parts and labor, reducing your long-term expenses.

If you're running a small business, prioritize speed and efficiency. A high-power machine, such as the High-Power Laser Cutter, can cut through thick materials like 20mm acrylic or 18mm plywood in a single pass. While these machines come with a higher price tag, their ability to handle large volumes of work makes them a cost-effective choice for business owners.

Did You Know? An enclosed laser cutter not only enhances safety but also reduces the need for frequent cleaning and maintenance. This feature can save you time and money in the long run.

Finally, consider the total cost of ownership. Beyond the initial purchase price, factor in expenses like software, replacement parts, and ventilation systems. Machines with built-in air filtration, like many enclosed laser cutters, can help you save on additional equipment. By weighing these factors, you can find a machine that fits your budget while meeting your needs.

Choosing the right home laser cutter involves more than just looking at the price tag. By understanding the price ranges and balancing cost with features, you can make an informed decision. Whether you're a beginner or a seasoned user, investing in a machine that aligns with your goals ensures you get the most value for your money.

Material Compatibility: What Materials Can You Use with a Laser Cutting Machine?

Understanding material compatibility is crucial when choosing a laser cutting machine for home use. The materials you work with will determine the type of laser cutter you need and the results you can achieve. Let’s explore the materials you can use and those you should avoid.

Common Materials for Home Laser Cutting

Home laser cutters are incredibly versatile, allowing you to work with a wide range of materials. Here are some of the most popular options:

- Wood: Perfect for crafting, wood is one of the most commonly used materials in laser cutting. Machines like CO2 laser cutters can handle plywood, MDF, and hardwood with ease. You can create anything from intricate engravings to custom furniture pieces.

- Acrylic: Known for its clean cuts and polished edges, acrylic is ideal for signage, jewelry, and decorative items. Laser cutters produce precise results, making it a favorite among hobbyists and small business owners.

- Leather: Whether you’re designing wallets, belts, or custom patches, laser cutters can engrave and cut leather with precision. Both natural and synthetic leather work well, though synthetic options may require extra care due to potential fumes.

- Fabric: Laser cutters can handle fabrics like cotton, felt, and polyester. This makes them great for creating custom clothing, appliqués, or home décor items.

- Glass: While you can’t cut glass with most home laser cutters, engraving is possible. You can personalize glassware, mirrors, or decorative panels with intricate designs.

- Paper and Cardboard: These materials are excellent for prototyping, scrapbooking, or creating custom packaging. Laser cutters can produce detailed cuts without damaging the material.

Pro Tip: If you’re working with multiple materials, consider a CO2 laser cutter. Its versatility makes it a reliable choice for non-metal projects.

Some advanced machines, like fiber laser cutters, can even handle metals such as stainless steel, aluminum, and brass. However, these machines are typically more expensive and suited for users focused on metalwork.

Materials to Avoid

Not all materials are safe or suitable for laser cutting. Some can damage your machine or release harmful fumes. Here’s what to steer clear of:

- PVC (Polyvinyl Chloride): Cutting PVC releases toxic chlorine gas, which can harm both you and your machine. Avoid using this material at all costs.

- Polycarbonate: This material doesn’t cut well with lasers and often produces poor results. It can also release harmful fumes.

- Foam Core Boards: While tempting for lightweight projects, foam core boards can melt or catch fire during cutting.

- Fiberglass: A mix of glass and resin, fiberglass is not suitable for laser cutting. It can emit dangerous fumes and damage your machine’s optics.

- Coated Metals: Unless you’re using a fiber laser cutter, coated metals can be challenging to work with. The coating may burn unevenly, leaving unsatisfactory results.

Safety Tip: Always check the material’s specifications before using it with your laser cutter. If you’re unsure, consult the manufacturer’s guidelines or test a small sample first.

By understanding what materials work best and which ones to avoid, you can maximize the potential of your laser cutting machine. Whether you’re crafting with wood, engraving glass, or experimenting with acrylic, choosing the right materials ensures safe and successful projects every time.

Ease of Use and Maintenance: How to Choose a Home Laser Cutter

When selecting a laser cutter for home use, ease of operation and maintenance play a significant role. A machine that’s simple to handle and maintain ensures a smoother experience, especially for beginners. Let’s break down what you need to know.

Learning Curve

The learning curve of a laser cutter depends on its design and features. Some machines are more intuitive, making them ideal for first-time users. For example, many modern models come with pre-installed software and user-friendly interfaces. These features allow you to start creating without spending hours figuring out how the machine works.

If you’re new to laser cutting, look for machines labeled as “easy to use.” These often include step-by-step guides, preloaded templates, and simple controls. An enclosed laser cutter is another excellent choice for beginners. Its design not only enhances safety but also simplifies the setup process by containing the laser beam and fumes within a protective enclosure.

Tip: Start with small projects to familiarize yourself with the machine’s capabilities. Gradually experiment with different materials and settings to build confidence.

For advanced users, machines with customizable settings and advanced software provide more control. However, these may require additional time to master. Always consider your skill level and the time you’re willing to invest in learning before making a purchase.

Maintenance Requirements

Proper maintenance keeps your laser cutter running smoothly and extends its lifespan. While some machines require minimal upkeep, others demand regular attention. Understanding the maintenance needs of your chosen model helps you avoid unexpected issues.

Here’s what to focus on:

- Cleaning the Optics: Dust and debris can accumulate on the laser lens and mirrors, affecting performance. Regular cleaning ensures precise cuts and engravings.

- Replacing Consumables: Components like laser tubes and filters wear out over time. Check the manufacturer’s guidelines for replacement intervals.

- Ventilation System: Machines with built-in air filtration systems, such as enclosed laser cutters, require periodic filter changes. This step is crucial for maintaining air quality in your workspace.

- Software Updates: Keeping the software up-to-date ensures compatibility with new design tools and operating systems.

Pro Tip: Choose a machine with a detailed maintenance manual. Clear instructions make it easier to perform routine tasks and troubleshoot minor issues.

Some models, especially high-end ones, come with self-diagnostic features. These tools alert you to potential problems, allowing you to address them before they escalate. While these machines may cost more upfront, they save time and effort in the long run.

Customer Support and Community

Reliable customer support can make a world of difference, especially when you encounter challenges. Manufacturers that offer responsive support teams and comprehensive resources help you resolve issues quickly. Look for companies with a reputation for excellent service.

In addition to official support, an active user community provides valuable insights. Many laser cutter brands have online forums or social media groups where users share tips, troubleshoot problems, and showcase their creations. Joining these communities connects you with others who can guide you through the learning process.

Why It Matters: A strong support network ensures you’re never stuck when facing technical difficulties. Whether it’s a quick question about settings or advice on complex projects, having access to knowledgeable individuals boosts your confidence.

When evaluating customer support, consider the availability of tutorials, FAQs, and live chat options. Some brands even offer virtual training sessions to help you get started. These resources make the machine easier to use and maintain, enhancing your overall experience.

By focusing on ease of use and maintenance, you can choose a laser cutter that fits seamlessly into your workflow. Whether you’re a beginner or an experienced user, prioritizing user-friendly features, manageable upkeep, and reliable support ensures a hassle-free journey into laser cutting.

Safety Features: Ensuring Safe Use of a Laser Cutting Machine at Home

When working with a laser cutting machine at home, safety should always come first. These machines are powerful tools, but without proper precautions, they can pose risks. By understanding key safety features and creating a secure workspace, you can enjoy your projects with peace of mind.

Key Safety Features to Look For

Modern laser cutting machines come equipped with various safety features designed to protect you during operation. Here are the most important ones to consider:

- Enclosed Design: An enclosed laser cutter is one of the safest options for home use. Its protective casing prevents accidental exposure to the laser beam and contains fumes and debris generated during cutting. This feature is especially useful if you’re working in a shared or small space.

- Laser Class 1 Safety Certification: Machines with this certification meet strict safety standards, ensuring minimal risk during operation. These models are designed to prevent harmful laser radiation from escaping the enclosure, making them ideal for home environments.

- Emergency Stop Button: This feature allows you to immediately halt the machine if something goes wrong. Whether it’s a material catching fire or an unexpected malfunction, the emergency stop button provides an instant safeguard.

- Air Filtration Systems: Cutting materials like wood or acrylic can produce smoke and harmful fumes. Machines with built-in air filtration systems, such as HEPA or activated carbon filters, help maintain clean air in your workspace.

- Safety Sensors: Advanced models often include sensors that detect overheating or obstructions. These sensors automatically pause the machine to prevent accidents or damage.

Tip: Always wear protective goggles when operating a laser cutter, even if the machine has an enclosed design. This extra layer of protection ensures your eyes stay safe from any stray reflections.

Setting Up a Safe Workspace

A well-organized and ventilated workspace is just as important as the safety features of your machine. Here’s how to create an environment that minimizes risks:

- Choose a Stable Surface: Place your laser cutter on a sturdy, non-flammable surface. Avoid using wooden tables or other combustible materials, as they can increase the risk of fire.

- Ensure Proper Ventilation: Laser cutting generates fumes and odors, especially when working with materials like acrylic or leather. Set up your machine in a well-ventilated area or use an external exhaust system to direct fumes outside. Machines with built-in air filtration systems can also help maintain air quality.

- Maintain Adequate Space: Leave enough room around your machine for easy access and ventilation. Crowded spaces can make it harder to operate the machine safely and may increase the risk of accidents.

- Keep a Fire Extinguisher Nearby: Even with all precautions, accidents can happen. A fire extinguisher designed for electrical fires is a must-have in any workspace with a laser cutter.

- Organize Your Materials: Store compatible materials like wood, acrylic, and fabric in a dry, safe place. Keep incompatible materials, such as PVC or polycarbonate, far away from your workspace to avoid accidental use.

Pro Tip: Regularly inspect your machine for wear and tear. Clean the optics, replace filters, and check for any loose connections to ensure it operates safely and efficiently.

By combining a laser safety machine with a well-prepared workspace, you can significantly reduce risks and focus on your creative projects. Always follow the manufacturer’s guidelines and stay informed about best practices for safe laser cutting.

Choosing the right laser cutter for your home starts with understanding your needs. Think about the materials you’ll work with, your budget, and the features that matter most. Whether you’re exploring what is the best laser cutting machine for home or looking for the best laser cutter for home use, focus on the factors to consider like safety, ease of use, and material compatibility. If you’re a beginner, start with an entry-level home laser cutter to build confidence. Always prioritize safety and user-friendliness to make your laser cutting experience enjoyable and efficient.

FAQ

What materials can I cut or engrave with a home laser cutter?

You can work with a variety of materials using a laser cutter. Common options include wood, acrylic, leather, fabric, and paper. CO2 laser cutters handle non-metals like wood and acrylic exceptionally well. Diode lasers excel at engraving materials such as wood and plastic. Fiber lasers are ideal for metals like stainless steel and aluminum. However, avoid materials like PVC and polycarbonate, as they release harmful fumes when cut.

Tip: Always check the material compatibility of your machine before starting a project to ensure safety and optimal results.

Is it safe to use a laser cutter at home?

Yes, laser cutters are safe for home use if you follow proper safety guidelines. Machines with enclosed designs and built-in air filtration systems enhance safety by containing fumes and debris. Always wear protective goggles, ensure proper ventilation, and keep a fire extinguisher nearby. Avoid placing the machine on combustible surfaces like wood.

Pro Tip: Look for models with safety features like emergency stop buttons and fire-sensing systems for added peace of mind.

Do I need special training to operate a laser cutter?

While laser cutters are user-friendly, understanding their operation is essential. Many machines come with user manuals and tutorials to guide you. For advanced models, learning how to adjust settings like laser power and speed may take some practice. If you're new, start with beginner-friendly machines that include preloaded templates and simple controls.

Did You Know? Some manufacturers offer virtual training sessions or online communities where you can learn tips and tricks from other users.

How do I maintain my laser cutter?

Regular maintenance keeps your laser cutter running smoothly. Clean the optics to remove dust and debris, replace filters in air filtration systems, and check for wear on parts like laser tubes. Keep the software updated to ensure compatibility with design tools. Machines with detailed maintenance manuals make these tasks easier.

Pro Tip: Choose a model with self-diagnostic features to identify potential issues before they become major problems.

What kind of workspace do I need for a laser cutter?

A stable, non-flammable surface is essential for your laser cutter. Ensure the area has proper ventilation to manage fumes and smoke. If you don’t have access to a window, consider investing in a powerful air purifier system. Leave enough space around the machine for easy access and maintenance.

Safety Tip: Keep incompatible materials like PVC far from your workspace to avoid accidental use.

Can I use a laser cutter for metal projects?

Yes, but it depends on the type of laser cutter. Fiber lasers are specifically designed for cutting and engraving metals like stainless steel and brass. CO2 and diode lasers are better suited for non-metal materials. If metalwork is your focus, invest in a fiber laser cutter for precise and professional results.

How do I ensure proper ventilation when using a laser cutter?

Proper ventilation is crucial to avoid exposure to harmful fumes. Machines with built-in air filtration systems, such as HEPA or activated carbon filters, help maintain clean air. If your machine doesn’t include this feature, set up an external exhaust system or use a high-quality air purifier.

Tip: Position your machine near a window or in a well-ventilated area for the best airflow.

What safety features should I look for in a laser cutter?

Key safety features include an enclosed design, emergency stop button, and air filtration systems. Machines with safety sensors that detect overheating or obstructions add an extra layer of protection. Always prioritize models with Laser Class 1 Safety Certification for home use.

Did You Know? Enclosed laser cutters not only enhance safety but also reduce the need for frequent cleaning by containing debris and fumes.

How much does a home laser cutter cost?

The cost varies based on the machine's power and features. Entry-level models start around $999 and are great for beginners. Mid-range options range from $1,500 to $3,000, offering more power and versatility. High-end models, designed for professionals, can exceed $3,000 but deliver unmatched precision and functionality.

Pro Tip: Look for refurbished models or sales to get reliable machines at a lower cost.

Can I use a laser cutter in a small space?

Yes, compact laser cutters are perfect for small spaces. Many models are designed with portability in mind and include features like wireless connectivity to reduce clutter. Enclosed designs also make them safer for tight areas by containing fumes and laser beams.

Tip: Measure your workspace before purchasing to ensure the machine fits comfortably while leaving room for ventilation.

See Also

Essential Advice for Selecting Top Water Jet Cutters

Effective Techniques for Operating a Laser Cutting Machine

Guidelines for Selecting the Ideal Wood Cutting Machine