Best CNC Laser Cutting Machines in 2024

CNC laser cutting machines, which are essential tools in modern manufacturing, have revolutionized how you can create products with precision and efficiency. So, what is a CNC laser cutting machine? These machines deliver unmatched accuracy, making them ideal for crafting intricate designs or cutting a variety of materials like wood, metal, and acrylic. For a small business, they offer a perfect balance of affordability and performance, helping you produce high-quality items without breaking the bank. Unlike traditional cutting methods, CNC laser cutters work faster and reduce material waste, saving you time and money. Investing in one could transform your operations and elevate the quality of your work.

What Is a CNC Laser Cutting Machine and How Does It Work?

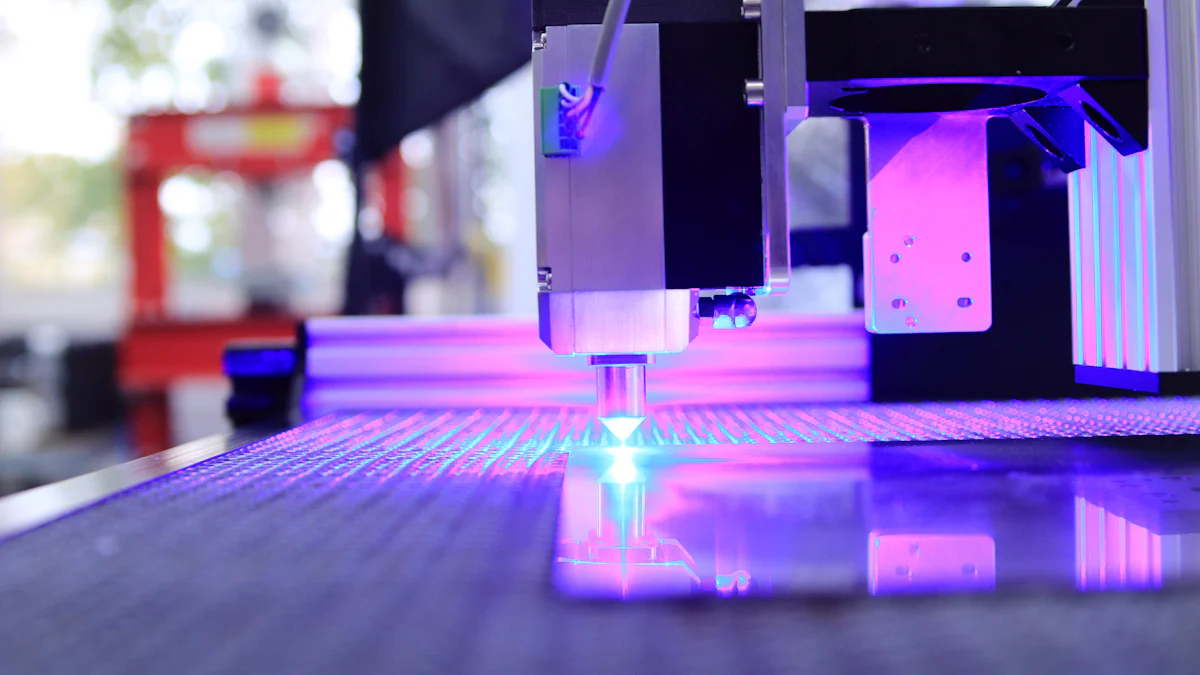

CNC laser cutting machines have become a game-changer in modern manufacturing. But what is a CNC laser cutting machine? At its core, it’s a tool that uses a high-powered laser beam, guided by computer instructions, to cut or engrave materials with incredible precision. These machines are widely used in industries like automotive, aerospace, and electronics, but they’re also perfect for small businesses looking to create intricate designs or custom products. With their ability to handle complex shapes and patterns, CNC laser cutters make tasks that were once impossible by hand entirely achievable.

Overview of CNC Laser Cutting Technology

CNC laser cutting technology combines the power of lasers with computer numerical control (CNC) systems. The laser emits a focused beam of light that generates intense heat, melting or vaporizing the material it touches. The CNC system ensures the laser follows a precise path, creating clean cuts or detailed engravings. This technology works on a variety of materials, including wood, metal, plastic, and acrylic. Whether you’re crafting jewelry, signage, or industrial components, CNC laser cutting offers unmatched accuracy and efficiency.

One of the standout features of this technology is its versatility. You can use it for both industrial applications and artistic projects. The ability to switch between cutting and engraving makes it a valuable tool for businesses of all sizes. Plus, the process minimizes material waste, saving you money in the long run.

Key Components of a CNC Laser Cutter

To understand how these machines work, it helps to know their main components. A typical CNC laser cutter includes:

- Laser Generator: Produces the high-powered laser beam used for cutting or engraving.

- Beam Transmission System: Directs the laser beam to the material.

- Workbench (Machine Bed): Provides a stable surface for the material being cut.

- CNC Control System: Manages the movement and speed of the laser, ensuring precision.

- Cooling System: Prevents the machine from overheating during operation.

- Software: Allows you to design and upload patterns or instructions for the machine to follow.

Each component plays a crucial role in delivering the precision and efficiency that CNC laser cutters are known for. Together, they automate the entire cutting process, so you can focus on designing while the machine handles the rest.

How CNC Laser Cutting Machines Operate

Operating a CNC laser cutting machine is simpler than you might think. First, you create a design using compatible software. Once the design is ready, you upload it to the machine. The CNC system then translates your design into precise movements for the laser. The laser beam cuts or engraves the material based on the instructions, following the exact path you’ve programmed.

The process is fast and efficient. The laser’s intense heat ensures clean cuts without physical contact, reducing the risk of damage to the material. You can adjust the laser’s power and speed to suit different materials and project requirements. For example, cutting through thick metal might require more power, while engraving delicate wood needs a lighter touch.

By automating the cutting process, CNC laser machines save you time and effort. They also deliver consistent results, making them ideal for both one-off projects and large-scale production.

Top CNC Laser Cutting Machines for Small Businesses in 2024

Choosing the right CNC laser cutter can transform your small business. Whether you’re crafting intricate designs or producing custom products, the right machine ensures precision, efficiency, and value. Below, you’ll find detailed reviews of some of the best CNC laser cutting machines available in 2024. These recommendations are tailored to help you make an informed decision.

xTool P2 55W CO2 Laser Cutter

Key Features

The xTool P2 55W CO2 Laser Cutter stands out for its versatility and power. It can cut and engrave a wide range of materials, including wood, acrylic, leather, rubber, and paper. With a stable output power and engraving speeds of up to 600mm/s, this machine delivers smooth, clean cuts and precise engravings. One of its most impressive capabilities is cutting 20mm acrylic in a single pass, making it ideal for demanding projects.

Key features include:

- 55W CO2 laser power for high performance.

- Compatibility with various materials.

- Fast engraving speeds for efficient production.

- Advanced software integration for seamless design uploads.

Pros and Cons

Pros:

- Exceptional precision and speed.

- Handles thick materials with ease.

- Versatile for both cutting and engraving tasks.

Cons:

- Higher price point compared to entry-level models.

- Requires adequate space due to its size.

Pricing and Value for Money

The xTool P2 offers premium features at a competitive price. While it may cost more upfront, its durability and performance make it a worthwhile investment for any small business. If you’re looking for a reliable CNC laser cutter that delivers professional results, this machine is a top choice.

xTool S1 Diode Laser Cutter

Key Features

The xTool S1 Diode Laser Cutter is a powerful enclosed diode laser machine designed for precision and safety. It features a 40W diode laser module capable of cutting through 18mm wood in a single pass. This makes it perfect for small businesses focused on woodworking or intricate designs. Its enclosed design ensures safe operation, especially in shared workspaces.

Key features include:

- 40W diode laser for powerful cutting.

- Enclosed design for enhanced safety.

- Ability to handle thick wood and other materials.

- Compact size suitable for smaller workspaces.

Pros and Cons

Pros:

- High cutting power for a diode laser.

- Safe and user-friendly design.

- Compact and space-saving.

Cons:

- Limited material compatibility compared to CO2 lasers.

- Slower engraving speeds than higher-end models.

Pricing and Value for Money

The xTool S1 offers excellent value for small businesses seeking a safe and efficient laser cutter. Its price is reasonable for the features it provides, making it a great entry point for those new to CNC laser cutting.

OMTech CO2 Laser Cutter

Key Features

The OMTech CO2 Laser Cutter is a popular choice among small business owners for its affordability and functionality. It combines reliable performance with user-friendly features, making it accessible even for beginners. This machine works well with materials like wood, acrylic, and leather, offering flexibility for various projects.

Key features include:

- CO2 laser technology for versatile cutting and engraving.

- Affordable pricing for small businesses.

- Easy-to-use interface for quick setup and operation.

Pros and Cons

Pros:

- Budget-friendly without compromising quality.

- Suitable for a wide range of materials.

- Simple to operate, even for beginners.

Cons:

- Slower speeds compared to premium models.

- May require additional maintenance over time.

Pricing and Value for Money

The OMTech CO2 Laser Cutter is one of the most affordable options on the market. It’s perfect for small businesses looking to start with CNC laser cutting without a significant upfront investment. Its balance of cost and functionality makes it a smart choice for entrepreneurs.

Laguna Tools SmartShop EX CNC Laser Cutter

Key Features

The Laguna Tools SmartShop EX CNC Laser Cutter is a premium choice for businesses that demand top-tier performance. This machine combines cutting-edge technology with robust construction, making it ideal for high-volume production or intricate designs. Its advanced features ensure precision and efficiency, even for the most challenging projects.

Key features include:

- A powerful CO2 laser system for precise cutting and engraving.

- High-speed operation to handle large-scale tasks efficiently.

- Compatibility with a wide range of materials, including wood, acrylic, and metal.

- An intuitive control system that simplifies operation.

- A durable build designed for long-term use in demanding environments.

This laser cutter excels in delivering consistent results, whether you're crafting custom signage, intricate art pieces, or industrial components.

Pros and Cons

Pros:

- Exceptional build quality ensures durability.

- Handles both small-scale and large-scale projects with ease.

- Offers high precision for detailed work.

Cons:

- Higher price point may not suit all budgets.

- Requires a larger workspace due to its size.

Pricing and Value for Money

The Laguna Tools SmartShop EX comes with a premium price tag of $9,999. While this may seem steep, the machine's performance and reliability justify the investment. If your business requires a high-performance cnc laser cutter for demanding tasks, this model offers excellent value for money.

Creality Falcon2 Laser Engraver and Cutter

Key Features

The Creality Falcon2 Laser Engraver and Cutter is an affordable yet capable option for small businesses and hobbyists. Priced at just $699, it provides impressive functionality without breaking the bank. This machine is perfect for startups or craft businesses looking to explore cnc laser cutting without a significant upfront investment.

Key features include:

- A compact design that fits easily into smaller workspaces.

- A user-friendly interface for quick setup and operation.

- Compatibility with materials like wood, leather, and acrylic.

- Reliable performance for both cutting and engraving tasks.

Its affordability and ease of use make it a great entry-level option for those new to cnc laser cutters.

Pros and Cons

Pros:

- Budget-friendly price makes it accessible to small businesses.

- Compact size saves workspace.

- Easy to operate, even for beginners.

Cons:

- Limited power compared to higher-end models.

- Slower speeds may not suit high-volume production.

Pricing and Value for Money

At $699, the Creality Falcon2 offers incredible value for its price. It’s an excellent choice for small businesses or individuals who want to experiment with laser cutting machines without a hefty investment. While it may not match the capabilities of premium models, it delivers reliable performance for its price range.

Honorable Mentions

Turbo646 Laser Engraving Machine

The Turbo646 Laser Engraving Machine strikes a balance between functionality and cost-effectiveness. It’s a versatile option for small businesses that need a reliable cnc laser cutter for various projects. With its user-friendly design and solid performance, it’s a great alternative for those seeking affordability without compromising quality.

2024 CO2 Laser Cutter for Small Business and Home Use

The 2024 CO2 Laser Cutter for Small Business and Home Use is another noteworthy option. Priced at $3,200, it caters to entrepreneurs and hobbyists alike. This machine offers a good mix of power and precision, making it suitable for a wide range of applications. Whether you’re crafting custom products or exploring creative projects, this laser cutter provides dependable results.

Advantages of CNC Laser Cutting Machines

Precision and Accuracy

When it comes to creating intricate designs and accurate cuts, CNC laser cutting machines excel. These machines use advanced technology to deliver high precision and resolution, ensuring every cut or engraving matches your design perfectly. Whether you're working on delicate patterns or complex shapes, the laser's focused beam guarantees flawless results. This level of precision in design is especially valuable for businesses that prioritize quality in their products.

For example, the xTool P2 is renowned for its precision. It allows you to achieve smooth edges and detailed engravings, even on challenging materials like acrylic or leather. With such tools, you can confidently produce professional-grade items that stand out in the market.

Versatility Across Materials

CNC laser cutting machines are incredibly versatile. They can handle a wide range of materials, including wood, metal, acrylic, leather, and more. This versatility makes them an essential tool for businesses that work on diverse projects. You can switch between materials without needing multiple machines, saving both time and resources.

The xTool P2, for instance, showcases this versatility by cutting through thick acrylic in a single pass while also engraving delicate designs on wood. This adaptability ensures you can meet various customer demands without compromising efficiency. Whether you're crafting custom signage or intricate jewelry, a laser cutting machine empowers you to explore endless possibilities.

Cost-Effectiveness for Small Businesses

Investing in a CNC laser cutting machine offers efficiency and cost-effectiveness for small businesses. These machines reduce material waste by delivering precise cuts, which means you get the most out of your raw materials. Additionally, their speed and automation improve productivity, allowing you to complete projects faster and take on more orders.

The xTool P2 combines power and speed to minimize operation time, boosting your overall efficiency. By automating repetitive tasks, it frees up your time to focus on growing your business. While the initial investment might seem significant, the long-term savings and increased productivity make it a smart choice for entrepreneurs.

Scalability for Growing Operations

As your business grows, you need tools that can keep up with increasing demands. CNC laser cutting machines offer the scalability required to handle larger workloads without compromising quality or efficiency. These machines adapt to your needs, making them a smart investment for businesses planning to expand.

One of the standout options for scalability is the xTool P2. This machine combines power and precision, allowing you to tackle more complex projects as your operations grow. Its ability to cut a wide range of materials ensures you can diversify your product offerings. Whether you're working with wood, acrylic, or leather, the xTool P2 delivers consistent results, even under heavy use.

"The xTool P2 is a great investment for businesses that need a versatile, precise, and efficient machine for laser cutting various materials."

CNC laser cutters also save time, which becomes crucial as your order volume increases. Machines like the xTool P2 minimize operation time with their high-speed performance. This means you can complete more projects in less time, boosting your overall productivity. By automating repetitive tasks, these machines free up your resources, allowing you to focus on scaling other aspects of your business.

Another advantage is the ability to handle both small-scale and large-scale production. Whether you're fulfilling a single custom order or producing items in bulk, CNC laser cutters maintain the same level of precision. This flexibility ensures you can meet customer demands without needing additional equipment.

Scalability also extends to the software used with these machines. Many CNC laser cutters come with advanced software that grows with your business. You can start with basic designs and gradually move to more intricate patterns as your skills and customer requirements evolve. This adaptability ensures your machine remains a valuable asset, no matter how much your business expands.

In short, CNC laser cutting machines like the xTool P2 provide the tools you need to scale your operations efficiently. They combine speed, precision, and versatility, making them indispensable for growing businesses. With the right machine, you can confidently take on larger projects and explore new opportunities without worrying about outgrowing your equipment.

Types of CNC Laser Cutting Machines

When choosing a CNC laser cutting machine, understanding the different types available can help you make the best decision for your needs. Each type offers unique features and benefits, making them suitable for specific applications. Let’s explore the three main types of CNC laser cutters.

CO2 Laser Cutters

CO2 laser cutters are among the most popular options for businesses. These machines use a gas mixture, primarily carbon dioxide, to generate a laser beam. They excel at cutting non-metal materials like wood, acrylic, leather, and plastics. If your projects involve intricate designs or engraving on these materials, a CO2 laser cutter is a fantastic choice.

One of the standout features of CO2 laser cutters is their versatility. You can use them for both cutting and engraving tasks, making them ideal for small businesses that handle diverse projects. For example, crafting custom signage or detailed art pieces becomes effortless with this type of machine. Additionally, CO2 lasers produce smooth edges and clean cuts, reducing the need for post-processing.

"CO2 laser cutters are perfect for businesses that prioritize precision and versatility in non-metal applications."

However, CO2 laser cutters may not be the best option for cutting metals. They lack the power and efficiency required for thicker or harder materials. If your work involves metals, you might want to consider other types of laser cutters.

Fiber Laser Cutters

Fiber laser cutters are the go-to choice for cutting metals. These machines use optical fibers to amplify the laser beam, resulting in a highly concentrated and powerful output. This makes them perfect for cutting materials like stainless steel, aluminum, and brass. If your business focuses on metal fabrication or industrial applications, a fiber laser cutter is an excellent investment.

Fiber laser cutters stand out for their speed and precision. They deliver faster processing times compared to other types, allowing you to complete projects more efficiently. The smaller beam diameter ensures high accuracy, even on intricate designs. Additionally, fiber lasers require less maintenance, making them a cost-effective option in the long run.

"Fiber laser cutters combine power and precision, making them indispensable for metalworking businesses."

While fiber laser cutters excel at cutting metals, they may not perform as well on non-metal materials. If your projects involve a mix of materials, you might need to pair a fiber laser cutter with another type of machine for optimal results.

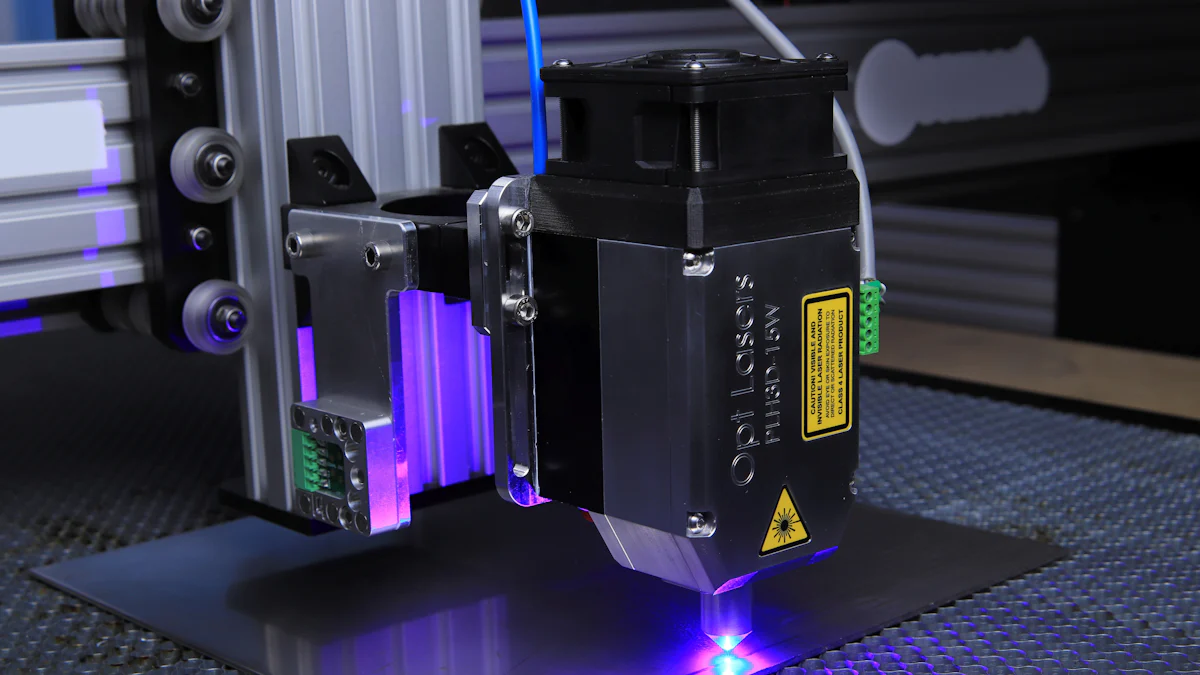

Diode Laser Cutters

Diode laser cutters are compact and affordable, making them a great entry-level option for small businesses or hobbyists. These machines use semiconductor diodes to generate the laser beam. While they may not match the power of CO2 or fiber lasers, diode laser cutters are perfect for light-duty tasks like engraving or cutting thin materials.

The biggest advantage of diode laser cutters is their accessibility. They are easy to set up and operate, even for beginners. Their compact size also makes them suitable for smaller workspaces. If you’re just starting with CNC laser cutting or focusing on projects like engraving wood or leather, a diode laser cutter is a practical choice.

However, diode laser cutters have limitations. They struggle with thicker materials and may not deliver the same level of precision as CO2 or fiber lasers. For businesses with more demanding requirements, upgrading to a more powerful machine might be necessary.

Each type of CNC laser cutter offers unique advantages. A CO2 laser cutter provides unmatched versatility for non-metal materials. A fiber laser cutter delivers exceptional performance for metalworking. A diode laser cutter offers an affordable and user-friendly solution for light-duty tasks. By understanding these differences, you can choose the machine that aligns with your business goals and project needs.

Comparison of Types for Small Businesses

Choosing the right CNC laser cutting machine for your small business can feel overwhelming, especially with so many options available. Each type—CO2, fiber, and diode—offers unique advantages, and understanding how they compare can help you make the best decision for your needs. Let’s break it down.

1. CO2 Laser Cutters: The All-Rounder

CO2 laser cutters are known for their versatility. They excel at cutting and engraving non-metal materials like wood, acrylic, leather, and plastics. If your business involves crafting custom signage, intricate art pieces, or detailed engravings, a CO2 laser cutter is a fantastic choice. These machines deliver smooth edges and clean cuts, reducing the need for additional finishing work.

Key Insight: "CO2 laser cutters are perfect for businesses that prioritize precision and versatility in non-metal applications."

However, CO2 lasers may not perform well on metals. If your projects require cutting thicker or harder materials, you might need to explore other options.

2. Fiber Laser Cutters: The Metal Specialist

Fiber laser cutters are the go-to choice for metalworking. They use optical fibers to amplify the laser beam, resulting in exceptional power and precision. These machines handle materials like stainless steel, aluminum, and brass with ease. If your business focuses on metal fabrication or industrial applications, a fiber laser cutter is an excellent investment.

Fiber lasers also stand out for their speed. They process projects faster than other types, making them ideal for businesses with high production demands. Additionally, they require less maintenance, which helps reduce long-term costs.

Quick Tip: Fiber laser cutters are best for businesses that need fast, precise cutting of metals.

On the downside, fiber lasers may not be as effective on non-metal materials. If your work involves a mix of materials, you might need a secondary machine for non-metal tasks.

3. Diode Laser Cutters: The Budget-Friendly Option

Diode laser cutters are compact, affordable, and beginner-friendly. They’re perfect for light-duty tasks like engraving or cutting thin materials. If you’re just starting out or working on smaller projects, a diode laser cutter offers a practical and cost-effective solution.

These machines are easy to set up and operate, even for those new to CNC laser cutting. Their compact size makes them ideal for businesses with limited workspace. However, diode lasers lack the power of CO2 or fiber lasers, which limits their ability to handle thicker materials or high-volume production.

Pro Tip: Diode laser cutters are great for small-scale projects or hobbyists exploring CNC laser cutting.

4. Comparing Across the Board

Here’s a quick comparison to help you decide:

| Feature | CO2 Laser Cutter | Fiber Laser Cutter | Diode Laser Cutter | |---------------------------|----------------------------|----------------------------|----------------------------| | Material Compatibility | Non-metals (wood, acrylic) | Metals (steel, aluminum) | Thin materials (wood, leather) | | Precision | High | Very High | Moderate | | Speed | Moderate | Fast | Slow | | Cost | Moderate | High | Low | | Versatility | High | Moderate | Low |

Each type of CNC laser cutter has its strengths. CO2 lasers offer unmatched versatility for non-metal projects. Fiber lasers dominate in metalworking with their speed and precision. Diode lasers provide an affordable entry point for light-duty tasks. By understanding your business needs and project requirements, you can choose the machine that aligns perfectly with your goals.

Materials That Can Be Cut with CNC Laser Machines

CNC laser cutting machines are incredibly versatile tools. They can handle a wide range of materials, making them a valuable asset for businesses and hobbyists alike. Whether you're working with metals, plastics, or wood, these machines deliver precision and efficiency. Let’s explore the materials you can cut and how these machines excel with each one.

Metals

CNC laser cutters are a game-changer when it comes to working with metals. They can cut through materials like stainless steel, aluminum, brass, and even titanium with remarkable accuracy. This makes them ideal for industries such as automotive, aerospace, and jewelry design. If your business involves creating metal components or intricate designs, a CNC laser cutter can save you time and effort.

Did you know? Fiber laser cutters are particularly effective for metals. Their concentrated laser beam ensures clean cuts and smooth edges, even on thick materials.

Using a CNC laser cutter for metals also reduces waste. The precision of the laser minimizes errors, so you get the most out of your raw materials. This efficiency not only saves money but also boosts productivity. For small businesses, this can make a significant difference in scaling operations.

Plastics

Plastics are another material that CNC laser machines handle exceptionally well. Whether you're cutting acrylic, polycarbonate, or PVC, these machines deliver clean and precise results. Acrylic, in particular, is a popular choice for laser cutting due to its clarity and versatility. You can use it to create signage, display cases, or decorative items.

One of the biggest advantages of using a CNC laser cutter for plastics is the smooth finish it provides. The laser melts the edges as it cuts, eliminating the need for additional polishing. This saves you time and ensures a professional look for your products.

Pro Tip: When working with plastics, adjust the laser's power settings to avoid overheating or warping the material. This ensures optimal results every time.

CNC laser cutters also allow you to experiment with intricate patterns and designs. Whether you're engraving logos or crafting custom pieces, the possibilities are endless. This versatility makes them a favorite among designers and manufacturers.

Wood and MDF

Wood and MDF (Medium-Density Fiberboard) are some of the most commonly used materials in laser cutting. CNC laser machines can cut and engrave these materials with incredible detail, making them perfect for creating furniture, home décor, or custom art pieces. If you're in the woodworking business, a laser cutter can take your craftsmanship to the next level.

The precision of CNC laser cutters ensures that every cut is clean and accurate. This is especially important when working with intricate designs or tight tolerances. You can also use these machines to engrave detailed patterns or text, adding a personal touch to your creations.

Why it matters: Laser cutting wood produces minimal waste, which means you can maximize your material usage and reduce costs.

MDF, a popular alternative to solid wood, works exceptionally well with laser cutters. Its uniform density allows for consistent results, whether you're cutting shapes or engraving designs. This makes it a cost-effective option for businesses looking to produce high-quality products without breaking the bank.

CNC laser cutting machines open up a world of possibilities by allowing you to work with a variety of materials. From metals to plastics to wood, these machines provide the precision and versatility you need to bring your ideas to life. Whether you're crafting intricate designs or producing functional components, a CNC laser cutter is an invaluable tool for any project.

Other Materials (e.g., Glass, Leather, Acrylic)

CNC laser cutting machines shine when working with materials like glass, leather, and acrylic. These materials open up creative possibilities for businesses, allowing you to craft unique and high-quality products. Let’s dive into how these machines handle each material and why they’re a game-changer for your projects.

Glass

Cutting or engraving glass with a CNC laser cutter creates stunning results. The laser’s precision allows you to etch intricate designs, logos, or text onto glass surfaces without causing cracks or damage. Whether you’re personalizing wine glasses, creating decorative panels, or crafting awards, the results are always professional and eye-catching.

Pro Tip: Use lower power settings when engraving glass to avoid overheating and ensure smooth, detailed designs.

One of the biggest advantages of using a laser cutter for glass is its ability to produce consistent results. You can replicate the same design across multiple pieces, saving time and ensuring uniformity. This makes it ideal for businesses that need to produce large quantities of customized glassware.

Leather

Leather is another material where CNC laser cutters excel. These machines can cut through leather with precision, creating clean edges and intricate patterns. Whether you’re making wallets, belts, or custom patches, a laser cutter ensures every piece meets your exact specifications.

The versatility of laser cutters allows you to experiment with different types of leather, from soft suede to thick hides. You can also use them to engrave detailed designs, adding a personal touch to your products. This level of customization helps your business stand out in a competitive market.

Why It Matters: Laser cutting leather reduces waste by maximizing material usage. This efficiency saves money and supports sustainable practices.

Acrylic

Acrylic is one of the most popular materials for laser cutting, and for good reason. CNC laser cutters deliver smooth, polished edges that require no additional finishing. This makes them perfect for creating signage, display cases, or decorative items.

The precision of a laser cutter allows you to work with intricate designs, whether you’re cutting shapes or engraving patterns. Acrylic’s versatility means you can use it for both functional and artistic projects, giving you endless possibilities to explore.

Quick Insight: Acrylic melts slightly during the cutting process, which creates a polished edge. This eliminates the need for sanding or polishing, saving you time.

Why These Materials Matter for Your Business

Using CNC laser cutters for glass, leather, and acrylic offers several benefits:

- Precision: Achieve detailed designs and clean cuts every time.

- Efficiency: Save time by automating the cutting and engraving process.

- Versatility: Work with a variety of materials to expand your product offerings.

- Cost-Effectiveness: Reduce waste and maximize material usage.

By incorporating these materials into your projects, you can create unique, high-quality products that appeal to a wide range of customers. Whether you’re crafting personalized gifts, functional items, or decorative pieces, CNC laser cutting machines give you the tools to bring your ideas to life.

Key Factors to Consider When Choosing a CNC Laser Cutting Machine

When you're in the market for a CNC laser cutting machine, making the right choice can feel overwhelming. With so many options available, it's essential to focus on the key factors that will impact your business. Let’s break it down step by step.

Budget and Pricing

Your budget plays a significant role in determining which CNC laser cutter is right for you. These machines come in a wide price range, from affordable entry-level models to high-end industrial-grade options. Before making a decision, think about how much you're willing to invest and what features you truly need.

For small businesses or hobbyists, a diode laser cutter might be a great starting point. These machines are budget-friendly and handle light-duty tasks like engraving wood or cutting thin materials. On the other hand, if you're looking for versatility and the ability to work with a variety of materials, a CO2 laser cutter offers excellent value for its price. Businesses focused on metal cutting should consider a fiber laser cutter, though these tend to be more expensive due to their advanced capabilities.

Pro Tip: Don’t just look at the upfront cost. Factor in maintenance, software, and potential upgrades when evaluating your budget considerations.

Material Compatibility

Not all CNC laser cutters are created equal when it comes to material compatibility. The type of projects you plan to work on will determine which machine suits your needs. For example, CO2 laser cutters are incredibly versatile and can handle both metals and non-metals like wood, acrylic, and leather. If your focus is on cutting metals like stainless steel or aluminum, a fiber laser cutter is the better choice. Diode laser cutters, while more affordable, are best for lighter materials such as plywood, cardboard, and leather.

Quick Insight: If your business requires working with multiple materials, consider a machine that offers dual laser sources, such as CO2 and fiber, for added flexibility.

Understanding the materials you’ll use most often ensures you choose a machine that delivers consistent results. This saves you time and prevents costly mistakes down the line.

Machine Size and Workspace Requirements

The size of the machine and the space you have available are crucial factors to consider. CNC laser cutters come in various sizes, from compact desktop models to large industrial machines. If you’re working in a small workshop or home studio, a diode laser cutter or a compact CO2 model might be the best fit. These machines are designed to save space without compromising functionality.

For larger operations or businesses handling high-volume production, you’ll need a machine with a bigger work area. Industrial-grade CO2 or fiber laser cutters often require dedicated workspace and proper ventilation systems. Make sure to measure your available space and check the machine’s dimensions before purchasing.

Did You Know? Some machines come with adjustable workbenches, allowing you to accommodate different project sizes without needing additional equipment.

Choosing the right size ensures your machine fits seamlessly into your workspace and supports your production needs.

By focusing on these key factors—budget, material compatibility, and workspace requirements—you can confidently select a CNC laser cutting machine that aligns with your business goals. Whether you're just starting out or scaling up, the right machine will help you achieve precision, efficiency, and success.

Software and Ease of Use

The software that powers a CNC laser cutting machine plays a crucial role in how smoothly your projects run. A user-friendly interface can make all the difference, especially if you're new to laser cutting. Most machines come with dedicated software that allows you to design, edit, and upload patterns directly to the cutter. The best software simplifies the process, so you can focus on creativity rather than technical hurdles.

When evaluating a machine, check for software that supports a wide range of file formats. This ensures compatibility with popular design tools like Adobe Illustrator or CorelDRAW. For example, CO2 laser cutters often include software that integrates seamlessly with these programs, making it easy to transfer your designs. Some machines even offer cloud-based options, allowing you to access your projects from anywhere.

Ease of use extends beyond the software itself. Look for features like pre-installed templates, drag-and-drop functionality, and real-time previews. These tools help you visualize your work before cutting, reducing errors and saving materials. Machines like diode laser cutters are known for their straightforward setup and operation, making them ideal for beginners.

"A machine with intuitive software and simple controls can save you hours of frustration and boost your productivity."

Another factor to consider is the learning curve. Some machines come with detailed tutorials or customer support to help you get started. Others may require more technical knowledge, which could slow you down. Always choose a machine that matches your skill level and offers the support you need to succeed.

Maintenance and Support

Keeping your CNC laser cutting machine in top condition ensures consistent performance and extends its lifespan. Regular maintenance might sound tedious, but it’s essential for avoiding costly repairs and downtime. Most machines come with a maintenance guide, outlining tasks like cleaning the lenses, checking the cooling system, and calibrating the laser.

For example, fiber laser cutters require minimal maintenance compared to other types. Their design eliminates the need for frequent part replacements, making them a cost-effective choice for long-term use. On the other hand, CO2 laser cutters may need more attention, especially when working with materials that produce residue, like wood or acrylic.

"Routine maintenance not only keeps your machine running smoothly but also ensures the quality of your cuts and engravings."

Support is another critical aspect to consider. A reliable manufacturer will offer customer service, troubleshooting guides, and replacement parts. Some brands even provide online communities or forums where users share tips and solutions. Machines like diode laser cutters often come with excellent support for beginners, including step-by-step guides and responsive customer service teams.

When choosing a machine, ask about warranty coverage and the availability of spare parts. A good warranty protects your investment, while easy access to parts ensures quick repairs. This is especially important for small businesses, where downtime can impact your bottom line.

Popular Projects for CNC Laser Cutting Machines

CNC laser cutting machines have unlocked endless possibilities for creative and practical projects. Whether you're running a small business or pursuing a hobby, these machines allow you to craft unique and customized products with precision and efficiency. Let’s explore some of the most popular projects you can tackle with a CNC laser cutter.

Custom Signage and Engravings

Creating custom signage and engravings is one of the most common uses for CNC laser cutting machines. These machines excel at producing intricate designs, making them perfect for crafting personalized signs for businesses, events, or home décor. You can cut materials like wood, acrylic, and even metal to create eye-catching signs that stand out.

For example, a CO2 laser cutter works exceptionally well for non-metal materials like wood and acrylic. It delivers smooth edges and detailed engravings, ensuring your designs look professional. If you're working with metals, a fiber laser cutter offers the precision needed to engrave logos or text onto surfaces like stainless steel or aluminum.

Tip: Experiment with different fonts, shapes, and materials to create signage that truly reflects your client’s brand or personal style.

Engraving projects also extend to items like plaques, awards, and nameplates. With a CNC laser cutter, you can add a personal touch to these items, making them more meaningful and memorable. Whether you're engraving a heartfelt message or a company logo, the results are always sharp and precise.

Jewelry and Accessories

Jewelry and accessory design is another exciting application for CNC laser cutting machines. These machines allow you to craft intricate pieces with unmatched precision, whether you're working with metals, leather, or acrylic. From delicate earrings to bold statement necklaces, the possibilities are endless.

Fiber laser cutters are ideal for metal jewelry, as they can handle materials like gold, silver, and stainless steel with ease. They produce clean cuts and detailed engravings, ensuring every piece meets your exact specifications. For non-metal accessories, a CO2 laser cutter offers the versatility to work with materials like leather and acrylic, allowing you to create unique designs.

Did you know? Laser cutters can also engrave patterns or textures onto jewelry, adding an extra layer of customization to your creations.

Accessories like keychains, bracelets, and bag tags are also popular projects. These items make great gifts or promotional products, and their small size makes them easy to produce in bulk. With a CNC laser cutter, you can experiment with different shapes, materials, and finishes to create truly one-of-a-kind pieces.

Prototyping and Product Design

CNC laser cutting machines are invaluable tools for prototyping and product design. They allow you to quickly and accurately create models or components, helping you bring your ideas to life. Whether you're designing a new product or refining an existing one, a laser cutter streamlines the process and ensures precision.

For prototyping, CO2 laser cutters are a versatile choice. They can cut and engrave a wide range of materials, including wood, acrylic, and plastics, making them ideal for creating functional prototypes or visual models. If your design involves metal components, a fiber laser cutter provides the power and accuracy needed to achieve professional results.

Pro Tip: Use your laser cutter to test different materials and designs before committing to large-scale production. This saves time and reduces waste.

Product design projects can range from furniture and home décor to gadgets and tools. With a CNC laser cutter, you can experiment with complex shapes and intricate details that would be difficult to achieve by hand. This level of precision allows you to create products that are not only functional but also visually appealing.

CNC laser cutting machines open up a world of creative opportunities. Whether you're crafting custom signage, designing jewelry, or prototyping new products, these machines give you the tools to produce high-quality, unique and customized products. With the right machine and a bit of imagination, the possibilities are endless.

Home Décor and Art Pieces

CNC laser cutting machines open up endless possibilities for creating stunning home décor and art pieces. Whether you’re designing intricate wall hangings, custom furniture accents, or unique decorative items, these machines give you the precision and flexibility to bring your ideas to life.

Why CNC Laser Cutting Works for Home Décor

The ability to cut and engrave a wide range of materials makes CNC laser cutters perfect for home décor projects. You can work with wood, acrylic, leather, and even glass to craft pieces that stand out. For example, CO2 laser cutters are highly versatile and excel at cutting non-metal materials like wood and acrylic. This makes them ideal for creating detailed designs for wall art, lampshades, or decorative panels.

"CO2 laser cutters are the go-to choice for businesses and hobbyists focusing on non-metal home décor projects."

If you’re just starting out or working on smaller projects, diode laser cutters offer an affordable and beginner-friendly option. They’re great for engraving patterns on leather coasters or cutting thin wooden ornaments. For more advanced projects involving metal accents, fiber laser cutters provide the precision needed to engrave or cut intricate designs into metal surfaces.

Popular Home Décor Projects

Here are some creative ideas to inspire your next project:

- Wall Art: Use a CNC laser cutter to design intricate wooden or acrylic wall hangings. You can create geometric patterns, nature-inspired designs, or even personalized name plaques.

- Custom Lampshades: Cut unique patterns into wood or acrylic to craft one-of-a-kind lampshades that cast beautiful shadows.

- Decorative Panels: Design laser-cut panels for room dividers, headboards, or window accents. These add a touch of elegance to any space.

- Tabletop Décor: Create engraved coasters, centerpiece trays, or decorative bowls using materials like wood or leather.

- Seasonal Decorations: Craft holiday ornaments, wreaths, or themed décor pieces for special occasions.

Art Pieces That Stand Out

CNC laser cutters also shine when it comes to creating art pieces. Whether you’re an artist or a small business owner, these machines let you experiment with complex designs and materials. For instance, you can use a CO2 laser cutter to engrave detailed patterns onto wood or acrylic, turning simple materials into gallery-worthy art.

Artists often use laser cutters to layer materials, creating 3D effects in their work. Imagine combining laser-cut wood, acrylic, and metal to produce a mixed-media masterpiece. The precision of the laser ensures every piece fits perfectly, making your artwork look polished and professional.

Benefits of Using CNC Laser Cutters for Décor and Art

- Precision: Achieve intricate details that would be difficult or impossible by hand.

- Versatility: Work with a variety of materials to suit different styles and projects.

- Efficiency: Save time by automating the cutting and engraving process.

- Customization: Personalize every piece to match your vision or your client’s preferences.

With a CNC laser cutter, you can turn your creative ideas into reality. Whether you’re crafting home décor or producing art pieces, these machines give you the tools to make something truly unique.

CNC laser cutting machines are game-changers for small businesses. They combine precision, efficiency, and versatility, allowing you to create high-quality products across various materials like wood, acrylic, and leather. Whether you need a machine with exceptional power and speed or one tailored to your budget, the right choice can elevate your productivity and streamline your operations. Explore the detailed reviews in this guide to find the perfect fit for your needs. With the right laser cutting machine, you can take your business to the next level and deliver unmatched quality to your customers.

FAQ

What materials can a CNC laser cutting machine handle?

CNC laser cutting machines work with a wide variety of materials. You can cut or engrave wood, acrylic, leather, fabric, plywood, and even metal. For example, acrylic is perfect for creating clean edges and intricate designs, while leather allows for precise cuts in fashion or craft projects. These machines also excel at cutting plywood for personalized signs or fabric for custom patterns. Their versatility makes them ideal for businesses that need to work with multiple materials.

Can I use a CNC laser cutter for personalized projects?

Absolutely! CNC laser cutters are perfect for creating personalized items. You can make custom signs for businesses, shops, or special occasions using materials like acrylic, plywood, and leather. They also allow you to add personal touches such as names, dates, or monograms to products like home décor, jewelry, or gifts. Whether you're crafting for clients or personal use, these machines make customization easy and professional.

Are CNC laser cutting machines beginner-friendly?

Yes, many CNC laser cutting machines are designed with beginners in mind. Models like diode laser cutters are compact, affordable, and easy to operate. They often come with user-friendly software and pre-installed templates to help you get started. If you're new to laser cutting, look for machines with straightforward controls and tutorials to guide you through the process.

How do I maintain a CNC laser cutting machine?

Maintaining your CNC laser cutter is essential for consistent performance. Regularly clean the lenses and mirrors to ensure the laser beam stays precise. Check the cooling system to prevent overheating, especially during long projects. For machines like CO2 laser cutters, remove residue from materials like wood or acrylic after each use. Following the manufacturer’s maintenance guide will keep your machine running smoothly and extend its lifespan.

What software do I need to operate a CNC laser cutter?

Most CNC laser cutters come with dedicated software that allows you to design and upload patterns. Look for software that supports popular file formats like SVG, DXF, or PDF. Many machines integrate seamlessly with design tools like Adobe Illustrator or CorelDRAW. Some even offer cloud-based options, so you can access your projects from anywhere. User-friendly software simplifies the process, making it easier to focus on your designs.

Can a CNC laser cutter handle high-volume production?

Yes, CNC laser cutters are excellent for high-volume production. Machines like fiber laser cutters deliver fast processing speeds, making them ideal for businesses with large workloads. They maintain precision and consistency, even when producing items in bulk. Whether you're crafting custom signage or manufacturing components, these machines can handle the demands of growing operations.

Is laser cutting safe to use in a small workspace?

Laser cutting is safe when proper precautions are taken. Many machines, like enclosed diode laser cutters, are designed for small workspaces and prioritize safety. Ensure your workspace has adequate ventilation to remove fumes from materials like wood or acrylic. Always follow the manufacturer’s safety guidelines, and consider using protective eyewear when operating the machine.

What’s the difference between CO2, fiber, and diode laser cutters?

Each type of laser cutter serves different purposes:

- CO2 Laser Cutters: Best for non-metal materials like wood, acrylic, and leather. They’re versatile and ideal for detailed engraving or cutting.

- Fiber Laser Cutters: Perfect for metals like stainless steel or aluminum. They offer high speed and precision for industrial applications.

- Diode Laser Cutters: Compact and affordable, great for light-duty tasks like engraving wood or cutting thin materials.

Choose the type that matches your project needs and materials.

How much does a CNC laser cutting machine cost?

The cost varies depending on the type and features of the machine. Entry-level diode laser cutters start around $500-$700, making them accessible for beginners. Mid-range CO2 laser cutters typically cost between $2,000 and $5,000, offering versatility for small businesses. High-end fiber laser cutters can exceed $10,000 but provide exceptional performance for industrial use. Consider your budget and project requirements when choosing a machine.

Can I use a CNC laser cutter for artistic projects?

Yes, CNC laser cutters are fantastic for artistic projects. You can create intricate wall art, custom lampshades, or decorative panels using materials like wood, acrylic, and glass. These machines allow you to experiment with complex designs and layered materials, making them perfect for mixed-media art. Whether you're an artist or a hobbyist, a CNC laser cutter helps bring your creative ideas to life.

See Also

The 10 Best Vinyl Cutters You Need This Year

Five Essential Plasma Cutters for Industrial Applications

Understanding The Functionality Of CNC Laser Cutters