What Is the Best CNC Laser Cutting Machine?

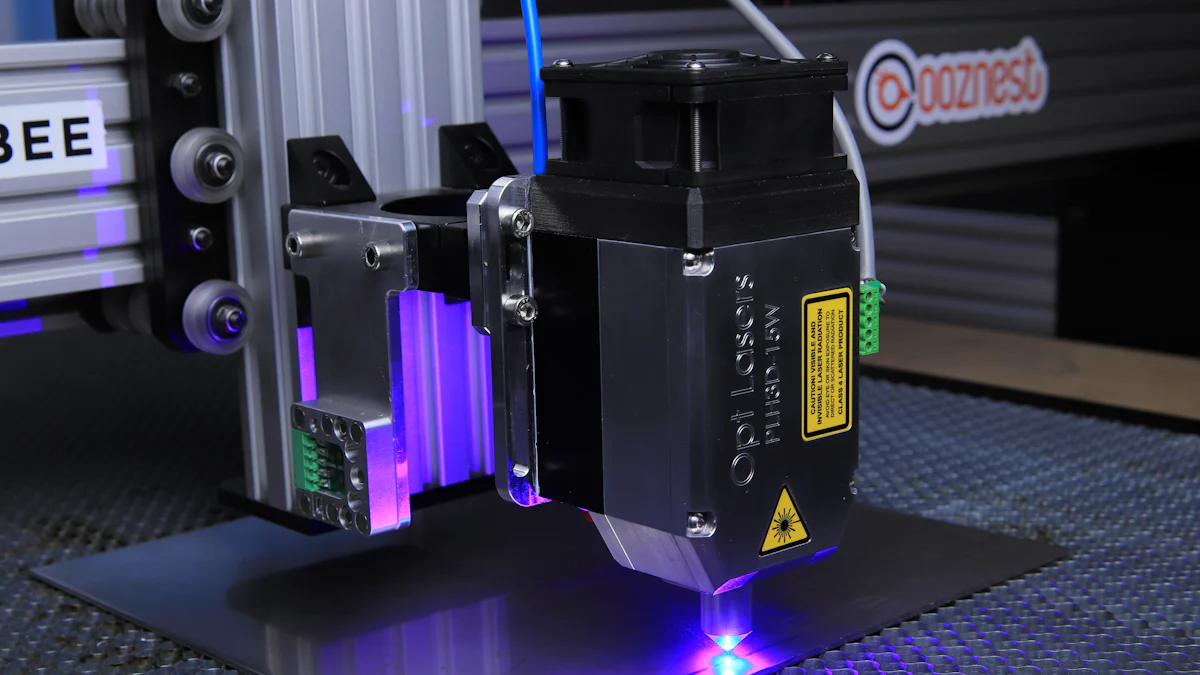

When it comes to precision and efficiency, CNC laser cutting machines stand out as a game-changer for small businesses. If you're wondering what is the best CNC laser cutting machine, options like Glowforge, OMTech, and Boss Laser have earned their reputation for delivering exceptional results. Glowforge offers an intuitive interface, making it perfect for beginners. OMTech impresses with its versatility and power, while Boss Laser is known for its durability in demanding tasks. Your choice depends on factors like your budget, the materials you work with, and your production goals. These machines empower you to create intricate designs and boost productivity with ease.

Key Factors to Consider When Choosing a CNC Laser Cutting Machine

When you're selecting the right CNC laser cutting machine, understanding the key factors can make all the difference. Let’s break it down step by step.

Precision and Accuracy

Importance of precision for intricate designs and small-scale production

Precision is the backbone of any CNC laser cutting machine. If your business focuses on creating intricate designs, like custom jewelry or detailed engravings, you need a machine that delivers pinpoint accuracy. High precision ensures that every cut matches your design perfectly, which is especially important for small-scale production where even minor errors can lead to wasted materials and time. A reliable machine helps you maintain consistency, which builds trust with your customers.

How to evaluate a machine's accuracy specifications

Evaluating a machine's accuracy might seem tricky, but it’s simpler than you think. Start by checking the positioning accuracy and repeatability specifications. These numbers tell you how closely the machine can follow your design and how consistently it can replicate the same cut. Machines with advanced motion control systems and high-quality laser heads often offer better accuracy. Don’t forget to read reviews or watch demonstrations to see how the machine performs in real-world scenarios.

Material Compatibility

Common materials used in small businesses (e.g., wood, acrylic, metal)

The materials you work with play a huge role in your choice of machine. Many small businesses use materials like wood, acrylic, and metal for their projects. For example, wood is popular for furniture and crafts, while acrylic is ideal for signage and displays. Metal, on the other hand, is often used for industrial parts or decorative items. Each material has unique cutting requirements, so your machine must handle them effectively.

Machines that handle multiple materials effectively

Material versatility is a game-changer. Some CNC laser cutting machines are designed to cut through a wide range of materials without compromising quality. For instance, machines like Glowforge excel at cutting wood and acrylic, while Boss Laser offers robust options for metal. Look for machines with adjustable power settings and compatible software to ensure smooth transitions between different materials. This flexibility can save you money and expand your business opportunities.

Costs and Budget

Initial investment vs. long-term operational costs

The cost of a CNC laser cutting machine goes beyond the upfront costs. While the initial investment might seem steep, consider the long-term operational costs as well. Machines with higher energy efficiency and lower maintenance needs can save you money over time. Think about how often you'll use the machine and whether its features justify the price tag.

Balancing affordability with quality and features

Finding the right balance between affordability and quality is crucial. Cheaper machines might seem appealing, but they often lack the durability or advanced features needed for professional use. On the other hand, high-end machines may offer exceptional performance but could strain your budget. Focus on the features that matter most to your business, like precision, material compatibility, and ease of use. Financing or leasing options can also help you manage the costs without compromising on quality.

Ease of Use and Maintenance

User-friendly software and setup for small business owners

When you're running a small business, time is everything. A CNC laser cutting machine with user-friendly software can save you hours of frustration. Look for machines that come with intuitive interfaces and straightforward setup processes. For example, Glowforge is known for its easy-to-use design, making it a favorite among beginners. Its software simplifies the process of uploading designs and adjusting settings, so you can focus on creating instead of troubleshooting.

Some machines also offer pre-installed templates or design libraries. These features can help you get started quickly, even if you're new to laser cutting. Machines with clear instructions and minimal assembly requirements are ideal for small business owners who want to hit the ground running. Always check for tutorials, customer support, or online communities that can guide you through the learning curve.

Maintenance requirements and associated costs

Keeping your CNC laser cutting machine in top shape is essential for consistent performance. Regular maintenance ensures that your machine delivers precise cuts and lasts longer. Tasks like cleaning the laser head, checking the motion control system, and replacing worn-out parts should be part of your routine. Machines with high-quality components often require less frequent maintenance, saving you time and money.

It's also important to consider the associated costs. Some machines have affordable replacement parts, while others might require expensive components. For instance, Boss Laser machines are known for their durability, which can reduce the need for frequent repairs. However, you should still budget for occasional part replacements and cleaning supplies. Proper maintenance not only extends the life of your machine but also prevents costly downtime.

"A well-maintained machine is a reliable machine." This saying holds true for CNC laser cutters. Investing a little time in upkeep can save you from bigger headaches down the road.

Comparison of the Top CNC Laser Cutting Machines

When choosing the best CNC laser cutting machine for your business, understanding the strengths and weaknesses of each option can help you make an informed decision. Let’s dive into the details of three popular machines: Glowforge, OMTech, and Boss Laser.

Glowforge

Features and benefits for small businesses

Glowforge stands out for its simplicity and user-friendly design. It’s perfect if you’re new to CNC laser cutting or want a machine that doesn’t require extensive technical knowledge. Glowforge machines come with cloud-based software, making it easy to upload designs and start cutting right away. The compact size fits well in small workspaces, which is ideal for home-based businesses or startups.

Glowforge excels at cutting and engraving materials like wood, acrylic, leather, and even fabric. Its precision allows you to create intricate designs, making it a favorite for crafting, jewelry, and personalized gifts. The built-in camera system helps you align your designs accurately, reducing errors and material waste.

Advantages and disadvantages of using Glowforge

Advantages:

- Intuitive software and setup make it beginner-friendly.

- Compact design saves space in small workshops.

- Versatile material compatibility supports creative projects.

Disadvantages:

- Limited power output struggles with thicker materials or metals.

- Cloud-based software requires a stable internet connection.

- Higher price point compared to other entry-level machines.

"Glowforge is a great choice if ease of use and versatility are your top priorities."

OMTech

Key features and affordability for startups

OMTech offers a balance of affordability and performance, making it a popular choice for small businesses on a budget. These machines provide powerful laser cutting capabilities at a fraction of the cost of high-end models. OMTech machines are available in various sizes and power levels, so you can choose one that fits your specific needs.

OMTech machines handle a wide range of materials, including wood, acrylic, glass, and some metals. They also come with advanced features like adjustable power settings and precise motion control, ensuring clean and accurate cuts. If you’re looking for a cost-effective way to start your laser cutting journey, OMTech delivers excellent value.

Advantages and disadvantages of OMTech machines

Advantages:

- Affordable pricing makes it accessible for startups.

- Wide range of models offers flexibility for different needs.

- Strong cutting power handles thicker materials effectively.

Disadvantages:

- Steeper learning curve compared to Glowforge.

- Larger models may require more workspace.

- Customer support can be inconsistent.

"OMTech is ideal if you want powerful laser cutting without breaking the bank."

Boss Laser

Performance and durability for small-scale production

Boss Laser machines are built for durability and high performance, making them a reliable choice for small-scale production. These machines are designed to handle demanding tasks, offering consistent results even with heavy use. Boss Laser models come with industrial-grade components, ensuring long-term reliability.

Boss Laser machines excel at cutting and engraving a variety of materials, including wood, acrylic, metal, and stone. Their high power output allows you to work with thicker materials, which is essential for businesses producing industrial parts or large-scale projects. The robust design ensures minimal downtime, so you can focus on growing your business.

Advantages and disadvantages of Boss Laser machines

Advantages:

- Durable construction ensures long-lasting performance.

- High power output handles thick and tough materials.

- Excellent for small-scale production and industrial applications.

Disadvantages:

- Higher initial investment compared to other options.

- Larger size requires more workspace.

- Maintenance costs can add up over time.

"Boss Laser is the go-to choice for businesses that need durability and power for demanding projects."

Each of these CNC laser cutting machines offers unique benefits tailored to different business needs. Glowforge shines in ease of use, OMTech impresses with affordability, and Boss Laser delivers unmatched durability. Your choice depends on your priorities, whether it’s simplicity, budget, or performance.

Evaluating the Best Machine for Your Business Needs

Choosing the right CNC laser cutting machine can feel overwhelming, but breaking it down into clear steps makes the process manageable. Let’s explore how you can evaluate the best option for your business.

Identifying Your Business Goals

Determining production scale and material requirements

Start by asking yourself: What’s the scale of your production? If you’re running a small business focused on custom orders, a machine like Glowforge might suit you. It’s compact and handles intricate designs well. For larger-scale production or thicker materials, Boss Laser machines offer the durability and power you’ll need.

Think about the materials you’ll work with most often. Wood, acrylic, and metal are common choices, but not all machines handle them equally. OMTech machines excel at cutting acrylic and MDF, making them ideal for specific applications. On the other hand, Glowforge provides more versatility, allowing you to experiment with a broader range of materials.

Considering customization and design needs

Customization is key for many small businesses. Do you need a machine that offers design freedom? Glowforge’s user-friendly software simplifies the process of creating unique designs. Its built-in camera system ensures precise alignment, giving you more control over your projects. If you’re looking for advanced features like rotary attachments for cylindrical objects, OMTech machines provide that flexibility. Boss Laser machines, with their industrial-grade components, are perfect for businesses requiring high-quality, professional-grade designs.

"Your business goals should guide your choice. The right machine will align with your production needs and material preferences."

Balancing Features with Budget

Prioritizing essential features over advanced options

It’s tempting to go for machines packed with features, but not all of them may be necessary for your business. Focus on what matters most. If ease of use and versatility are your priorities, Glowforge is a great pick. For cost-effectiveness and power, OMTech offers excellent value. Boss Laser machines, while pricier, deliver unmatched quality and durability for demanding tasks.

Consider the trade-offs. Glowforge lacks the high wattage of Boss Laser or OMTech, which limits its ability to cut thicker materials. However, its intuitive design and active community make it a favorite for beginners. Decide which features will directly impact your workflow and stick to those.

Exploring financing or leasing options for small businesses

A CNC laser cutting machine is a significant investment, but there are ways to manage the cost. Many manufacturers, including Boss Laser, offer financing plans to help small businesses spread out payments. Leasing options can also be a smart move if you’re testing the waters or working with a tight budget. These options allow you to access high-quality machines without a hefty upfront cost. Always weigh the long-term benefits against the initial expense to ensure you’re making a sound financial decision.

Seeking Expert Advice and Reviews

Importance of customer reviews and testimonials

Customer reviews are a goldmine of information. They give you real-world insights into a machine’s performance, reliability, and ease of use. Glowforge, for instance, is often praised for its excellent customer service and active online community. OMTech machines, while powerful, sometimes receive mixed feedback about after-sale support. Boss Laser machines consistently earn high marks for their durability and professional-grade performance.

Look for testimonials from businesses similar to yours. If you’re in crafting, Glowforge users often share tips and tricks that can help you get started. For industrial applications, Boss Laser reviews highlight its ability to handle heavy workloads with precision.

Consulting with industry professionals or suppliers

Don’t hesitate to reach out to industry experts or suppliers. They can provide valuable advice tailored to your business needs. Suppliers often have in-depth knowledge about the machines they sell and can recommend models based on your budget and goals. Industry professionals can share their experiences, helping you avoid common pitfalls. This step ensures you make an informed decision and invest in a machine that aligns with your vision.

"Expert advice and customer feedback can save you time and money. Use these resources to make a confident choice."

Evaluating the best CNC laser cutting machine for your business requires a clear understanding of your goals, budget, and available options. By focusing on what matters most—whether it’s design freedom, cost-effectiveness, or quality—you’ll find a machine that fits your needs perfectly.

Advantages and Disadvantages of Using CNC Laser Cutting Machines for Small Businesses

When considering CNC laser cutting machines for your small business, it’s essential to weigh the advantages and disadvantages. These machines offer incredible benefits but also come with challenges that you should understand before making a decision.

Advantages

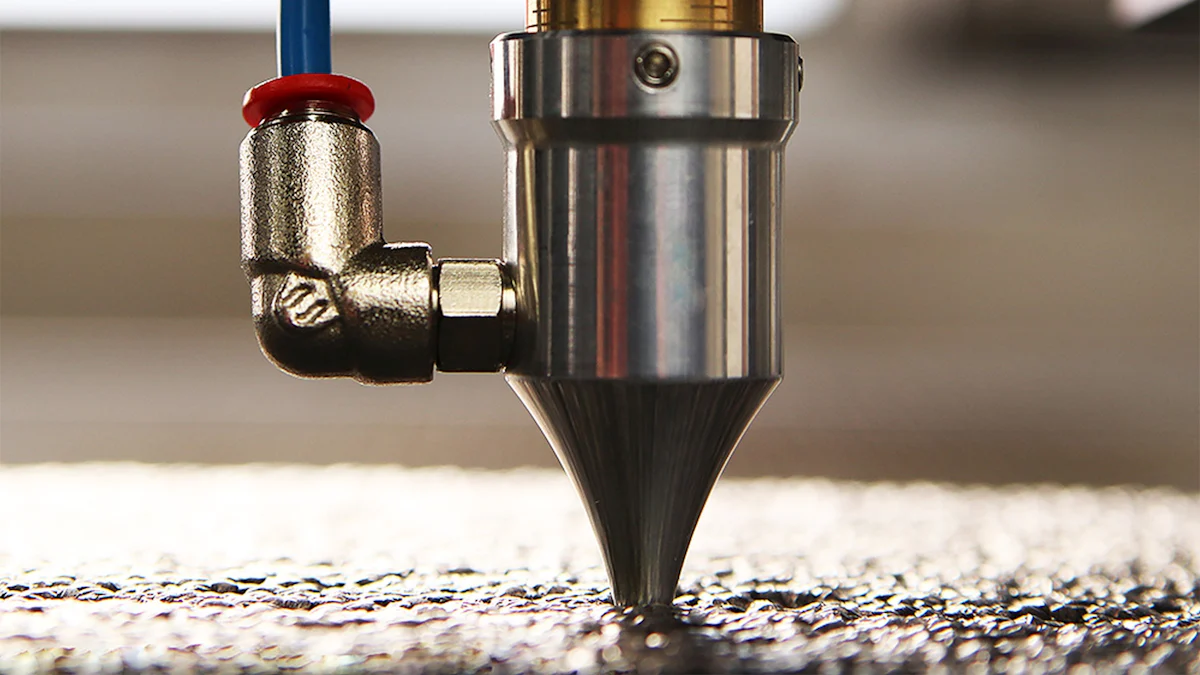

High precision and efficiency for detailed work

One of the biggest advantages of laser cutting is its high precision. These machines can create intricate designs with unmatched accuracy, making them ideal for projects like custom jewelry, signage, or decorative items. The high speed of CNC laser cutting also boosts production efficiency, allowing you to complete more orders in less time. This combination of precision and speed ensures that your work stands out in competitive markets.

"CNC laser cutting machines are known for their ability to deliver clean cutting results, even on the most complex designs."

Versatility in handling various materials and designs

Another key benefit is the versatility these machines bring to your business. Whether you’re working with wood, acrylic, metal, or even fabric, CNC laser cutting machines can handle it all. This flexibility allows you to diversify your product offerings and cater to a broader audience. Additionally, the freedom to experiment with different designs opens up endless creative possibilities, helping you stay ahead of trends and customer demands.

Potential for increased productivity and profitability

By improving efficiency and reducing material waste, CNC laser cutting machines can significantly boost your profitability. Their ability to automate repetitive tasks means you can focus on scaling your business rather than spending hours on manual labor. Over time, this increased productivity translates into higher revenue, making the machine a worthwhile investment despite its upfront costs.

Disadvantages

High initial investment for quality machines

The most notable drawback is the significant investment required to purchase a high-quality CNC laser cutter. While the long-term benefits often outweigh the initial expense, the upfront cost can be a barrier for small businesses just starting out. Financing options or leasing plans can help, but it’s crucial to plan your budget carefully.

Learning curve for operating and maintaining the machine

Operating a CNC laser cutter isn’t always straightforward, especially if you’re new to the technology. There’s a learning curve involved in mastering the software, adjusting settings, and maintaining the machine. Regular upkeep, such as cleaning the laser head and replacing parts, adds to the challenge. However, many manufacturers provide tutorials and customer support to help you get started.

Limitations in cutting certain materials or thicknesses

While CNC laser cutting machines are versatile, they do have limitations. Some models struggle with cutting thicker materials or specific types of metal. This can restrict the range of projects you can take on, especially if your business requires heavy-duty cutting capabilities. Understanding these disadvantages of laser cutting will help you choose a machine that aligns with your needs.

CNC laser cutting machines offer a mix of advantages and disadvantages. Their high precision, efficiency, and versatility make them a valuable asset for small businesses. However, the disadvantages, such as the high upfront cost and learning curve, require careful consideration. By understanding both sides, you can make an informed decision that supports your business goals.

Choosing the right CNC laser cutting machine requires careful consideration of several factors. Precision, material compatibility, costs, and ease of use should guide your decision. Each machine offers unique strengths. Glowforge simplifies operations, making it ideal for beginners. OMTech provides affordability without sacrificing performance. Boss Laser stands out for its durability and power, perfect for demanding tasks. Align the machine’s features with your business needs to maximize efficiency and profitability. While the initial investment may seem high, the long-term benefits of laser cutting can transform your business into a more productive and creative venture.

FAQ

What is a CNC laser cutting machine?

A CNC laser cutting machine uses a high-powered laser beam to cut, engrave, or etch materials with precision. The "CNC" stands for Computer Numerical Control, meaning the machine follows computer-generated designs to create accurate cuts. These machines are popular for their ability to handle intricate designs and a variety of materials like wood, acrylic, and metal.

How do I choose the right CNC laser cutting machine for my business?

Start by identifying your business needs. Think about the materials you’ll work with, the level of precision required, and your budget. Machines like Glowforge are great for beginners due to their ease of use, while OMTech offers affordability and versatility. Boss Laser is ideal if you need durability for heavy-duty tasks. Always compare features, read reviews, and consider your production goals before making a decision.

Can CNC laser cutting machines handle multiple materials?

Yes, most CNC laser cutting machines can work with a variety of materials. Common options include wood, acrylic, leather, glass, and some metals. Machines like Glowforge excel at cutting softer materials, while Boss Laser can handle tougher materials like metal and stone. Check the machine’s specifications to ensure it supports the materials you plan to use.

Are CNC laser cutting machines expensive?

The cost varies depending on the machine’s features and capabilities. Entry-level machines like OMTech are more affordable, starting at a few thousand dollars. High-end models like Boss Laser can cost significantly more but offer advanced features and durability. Don’t forget to factor in operational costs like maintenance, power consumption, and replacement parts.

Is it hard to learn how to use a CNC laser cutting machine?

It depends on the machine and your experience level. Machines like Glowforge are designed with user-friendly software, making them easier for beginners. Others, like OMTech, may have a steeper learning curve but offer more customization options. Many manufacturers provide tutorials, guides, and customer support to help you get started.

What kind of maintenance does a CNC laser cutting machine require?

Regular maintenance includes cleaning the laser head, checking the motion system, and replacing worn-out parts. Proper upkeep ensures consistent performance and extends the machine’s lifespan. Machines with high-quality components, like Boss Laser, often require less frequent maintenance. Always follow the manufacturer’s guidelines for best results.

Can I use a CNC laser cutting machine in a small workspace?

Yes, many CNC laser cutting machines are compact enough for small workspaces. Glowforge, for example, is designed to fit on a standard desk, making it ideal for home-based businesses. Larger models, like some Boss Laser machines, may require more space. Measure your available area and choose a machine that fits comfortably.

Are there safety concerns when using a CNC laser cutting machine?

Yes, safety is important. Laser cutting can produce fumes, especially when cutting certain materials, so proper ventilation is essential. Always wear protective eyewear and follow the manufacturer’s safety guidelines. Some machines come with built-in safety features like enclosed designs or automatic shutoff systems for added protection.

Can I finance or lease a CNC laser cutting machine?

Yes, many manufacturers and suppliers offer financing or leasing options. This can make it easier to afford a high-quality machine without a large upfront cost. Leasing is also a good option if you’re unsure about long-term use or want to test the technology before committing to a purchase.

How can a CNC laser cutting machine benefit my small business?

A CNC laser cutting machine can boost your productivity, improve design precision, and expand your product offerings. It allows you to create intricate designs quickly and efficiently, reducing material waste. Over time, this can increase profitability and help your business stand out in competitive markets.

See Also

Understanding The Functionality Of CNC Laser Cutters

Exploring Different Types Of CNC Cutting Machines

Comparing CNC Machines And Laser Cutters For Acrylic