What Are The Benefits Of Laser Machines For Hardboard

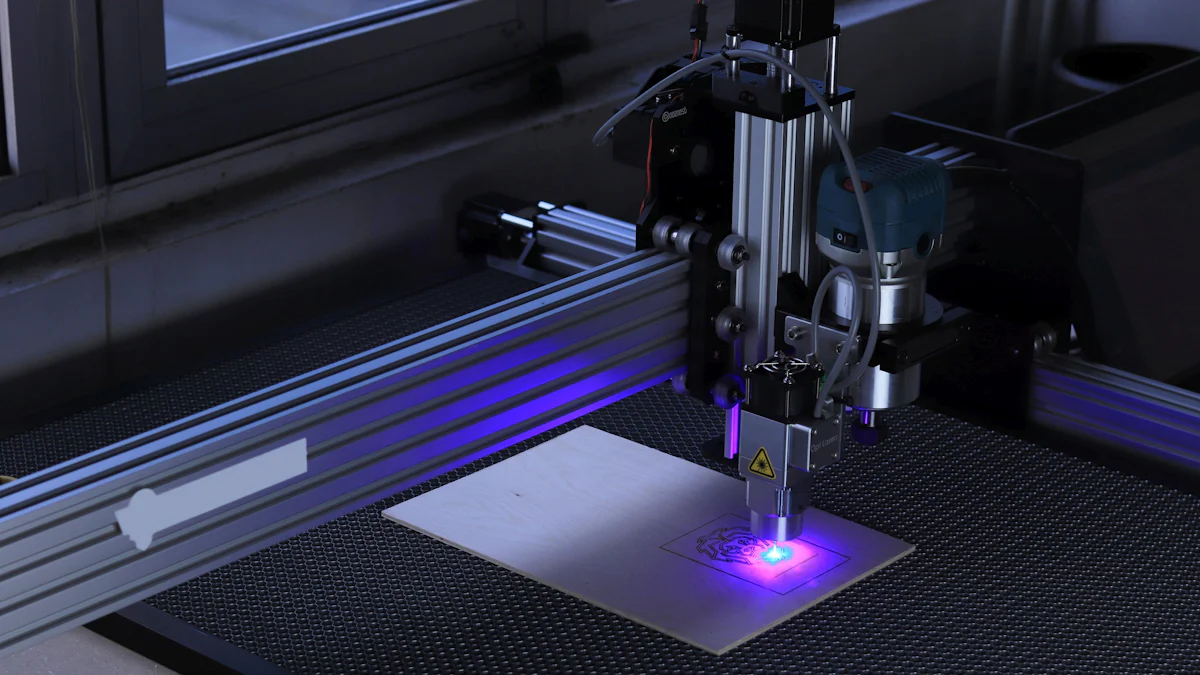

Laser machines revolutionize your hardboard projects by offering unparalleled accuracy and precision. These machines ensure high-quality outcomes, whether you're cutting or engraving. You benefit from their efficiency, as they significantly reduce production time compared to traditional methods. The versatility of laser technology allows you to work on various hardboard types, making it an ideal choice for diverse projects. Additionally, laser machines minimize waste, optimizing material use and promoting sustainable practices. With user-friendly interfaces, you find them easy to operate, enhancing your project's success. So, do laser cutter and engraver machines cut hardboard? Absolutely, and with remarkable results.

Do Laser Cutter and Engraver Machines Cut Hardboard?

When you work with hardboard, you might wonder, "Do laser cutter and engraver machines cut hardboard?" The answer is a resounding yes. These machines excel in delivering high-quality results, thanks to their remarkable accuracy and precision.

High Precision Cutting

Laser machines offer high precision cutting, which is essential for achieving detailed designs on hardboard. You can create intricate designs with ease, ensuring each cut is clean and precise. This precision allows you to produce consistent quality in every project. Whether you're crafting a simple shape or a complex pattern, the laser ensures that each piece meets your exact specifications.

Detailed Designs

With laser technology, you can achieve detailed designs that would be challenging with traditional cutting methods. The laser's fine beam allows you to cut even the most intricate patterns without compromising quality. This capability opens up a world of creative possibilities, enabling you to bring your artistic visions to life.

Consistent Quality

Consistency is key in any project, and laser machines deliver just that. Each cut maintains the same level of quality, ensuring that your final product looks professional and polished. You can rely on the laser to produce uniform results, whether you're working on a single piece or a large batch.

Intricate Engraving

In addition to cutting, laser machines excel at intricate engraving. You can add fine details to your hardboard projects, enhancing their visual appeal. The laser's precision ensures that each engraved line is sharp and clear, making your designs stand out.

Fine Details

Engraving with a laser allows you to incorporate fine details into your projects. You can create complex patterns, logos, or text with ease. The laser's ability to produce such detailed work makes it an invaluable tool for artists and designers looking to add a personal touch to their creations.

Customization Options

Customization is another significant advantage of using laser machines. You can tailor your designs to meet specific requirements, whether for personal use or commercial purposes. The flexibility of laser technology allows you to experiment with different styles and techniques, ensuring that your projects are unique and tailored to your needs.

Speed and Efficiency

When you use laser machines for hardboard projects, you experience remarkable speed and efficiency. These machines transform your workflow, allowing you to complete tasks faster than traditional methods.

Fast Production Times

Laser machines excel in delivering fast production times. You can achieve a quick turnaround on your projects, which is crucial in meeting tight deadlines. The laser's ability to cut and engrave with high precision ensures that each piece is ready for the next stage without delay.

Quick Turnaround

With laser technology, you can significantly reduce the time it takes to complete a project. The laser's speed allows you to move from design to finished product swiftly. This quick turnaround is especially beneficial in industries where time is of the essence, such as manufacturing and design.

Increased Output

The efficiency of laser machines means you can increase your output without sacrificing quality. You can produce more pieces in less time, which boosts your productivity. This increased output is a game-changer for businesses looking to scale their operations and meet growing demand.

Automation Capabilities

Laser machines offer advanced automation capabilities that streamline your processes. You can reduce manual labor, allowing you to focus on other important aspects of your projects.

Reduced Manual Labor

Automation reduces the need for manual intervention, saving you time and effort. The laser handles complex tasks with ease, freeing you up to concentrate on design and planning. This reduction in manual labor not only increases efficiency but also minimizes the risk of human error.

Streamlined Processes

Laser machines streamline your processes by integrating seamlessly into your workflow. You can automate repetitive tasks, ensuring consistency and accuracy in every project. This streamlined approach enhances your overall efficiency, making laser technology an invaluable asset in your toolkit.

Versatility

Laser machines offer remarkable versatility, making them an excellent choice for a wide range of applications. Whether you're cutting or engraving, these machines adapt to your needs, providing flexibility and creativity in your projects.

Wide Range of Applications

Cutting and Engraving

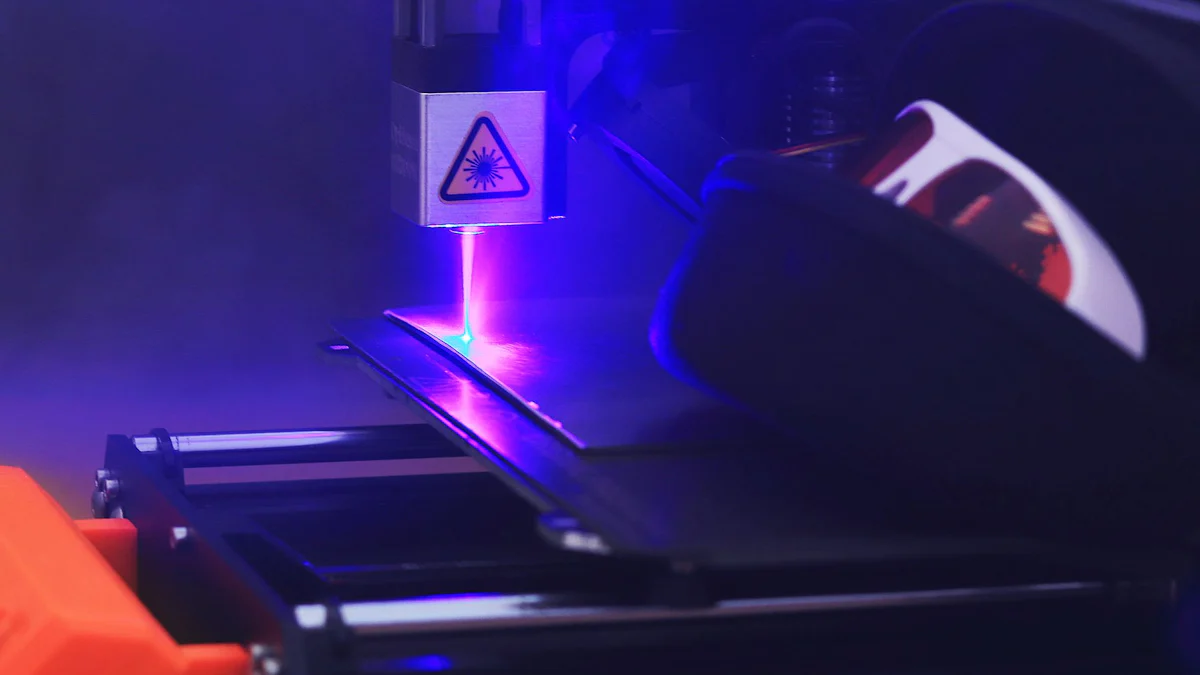

With laser machines, you can easily cut and engrave hardboard. The contactless process ensures smooth edges and prevents splinters, enhancing the quality of your work. You can create personalized products and gifts with precision and ease. The ability to switch between cutting and engraving allows you to explore various design possibilities, making your projects unique and tailored to your vision.

Prototyping and Production

Laser cut hardboard is ideal for prototyping due to its durability and resistance to warping. You can experiment with different designs without worrying about material failure. This makes laser machines a valuable tool in the production phase as well. You can efficiently produce high-quality prototypes that meet your specifications, saving time and resources. The affordability of laser cut hardboard also helps you manage costs while maintaining excellent quality.

Material Compatibility

Various Hardboard Types

Laser machines are compatible with various types of hardboard. This compatibility allows you to choose the best material for your specific project needs. Whether you're working with standard hardboard or specialized variants, the laser ensures precise cuts and engravings. This adaptability makes it easier for you to achieve the desired results, regardless of the material's characteristics.

Mixed Material Projects

In addition to hardboard, laser machines handle mixed material projects with ease. You can combine hardboard with other materials, such as acrylic or fabric, to create innovative designs. The laser's precision ensures that each material is cut or engraved accurately, maintaining the integrity of your design. This capability expands your creative options, allowing you to explore new ideas and techniques in your projects.

Minimal Waste

Laser machines excel in reducing waste, making them an environmentally friendly choice for hardboard projects. By using precision cutting, you can optimize material use and achieve significant cost savings.

Precision Cutting Reduces Waste

Laser technology allows you to cut hardboard with remarkable accuracy. This precision ensures that you use the material efficiently, leaving minimal waste behind. The laser beam cuts through the hardboard cleanly, reducing the amount of scrap produced. This efficient use of materials not only saves costs but also contributes to a more sustainable production process.

Optimized Material Use

When you use a laser machine, you maximize the use of your hardboard. The precise cuts mean you can fit more pieces into a single sheet, minimizing offcuts. This optimized material use translates to fewer resources needed for your projects, which is both cost-effective and environmentally responsible.

Cost Savings

By reducing waste, laser machines help you save money. You spend less on materials because you use them more efficiently. The reduction in scrap also means lower disposal costs. These savings can add up, making laser technology a smart investment for your hardboard projects.

Environmentally Friendly

Laser machines support sustainable practices by minimizing waste and reducing environmental impact. Their efficiency and precision make them a key player in eco-friendly manufacturing.

Sustainable Practices

Using laser technology aligns with sustainable practices. The minimal waste generated by laser cutting means less material ends up in landfills. This approach supports a circular economy, where resources are used more responsibly and efficiently.

Reduced Scrap

The precision of laser cutting results in reduced scrap. You produce less waste, which means fewer raw materials are needed for future projects. This reduction in scrap not only benefits the environment but also enhances the overall sustainability of your operations.

Ease of Use

Laser machines are designed to be easy to use, making them accessible to both beginners and experienced users. The integration of user-friendly software enhances this ease, allowing you to focus on creativity rather than technical challenges.

User-Friendly Software

Modern laser machines come equipped with intuitive software interfaces. These interfaces simplify the process of creating and executing designs. You can use popular design programs like Adobe Illustrator or CAD software to craft your digital designs. Once your design is ready, the software generates the necessary G-code for the machine to follow. This process ensures precision and minimizes errors, even when working with intricate details.

Intuitive Interfaces

The software's intuitive nature means you can quickly learn how to operate the machine. Clear menus and straightforward controls guide you through each step, from design to execution. This simplicity reduces the learning curve, allowing you to start producing high-quality work without extensive training.

Design Flexibility

With user-friendly software, you have the flexibility to experiment with various designs. You can easily adjust settings such as laser power and speed to suit different materials and achieve the desired results. This flexibility empowers you to explore new creative possibilities and refine your projects to perfection.

Low Maintenance Requirements

Laser machines are not only easy to use but also require minimal maintenance. Regular upkeep ensures that your machine operates efficiently and prolongs its lifespan.

Durable Equipment

Manufacturers design laser machines to withstand regular use. Durable components reduce the need for frequent repairs, saving you time and money. By following the manufacturer's maintenance guidelines, you can keep your machine in top condition.

Minimal Downtime

Routine maintenance tasks, such as cleaning optics and checking ventilation, are straightforward and quick to perform. This simplicity minimizes downtime, ensuring that your machine is always ready for the next project. By maintaining your equipment properly, you can avoid unexpected breakdowns and maintain a smooth workflow.

Laser technology offers numerous benefits for your hardboard projects. You gain precision and efficiency, ensuring high-quality outcomes. The contactless process prevents splinters and smooths edges, enhancing the final product. Laser machines also allow for personalization, making them ideal for diverse applications. By minimizing waste, they support sustainable practices and reduce costs. Their user-friendly nature makes them accessible, whether you're a beginner or an expert. Embracing laser technology in your projects not only improves results but also streamlines your workflow, making it an invaluable tool in modern manufacturing.

FAQ

Can a plywood laser cutting machine be used to engrave designs on plywood?

Yes, a plywood laser cutting machine can engrave designs on plywood. These machines are versatile and work on various materials, including wood, acrylic, fabric, leather, metal, and paper. This versatility makes them ideal for enhancing products in any business.

How does a plywood laser cutting machine cut through plywood?

A plywood laser cutting machine uses a focused laser beam to cut through plywood. The beam's intensity vaporizes the material along the cutting path, resulting in precise and clean cuts. This method ensures accuracy and reduces the need for additional finishing.

What are the benefits of using a plywood laser cutting machine for laser wood cutting?

Using a plywood laser cutting machine for laser wood cutting offers several benefits:

- Precision: Achieve intricate designs with high accuracy.

- Efficiency: Complete projects faster than traditional methods.

- Versatility: Work with various wood types and other materials.

- Minimal Waste: Optimize material use and reduce scrap.

Is it possible to cut through plywood of different thicknesses with a plywood laser cutting machine?

Yes, a plywood laser cutting machine can cut through plywood of varying thicknesses. The machine's settings, such as laser power and speed, can be adjusted to accommodate different thicknesses, ensuring clean and precise cuts every time.

How does a plywood laser cutting machine enhance the quality of laser wood cutting projects?

A plywood laser cutting machine enhances the quality of laser wood cutting projects by providing:

- Smooth Edges: The laser beam produces clean cuts, eliminating the need for sanding.

- Consistent Results: Each cut maintains the same quality, ensuring uniformity across projects.

- Detailed Designs: The machine can create intricate patterns that are difficult to achieve with traditional tools.

Can a plywood laser cutting machine be used for both cutting and engraving?

Absolutely, a plywood laser cutting machine can perform both cutting and engraving tasks. This dual functionality allows you to switch between creating cutouts and adding detailed engravings, making it a versatile tool for various projects.

What factors should be considered when choosing a plywood laser cutting machine for laser wood cutting?

When selecting a plywood laser cutting machine for laser wood cutting, consider the following factors:

- Power: Ensure the machine has sufficient power to cut through the desired material thickness.

- Size: Choose a machine that accommodates the size of your projects.

- Software Compatibility: Verify that the machine's software is compatible with your design programs.

- Maintenance: Consider the ease of maintenance and availability of support.

How does a plywood laser cutting machine contribute to sustainable practices?

A plywood laser cutting machine contributes to sustainable practices by minimizing waste. Its precision cutting reduces material scrap, optimizing resource use. This efficiency supports eco-friendly manufacturing and aligns with sustainable business goals.

See Also

Maximizing Efficiency with Your Laser Cutting Machine

Understanding Laser Cutting Machines in Industrial Applications

The Benefits and Drawbacks of Laser Cutting Machines