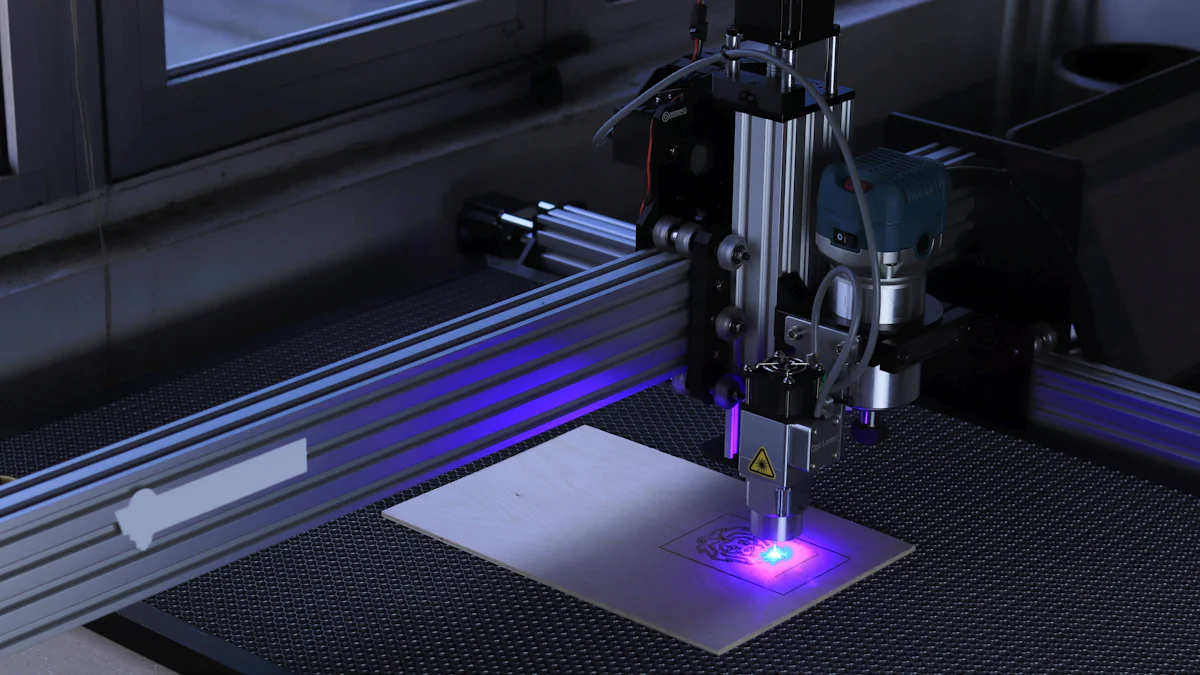

Beginner's Guide to Using Laser Cutting Machines

Welcome to the fascinating world of laser cutting machines! These powerful tools use focused laser beams to cut through various materials with precision and speed. You might wonder, how to use a laser cutting machine? It's a device that employs a high-powered laser to slice through materials like metal, wood, and acrylic. The basic components include a laser source, mirrors, and a cutting head. Understanding how to use a laser cutting machine involves knowing these parts and how they work together. The laser beam, guided by mirrors, focuses on the material, vaporizing it along the desired path. This technology has revolutionized industries, making intricate designs possible with ease.

Types of Laser Cutting Machines

When diving into the world of laser cutting, you'll encounter several types of laser cutting machines, each with unique features and applications. Understanding these differences will help you choose the right laser cutter for your needs.

CO2 Laser Cutters

CO2 Laser Cutters are among the most popular types of laser cutting machines. They excel at cutting non-metal materials like wood, plastic, and glass. These machines use a gas mixture to produce a laser beam, which is highly efficient for cutting thicker materials. If you're working on projects that involve intricate designs on non-metals, a CO2 laser cutter might be your best bet. Its precision and efficiency make it a favorite in many industries.

Fiber Laser Cutters

Fiber Laser Cutters are revolutionizing the way we cut metals. Unlike traditional methods, these machines offer versatile cutting modes and automatic material savings. They are particularly effective for cutting metals like stainless steel, carbon steel, and aluminum. One of the standout features of fiber laser cutters is that their mechanical components never touch the workpiece. This ensures safety and reduces the risk of damage during operation. If you're looking for a laser cutting machine that handles metal with ease, consider a fiber laser cutter.

Nd:YAG Laser Cutters

Nd:YAG Laser Cutters are specialized for cutting and processing metals, especially thin sheets and high-precision materials. They work well with metals such as brass and copper, as well as ceramics and certain plastics. These machines are ideal for projects requiring detailed and precise cuts. If your work involves high-precision tasks, an Nd:YAG laser cutter could be the perfect tool for you.

Exploring these types of laser cutting machines will give you a better understanding of their capabilities and help you make informed decisions for your projects. Each type offers distinct advantages, so consider your specific needs when choosing a laser cutter.

Diode Laser Cutters

Diode laser cutters are a fantastic choice for beginners and hobbyists. These machines use semiconductor diodes to produce the laser beam, making them compact and affordable. You can easily set up a diode laser cutter in your home workshop without needing a large space. They excel at cutting and engraving softer materials like wood, leather, and certain plastics. If you're looking to start small projects or crafts, a diode laser cutter might be just what you need.

One of the best things about diode laser cutters is their user-friendly nature. You don't need extensive training to operate them. With a bit of practice, you'll be creating intricate designs in no time. These machines are perfect for personalizing items, making custom gifts, or even starting a small business. The versatility of a diode laser cutter allows you to explore various creative avenues.

When using a diode laser cutting machine, always consider the material you're working with. Some materials may not be suitable due to the laser's power limitations. However, for most hobbyist projects, a diode laser cutter provides more than enough capability. You can experiment with different settings to achieve the desired results, whether you're cutting or engraving.

Applications of Laser Cutting

Laser cutting machines have transformed various fields with their precision and versatility. Let's explore some of the exciting applications where these machines shine.

Industrial Applications

In the industrial sector, laser cutters play a crucial role. You can find them in automotive, aerospace, and electronics industries. These machines excel at cutting metals like steel and aluminum, ensuring high-quality results. The precision of a laser cutting machine allows you to create intricate parts with minimal waste. This efficiency not only saves materials but also reduces production costs. Industries rely on laser cutting for tasks that demand accuracy and speed.

Artistic and Creative Uses

Laser cutting isn't just for industrial purposes. Artists and designers love using laser cutters to bring their creative visions to life. You can craft detailed patterns on wood, acrylic, and even fabric. The ability to cut complex shapes with ease opens up endless possibilities for artistic expression. Whether you're making custom jewelry, intricate sculptures, or personalized gifts, a laser cutter can help you achieve stunning results. The quality of the cuts ensures that your creations look professional and polished.

Educational and Prototyping Uses

In educational settings, laser cutting machines serve as valuable tools for learning and innovation. Students can use them to prototype designs and test ideas quickly. This hands-on experience fosters creativity and problem-solving skills. You can experiment with different materials and techniques, gaining insights into the manufacturing process. Laser cutters also support STEM education by allowing students to explore engineering and design concepts in a practical way. The quality of the output helps students see the real-world applications of their projects.

Laser cutting machines offer diverse applications across various fields. Whether you're in industry, art, or education, these machines provide the tools you need to achieve high-quality results. Embrace the possibilities and see where your creativity takes you!

How to Use a Laser Cutting Machine

Learning how to use a laser cutting machine can open up a world of creative possibilities. This step-by-step guide will walk you through the process, ensuring you achieve high levels of precision and quality in your projects.

Material Preparation

Before you start, choose the right material for your project. Laser cutters can handle a variety of materials, including wood, metals, and plastics. Each material reacts differently to the laser, so understanding these differences is crucial. For instance, wood is great for intricate designs, while metals require more power. Ensure your material is clean and free from any debris that might affect the cut. Proper preparation sets the stage for achieving clean cuts and high-quality results.

Setting Up the Laser Cutter

Once your material is ready, it's time to set up the laser cutter. This involves a few key steps:

Adjusting Laser Settings

Adjusting the machine's settings is vital for achieving the desired outcome. You'll need to configure the power, speed, and focus based on the material you're using. For example, cutting metals requires higher power settings compared to wood. Most laser cutting machines come with software that helps you input these settings accurately. Take your time to ensure everything is set correctly, as this directly impacts the quality of the cut.

Calibrating the Machine

Calibration ensures your laser cutter operates with precision. This involves aligning the laser beam and checking the focus. Many tutorials are available online to guide you through this process. Proper calibration minimizes errors and enhances the performance of your machine. Remember, a well-calibrated laser cutter is key to achieving high levels of precision in your work.

Executing the Cut

With your machine set up, you're ready to execute the cut. Follow these steps to ensure a smooth process:

Loading the Material

Carefully load your prepared material onto the laser cutter's bed. Make sure it's securely placed to prevent any movement during the cutting process. This stability is essential for maintaining accuracy and achieving the desired design.

Monitoring the Cutting Process

As the laser cutter begins its work, keep a close eye on the process. Monitoring allows you to catch any issues early, such as misalignment or unexpected errors. Safety precautions are important here; never leave the machine unattended while it's operating. This vigilance ensures both the safety of your project and the quality of the final product.

By following this guide, you'll gain confidence in using a laser cutting machine. Whether you're working with wood, metals, or other materials, understanding how to use laser cutting machine effectively will enhance your projects. Embrace the tutorials available and experiment with different settings to unlock the full potential of your laser cutter.

Advanced Tips and Tricks for Laser Cutting

Mastering laser cutting involves more than just knowing the basics. You can elevate your projects by optimizing performance and exploring creative uses. Let's dive into some advanced tips and tricks that will help you achieve top-notch quality in your laser cutting endeavors.

Optimizing Performance

To get the best out of your laser cutting machine, focus on optimizing its performance. Here are some steps you can take:

-

Regular Maintenance: Keep your machine in peak condition by performing regular maintenance checks. Ensure the oil level, water, and air circuits are functioning correctly. Check the coaxial alignment of the laser and nozzle. This ensures the laser beam hits the material precisely, improving the cut quality.

-

Adjust Print Settings: Tailor the print settings to match the material you're working with. Different materials require different power and speed settings. For instance, metals need higher power compared to wood. Adjusting these settings helps you achieve the desired cut quality and prevents material wastage.

-

Use Vector and Raster Modes: Understand when to use vector and raster modes. Vector mode is ideal for cutting and engraving outlines, while raster mode works best for detailed laser engraving. Switching between these modes based on your project needs can enhance the final product quality.

-

Monitor Gas Pressure: Ensure the cutting assist gas connection and pressure are optimal. Proper gas pressure aids in achieving clean cuts and prevents material burning. This step is crucial for maintaining high product quality.

-

Calibrate Regularly: Regular calibration of your machine ensures precision. Align the laser beam and focus it correctly. This reduces errors and enhances the quality of your cuts and engravings.

Creative Uses and Projects

Laser cutting isn't just about precision; it's also about creativity. Here are some ideas to inspire your next project:

-

Custom Jewelry: Use your laser cutter to create intricate jewelry designs. You can engrave patterns on metal or cut delicate shapes from wood or acrylic. This allows you to produce unique pieces that stand out.

-

Personalized Gifts: Create personalized gifts by engraving names or messages on items like keychains, coasters, or picture frames. This adds a personal touch and makes your gifts memorable.

-

Home Décor: Design and cut decorative items for your home. You can create wall art, lampshades, or even custom furniture pieces. The precision of laser cutting ensures your designs look professional and polished.

-

Educational Projects: Use laser cutting for educational purposes. Create models or prototypes for science or engineering projects. This hands-on approach enhances learning and helps students understand complex concepts.

By implementing these advanced tips and exploring creative projects, you'll not only improve your laser cutting skills but also produce high-quality products. Embrace the versatility of laser cutting and let your imagination guide you to new and exciting creations.

Troubleshooting Common Issues with Laser Cutters

Laser cutting machines are fantastic tools, but like any technology, they can sometimes encounter issues. Knowing how to troubleshoot these problems can save you time and frustration. Let's dive into some common issues and how you can address them effectively.

Addressing Cutting Inconsistencies

Cutting inconsistencies can be a real headache. You might notice uneven edges or incomplete cuts. Here’s how you can tackle these problems:

-

Check the Laser Power: Ensure that the laser power matches the material and its thickness. Using too much power can lead to poor cutting outcomes. Adjust the power settings to suit your specific project needs.

-

Focus Position: The relationship between the beam focus and the material's surface is crucial. Adjust the focus position by testing and fine-tuning it. When the focus is perfect, you'll see minimal slag and the smallest cut size.

-

Cutting Speed: The right cutting speed improves efficiency and quality. If the speed is too fast, the cut might not go through the material completely. Conversely, too slow a speed can cause burning. Find the sweet spot for your material.

-

Cutting Gas and Pressure: The choice of cutting gas and its pressure significantly impacts the cut quality. Proper cutting gas helps in combustion and heat dissipation. Make sure you select the appropriate gas and pressure for your material.

Resolving Machine Errors

Machine errors can disrupt your workflow. Here’s how you can resolve them:

-

Regular Maintenance: Keep your machine in top condition. Regularly check the oil level, water, and air circuits. Ensure the coaxial alignment of the laser and nozzle. This maintenance helps prevent errors and keeps your machine running smoothly.

-

Software Updates: Ensure your laser cutter's software is up-to-date. Manufacturers often release updates to fix bugs and improve performance. Keeping your software current can resolve many common issues.

-

Calibration: Regularly calibrate your machine. Align the laser beam and check the focus. Proper calibration reduces errors and enhances precision.

-

Error Messages: Pay attention to any error messages displayed by your machine. These messages can provide clues about what’s wrong. Refer to your machine’s manual or contact support for guidance on resolving specific errors.

By addressing these common issues, you can keep your laser cutting projects on track. Regular maintenance and careful adjustments will help you achieve consistent, high-quality results. Remember, troubleshooting is part of the learning process, and each challenge you overcome makes you a more skilled laser cutter user.

You've now got a solid foundation in using laser cutting machines. Remember, the key to mastering this tool lies in practice and experimentation. Don't hesitate to try new materials and techniques. Each project is an opportunity to learn and innovate. Laser cutting opens up endless possibilities for creativity and precision. Whether you're crafting intricate designs or prototyping new ideas, the potential for innovation is immense. Keep exploring, stay curious, and let your imagination guide you. With each cut, you're not just shaping materials; you're shaping the future of your creations.

FAQ

What materials can I cut with a laser cutting machine?

You can cut a wide range of materials with a laser cutting machine. Common options include wood, acrylic, metal, leather, and fabric. Each material reacts differently to the laser, so it's important to adjust the settings accordingly. Avoid materials like PVC, which release harmful gases when cut.

How do I choose the right laser cutting machine for my needs?

Consider the materials you plan to work with and the complexity of your projects. CO2 lasers are great for non-metals, while fiber lasers excel with metals. Diode lasers are perfect for beginners and hobbyists. Evaluate your budget and workspace as well.

Is laser cutting safe?

Yes, laser cutting is generally safe when you follow proper safety guidelines. Always wear protective eyewear and ensure good ventilation in your workspace. Never leave the machine unattended while it's operating. Regular maintenance also helps keep the machine safe to use.

Can I use a laser cutter for engraving?

Absolutely! Laser cutters are excellent for engraving. You can engrave intricate designs on various materials, including wood, glass, and metal. Adjust the settings to achieve the desired depth and detail in your engravings.

How do I maintain my laser cutting machine?

Regular maintenance is key to keeping your machine in top condition. Clean the lenses and mirrors, check the alignment, and ensure the cooling system works properly. Follow the manufacturer's guidelines for maintenance tasks and schedule regular check-ups.

What are the latest advancements in laser cutting technology?

Recent advancements include the integration of AI and machine learning, which enhance precision and efficiency. These technologies allow for more complex designs and improved automation. The future of laser cutting looks promising with these innovations.

Can laser cutting improve manufacturing efficiency?

Yes, laser cutting revolutionizes manufacturing by offering precision and speed. It reduces material waste and allows for automation, which lowers production costs. Industries like automotive and aerospace rely on laser cutting for high-quality components.

How do I troubleshoot common issues with my laser cutter?

Start by checking the laser power and focus position. Ensure the cutting speed and gas pressure are optimal. Regular calibration and software updates can resolve many issues. If problems persist, consult the machine's manual or contact support.

What creative projects can I try with a laser cutter?

The possibilities are endless! Create custom jewelry, personalized gifts, or home décor items. Use the machine for educational projects or prototypes. Let your imagination guide you to explore new and exciting creations.

How does laser cutting contribute to innovation?

Laser cutting plays a critical role in research and development. It allows for precise material processing and design capabilities. This technology drives the development of new products and opens up opportunities for creative applications across various industries.

See Also

Maximizing Efficiency With Your Laser Cutting Machine

Effective Techniques for Operating a Plasma Cutter

Comprehensive Guide for Using Hair Cutting Machines